Professional PCB Assembly

High-quality printed circuit boards and assembly services with fast turnaround times and competitive pricing.

Electronics Manufacturing Service

What we can do goes far beyond Turnkey PCB Assembly

-

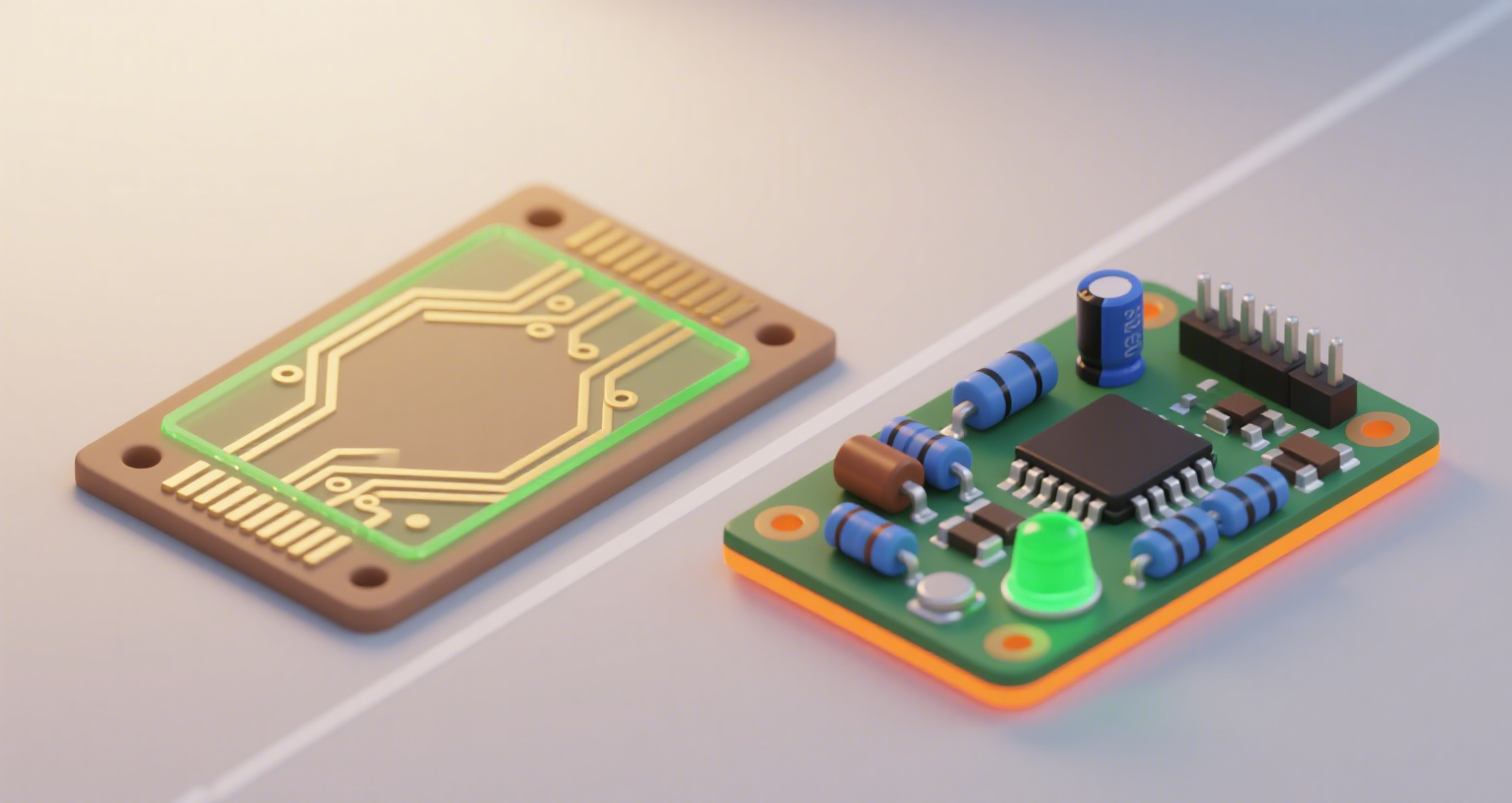

Bare PCB Fabrication

Large Quantities =

Better Price

-

Global Electronic Component Sourcing

Genuine Parts =

Reliable Performance

-

SMT/DIP Assembly & Soldering

Precision Assembly =

Flawless Functionality

-

Full-Process Testing

Comprehensive Testing =

Zero Defects

Through-Hole Assembly

Mixed SMD & Through-Hole

Press-fit Assembly

Bonding

Single & Double-Sided PCBA

Flex PCB & Rigid-Flex PCB

Special Offer Sale

Sign up for free samples

PCBMASTER Turnkey PCB Assembly – Manufacturing Advantages

Five Core Advantages

PCBA Product Display

We provide high - end PCBs to empower thousands of industries and we are worthy of your trust!

Compare Our Service Options

Choose the assembly service that best fits your project requirements, budget and supply chain strategy.

| Features |

Turnkey

PCBMASTER supplies parts

|

Kitted/Consigned

Customer supplies parts

|

Combo

Shared supply

|

|---|---|---|---|

| PCB/Component Sourcing | PCBMASTER | Customer | Both |

| Cost Efficiency | |||

| Lead Time | Fast (1-2 weeks) | Medium (1-3 weeks) | Medium (1-3 weeks) |

| Inventory Management | Handled by PCBMASTER | Handled by Customer | Shared Responsibility |

| Minimum Order Quantity | 1 unit | 1 unit | 1 unit |

| Component Quality Control | Full QC by PCBMASTER | Basic inspection | QC on supplied parts |

| Best For | Turnkey PCBA one-stop service | Controlled supply chain | Mixed requirements |

Not sure which option is right for you? Our experts can help you decide based on your specific needs.

