Printed Circuit Board Definition: What Is a PCB and How It Works

Inside every electronic device, there’s a small part that quietly makes everything work. This part is called a Printed Circuit Board (PCB). It may look like a flat board with some lines on it, but it connects all the tiny components and allows your device to function properly. Without PCBs, devices like smartphones, laptops, and even modern cars wouldn’t be able to work at all.

The PCB market is growing fast. In 2025, it was worth about USD 81 billion, and by 2030, it is expected to reach over USD 104 billion. This shows how essential PCBs are in electronics, from everyday gadgets to advanced medical and industrial devices.

In this guide, we will explain what PCBs are, how they are built, the different types, how they work, and where they are used. By the end, even if you are new to electronics, you will understand why this simple-looking board is so important for modern technology.

Definition of a Printed Circuit Board (PCB)

A Printed Circuit Board, or PCB, is a flat board that holds and connects all the electronic parts inside a device. It acts as a platform where tiny components like chips, resistors, and capacitors sit and work together.

Unlike traditional wiring methods, where each wire is connected by hand, a PCB has printed copper paths that automatically connect all the components. This makes the board neater, smaller, and more reliable.

PCBs are found in almost every electronic device you use. They are the key part that allows your smartphone to run apps, your computer to process programs, and even your car’s sensors to operate. Without a PCB, electronic devices would be a mess of loose wires, and they simply wouldn’t function properly.

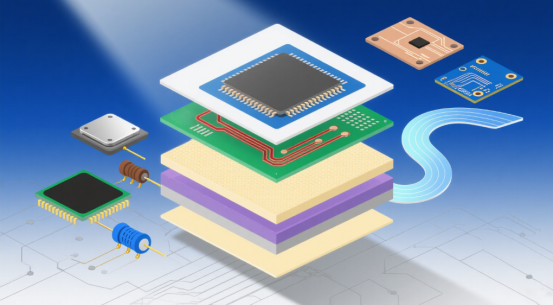

Basic Structure of a Printed Circuit Board (PCB)

A Printed Circuit Board consists of several layers, each performing a specific function. These layers work together to support electronic components and connect them electrically. Below are the main parts explained clearly:

Substrate

Serving as the foundation of a PCB, the substrate is usually made from materials like FR-4, CEM-1, or flexible films. It provides strength and stability, holding all other layers together. Flexible substrates allow boards to bend or fold, making them ideal for small or uniquely shaped devices.

Conductive Layer

Copper forms the conductive layer, which creates traces or paths to carry electrical signals between components. Proper design of these paths is essential to ensure smooth signal flow and avoid short circuits or electrical interference.

Solder Mask

A thin protective layer, the solder mask covers the copper traces to prevent unintended contact between them. It also shields the copper from damage or corrosion and guides solder to the correct spots during component assembly.

Silkscreen

Printed markings on the surface, known as the silkscreen layer, show component locations, part numbers, and reference symbols. These labels make assembly and maintenance easier and more accurate.

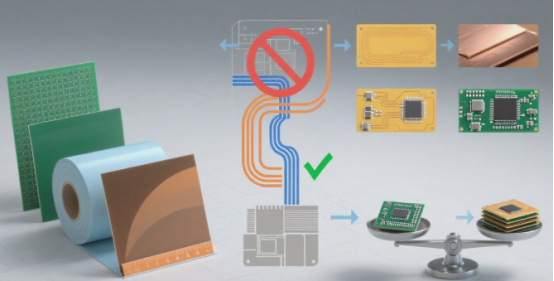

Types of Printed Circuit Boards (PCBs)

Printed Circuit Boards come in different types, depending on the number of layers and whether they are rigid or flexible. Each type is designed to meet different needs in electronics.

Single-sided PCB

Single-sided PCBs feature copper traces on only one side of the board. This simple design makes them easy to manufacture and low in cost, ideal for basic electronic devices. Examples include calculators, toys, and simple household gadgets. Their limitation is that all connections must fit on one side, which restricts complexity.

