High-Speed PCB

5G-200G High-Speed PCB, Ultra-Low Loss Material, Stable Dielectric Constant (Dk), Stack-Up Design & Optimization, Impedance Accuracy ±5%

Why Choose Our High-Speed PCBs?

We deliver more than circuit boards – Our Commitment to Performance and Dedicated Service Powers Your Critical Applications

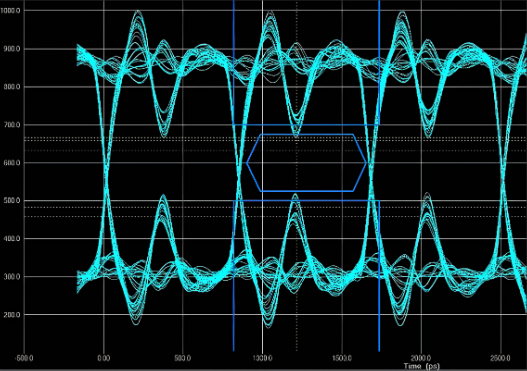

Signal Integrity (SI)

Precise impedance control, extremely low return loss and crosstalk

Power Integrity (PI)

Ultra-low target impedance, providing stable and clean power supply

One-Stop Design Support

From stack-up design to SI/PI simulation consultation

Rapid Prototype Delivery

High-speed prototypes accelerate your product launch

High-Speed PCB Solutions Across Diverse Industries

High-Speed PCB refers to a printed circuit board with a signal transmission rate ≥1Gbps (current mainstream scenarios have reached 5G-200Gbps), and its core design goal is to "ensure Signal Integrity (SI)". Its key logic is not simply pursuing "fast transmission speed".

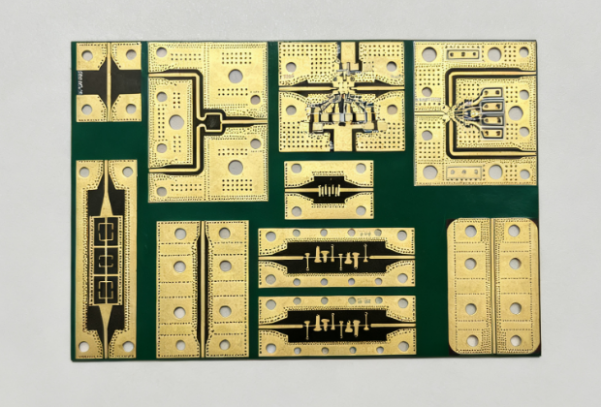

High-Speed PCB products manufacturable by PCBMASTER include:

| Core Application Areas | |

|---|---|

| Data Centers & Cloud Computing | Server motherboards, switches, routers, optical modules |

| High-Speed Communication Equipment | 400G/800G Ethernet, OTN equipment |

| Artificial Intelligence/Machine Learning | GPU acceleration cards, AI training servers |

| High-Performance Computing | Workstations, supercomputer motherboards |

| Medical Instruments | High-frequency imaging equipment, etc. |

With decades of proven expertise in high-speed PCB manufacturing, our solutions span a wide range of industries and deliver uncompromising performance and rock-solid reliability—even in Harsh Industrial Environments.

2L High-Speed Antenna PCB

8L High-Speed Rigid-Flex board

14L High-Speed Rigid-Flex board

10L 400G Optical Transceiver PCB

20L ATE BIB PCB

26-Layer Switch Board

28-Layer ATE Probe Card

32L Immersion gold ATE Load PCB

High-Speed PCB Material Selection

We partner with the industry's top material suppliers to deliver PCBs optimized for your exact performance needs.

| High-Speed Series | Material Model | Suitable For |

|---|---|---|

| 1-5G | TU-862, S7038, S1165, Isola-FR408HR, Isola-FR406, Taiguang-EM370, EM828G, IT170GRA, Nanya NP175FM | Servers, Switches, Base station backplanes/line cards, High-performance computing, Office routers, etc. |

| 5-10G | MEG4, TU-872, N4000-13, TU-863(Halogen-Free), SYTECH Synamic4, EM-888, I-Speed(Isola), N4800-20SI(Nelco), IT-958G | Backplanes, High-performance computing, Line cards, Storage, Servers, Telecommunications, Base stations, etc. |

| 10-25G | MEG6, TU-883, SYTECH Synamic6, Meteorwave1000/2000/3000 Series(Nelco),Taiguang EM-891, EM-888K, IT-968, I-Tera MT40(Isola) | Ultra-high-speed network equipment, Servers, Switches, Storage, Routers, Base station BBUs, High-performance computing, High-frequency measurement instruments, Optical communication products, etc. |

| 25G-50G | MEG7, TU-933, Meteorwave4000(Nelco), IT-988, Tachyon 100G(Isola) | ICT infrastructure equipment, Supercomputers, Routers, Servers, Measurement equipment, Communications, Antennas, etc. |

| >50G | MEG8, IT-998TC, ISOLA Tachyon 100G, AGC METEORWAVE-4000 | 50Gbps+ applications such as automotive radar, Satellite equipment, High-speed switches, Supercomputers, Communications |

Key Technologies for High-Speed PCB

Our proprietary processes deliver PCBs that outperform standard solutions in the most demanding environments.

