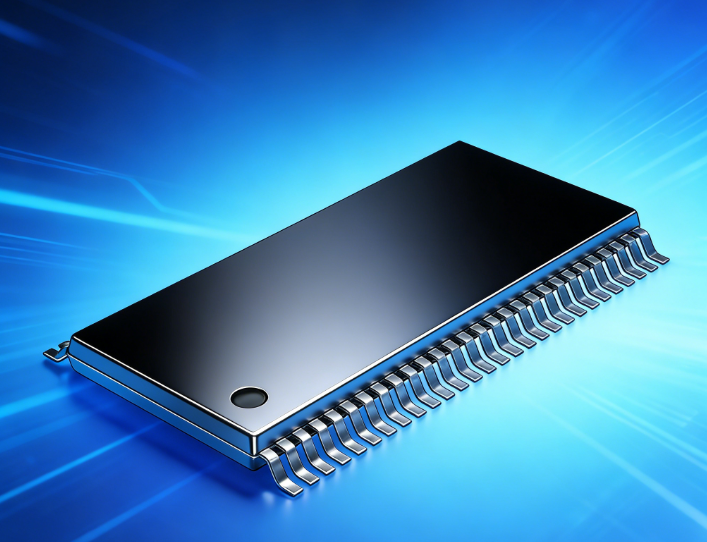

What is TSOP (Thin Small Outline Package)? Key Features, Advantages & Challenges

When size is everything, the Thin Small Outline Package (TSOP) steps in as the silent powerhouse behind today’s ultra-compact devices. From high-speed memory cards to slim laptops, this unassuming package plays a crucial role in making high-performance electronics possible in the smallest spaces. Its ability to pack more pins into a thinner profile without sacrificing efficiency is why TSOP has become essential in industries where every millimeter counts. Let’s explore why this tiny package is making a big impact on the future of tech.

Introduction to TSOP (Thin Small Outline Package)

Definition and Purpose

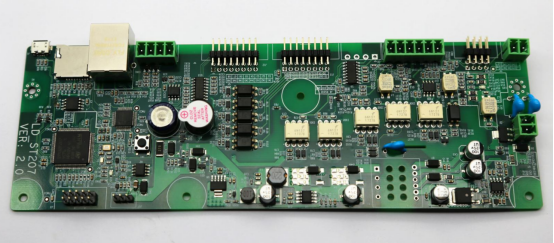

The Thin Small Outline Package (TSOP) is a type of surface-mount package used for electronic components, particularly memory chips like SRAM (Static Random-Access Memory), Flash Memory, and EEPROM (Electrically Erasable Programmable Read-Only Memory). It is characterized by its ultra-thin profile, typically ranging from 0.5mm to 1.2mm in thickness. This slim design allows TSOP to fit into small, compact devices, making it ideal for products where space is limited, such as laptops, USB drives, and memory cards. Unlike traditional packages, TSOP is designed to be mounted directly onto the surface of a printed circuit board (PCB), eliminating the need for holes or pins. Its primary purpose is to provide an efficient and cost-effective way to integrate memory components into modern electronics.

Importance in Modern Electronics

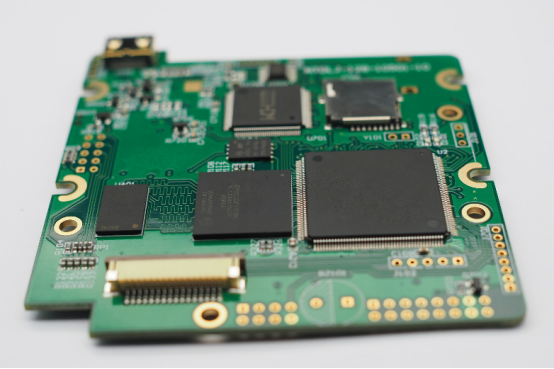

TSOP plays a crucial role in the miniaturization of electronic devices. As technology evolves, devices are becoming thinner and more compact, pushing manufacturers to create smaller and more efficient components. TSOP is a key enabler of this trend, offering a solution to incorporate memory and storage in tight spaces. For example, in laptops and smartphones, where space is at a premium, TSOP packages allow for high-density memory chips without increasing the overall size of the device.

