Ceramic PCB Manufacturing

With over 10 years of R&D and production experience in ceramic substrates, we focus on tech breakthroughs for peak product performance, quality and higher production efficiency.

20 ~ 220 W/(m·K)

Thermal Conductivity

< 0.03%

Defective Rate

96hrs / 10-15d

Prototype/Batch Urgent Order

Ceramic Substrate Product Series

Tailored for diverse scenario requirements, we offer optimized material solutions to balance performance, reliability and cost-efficiency.

The ceramic PCB materials we produce include alumina, aluminum nitride, silicon nitride, beryllium oxide (BeO), sapphire, glass, ferrite and diamond.

High-purity alumina (≥96% Al₂O₃) with excellent electrical insulation and thermal conductivity, ideal for medium-power electronics.

.webp)

Alumina(Al₂O₃)

Exceptional thermal conductivity and matched thermal expansion, designed for high-power high-reliability applications.

.webp)

Aluminum Nitride(AlN)

Outstanding high-temperature, corrosion and radiation resistance, engineered for aerospace and energy-intensive environments.

Silicon Nitride(Si₃N₄)

ZTA ceramic substrates, a zirconia-toughened alumina material, offer enhanced toughness, balanced performance (high strength, hardness, impact resistance), as well as high temperature and corrosion resistance.

.webp)

Zirconia Toughened Alumina(ZTA)

Different Material Comparison

| Material | Thermal Conductivity | Insulation | Toughness | Cost |

|---|---|---|---|---|

| Alumina (Al₂O₃) |

Sufficient for low-power devices

|

Superior electrical isolation

|

Brittle, prone to chipping

|

Low

Mature production process

|

| Aluminum Nitride (AlN) |

Superior heat dissipation

|

Suitable for most electronics

|

Lower than silicon nitride

|

Medium-High

Higher raw material cost

|

| Silicon Nitride (Si₃N₄) |

Dependent on sintering process

|

Adequate for structural applications

|

Highest fracture resistance

|

High

Complex manufacturing

|

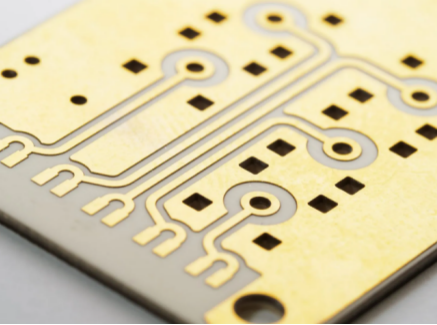

Core Technical Advantages

From material selection to process control, every detail follows "high-reliability" standards to create industry-leading ceramic substrates.

Excellent Thermal Conductivity

Substrate thermal conductivity reaches up to 220 W/(m·K), 500-600x that of traditional FR-4, reducing component operating temperature and extending lifespan.

Extreme Temperature Resistance

Stable operation in -55℃ to 1500℃ extreme temperature ranges, meeting strict requirements of aerospace and military industries for high-temperature resistance.