Signal Integrity Technologies

Power Integrity-Specific Technologies

| Comparison Dimension |

High-Frequency PCB

Analog/RF signal-centric |

High-Speed PCB

Digital signal-centric |

|---|---|---|

| Core Focus | Signal frequency, phase, and power | Signal timing, integrity, and quality |

| Key Indicators |

|

|

| Primary Challenge | Reduce signal energy loss and phase distortion during transmission | Prevent signal distortion (reflection, crosstalk) to ensure correct timing and logical judgment |

| Core Material Requirements | Stable Dk, Ultra-low Df, Tight Dk tolerance | Controlled and stable Dk, Low to moderate Df, Good thermal reliability (high Tg) |

| Common Materials |

High-performance specialized materials: PTFE, Ceramic-filled PTFE/hydrocarbon resin, Liquid Crystal Polymer (LCP) |

Mid- to high-performance materials: Medium- to low-loss FR-4, Halogen-free, low-loss materials, Modified epoxy/PPO systems |

| Design & Simulation Focus | Electromagnetic simulation, Transmission line structures, Impedance matching: 50Ω (single-ended) or 100Ω (differential) | Circuit/system simulation, Topology/termination, Termination matching, Power integrity |

| Typical Application Areas | Wireless communications, Radar/satellite, Aerospace/defense, Test/measurement | Data telecom, Computing/storage, High-end consumer electronics, Automotive |

| Manufacturing Challenges |

|

|

Blog & NEWS

-

High-Speed PCB vs. High-Frequency PCB: Key Differences Explained by PCBMASTERHigh-Speed and High-Frequency PCBs: Different Goals, Same SystemHigh-speed PCBs and high-frequency PCBs may sound similar, but they are not the same. They have different design goals, performance requirements, and application scenarios. Yet...Sep 22, 2025More

High-Speed PCB vs. High-Frequency PCB: Key Differences Explained by PCBMASTERHigh-Speed and High-Frequency PCBs: Different Goals, Same SystemHigh-speed PCBs and high-frequency PCBs may sound similar, but they are not the same. They have different design goals, performance requirements, and application scenarios. Yet...Sep 22, 2025More -

High-Speed PCB Engineering Practical Guide Core Technology Analysis of Signal Integrity and Design Optimization1. Physical Nature and Challenges of High-Speed Signal Transmission (Establishing foundational knowledge using classical microwave theory)At the 5G NR 39GHz frequency band, FR4 substrate material with a dielectric loss tangent (Df) of 0.025...Apr 22, 2025More

High-Speed PCB Engineering Practical Guide Core Technology Analysis of Signal Integrity and Design Optimization1. Physical Nature and Challenges of High-Speed Signal Transmission (Establishing foundational knowledge using classical microwave theory)At the 5G NR 39GHz frequency band, FR4 substrate material with a dielectric loss tangent (Df) of 0.025...Apr 22, 2025More -

PCB High-Speed Material Technology Roadmap and Market Transformation The Evolution from Lab to IndustryIn 2019, a leading smartphone manufacturer faced a major setback with its 5G millimeter-wave antenna module—signal loss at the 28 GHz band was 30% higher than expected. After three months of troubleshooting, engineers traced the root cause...Mar 20, 2025More

PCB High-Speed Material Technology Roadmap and Market Transformation The Evolution from Lab to IndustryIn 2019, a leading smartphone manufacturer faced a major setback with its 5G millimeter-wave antenna module—signal loss at the 28 GHz band was 30% higher than expected. After three months of troubleshooting, engineers traced the root cause...Mar 20, 2025More -

PCB High-Speed Material Technology Guide Key Selection Criteria and Practical ApplicationsIn a laboratory of a Shenzhen-based communications equipment manufacturer, Engineers stared at the distorted signal waveform on his oscilloscope, frustrated. His 5G base station power amplifier board exhibited severe signal distortion at 24...Mar 18, 2025More

PCB High-Speed Material Technology Guide Key Selection Criteria and Practical ApplicationsIn a laboratory of a Shenzhen-based communications equipment manufacturer, Engineers stared at the distorted signal waveform on his oscilloscope, frustrated. His 5G base station power amplifier board exhibited severe signal distortion at 24...Mar 18, 2025More

Frequently Asked Questions

Have any questions? Our technical team is ready to help.