What is an SOP Package? A Deep Dive into Small Outline Packaging in Electronics

When it comes to designing compact, efficient electronic devices, the packaging often makes or breaks the final product. Among the countless options available, the Small Outline Package (SOP) has earned its reputation as a reliable, cost-effective choice. Whether powering your smartphone, controlling an appliance, or driving an industrial motor, SOPs play a silent yet vital role in everyday technology. But what makes this unassuming package so essential to modern electronics? Let's dive into the key features that make SOP the preferred solution for manufacturers worldwide.

Introduction to Small Outline Package (SOP)

What is an SOP Package?

A Small Outline Package (SOP) is a type of surface-mount package used to house electronic components such as integrated circuits (ICs). It features a small, rectangular body with leads (metal contacts) on both sides, allowing it to be easily mounted onto a printed circuit board (PCB) during assembly. The SOP is designed to be compact, efficient, and cost-effective, making it one of the most common package types used in electronic devices.

Think of the SOP like a small "box" that protects and connects the tiny parts inside electronic gadgets like smartphones, TVs, and home appliances. The leads on the package make it easy to connect the component to the board, ensuring it works properly within the larger system. This compact design makes SOPs ideal for applications that require moderate-sized components with relatively few pins (usually between 8 to 48).

Importance in Electronics Manufacturing

SOPs are crucial in the world of electronics because they offer a cost-effective solution for manufacturing small-to-medium-scale electronic devices. Their small size, ease of assembly, and low production costs make them highly efficient for mass production. For many manufacturers, SOPs provide a way to balance performance with cost.

For example, in the assembly of consumer electronics like smartphones and wearables, SOPs are a preferred choice due to their ability to house essential components like power management ICs and audio chips. Manufacturers can produce large quantities of these components at a low cost while maintaining the reliability and quality needed for mass-market products.

The simplicity of the SOP also means that it can be handled using both automated processes and manual soldering, which is beneficial for both large and small production runs. This flexibility allows companies to use SOPs for everything from prototype development to high-volume production without significant changes in manufacturing processes.

SOP vs. Other Packaging Types

SOPs are not the only packaging option available in the electronics industry. Other common packaging types include QFP (Quad Flat Package), BGA (Ball Grid Array), and CSP (Chip Scale Package). While each packaging type has its own strengths and weaknesses, SOPs are often chosen for applications that need a balance between cost, size, and performance.

Let's take a quick look at how SOP compares with these other packaging types:

| Feature | SOP | QFP | BGA | CSP |

| Size | Compact, rectangular | Larger, square | Small, compact | Extremely small |

| Pin Count | 8–48 pins | 16–240 pins | 50–1000+ pins | 8–256 pins |

| Ease of Assembly | Easy to assemble, both manual and automated | Complex, requires more precise assembly | Highly automated; challenging for manual assembly | Requires advanced techniques for assembly |

| Cost | Low-cost, mass production | Moderate to high cost | High cost, best for high-pin count components | Very high cost for small batches |

| Thermal Management | Limited, suitable for low-power components | Better thermal performance | Excellent thermal performance | Limited, similar to SOP |

| Common Applications | Consumer electronics, home appliances, automotive | High-performance systems, complex ICs | High-performance chips, processors | Mobile devices, high-density applications |

Key Differences:

SOP is ideal for simpler, small-to-medium-sized components, while QFP and BGA are better for higher pin counts and more complex systems.

BGA offers superior thermal management, making it ideal for high-power applications, unlike SOP, which has limited heat dissipation.

CSP is much smaller than SOP, making it suitable for devices that need ultra-compact designs, such as mobile phones and wearables.

Key Characteristics of SOP Packaging

1. Package Size and Dimensions

One of the most notable features of the SOP is its compact size. SOP packages typically measure between 5mm and 15mm in length and 3mm to 8mm in width. This size range is ideal for small-to-medium-sized electronic components, allowing them to fit into a wide variety of devices without taking up too much space.

