PCBMASTER Flexible PCBs Advantages

Specialized Bend-Resistant Flexible Materials for Diverse Flexing Applications

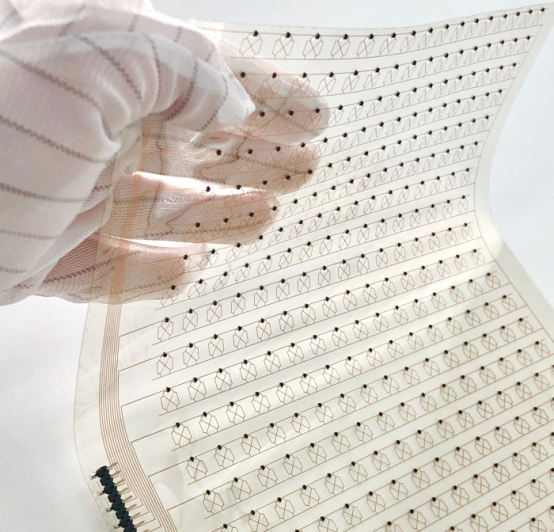

Manufactured with internationally renowned materials from DuPont, Panasonic, SYTECH, I-tec, Taiwan Union, etc., combined with high-standard manufacturing processes. Ensures ultra-high flexibility while guaranteeing product service life and reliability. FPC products can withstand over 100 million folding cycles

Self-Developed Custom Ultra-Thin Materials | Double-Sided + Coverlay Thickness as Low as 0.08mm

PCBMASTER independently researches and fabricates special FPC materials based on clients' design requirements. The minimum finished thickness of FPC can reach 0.08mm, meeting clients' personalized special needs.

PCBMASTER's Ultra-High Precision FPC Manufacturing Capabilities

Leveraging extensive FPC manufacturing experience, PCBMASTER pushes FPC manufacturing precision to the extreme. Current production limits for FPC achieve: Min line width/spacing of 0.05mm, line width tolerance of ±10% and outline tolerance of ±0.05mm。

PCBMASTER Provides Professional Technical Support to Help Clients Identify Design Flaws

With full-process technical support from our professional engineering team, we offer design file optimization, cost-effective material selection, stackup optimization and precise DFM analysis – proactively identifying design flaws to avoid wasting clients' time and economic costs.

PCBMASTER Proactively Provides Cost Optimization Suggestions

PCBMASTER engineers analyze your designs and manufacturing costs, then tailor optimizations (design, materials, stackup) and DFM analysis to your product's needs. This proactive approach cuts costs at the source while enhancing quality, performance and value.

The Products We Make

Customized FPCs, your own circuit solution.

Ultra-thin double-sided 0.08mm

- Track/Spacing: 0.075/0.075mm

- Material: PI Polyimide Adhesive-Free Rolled Substrate

- Special technology: Ultra-Thin Double-Sided + Coverlay.Finsih thick ness 0.08mm

4Layer FPC

- Track/Spacing: 0.065/0.06mm

- Material: DuPont PI Polyimide Adhesive-Free Rolled Substrate

- Special technology: Soft Ink, Electromagnetic Shielding Film, FR-4 Stiffener, PI Stiffener

FPC Prototype

Special Offer- QTY: 5pcs

- Layer: 1 or 2 layer

- Surface finish: Immersion gold 1u"

- Size: ≤100*100mm

- FPC thickness: 0.1 or 0.11mm

- Board type: Single piece

Advanced Flexible Circuit Solutions

Professional R&D and manufacturing team, 20 Years of PCB experience, Dive into a world of innovative PCB possibilities

Research Institute of a University

Rigid-Flex Project

Transforming an 8-layer rigid-flex design into a cost-effective 4-layer FPC solution for industrial control sensors

-

Design Review

Comprehensive analysis of your DXF design files and requirements

-

Feasibility Assessment

Evaluation of manufacturing feasibility and potential risks

-

Optimization Proposal

Tailored design optimization proposal with cost projections

-

Validation & Delivery

Prototype manufacturing, testing and final solution delivery

Technical Specifications

| Layers | 4-layer pure FPC with PI reinforcement |

| Finished Thickness | 0.23mm |

| PI Reinforcement | 0.20mm thickness |

| Copper Thickness | 0.5oz base, 25-35μm finished |

| Substrate | Rolled annealed copper |

| Surface Finish | Immersion gold |

Project Background

Research Institute of a University approached us with a complex 8-layer rigid-flex board design for an industrial control sensor, seeking manufacturing feasibility and cost optimization.

Design Features

- Central rigid board area with surrounding flexible layers

- Chip placement in both rigid and flexible zones (3.5mm×3.5mm)

- Complex layer stackup with tight spacing requirements

Technical Questions

- Does the design spacing meet rigid-flex minimum requirements?

- What are the process risks of placing 3.5mm×3.5mm chips in both zones?

- Recommended reliability measures for rigid-flex junctions?

- Are critical design adjustments needed for manufacturability?

- Potential manufacturing or reliability risks to be addressed?