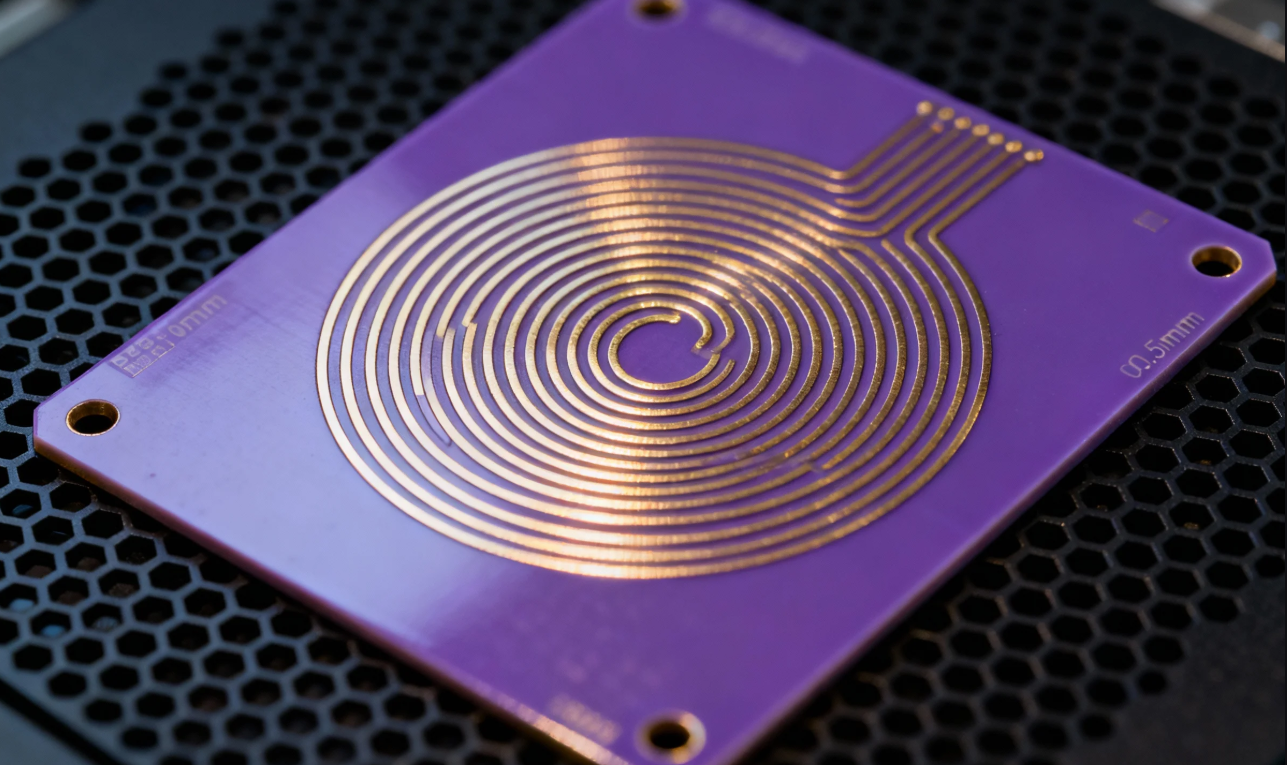

Precision Circuitry

Advanced processing enables 0.05mm ultra-fine lines and 0.1mm micro-vias, satisfying high hermeticity, low outgassing and high-frequency and high-speed signal transmission needs.

CTE Matching Design

Thermal Expansion Coefficient (CTE) matches chips at 3ppm/℃, effectively reducing solder joint thermal stress and improving product reliability.

Full-process Quality Control

Compliant with AS9100, IATF16949 standards, thermal shock testing, with defect rates controlled below 0.03%.

Customized Solutions

We offer one-stop services, including material selection, structural design, SMT assembly, IC packaging and thermal simulation, to optimize performance and cost for specific scenarios.

Traditional PCB vs Ceramic Substrate

Ceramic substrates have significant advantages in thermal conductivity, high-temperature resistance and reliability—ideal for high-power and high-reliability applications.

- Heat Dissipation Capacity +600%

- Expanded Operating Temperature Range

- Service Life +3-10x

- Power Density +2-10x

Precision Manufacturing Capabilities

With "millimeter-level precision, micrometer-level control" as the standard, we ensure high quality through five core processes.

Application Fields

From new energy vehicles to medical devices, from 5G communication to aerospace, our ceramic substrate solutions are the core choice for high-end fields.

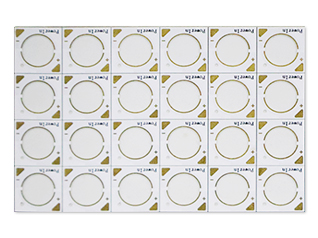

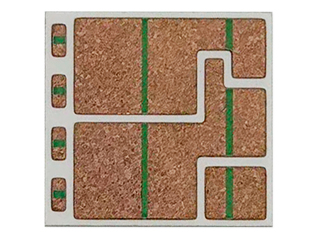

99% Alumina Ceramic PCB

- Material: 99% Alumina Ceramic PCB

- Layers: 2 Layers

- Thickness: 1.00mm

- Track/Spacing: 8mil

- Surface finish: OSP

- Special technology: High-purity 99% alumina ceramic; High flatness of filled holes