The compact dimensions of SOP packages make them suitable for space-constrained applications. For example, in smartphones, where internal space is limited, the small size of SOPs allows manufacturers to use more components without increasing the overall size of the device. Similarly, home appliances like microwaves or washing machines benefit from SOP packages because they can pack more features into a smaller, efficient form.

The small size also offers flexibility in design. Engineers can design smaller PCBs (Printed Circuit Boards), which can lead to lighter and more portable products. This flexibility is a key reason why SOPs are so widely used across different industries.

2. Lead Configuration and Spacing

SOP packages have dual-side leads, which are small metal pins that extend from both sides of the package. These leads connect the component to the PCB and are essential for creating electrical connections. The spacing between these leads typically ranges from 0.5mm to 1.27mm.

This spacing is an important factor when considering assembly methods. The relatively wide spacing (compared to smaller packages like QFN) allows for easier manual soldering, making SOP a great choice for small production runs, prototypes, and repairs. Even without expensive automated equipment, technicians can solder the leads by hand in smaller batches.

However, the lead spacing also makes SOP packages compatible with automated soldering machines. In larger-scale production, automated machines can place the components on the PCB and solder the leads quickly and accurately, reducing labor costs and assembly time. This dual compatibility—for both manual and automated soldering—adds to SOP's appeal in both high-volume and custom electronics manufacturing.

3. Material and Construction

The typical construction of an SOP package includes a plastic body and lead-frame. The plastic body serves as the outer shell of the package, protecting the internal components, while the lead-frame provides the metal contacts that link the component to the PCB.

Plastic Body: The plastic body is lightweight and durable, but it has limitations when it comes to heat dissipation. SOP packages generally have a maximum power dissipation of about 2 watts. Therefore, they are most suitable for low- to moderate-power applications where thermal management is less critical. For instance, small logic ICs or power management chips in smartphones might use SOP because they don’t generate significant heat during operation.

Lead-Frame: The lead-frame is typically made of copper or alloy materials to ensure good electrical conductivity. The leads are plated with a thin layer of tin-lead or gold to ensure a reliable connection with the PCB. The lead-frame’s durability ensures the package can withstand the soldering process without deforming, which is crucial during manufacturing.

The materials used in the SOP package are selected for their affordability, ease of manufacture, and adequate performance in most consumer and industrial electronics. However, for high-power applications, other packaging types, like BGA or CSP, may be better suited due to their superior thermal dissipation.

Types of SOP Packages

There are several variations of the Small Outline Package (SOP), each designed to meet different needs in the world of electronics. The most common types are SOIC, TSOP, and VSOP, and each type offers unique advantages depending on the specific application. In this section, we’ll explore each of these SOP package types in detail.

1. SOIC (Small Outline Integrated Circuit)

SOIC(Small Outline Integrated Circuit) is one of the most widely used types of SOP. It comes in a range of sizes, but the most common are SOIC-8 and SOIC-16, which have 8 and 16 pins, respectively. These are used for various low-to-medium pin-count applications like microcontrollers, memory chips, and analog ICs.

SOIC-8: This package typically has 8 pins and is commonly used for simple ICs that require only a few connections to a circuit. It is a popular choice for applications like voltage regulators or small sensors.

SOIC-16: With 16 pins, this package type is used for slightly more complex chips like amplifiers or interface ICs. The extra pins allow for more connections, making it ideal for medium-complexity components.

SOIC packages offer easy assembly and affordable production costs, making them suitable for large-scale manufacturing in electronics like smartphones, home appliances, and automotive systems.

2. TSOP (Thin Small Outline Package)

The TSOP (Thin Small Outline Package) is a variation of the standard SOP, designed with a thinner profile. TSOP packages are usually thinner than regular SOPs, making them ideal for applications where space-saving is essential. These packages are commonly used for memory chips, such as flash memory and DRAM, that need to be placed in space-constrained devices like mobile phones and laptops.

The main difference between SOP and TSOP is the thickness. While both have the same general layout and lead configuration, TSOPs are much thinner, allowing them to fit into even smaller devices or into devices where thermal management is critical.