Moreover, TSOP's ability to handle high pin counts in a narrow width allows manufacturers to fit more memory into smaller spaces, crucial for products like high-speed SD cards, USB flash drives, and even 5G telecom equipment. In industries such as consumer electronics, telecommunications, and industrial sectors, TSOP's space-saving design and efficient performance are essential for creating the next generation of slim, powerful devices.

Core Features of TSOP Package

Ultra-Thin Profile for Space-Constrained Devices

The TSOP has a very thin design, with thickness ranging from 0.5mm to 1.2mm. This thin profile is especially important for devices that need to be compact, like smartphones, ultrabooks, and portable memory cards. For example, ultrabook laptops that are only a few millimeters thick can fit TSOP memory chips without compromising their slim design.

When compared to other types of packages like the Small Outline Package (SOP) and the Quad Flat Package (QFP), TSOP is significantly thinner. The SOP typically has a thickness of about 1.4mm, while TSOP can be up to 50% thinner, making it ideal for smaller devices where every millimeter of space counts. In short, TSOP's ultra-thin profile allows it to be used in devices that require both performance and a compact form factor.

Tight Lead Spacing for High Pin Counts

TSOP is designed with a tight lead spacing, typically ranging from 0.5mm to 0.8mm. This small spacing allows it to accommodate a higher number of pins within a narrow area. For example, a TSOP package can have up to 48 pins in just 10mm of width, which is essential for high-density memory chips that need many connections.

This compact design is beneficial in devices where space is limited, but performance cannot be sacrificed. In situations where large amounts of memory need to be packed into a small space—like in USB flash drives or SD cards—TSOP ensures that the chip can have enough pins for its memory functions without taking up too much space. The tight lead spacing also allows for faster data transfer, making TSOP a popular choice for high-performance memory applications.

Surface-Mount Technology (SMT) for Efficient Assembly

TSOP packages use Surface-Mount Technology (SMT), which means they are placed directly onto the surface of a PCB (Printed Circuit Board) without the need for holes or pins. This design saves valuable space on the PCB and simplifies the assembly process.

SMT also benefits manufacturers by reducing the complexity of production. Since TSOP is compatible with automated SMT assembly lines, it can be assembled quickly and accurately. This leads to lower costs and faster production times. For instance, companies that produce large volumes of memory cards or storage devices can rely on automated processes to place TSOP packages efficiently, reducing the chance of errors and speeding up manufacturing.

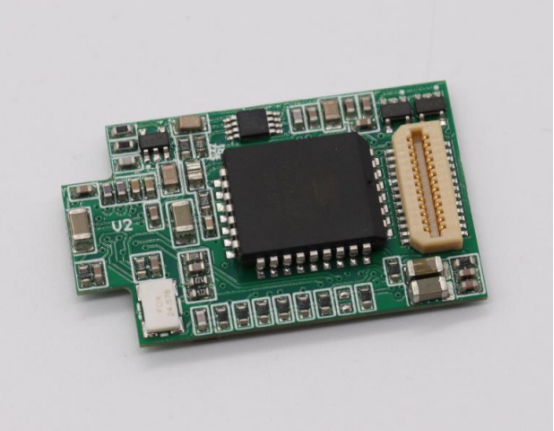

Memory-Optimized Design

TSOP is specifically designed for memory applications, making it a perfect fit for certain types of memory chips like SRAM, Flash Memory, and EEPROM. These memory types require a small yet efficient package to meet both space and performance demands in devices like smartphones, laptops, and memory cards.

The memory-optimized design of TSOP allows it to handle the electrical needs of these memory chips while maintaining a compact size. For example, Flash Memory chips used in USB flash drives rely on TSOP’s efficient design to store large amounts of data in a small, portable package. This makes TSOP a go-to choice for manufacturers aiming to balance high storage capacity with a slim device profile.

