Surface Mount PCB Assembly Solutions | Precision, Speed, and Reliability

Every electronic device you use—like your phone, TV, or even a car—depends on something called a printed circuit board (PCB). To make these boards work, tiny electronic parts must be placed on them in the right way. This process is called Surface Mount PCB Assembly, or simply SMT.

Why is SMT so important? Because it gives us three big benefits:

Precision – parts are placed very accurately, even if they are smaller than a grain of rice.

Speed – machines can place thousands of parts in just one minute.

Reliability – the final boards are strong and work well for a long time.

In this article, we will look at how SMT solutions bring precision, speed, and reliability to modern electronics, and why this matters for the devices we use every day.

What is Surface Mount PCB Assembly?

To understand Surface Mount PCB Assembly (SMT), we first need to look at how electronic boards used to be made, using something called Through-Hole Technology (THT).

In THT, each electronic part, like a resistor or a chip, has long metal legs. These legs go through holes in the PCB and are soldered on the other side. This method works well, but it is slow, takes more space, and uses bigger parts.

In SMT, parts do not have long legs. Instead, tiny components are placed directly on the surface of the PCB. This method allows us to make smaller, lighter, and more advanced electronics. SMT also uses less material and can be done much faster than through-hole assembly.

How does SMT work?

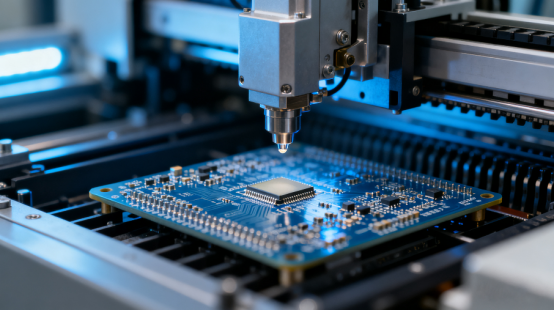

Pick-and-Place Machine – A fast machine picks up tiny parts and puts them in the correct position on the board. Some parts are smaller than a grain of rice, so this machine must be extremely precise.

Reflow Soldering – After placement, the PCB is heated in an oven. The solder paste melts, sticking the parts firmly to the board. Once cooled, the connections are strong and durable.

Automated Optical Inspection (AOI) – Cameras scan the board to make sure every part is in the right place and soldered correctly. AOI can detect tiny mistakes that humans might miss.

Why is SMT used today?

It allows manufacturers to make smaller and thinner devices, like smartphones, tablets, smartwatches, and other wearable electronics.

SMT is much faster and cheaper for large-scale production, which helps companies deliver products quickly.

Parts are placed very accurately, which improves the performance of the final product and makes it last longer.

SMT supports modern electronics design, where boards need to handle more circuits and high-speed signals in a small space.

Because of these advantages, almost every modern electronic device is made using SMT instead of the older through-hole method. It is faster, more precise, and perfect for today’s small, powerful electronics.

Precision: Making Sure Every Part Fits and Works

When we talk about precision in PCB assembly, we mean how accurately tiny electronic parts are placed on the board. Some of these parts are extremely small. For example, 01005 packages are even smaller than a grain of sand! If they are not placed in exactly the right spot, the whole circuit may fail or the device may not work at all.

Why is precision so important?

In high-frequency signal circuits, even a tiny mistake in placing a component can make the signal weaker or cause unwanted noise. This can make your device slower or less reliable.

RF boards, like those used in 5G networks and Wi-Fi devices, need perfect placement. Any small error may lead to dropped signals, slower connections, or poor device performance.

Medical electronics, such as pacemakers, heart monitors, or wearable health devices, require absolute accuracy. Even the tiniest mistake could affect a person’s health or safety.

How do we ensure precision in SMT?

Automated Machines – Pick-and-place machines can move faster than the human eye and place thousands of tiny parts in the exact positions on the PCB.

AOI (Automated Optical Inspection) – Cameras take very close-up pictures of the board to check if every part is aligned correctly and soldered properly.

X-Ray Inspection – Some parts are hidden under other components, so X-ray machines are used to see inside the board and ensure the solder joints are strong and perfect.

With these tools and techniques, manufacturers can make sure every single part is placed with perfect precision. This allows the PCB to be smaller, stronger, and more reliable, which is essential for today’s high-tech devices.

Speed: Making Electronics Faster and Faster

One of the biggest advantages of Surface Mount PCB Assembly (SMT) is speed. In today’s fast-moving world of electronics, being fast is very important. Companies need to make new products quickly and keep up with customer demands.