For example, TSOP memory chips are frequently used in smartphones or wearable devices that require fast memory access without taking up too much space. They are also well-suited for high-density applications where a thin profile allows for more components in a smaller area.

3. VSOP (Very Small Outline Package)

The VSOP(Very Small Outline Package) is a further evolution of the SOP package, designed for ultra-compact applications. These packages are much smaller than standard SOPs and have fewer pins, making them ideal for high-density circuits and miniaturized devices. VSOPs are typically used in advanced consumer electronics like smartwatches, hearing aids, and portable medical devices.

VSOP packages may have as few as 8 pins, but they are significantly smaller than regular SOPs, allowing designers to pack more components into smaller spaces.

Unlike SOPs, which are often used for medium-complexity chips, VSOPs are used in devices where minimizing PCB space is critical while still maintaining reliable performance.

VSOP packages are typically used in miniaturized devices where every millimeter counts. For example, smartwatches or fitness trackers use VSOP components to reduce the size of the device without sacrificing functionality.

Comparison Table: SOIC vs. TSOP vs. VSOP

Feature SOIC TSOP VSOP Size Compact, rectangular (5mm–15mm long, 3mm–8mm wide) Thinner than SOIC, but similar length and width Extremely small, much thinner than SOIC Pin Count Commonly 8, 16 pins Typically 8–16 pins Usually 8 pins, but extremely small Thermal Management Limited (suitable for low power) Better for thinner, space-limited designs Limited, optimized for compact designs Use Case Example Voltage regulators, amplifiers, microcontrollers Memory chips in smartphones, laptops Advanced consumer electronics, wearables

Advantages of Using SOP Packaging

SOP packaging is a popular choice in the electronics industry due to its numerous advantages. These benefits make SOP a highly cost-effective and versatile solution for a wide range of applications. Let’s break down these key advantages:

1. Affordability and Cost-Effectiveness

One of the biggest reasons for the popularity of SOP packaging is its affordability. Compared to other packaging types, such as BGA and CSP, SOPs are much less expensive to manufacture. The cost of producing a single SOP component typically ranges from $0.05 to $0.50 per unit, depending on factors like pin count, size, and the specific manufacturer.

This low cost makes SOP packaging an ideal choice for mass production, especially for consumer electronics that require high-volume assembly. For example, in smartphones, audio chips or power management ICs can be housed in SOP packages without driving up the production cost. Because SOP is simple to produce and easy to source, manufacturers can keep overall costs low, which is a major advantage in highly competitive industries.

2. Sourcing and Availability

SOP components are widely available and easy to source from electronics suppliers around the world. This is partly because SOP is one of the most common and established packaging types used in the industry. Since it has been around for a long time, there is an extensive supply chain that ensures SOP components are readily accessible, with minimal lead times.

Whether you are sourcing SOP packages for a prototype project or a large-scale production run, you will find that these components are easy to obtain. Suppliers often stock various sizes, pin counts, and configurations of SOP packages, making them ideal for projects of all sizes. For example, in industries like automotive electronics, home appliances, and industrial machinery, the availability of SOP components ensures that manufacturers can get the parts they need without facing long wait times.

3. Ease of Assembly

Another major advantage of SOP packaging is its ease of assembly. SOP components are designed for surface-mount technology (SMT), meaning they can be easily mounted onto a PCB without requiring complex or specialized equipment. This feature makes SOP an excellent choice for both low-volume and high-volume production.

For small-scale operations or prototype development, SOP components can even be hand-soldered. This is ideal for small companies or engineers working on custom projects who don’t have access to expensive automated soldering machines. Additionally, SOP packages are also compatible with automated soldering machines, which can speed up the production process in high-volume manufacturing settings.

The simplicity of assembly, combined with the low cost, makes SOP packaging particularly beneficial for small electronics manufacturers or businesses that need to quickly produce small batches of products. For instance, DIY electronics projects, educational kits, or small-batch consumer goods can all benefit from the ease of assembly SOP provides.