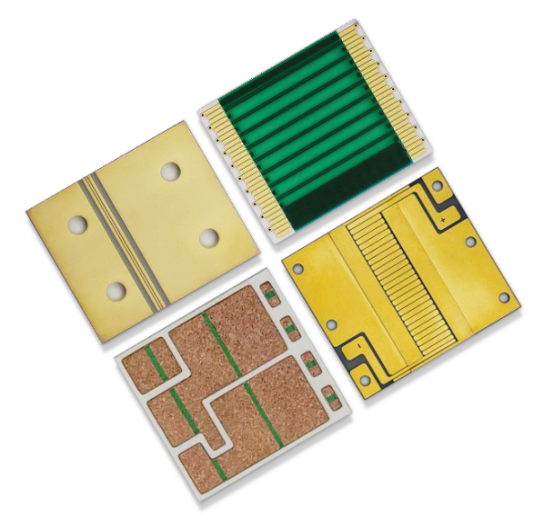

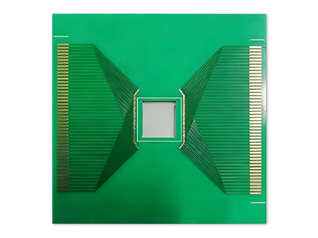

Zirconia Toughened Alumina PCB

- Material: Zirconia Toughened Alumina (ZTA)

- Layers: 2 Layers

- Thickness: 1.50mm

- Track/Spacing: 4/4mil

- Surface finish: Immersion gold

- Special technology: Impedance Control +/-7%

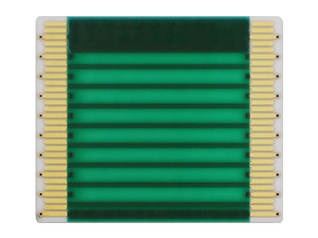

Aluminum Nitride Ceramic PCB

- Material: Aluminum Nitride Ceramic

- Layers: 2 Layers

- Thickness: 0.8mm

- Track/Spacing: 4/4mil

- Surface finish: Aluminum Nitride Ceramic Base material

- Special technology: little Line spacing.Dimensional accuracy.IC-bonding

Typical Customer Cases

Due to the power density of the RF module in a portable MRI device being increased to 20W/cm³, the traditional FR4 substrate (with a thermal conductivity of 0.3W/m·K) results in the chip junction temperature reaching 150℃ and thermal expansion mismatch causes solder joint cracking.

- Material Innovation: Adopt aluminum nitride (AlN) substrates with a thermal conductivity of 170W/m·K (567 times that of FR4) and a coefficient of thermal expansion (CTE) of 4.5ppm/℃. It is highly matched with silicon chips (3ppm/℃), fundamentally solving the thermal mismatch problem.

- Process Optimization: Achieve metallurgical bonding between ceramics and copper layers through the direct bonded copper (DBC) process, with an interface thermal resistance < 0.5℃·cm²/W. Combine with copper pillar array design to form vertical heat conduction channels, reducing the total thermal resistance to 0.15℃/W.

- Reliability Assurance: Use active metal brazing (AMB) to enhance thermal shock resistance. After 1000 cycles of testing at -55℃~150℃, the solder joint strength retention rate is > 95%.

- Results: The chip junction temperature is reduced to 85℃ and the power density reaches 22W/cm³. The product has passed ISO 13485 medical certification, meeting the device's 10-year service life requirement.