Double-sided PCB

Double-sided PCBs use copper traces on both sides of the board. This design allows for more connections and better routing of signals. They are commonly found in power supplies, audio amplifiers, and industrial controllers. With extra space for components, double-sided boards can handle moderately complex circuits that single-sided boards cannot.

Multi-layer PCB

In multi-layer PCBs, three or more copper layers are stacked with insulating layers in between. This structure supports high-density connections and compact layouts. Multi-layer boards are widely used in smartphones, laptops, servers, and advanced communication devices. Their design makes it possible to manage complex circuits and high-speed signals while keeping the device small.

Rigid-Flex PCB

Rigid-flex PCBs combine rigid sections for supporting heavy components and flexible sections that can bend or fold. They are perfect for devices where space is limited but durability is required. These boards appear in medical equipment, aerospace electronics, and compact consumer devices, allowing designers to save space and reduce the number of separate boards in a product.

Flexible PCB

Flexible PCBs are made entirely from bendable material, allowing them to twist, fold, or bend as needed. They are thin, lightweight, and ideal for compact or moving parts. Flexible boards are commonly used in wearable devices, foldable phones, cameras, and medical instruments, helping electronics fit into tight spaces while remaining reliable.

How a Printed Circuit Board Works

Every electronic device works because tiny parts talk to each other through a PCB. This board organizes electricity and signals so all the components can function together smoothly. Let’s look at how a PCB actually makes this happen.

Current Flow on a PCB

Electricity flows along the copper traces on a PCB, connecting all the components. These traces act like tiny roads, guiding the current to the correct parts. Components such as resistors, capacitors, and chips rely on these paths to work together properly. Without this organized network, electricity would have no clear route, and devices would not function.

Signal Transmission and Component Connections

Signals travel along the copper traces, carrying information between components. For example, in a smartphone, signals tell the processor to display images, play sounds, or connect to the network. The PCB ensures these signals reach the correct components quickly and without interference, keeping the device reliable.

Current and Voltage Distribution

Different areas of the PCB handle different amounts of current and voltage. Some traces carry more electricity, while others only need small signals. Proper PCB design ensures every component receives the correct power without overloading, which protects the device and prevents damage.

PCB’s Role in Controlling Electronics

The PCB organizes all electronic activity inside a device. It allows components to communicate, process information, and perform tasks efficiently. Without a PCB, a device would just be a mess of loose wires, making it unreliable and almost impossible to operate.

Applications of Printed Circuit Board

PCBs are everywhere in modern life. They are the hidden platform that makes electronic devices work reliably and efficiently. Different types of PCBs are used in different industries, depending on the complexity, size, and purpose of the device.

Consumer Electronics

PCBs are used in smartphones, tablets, and laptops, connecting tiny chips, displays, and batteries. They allow devices to process information, display graphics, and communicate with networks. Without PCBs, these gadgets would just be a pile of loose parts that cannot function together.

Industrial Control

In factories and automation systems, PCBs control machines and robots. They connect sensors, motors, and control boards, allowing machines to move accurately, monitor production, and respond to changes quickly. PCBs make industrial systems safe, reliable, and precise.

Automotive Electronics

Modern cars rely on PCBs for dashboards, sensors, and advanced driver-assistance systems (ADAS). They help monitor speed, control brakes, manage engine performance, and even assist with parking. Without PCBs, cars would lose smart control and safety features.

Medical Devices

PCBs are critical in portable monitoring devices and medical imaging equipment. They connect sensors, processors, and displays, allowing doctors and patients to measure vital signs, track health data, or perform scans accurately. Flexible and compact PCBs make these devices small, light, and easy to use.

Aerospace

In aerospace applications, PCBs are used in satellite systems, communication devices, and control electronics. They ensure high reliability in extreme conditions, such as space or harsh environments. Advanced PCBs allow equipment to perform complex tasks safely and consistently.