4. Versatility Across Applications

SOP packages are incredibly versatile and can be used in a wide range of electronic applications. These packages are suitable for components that perform various functions, from logic ICs to power management systems, and sensors.

For example:

Logic ICs like microcontrollers or signal processors often come in SOP packages, allowing designers to include them in everything from automotive systems to consumer electronics.

Power management ICs, which are responsible for regulating voltage in devices like smartphones or televisions, are also commonly housed in SOP packages.

Sensor ICs, which measure things like temperature, pressure, or humidity, can be found in SOP packages, especially in home automation systems or wearable devices.

Because of the broad range of components that can be housed in SOP packages, they are used across multiple industries, including:

Consumer electronics (smartphones, audio equipment, home appliances)

Automotive electronics (climate control, sensors)

Industrial equipment (motors, sensors)

Medical devices (wearables, small diagnostic equipment)

This versatility ensures that SOP packaging continues to play a critical role in multiple sectors, offering a reliable solution for many different electronic needs.

Disadvantages of SOP Packaging

While the Small Outline Package (SOP) is a popular and cost-effective choice for many electronic devices, it does have several limitations that make it less suitable for certain applications. These disadvantages include limited pin count, size constraints, thermal management issues, and fragility in high-temperature environments. Let’s dive deeper into each of these drawbacks.

1. Limited Pin Count

One of the main limitations of SOP packaging is its restricted pin count. Typically, SOP packages can accommodate a maximum of 48 pins. While this is sufficient for many low-to-medium complexity chips, it makes SOP unsuitable for complex components that require a larger number of pins for more connections.

For example, high-performance chips like processors, graphic cards, or high-speed memory modules need a large number of pins to handle multi-channel data transfers or complex electrical signals. In these cases, other packaging types, such as BGA or QFP, are more appropriate because they can support hundreds or even thousands of pins. These packages provide the necessary connections for high-performance circuits that cannot fit into the relatively small and limited pin layout of an SOP.

2. Size Limitations

Compared to smaller form-factor packages like CSP and BGA, the size of SOP packages can be considered bulky. While the SOP is still compact, it is much larger than both CSP and BGA, especially when considering the same number of pins.

For example, a 16-pin SOP might be roughly twice the size of a 16-pin CSP. This difference in size can be problematic in designs that require maximum space efficiency. When designing products like smartphones, wearable devices, or advanced medical equipment, every millimeter counts, and manufacturers often turn to smaller packaging options like CSP or BGA to achieve better miniaturization.

In applications where space-saving is crucial, SOP may not be the ideal choice. Designers may prefer other packaging types that allow for a smaller overall device footprint, which is especially important in consumer electronics where device size is often a key selling point.

3. Thermal Management

Another drawback of SOP packaging is its thermal management capabilities. The plastic body of the SOP package offers limited heat dissipation. Since the material is not highly efficient at conducting heat, SOPs are not suitable for high-power applications that generate a lot of heat during operation.

For instance, devices like high-power amplifiers, processors, or LED drivers can generate significant amounts of heat, which must be properly dissipated to prevent damage or malfunction. In these cases, SOP packaging might not provide the necessary thermal performance, making it unsuitable for components that require efficient heat management.

In contrast, packaging types like BGA or CSP often include heat sinks or use metal leads to better manage heat. These packages are ideal for high-performance systems where thermal management is critical to maintaining reliable operation.

4. Fragility in High-Temperature Environments

The material used in SOP packaging, typically plastic, has its limitations when exposed to high-temperature environments. While SOPs work well in most standard consumer electronics, they can become fragile and may not withstand extreme thermal conditions, such as those found in industrial or automotive environments.

For example, automotive electronics that are exposed to high temperatures or extreme temperature fluctuations might face issues with plastic degradation in SOP packages. As the plastic material weakens under high heat, it can lead to issues such as broken leads, poor solder connections, or even complete component failure.

This is why metal-based packages or those with better thermal properties are often preferred in high-temperature applications. While SOPs are excellent for low-power, standard electronics, they are not suited for environments where temperature control is critical for component longevity and reliability.