Why speed matters:

Rapid Prototyping – Startups or design teams often need a first version of a product, called a prototype, very quickly. With SMT, a working board can be made in just a few days instead of weeks. This allows engineers to test ideas, find mistakes early, and improve the design much faster.

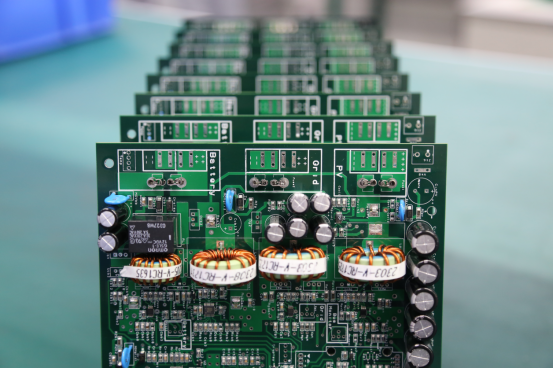

High-Speed Mass Production – When producing thousands or even millions of boards, automated SMT machines work much faster than humans. These machines can place thousands of tiny parts every minute, which greatly increases production efficiency. Faster production means companies can deliver more products to customers in less time, reducing waiting periods.

Quick-Turn Delivery – Markets can change quickly, and sometimes products are needed very fast. SMT allows quick-turn services, where boards can be designed, assembled, and shipped in days. This speed gives companies a competitive advantage, helping them get their products to market before others.

By combining fast prototyping, automated production, and quick delivery, SMT helps electronics companies save time, reduce costs, and stay ahead in the market. It is one of the main reasons modern electronics can be developed and released so quickly today.

Reliability: Making Electronics Last Longer

Another key advantage of Surface Mount PCB Assembly (SMT) is reliability. Reliability means that an electronic device works correctly and safely for a long time, even under heavy use. A reliable PCB is essential because any failure can cause serious problems, especially in critical devices like cars, medical equipment, or airplanes.

Why reliability matters:

Solder joint quality – The tiny connections that hold components to the board are called solder joints. Strong, well-made solder joints make the board last longer and prevent failures. Poor soldering can cause parts to fall off, short circuits, or complete device failure.

How reliability is ensured:

AOI (Automated Optical Inspection) – Cameras scan the board to check that every component is placed correctly and soldered properly.

ICT (In-Circuit Testing) – Special machines send small electric signals through the board to ensure each circuit works correctly.

Functional Testing (FCT) – The board is tested like it would work in the real device, to make sure all functions operate as intended.

Standards and certifications:

Boards that follow international standards like ISO, IPC, RoHS, and ITAR are more trustworthy. These certifications mean the manufacturer meets strict quality and safety rules, giving customers confidence in the product.

Industries that need high reliability:

Automotive electronics – Car systems like engine controls and safety sensors must be extremely dependable to keep drivers and passengers safe.

Medical devices – Pacemakers, heart monitors, and other health devices must work perfectly because lives depend on them.

Aerospace electronics – Electronics in airplanes and satellites must be highly reliable because failures can be dangerous or very costly.

By combining good soldering, thorough testing, and certified quality standards, SMT boards are built to last longer, perform safely, and withstand critical applications. This makes them the preferred choice for industries where failure is not an option.

Typical Applications of Surface Mount PCB Assembly

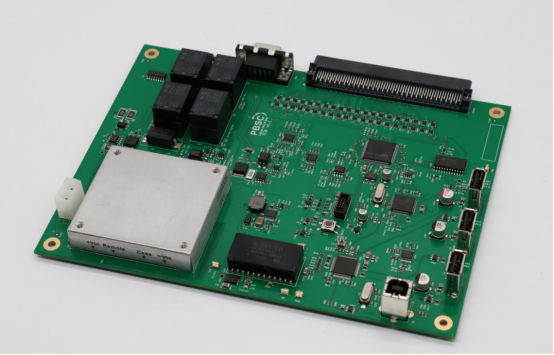

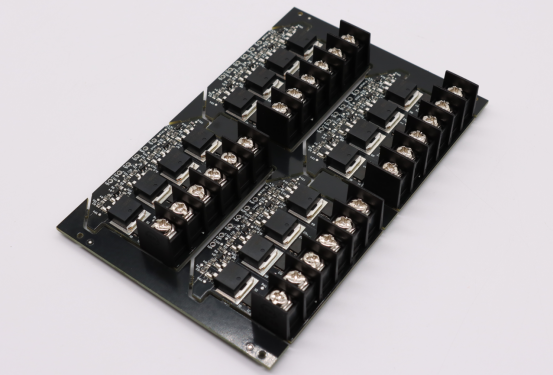

Surface Mount PCB Assembly (SMT) is used in many different electronic products. It allows manufacturers to make devices smaller, faster, and more reliable. Let’s look at the main areas where SMT is widely used:

Consumer Electronics – Smartphones, tablets, smartwatches, and fitness trackers use SMT. By placing tiny parts directly on the board, these devices can be smaller, lighter, and thinner, while still powerful. Without SMT, these products would be bigger, heavier, and slower.