Advantages of Using TSOP

Space Efficiency

TSOP packages are known for their compact design, making them ideal for ultra-thin devices. Devices like ultrabooks, thin laptops, and portable memory storage devices all benefit from the slim profile of TSOP, which typically ranges from 0.5mm to 1.2mm in thickness. For example, in a laptop where every millimeter counts, the use of TSOP memory chips helps keep the device lightweight and slim while still providing the performance required for tasks like data storage and quick access.

The space-saving design is especially critical in modern consumer electronics, where the trend is to reduce device thickness without sacrificing functionality. TSOP allows manufacturers to integrate memory components into the smallest spaces, ensuring that devices can remain both powerful and portable. This space efficiency has made TSOP the preferred choice for storage devices like USB flash drives and microSD cards, where a small form factor is essential.

High Pin Count in a Narrow Profile

One of the key advantages of TSOP is its ability to fit a high number of pins into a narrow profile. For example, a TSOP package that is just 10mm wide can accommodate up to 48 pins, allowing for dense memory configurations in compact devices. This high pin count is crucial for applications that require a lot of memory capacity, such as high-speed memory cards, solid-state drives (SSDs), and even mobile devices.

The narrow profile and high pin count work together to maximize the use of available space. For instance, in a device like a USB flash drive, TSOP enables high-density memory chips to be included without increasing the size of the device. This makes TSOP particularly well-suited for applications in which both performance and space constraints must be balanced.

Cost-Effective

TSOP packages are also cost-effective, with prices typically ranging from $0.05 to $0.30 per unit. This makes TSOP an affordable alternative to other memory packaging options, such as Chip-on-Board (COB) or Chip-Scale Packages (CSP), which can be more expensive due to their complexity and specialized requirements. The lower cost of TSOP is particularly attractive for manufacturers looking to reduce production expenses while still maintaining high memory capacity and reliability.

For example, a manufacturer producing high-volume memory products like SD cards or USB flash drives can significantly lower costs by using TSOP, which offers similar functionality to more expensive packages at a fraction of the price. This cost-effectiveness helps keep retail prices lower for end consumers, which is a major advantage in the competitive memory storage market.

Easy Integration in SMT Lines

TSOP packages are designed for easy integration into SMT assembly lines. Unlike traditional packages that may require more complex assembly processes, TSOP can be mounted directly onto the surface of a PCB without the need for drilling holes. This simplifies the manufacturing process, allowing for faster production times and fewer chances for assembly errors.

Because TSOP is compatible with standard SMT equipment, manufacturers can quickly adapt existing production lines without significant changes to their infrastructure. This ease of integration not only lowers production costs but also improves efficiency, making TSOP a popular choice for companies looking to streamline their assembly processes. For example, in the production of memory chips for consumer electronics, the ability to use standard SMT lines helps speed up the manufacturing process while maintaining quality control.

Challenges and Limitations of TSOP

Fragile Lead Structure

One of the main challenges of using TSOP is its fragile lead structure. TSOP packages have very thin leads, often measuring just 0.1mm in thickness. These delicate leads are essential for maintaining the slim design of the package, but they also make the TSOP prone to bending or breaking during handling, especially in high-volume production.

In large-scale manufacturing, where thousands or even millions of TSOP units are assembled, the risk of damaging these fragile leads increases. If a lead is bent or broken, the component may no longer function properly, leading to failures in the device. To address this, manufacturers must take extra care during assembly and handling, using automated systems designed to prevent lead damage. However, this added step can increase production costs and complexity, making TSOP less suitable for certain applications where durability is critical.

Limited Thermal Dissipation

TSOP packages are not designed to handle significant heat, which can limit their use in high-power applications. The thin body of a TSOP package restricts its ability to dissipate heat effectively. As a result, TSOP packages can only handle a maximum power dissipation of about 2 watts (W). This makes TSOP unsuitable for applications where the chip would generate more heat, such as power management ICs or high-performance processors.