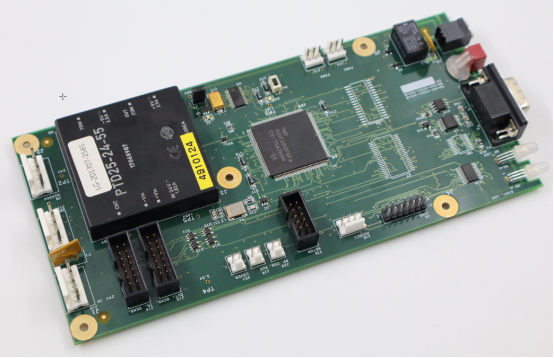

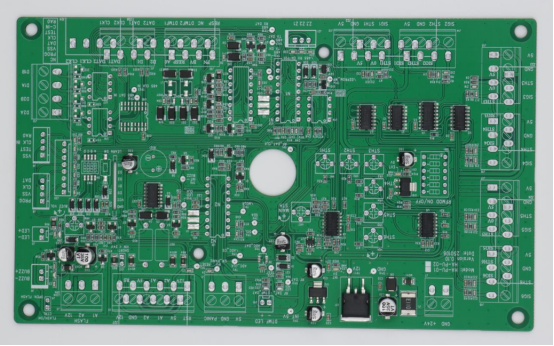

How SOP Works with Different PCB Types

The way a SOP interacts with different types of PCBs is an important factor in its use and effectiveness in electronics. SOPs are versatile, but they are better suited to some types of PCBs than others. In this section, we’ll explore how SOPs work with rigid, flexible, and rigid-flex PCBs, highlighting where they are most effective and when alternative packages may be a better choice.

1. Rigid PCBs

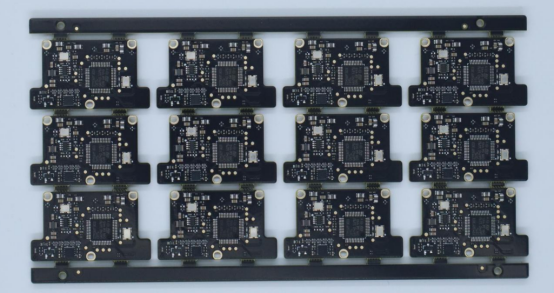

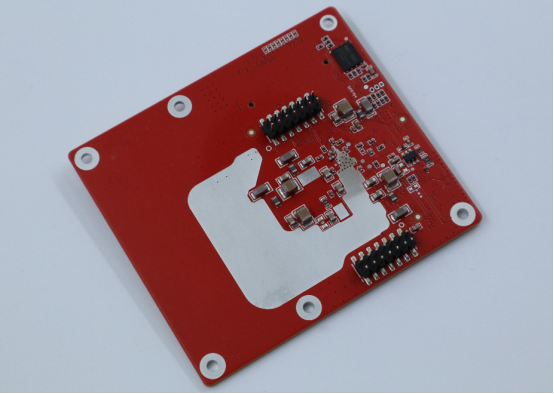

SOP packaging is highly compatible with rigid PCBs, which are the most common type of printed circuit boards used in electronic devices. Rigid PCBs are made from materials like fiberglass or epoxy, which are stiff and durable, making them ideal for mounting components like SOP packages.

Assembly Process: SOP components are designed for SMT, which means they can be easily soldered onto rigid PCBs. The leads of the SOP package are aligned with the PCB’s pads during the assembly process, where they are soldered either manually or using automated pick-and-place machines.

Suitability: Rigid PCBs are thick and inflexible, which provides a strong base for securely mounting SOP packages. Since SOPs are generally used in low to medium pin count applications, this makes them a perfect match for rigid PCBs, which are found in everyday devices such as smartphones, home appliances, and consumer electronics.

For example, a TV remote control or a microwave oven uses a rigid PCB with SOP components because of the simple, sturdy connections needed for the functionality of these devices. The rigidity of the board ensures that the SOP package remains securely in place over time.