Automotive Electronics – Modern cars have many electronic systems, including engine control units, advanced driver assistance systems (ADAS), and electric vehicle battery management systems. These systems need highly reliable SMT boards because a failure could affect car safety or performance.

Medical Devices – Pacemakers, heart monitors, glucose monitors, and wearable health trackers all rely on SMT. Precision and reliability are critical in these devices because a mistake could seriously affect a patient’s health or even be life-threatening.

Communication and 5G – Base stations, routers, high-frequency RF modules, and other communication devices depend on SMT. Accurate placement and high-quality assembly ensure these devices transmit signals efficiently, reduce signal loss, and provide stable connections.

Industrial Control and IoT (Internet of Things) – Sensors, PLCs (programmable logic controllers), smart factory equipment, and other industrial devices use SMT boards. These boards need to be produced quickly and reliably so factories and IoT devices can operate without interruption.

By using SMT, all these industries can create electronics that are smaller, faster, and more reliable, meeting the needs of modern technology. SMT makes it possible to build devices that are highly functional, durable, and ready for today’s fast-paced world.

Conclusion

In summary, Surface Mount PCB Assembly (SMT) brings three major advantages to modern electronics: precision, speed, and reliability. These benefits make devices smaller, lighter, faster, and more dependable than ever before.

Precision ensures that even the tiniest parts are placed correctly, so circuits work properly and devices perform as expected.

Speed allows prototypes to be made quickly and mass production to happen fast, helping companies get products to market sooner.

Reliability guarantees that devices can work safely and last longer, which is especially important in cars, medical devices, and aerospace equipment.

SMT is now an essential part of electronic manufacturing. Without it, many of the devices we use every day—smartphones, tablets, cars, medical monitors, and communication equipment—would not be possible or would be much larger and less reliable.

If you have any questions about PCBs or PCB assembly, you can contact PCB MASTER. They are a professional supplier of PCBs and PCB assembly solutions and can help you find the right solution for your project, whether you need small prototypes or large-scale production.

By understanding SMT and its benefits, you can see why it is the foundation of modern electronics and why so many industries rely on it every day.

FAQs

What types of components can be used in Surface Mount PCB Assembly?

Surface Mount PCB Assembly (SMT) can use many types of components, including resistors, capacitors, diodes, IC chips, LEDs, and tiny sensors. These parts come in very small packages, some smaller than a grain of sand. SMT allows these components to be placed directly on the board surface, which helps make devices smaller and more efficient. Special machines can handle parts of different sizes and shapes accurately.

Can Surface Mount Technology be used for both small and large production runs?

Yes! SMT is very flexible. For small production, like prototypes or custom devices, SMT machines can quickly assemble a few boards. For large-scale production, these machines can place thousands of parts per hour, making mass production fast, efficient, and cost-effective. This flexibility helps startups and big companies both benefit from SMT.

How does SMT improve the performance of electronic devices?

SMT improves performance in several ways. First, it allows smaller and denser circuits, meaning more features can fit on the same board. Second, precise placement reduces signal interference, which is important in high-speed and high-frequency devices like smartphones, Wi-Fi routers, and 5G modules. Third, reliable soldering ensures the device works consistently over time, reducing failures and maintenance needs.

Are there special tools or machines needed for SMT?

Yes, SMT requires special machines. The main tools include:

Pick-and-Place Machines to place tiny components accurately.

Reflow Ovens to melt solder paste and secure the parts.

Inspection Tools like AOI (Automated Optical Inspection) and X-Ray machines to check placement and soldering quality.

These tools make SMT fast, precise, and reliable, which would be very hard to achieve by hand.

Can SMT boards be repaired if something goes wrong?

Yes, SMT boards can be repaired, but it is more delicate than older through-hole boards. Technicians use special tools like soldering irons with tiny tips, hot air rework stations, and microscopes to carefully remove and replace faulty components. Because the parts are so small, repairs require skill and patience, but it is possible to fix many SMT boards without replacing the whole board.