Design and Manufacturing Basics of Printed Circuit Boards

Designing and making a PCB requires careful planning. Each step ensures that the board works well, lasts long, and is safe to use.

Material Selection and Thickness

The material of the PCB affects its strength, flexibility, and ability to handle heat. Common materials include FR-4 for rigid boards, flexible films for bendable boards, and CEM-1 for simple, low-cost devices. The thickness of the board also matters: thicker boards are stronger, but thinner boards are lighter and can fit in small spaces. Choosing the right material and thickness ensures the PCB meets the device’s needs.

Routing Rules and Signal Integrity

Copper traces must follow certain routing rules to work correctly. Traces should avoid sharp bends, and high-speed signals need careful layout to prevent interference or signal loss. Proper routing ensures that all components communicate clearly, so the device functions smoothly.

Manufacturing Process: Printing, Etching, and Soldering

PCB production involves several steps:

l Printing – copper is applied to the board to create the circuit pattern.

l Etching – excess copper is removed, leaving only the traces.

l Soldering – components are attached to the board so they can connect and work electrically.

Following these steps carefully ensures the PCB is accurate, reliable, and ready for use in electronics.

Cost Optimization and Reliability

Designing a PCB should also take cost and durability into account.Using fewer layers or simpler materials can reduce cost, while smart layout and quality materials improve reliability. The goal is to make a PCB that is affordable, long-lasting, and suitable for the device.

Conclusion

Printed Circuit Boards, or PCBs, are the heart of modern electronics. They provide a platform to support components, connect circuits, and control signals in almost every device we use. From their structure and types to how they carry electricity and signals, PCBs make devices work efficiently and reliably.

They appear in smartphones, laptops, cars, medical devices, industrial machines, and even satellites. No matter the industry, PCBs are essential for making electronics small, powerful, and dependable.

If you want to learn more about PCBs or explore custom PCB solutions, companies like PCB MASTER can help. They provide professional advice, manufacturing services, and guidance for choosing the right PCB for your project.

Remember, every electronic device you use depends on a PCB to make it work behind the scenes. Understanding PCBs is the first step to creating smarter, more reliable electronics.

FAQs

Why do some PCBs need to be flexible?

Flexible PCBs are used when a device has tight spaces or moving parts. Unlike rigid boards, flexible PCBs can bend, fold, or twist without breaking the connections. This allows electronics to fit into small gadgets, like smartwatches or foldable phones, or move parts in devices like cameras. Using flexible boards also reduces the number of separate boards and saves weight, which is important for portable and wearable devices.

How does the number of PCB layers affect device performance?

The number of layers in a PCB determines how complex the circuit can be. Single-sided boards are simple and cheap but can only handle basic circuits. Double-sided boards add more connections. Multi-layer boards, with three or more layers, allow high-density circuits and faster signal transmission. More layers help prevent signal interference, reduce noise, and save space, making devices faster, smaller, and more reliable.

Can a PCB fail, and what causes it?

Yes, PCBs can fail if they are designed or manufactured poorly. Common causes include:

l Broken copper traces from bending or too much stress.

l Poor soldering, which creates weak connections.

l Overheating, when the board cannot handle the electrical load.

l Moisture or dust, which can cause shorts or corrosion.

Proper design, good materials, careful assembly, and protective coatings make PCBs reliable and long-lasting, even in harsh environments like cars, factories, or aerospace applications.

How do designers choose the right PCB for a project?

Designers choose a PCB based on the device’s size, complexity, and function. They consider:

l Number of layers – Simple gadgets may use single-sided boards, while advanced devices need multi-layer PCBs.

l Material – Rigid boards are strong, flexible boards can bend, and special materials handle high heat.

l Current and signal requirements – High-speed circuits need careful layout to avoid interference.

l Environmental factors – Some PCBs must resist moisture, dust, or extreme temperatures.

By thinking about these factors, designers can pick a PCB that fits the device perfectly, works reliably, and lasts a long time.