2. Flexible PCBs

While SOP packaging is excellent for rigid PCBs, it is not well-suited for flexible PCBs. Flexible PCBs are made from materials like polyimide, which allow them to bend and conform to different shapes. These PCBs are typically used in wearable devices, smartphones, and other applications where the PCB needs to be bent or twisted.

Challenges with SOP: SOP packages are designed for rigid mounting, and their dual-side leads can create challenges when trying to apply them to a flexible PCB. The leads may not perform well under bending stress, potentially leading to damage or poor connections over time.

Alternatives for Flexible PCBs: For flexible PCBs, manufacturers usually turn to CSP, QFN (Quad Flat No-lead), or BGA. These packages are leadless or have small lead pitches, making them better suited for flexible designs where bending and movement are factors. QFN, in particular, is ideal for low-profile designs that require minimal height.

In a smartwatch, for example, a flexible PCB might use CSP or QFN packages to ensure that the components can be integrated into the compact, flexible design. The leadless or low-profile design helps the component remain secure even when the device is bent.

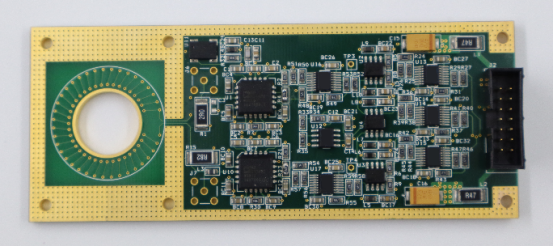

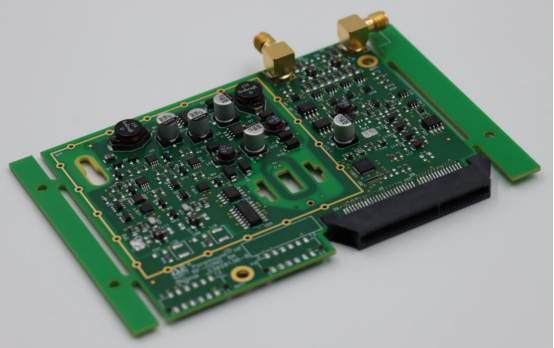

3. Rigid-Flex PCBs

Rigid-flex PCBs combine both rigid and flexible areas, offering a hybrid solution where certain sections of the PCB can bend while others remain rigid. These types of PCBs are commonly used in advanced electronics, such as smartphones, medical devices, and military equipment, where both flexibility and durability are needed.

Role of SOP in Rigid-Flex Designs: SOP packaging works very well in the rigid sections of rigid-flex PCBs. In the rigid areas, SOP packages can be easily mounted and soldered using standard SMT assembly methods. These sections offer a strong, stable base for attaching components, making them ideal for low- to medium-pin count SOP packages.

Why SOP Works Well Here: Since the rigid sections of the board do not require bending, the dual leads of SOP packages work effectively without the concern of physical stress. Components in the rigid sections can perform standard electronic functions like power management, signal processing, and control logic, which are common uses for SOP packages.

For example, in a medical device with a rigid-flex PCB, SOP packages may be used in the rigid section to control sensors or microcontrollers. These components can handle relatively low-power tasks in areas where the PCB does not need to bend, ensuring that the device remains functional and compact.

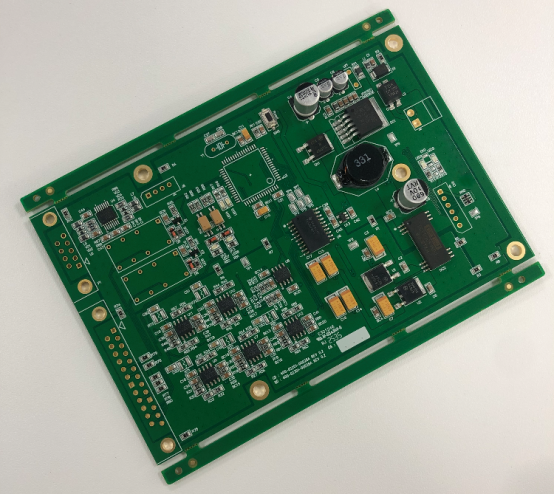

Manufacturing and Assembly Considerations for SOP Packages

When working with SOP in electronics manufacturing, several key considerations must be taken into account to ensure the components are properly integrated and function reliably in the final product. These considerations include soldering techniques, placement on PCBs, and testing and quality control. Let’s explore each aspect in detail.