For example, if TSOP were used in a high-power device like a graphics processing unit (GPU) or a central processing units (CPUs), the package could overheat, leading to performance issues or even permanent damage. In contrast, other packaging types, such as those with larger surfaces or built-in heat sinks, are designed to handle higher thermal loads. Therefore, TSOP is best suited for low-power memory applications, where heat generation is minimal and heat dissipation is not a major concern.

Not Suitable for Complex ICs

TSOP packages are specifically designed for memory chips, such as SRAM, Flash Memory, and EEPROM. However, they are not suitable for more complex integrated circuits (ICs), like systems on chips (SoCs) or multi-functional ICs. These more advanced chips often require a larger number of pins, more power dissipation, and a greater variety of functionalities that TSOP cannot accommodate due to its limited pin count and heat handling capacity.

For example, a SoC used in smartphones combines a processor, memory, and graphics processing into a single unit. TSOP would not be able to support such a complex chip because it cannot provide enough pins for all the necessary connections or manage the power requirements. As a result, while TSOP is an excellent choice for memory and storage applications, it is not suitable for chips that handle multiple functions or those that require more advanced capabilities.

Best Use Cases and Design Considerations for TSOP

Designing for TSOP in Thin Devices

When designing thin devices, such as ultrabooks, smartphones, and portable memory storage, TSOP is an excellent choice due to its ultra-thin profile. However, there are key design considerations to keep in mind when selecting TSOP for these compact devices. The primary consideration is the balance between pin count and space. TSOP can offer up to 48 pins in just a 10mm wide package, which is ideal for memory chips requiring high pin density.

Pin count refers to the number of electrical connections that the package can support. In devices with limited space, it's crucial to select a TSOP package that fits within the available area while still offering enough pins to meet the memory needs of the device. For instance, a smartphone may only have a small area for memory, but it still requires sufficient pins for functions like storage and data transfer. Therefore, designers must ensure that the chosen TSOP package can meet performance needs without taking up too much space.

For thin devices, TSOP packages provide a compact solution for memory integration, ensuring the device remains lightweight, efficient, and capable of handling essential tasks. The key to success is matching the number of pins required for the device's memory with the limited space available for the package.

Managing Heat Dissipation in Memory Modules

TSOP packages, due to their thin profile, can struggle with heat dissipation. In applications such as SSDs, USB drives, or other memory modules, heat can build up and affect the performance of the device. While TSOP packages are designed for low-power memory components, managing heat remains a critical consideration.

To mitigate heat challenges when using TSOP, manufacturers can apply a few strategies. First, improve airflow in the device by placing TSOP components in areas with better ventilation. For example, in a laptop, placing memory chips closer to the device’s cooling system can help disperse heat. Second, use heat sinks or thermal pads to improve heat dissipation. In certain high-performance memory applications, additional heat management solutions can help prevent overheating.

Lastly, limit power usage by ensuring that the TSOP package is not used in applications with high power demands, like GPUs or CPUs. Since TSOP packages are designed to handle only up to 2 watts of power, they should be used in low-power memory applications where heat generation is minimal.

By understanding the heat limitations of TSOP and applying these strategies, manufacturers can ensure that devices with TSOP packages remain efficient and reliable, even under extended use.

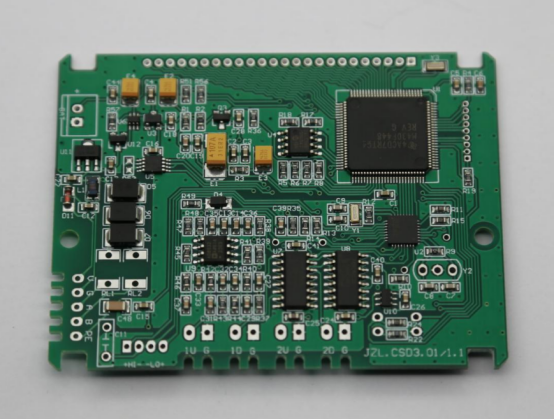

Reliability in High-Volume Manufacturing

TSOP packages are commonly used in high-volume production environments, where thousands of components are assembled daily. However, due to the fragile lead structure (0.1mm thin leads), TSOP components require careful handling during manufacturing to avoid lead damage. Damaged leads can lead to defective products, resulting in increased costs and manufacturing delays.