Blog & NEWS

-

Aluminum Oxide vs. Aluminum Nitride for Ceramic PCBs: How to Choose?Ceramic PCBs are essential components in modern electronics, offering superior performance in high-temperature, high-power, and high-frequency applications. These PCBs are made from ceramic materials, which provide better heat dissipation, ...Jan 22, 2026More

Aluminum Oxide vs. Aluminum Nitride for Ceramic PCBs: How to Choose?Ceramic PCBs are essential components in modern electronics, offering superior performance in high-temperature, high-power, and high-frequency applications. These PCBs are made from ceramic materials, which provide better heat dissipation, ...Jan 22, 2026More -

What is 99.6% Alumina Ceramic Substrate PCBIntroduction to Ceramic SubstratesCeramic substrates form the backbone of ceramic printed circuit boards, providing a robust and reliable platform for advanced electronic applications. Made from high-performance ceramic materials such as al...Oct 24, 2025More

What is 99.6% Alumina Ceramic Substrate PCBIntroduction to Ceramic SubstratesCeramic substrates form the backbone of ceramic printed circuit boards, providing a robust and reliable platform for advanced electronic applications. Made from high-performance ceramic materials such as al...Oct 24, 2025More -

Alumina Ceramic PCB vs. Aluminum Nitride Ceramic PCB Core Types, PCB Fabrication Processes, and Industry ApplicationsⅠ. Alumina Ceramic PCB vs. Aluminum Nitride Ceramic PCB: Type and Performance Comparison1. Alumina Ceramic PCB (Al₂O₃) ① Single-Layer Alumina Ceramic Substrate: Suitable for simple circuit designs, with a thermal conductivity of 20–27 ...May 16, 2025More

Alumina Ceramic PCB vs. Aluminum Nitride Ceramic PCB Core Types, PCB Fabrication Processes, and Industry ApplicationsⅠ. Alumina Ceramic PCB vs. Aluminum Nitride Ceramic PCB: Type and Performance Comparison1. Alumina Ceramic PCB (Al₂O₃) ① Single-Layer Alumina Ceramic Substrate: Suitable for simple circuit designs, with a thermal conductivity of 20–27 ...May 16, 2025More -

Applications of Ceramic-Based Aluminum Nitride PCBs Technological Innovations from 5G Base Stations to AerospaceⅠ. High-Power Applications: The Irreplaceability of AlN PCBs 1.1 5G Base Station AAU ModulesHuawei’s 5G Massive MIMO Antenna (Model AAU5613) uses AlN PCBs as core thermal management substrates. Test data reveals: ①Chip junction temperatu...May 10, 2025More

Applications of Ceramic-Based Aluminum Nitride PCBs Technological Innovations from 5G Base Stations to AerospaceⅠ. High-Power Applications: The Irreplaceability of AlN PCBs 1.1 5G Base Station AAU ModulesHuawei’s 5G Massive MIMO Antenna (Model AAU5613) uses AlN PCBs as core thermal management substrates. Test data reveals: ①Chip junction temperatu...May 10, 2025More

FAQs About Ceramic PCB

Have more questions? Our technical team is ready to help.

Customer Reviews

Authentic feedback from clients, validating our product quality and service level.

"Our industrial power modules operate long-term in high-temperature environments above 150℃. Previously, using ordinary PCBs led to frequent thermal failures. After switching to ceramic-based PCBs, the thermal conductivity efficiency has significantly improved. They've run continuously for 6 months with zero failures, and the device temperature has dropped by 28℃ compared to before. The stability has completely exceeded expectations—truly a reliable choice for high-power applications!"

—— Mark Reynolds, Senior Power Electronics Engineer

"The core heat dissipation area of our high-end projectors has long been limited by space constraints. The thin and lightweight properties of ceramic-based PCBs perfectly fit the product design: despite a thickness of only 0.6mm, they quickly conduct heat away from the chip. This allows the projector to operate continuously for 3 hours while keeping the body temperature below 45℃. User feedback indicates a significant improvement in experience, with the repair rate dropping by 35%."

—— Emily Carter, RF Systems Engineer

"When selecting a substrate for our automotive radar module, we compared multiple options and ultimately chose ceramic-based PCBs. Not only can they withstand vibration and impact during vehicle operation, but signal transmission remains stable within the wide temperature range of -40℃ to 125℃. After 1,000 thermal cycle tests, there was no cracking or desoldering whatsoever—fully meeting automotive-grade reliability requirements."

—— David Larson, R&D Electrical Engineer