1. Soldering Techniques

Soldering is the process of attaching components to a PCB by melting a metal (usually solder) to form a solid electrical connection between the component leads and the PCB pads. For SOP packages, two common soldering techniques are used: reflow soldering and hand soldering.

Reflow Soldering: Reflow soldering is the most common method for mounting SOP packages, especially in high-volume production. In this process, the SOP components are placed on the PCB pads, and the assembly is passed through an oven where the solder paste is melted. The heated air or infrared radiation melts the solder paste, which then cools and hardens to form a secure connection between the component leads and the PCB.

Hand Soldering: In smaller-scale or prototype production, hand soldering is often used. This method involves using a soldering iron to manually melt solder onto the joints of the SOP package. While more time-consuming and less precise than reflow soldering, hand soldering can be ideal for low-volume runs or when working with custom designs that require individual attention.

For example, when assembling a small electronic device like a custom gadget or a DIY project, hand soldering may be the best choice. However, for mass production of devices like smartphones or TV remotes, reflow soldering is preferred because it is faster, more efficient, and provides higher consistency.

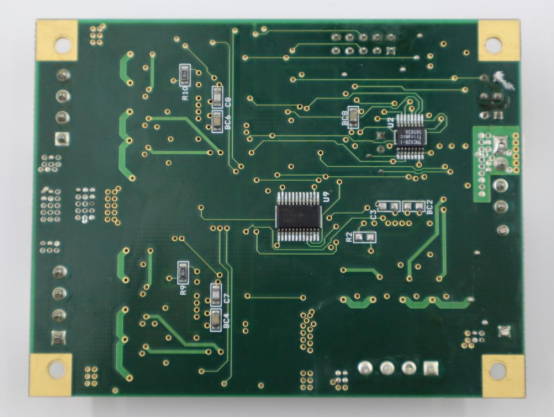

2. Placement on PCBs

Proper placement of SOP components on a PCB is critical for both functional performance and assembly efficiency. When designing a PCB for SOP components, engineers must carefully consider the following factors:

Pad Layout: The PCB pads must match the lead spacing and lead size of the SOP package. The distance between the leads should allow for proper soldering without causing bridging (where solder connects two leads unintentionally).

Orientation: SOP packages must be placed correctly on the PCB. Most SOP components have a specific orientation indicated by a marking or notch, which helps identify the proper way to mount the package. If the component is placed incorrectly, it can lead to malfunction or short circuits.

Component Density: When placing SOP components on a PCB, it’s important to consider the available space on the board. SOP packages are compact, but in designs with high-density components, placement may require careful planning to avoid interference with other components or to ensure easy access for soldering.

For example, when designing a microcontroller circuit for a consumer product, engineers will need to ensure that the SOP package is placed in an optimal position on the PCB for easy signal routing and effective power distribution.

3. Testing and Quality Control

Once the SOP components are mounted on the PCB, ensuring their reliability and performance through testing and quality control is essential. These steps help identify potential issues before the final product is shipped to customers.

Visual Inspection: One of the first steps in quality control is visual inspection. This process checks the solder joints to make sure they are solid and free of defects like cold solder joints or solder bridges. High-end automated optical inspection systems (AOI) can also be used to quickly scan the boards for potential defects.

X-Ray Inspection: In some cases, especially for complex multi-layer PCBs, X-ray inspection may be used to examine solder joints underneath the SOP package. This is particularly important for ensuring there are no issues with the hidden leads or connections that could lead to failures.

Functional Testing: After assembly, the product undergoes functional testing to ensure the entire circuit works as expected. For SOP-mounted circuits, this could involve checking signal flow, voltage regulation, or sensor readings to verify that the components are performing correctly.