Consult an ExpertProduction Process

Excellence begins with every precision detail

Incoming Material Inspection

-

Perform compliance inspection on

PCB boards (checking pad oxidation, dimensional tolerances)

Electronic components (verifying against datasheet specifications, visual integrity without damage)

Solder paste (validating viscosity, alloy composition)

-

Reference standards

IPC-A-600 (Acceptability of Printed Boards)

Component datasheets

Quarantine all non-conforming materials

PCB Loading and Solder Paste Printing

-

After the PCB is transferred to the printing station via the automatic PCB loader, the stencil (custom-designed based on PCB layout) achieves precision alignment with the PCB. The squeegee then prints solder paste onto the pads.

-

Key parameters

Solder paste thickness (<15μm)

Printing offset (<10% of stencil aperture width)

-

Real-time inspection is performed by SPI (Solder Paste Inspection system), with non-conforming boards automatically rejected for rework.

Component Placement

-

The pick-and-place machine utilizes vision alignment (CCD camera) to identify PCB fiducial marks and component positions, achieving a placement accuracy of ±0.030mm (placement accuracy for QFP components). It mounts them onto preprogrammed pad locations.

-

Supports multiple component types:

Passive components (resistors, capacitors)

Active components (ICs, chips)

Odd-form components (connectors)

-

High-speed placement rate reaches >100,000 components per hour (CPH).

Reflow Soldering

-

The assembled PCBs enter the reflow oven and go through four stages: preheating (150-180°C), soaking (to prevent component damage), peak temperature (approximately 245°C for lead-free solder paste) and cooling. This process melts the solder paste and forms solder joints.

-

The temperature profile must comply with the IPC-J-STD-001 standard to ensure good solder wetting (wetting angle < 90°). After soldering, AOI (Automated Optical Inspection) is used to check for defects such as cold solder joints and bridges. For sensitive components requiring reflow temperature adjustment, low-temperature solder paste should be used for low-temperature assembly.

DIP & Wave Soldering

-

For through-hole components that cannot be surface-mounted (such as high-power connectors and electrolytic capacitors), they are inserted into the PCB through-holes either manually or by automatic insertion machines, followed by wave soldering to complete the welding process (suitable for mass soldering of DIP components).

Final Inspection and Testing

-

Visual inspection

AOI (Automated Optical Inspection) or manual review is performed on the appearance of solder joints and components, with a focus on checking for solder balls and component misalignment.

-

Electrical testing (if required)

ICT (In-Circuit Test) is used to check circuit continuity and component parameters; FCT (Functional Test) simulates actual operating conditions to verify overall performance (such as signal transmission and voltage output). For complex boards, X-RAY inspection is required to examine hidden solder joints such as those of BGA components.

Packaging and Delivery

-

Conforming products are packaged in anti-static packaging (anti-static bags, trays) as required by the customer, accompanied by test reports (including AOI/X-RAY images and ICT/FCT data).

-

Batch information is recorded through the MES system to achieve full-process traceability.

Frequently Asked Questions

Find answers to common questions about our PCB manufacturing services

Blog & NEWS

We offer an all - inclusive experience. Let us take you on a journey to explore the world of wiring and get you familiar with us.

-

MoreThe Ultimate Guide to Turnkey PCB Assembly ServicesIntroduction to PCB AssemblyPCB assembly is a vital step in the creation of modern electronic devices, involving the precise placement and soldering of components onto a printed circuit board (PCB). This process transforms a bare board into...Aug 13, 2025

MoreThe Ultimate Guide to Turnkey PCB Assembly ServicesIntroduction to PCB AssemblyPCB assembly is a vital step in the creation of modern electronic devices, involving the precise placement and soldering of components onto a printed circuit board (PCB). This process transforms a bare board into...Aug 13, 2025 -

MoreA Detailed Explanation of the PCB Assembly Production ProcessPCB Assembly OverviewI. Basic Definition of PCB Assembly·PCB Assembly refers to the process of assembling electronic components (such as resistors, capacitors, chips, connectors, etc.) onto a PCB through soldering or mechanical fixation, ul...Jul 28, 2025

MoreA Detailed Explanation of the PCB Assembly Production ProcessPCB Assembly OverviewI. Basic Definition of PCB Assembly·PCB Assembly refers to the process of assembling electronic components (such as resistors, capacitors, chips, connectors, etc.) onto a PCB through soldering or mechanical fixation, ul...Jul 28, 2025 -

MoreComprehensive Guide to PCB Assembly Equipment From Core Technologies to Industry ApplicationsThe core processes of PCB assembly are mainly divided into two categories: Surface Mount Technology (SMT) and Through-Hole Technology (THT). Modern production lines are usually a hybrid of both (with SMT as the mainstay and THT as a supplem...Jul 19, 2025

MoreComprehensive Guide to PCB Assembly Equipment From Core Technologies to Industry ApplicationsThe core processes of PCB assembly are mainly divided into two categories: Surface Mount Technology (SMT) and Through-Hole Technology (THT). Modern production lines are usually a hybrid of both (with SMT as the mainstay and THT as a supplem...Jul 19, 2025

Get Your PCB Assembly Quote Today

Contact us to discuss your project requirements and receive a personalized quote from our technical experts.

Email Us

service@pcbmaster.com

Call Us

+86 0755-23002065

Visit Us

5F, Factory Building 1, Hezhou Anle Industrial Park, Hezhou Community, Hangcheng Street, Bao'an District, Shenzhen City, CHINA.