To improve reliability in high-volume manufacturing, manufacturers should take certain steps during assembly. First, use automated pick-and-place systems that are specifically designed for handling small and fragile components like TSOP. These systems ensure that components are picked up and placed onto the PCB without damaging the leads.

Second, employ protective packaging during shipping and handling to avoid physical damage before the components reach the assembly line. It's also essential to perform routine testing at different stages of production to identify any damaged leads or defective packages early in the process.

By focusing on careful handling, testing, and using the right equipment, manufacturers can increase the reliability of TSOP packages in high-volume production, minimizing defects and ensuring that the final products meet quality standards.

Conclusion

TSOP offers significant advantages for designing space-efficient, high-performance memory solutions in compact devices. Its ultra-thin profile, high pin count, and cost-effectiveness make it an ideal choice for products like ultrabooks, portable storage devices, and mobile electronics. However, challenges like fragile leads, limited thermal dissipation, and its suitability for only memory applications must be carefully considered during the design and manufacturing process.

For manufacturers looking to integrate TSOP packages into their products, choosing the right PCB supplier is crucial to ensuring reliability and efficiency. PCBMASTER, a leading PCB supplier, offers high-quality PCBs and expert guidance to help you design, manufacture, and assemble devices with TSOP packages. With their experience and attention to detail, PCBMASTER can assist in overcoming the common challenges of TSOP assembly, ensuring that your products meet the highest standards for performance and durability. Whether you are working on a consumer electronics project or a specialized industrial application, PCBMASTER is your trusted partner in creating innovative, space-saving solutions.

FAQs

What is the main advantage of using TSOP over other memory packages?

TSOP’s ultra-thin design and ability to fit high pin counts in a compact space make it ideal for slim devices with memory storage needs. Its small form factor allows it to be used in space-constrained devices such as ultrabooks, smartphones, and portable storage solutions, providing efficient memory without increasing the overall size of the device.

Why are TSOP leads considered fragile, and how can manufacturers address this issue?

TSOP’s thin leads (often just 0.1mm thick) are highly susceptible to bending or breaking during handling and assembly. This fragility can be problematic, especially in high-volume manufacturing where thousands of units are produced. Manufacturers can address this issue by using automated pick-and-place systems designed to handle delicate components like TSOP, and by applying protective packaging to minimize damage during shipping and handling. Additionally, using standard SMT lines can help reduce the risk of lead damage during assembly.

Is TSOP suitable for high-power applications?

No, TSOP is not ideal for high-power ICs. Due to its thin body, TSOP packages have limited heat dissipation capabilities, typically handling only up to 2 watts of power. This makes TSOP unsuitable for high-power applications like GPUs or CPUs, which require more robust heat management. TSOP is best suited for low-power memory applications where heat generation is minimal.

Can TSOP be used for devices other than memory chips?

No, TSOP is primarily designed for memory devices like SRAM, Flash Memory, and EEPROM. Its design limitations—such as the number of pins and its inability to manage high power—make it unsuitable for more complex ICs or SoCs. TSOP excels in memory storage but is not equipped to handle the diverse functions of more advanced chips.

What industries benefit the most from TSOP packages?

TSOP packages are widely used in industries where space efficiency and high-performance memory are essential. These industries include:

Consumer Electronics: Devices like smartphones, laptops, and USB flash drives rely on TSOP for their compact and efficient memory solutions.

Telecommunications: TSOP is crucial for memory components in 4G/5G routers and base stations, where space and performance are key factors.

Industrial Applications: TSOP is used in devices like data loggers and sensor memory that require small, efficient memory storage in space-constrained environments.

In all these sectors, TSOP’s slim design and high pin count offer the ideal balance between size, cost, and performance.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!