Thermal Testing: Thermal cycling or stress testing is often done to evaluate how the PCB and SOP components handle temperature changes. This is critical for detecting potential overheating issues or thermal-induced failures, especially if the device is intended for environments with extreme temperatures.

For instance, in the case of an automotive control system that uses SOP components, thermal testing will help ensure that the components can handle the heat generated by the vehicle's engine without failing.

Conclusion

SOP offers key benefits such as affordability, easy assembly, and versatility, making it a great choice for many electronic applications, from smartphones to home appliances. However, its limited pin count, size constraints, and thermal management challenges can make it less suitable for high-performance, high-power applications.

Looking ahead, SOP packaging may continue to evolve, with improvements in miniaturization and material technology helping it meet the growing demand for smaller and more efficient devices. Companies like PCBMASTER, a leading PCB supplier, provide reliable solutions to help manufacturers integrate SOP packages into their products, supporting the future of electronics innovation.

FAQs

1. What is the typical cost of an SOP component?

SOP components typically range from $0.05 to $0.50 per unit, though the exact cost can vary depending on several factors. These include the pin count (higher pin counts generally increase the cost), the manufacturer, and the quantity purchased. For example, a basic 8-pin SOP might cost closer to the lower end of the range, while a 48-pin SOP could be priced at the higher end. This price range makes SOP an attractive option for manufacturers looking for an affordable, reliable packaging solution for a variety of applications.

2. Can SOP packages be hand-soldered?

Yes, SOP packages are ideal for hand-soldering, which is one of their key advantages, especially in prototyping and small-volume production runs. The dual-side leads of SOP components are spaced appropriately (typically between 0.5mm and 1.27mm), making it easy for engineers or technicians to manually solder the leads onto the PCB pads using a soldering iron. This makes SOP a great option for low-volume or custom projects where automation might not be cost-effective, or in situations where quick modifications or repairs are needed.

3. How does SOP compare to QFN in terms of size?

SOP packages are generally bulkier than QFN packages. For instance, a 16-pin SOP is roughly twice the size of a 16-pin QFN package, both in terms of surface area and height. This size difference stems from the fact that SOP packages have leads on both sides, which increases the overall package size, whereas QFNs are leadless and typically have a much smaller profile. The larger size of SOP packages makes them less suitable for high-density designs where space efficiency is crucial, such as in smartphones or wearable devices. QFNs, being more compact, are better suited for these applications.

4. Why is heat dissipation a concern with SOP packages?

The primary concern with heat dissipation in SOP packages lies in their plastic body construction. The plastic material, though affordable and sufficient for many low- to medium-power applications, is not an effective heat conductor. This limits the package's ability to dissipate the heat generated by high-power components during operation. As a result, SOP packages are not well-suited for high-power or heat-sensitive applications such as power amplifiers, high-performance microprocessors, or LED drivers, which require better heat management. In such cases, alternative packaging solutions like BGA or CSP, which provide more efficient heat dissipation, are often preferred.

5. Which industries most commonly use SOP packages?

SOP packages are widely used in a range of industries that require reliable, affordable, and compact electronic components. Some of the most common industries using SOP packages include:

Consumer Electronics: SOPs are used in devices like smartphones, audio systems, and digital cameras. Components like audio chips, power management ICs, and wireless modules are often packaged in SOPs for these devices.

Home Appliances: In products like TV remote controls, washing machines, and microwave ovens, SOPs are commonly used to package microcontrollers, sensor interfaces, and LED drivers.

Automotive: SOP packages are found in automotive systems such as climate control modules, door lock ICs, and sensor interfaces. They are well-suited for these applications due to their reliability and cost-effectiveness in handling low- to medium-power components.

Industrial Electronics: In industrial settings, SOP packages are used for motor drivers, sensor interfaces, and control systems in small machinery and automation equipment.

The combination of low cost, ease of assembly, and versatility across various functions makes SOP packages an ideal choice for these industries.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!