5G mmWave Radar FPC

High-frequency solution for automotive 77GHz radar

0.42dB/cm insertion loss beats industry standard by 30%

— Automotive Electronics Engineer

"Challenge

Design antenna FPC for 77GHz radar with:

- 50Ω±10% characteristic impedance at 10GHz

- ≤0.5dB/cm insertion loss at 77GHz

- ≤2° phase error at 5mm bend radius

Solution

- Rogers RO3003® laminate (Dk=3.0, Df=0.0013)

- 3-layer stackup with microstrip and ground planes

- HDI technology for ±5μm trace tolerance

Implantable Cardiac Monitor

ISO 13485 certified solution for pacemaker interconnects

18 months of faultless operation in animal trials, 92% defect rate reduction vs original supplier

— R&D Director, Global Medical Device Leader

"Challenge

Develop ultra-thin FPC for pacemakers with:

- ≤0.1mm thickness for dynamic heart movement

- 10⁹Ω insulation after 134°C autoclave sterilization

- Zero biocompatibility failures in cytotoxicity tests

Solution

- DuPont Kapton® PI-HS substrate (50μm) with halogen-free adhesive

- 9μm RA copper foil with 1μm gold plating for oxidation resistance

- Laser drilling (50μm) and LPI coverlay for seamless encapsulation

Satellite Antenna Foldable FPC

LEO satellite solution for extreme space environments

2+ years of satellite operation, far exceeding NASA-STD-8739.8 requirements

— Project Engineer, Aerospace Group

"Challenge

Design foldable FPC for LEO satellites with:

- -196°C to +125°C operating temperature range

- ≥1×10⁵ Gy radiation tolerance (gamma rays)

- ≤1.5dB signal loss at 5GHz after 1M folds

Solution

- Asahi Kasei AP850 fluorinated PI substrate (1×10⁶ Gy tolerance)

- 5μm Parylene C coating for radiation shielding

- Ω serpentine routing with 30% length redundancy

Flexible Printed Circuit (FPC) Capabilities

Comprehensive technical specifications for flexible printed circuits from 2025 to 2027

| Type | 2025 | 2026 | 2027 | Remark | |

|---|---|---|---|---|---|

| Materials | Flexible substrate | Non-adhesive substrate, Adhesive substrate, LCP | Non-adhesive substrate, Adhesive substrate, LCP | Non-adhesive substrate, Adhesive substrate, LCP | / |

| Stiffener | PI, FR4, steel, Aluminium | PI, FR4, steel, Aluminium | PI, FR4, steel, Aluminium | / | |

| Adhesive Sheet | Epoxy glue, acrylic glue | Epoxy glue, acrylic glue | Epoxy glue, acrylic glue | / | |

| Covering film | Epoxy glue, acrylic glue | Epoxy glue, acrylic glue | Epoxy glue, acrylic glue | Acrylic adhesive is the main type. | |

| Layer | Flexible | 12 | 14 | 16 | / |

| Thickness | Finished | Min 0.03mm | Min 0.03mm | Min 0.03mm | single side FPC |

| Tolerance | Min ±0.015mm | Min ±0.015mm | Min ±0.015mm | / | |

| Finished copper | Inner copper | 1/3 - 2oZ | 1/4 - 2oZ | 1/4 - 2oZ | Base copper thickness |

| outer copper | 1/3 - 2oZ | 1/4 - 3oZ | 1/4 - 3oZ | Base copper thickness | |

| Size | Max Size | Min 2mm*10mm | Min 2mm*10mm | Min 2mm*5mm | / |

| Min Size | Max 500mm*610mm | Max 500mm*610mm | Max 500mm*610mm | / | |

| Track/Spacing | Inner Layer | 2mil/2mil | 2mil/2mil | 1.8mil/1.8mil | Finished Copper 0.5oZ |

| Out Layer | 2mil/2mil | 2mil/2mil | 1.8mil/1.8mil | Finished Copper 1oZ | |

| Finish hole size | CNC hole size | Min 0.1mm | Min 0.1mm | Min 0.1mm | / |

| Laser hole size | Min 0.075mm | Min 0.075mm | Min 0.05mm | / | |

| Thickness to diameter | CNC Drilling | Max 1:1 | Max 1:1 | Max 1:1 | / |

| Laser drilling | Max 12:1 | Max 15:1 | Max 15:1 | / | |

| Dielectric thickness | flexible core | Min 0.0125mm | Min 0.0125mm | Min 0.0125mm | / |

| Dimensional tolerance | Laser cutting | ±0.05mm | ±0.05mm | ±0.05mm | UV laser cutting |

| Die cutting | Min 0.05mm | Min 0.05mm | Min 0.05mm | Slow wire cutting steel die | |

Core Capabilities

- Max Layers (2027): 16

- Min Thickness: 0.03mm

- Substrate Type: Non-adhesive/Adhesive/LCP

- Stiffener Material: PI/FR4/Steel/Aluminium

Precision & Size

- Track/Spacing (2027): 1.8mil/1.8mil

- Min CNC Hole: 0.1mm

- Min Laser Hole (2027): 0.05mm

- Max Size: 500mm×610mm

| Order Type | Size | Standard Lead Time | Expedited Service |

|---|---|---|---|

| Prototypes | ≤3 ㎡ | 5 - 6 days | Expedited shipment available in 1 - 2 days |

| Small Batch | 3 - 10 ㎡ | 8 - 9 days | Expedited shipment available in 5 - 6 days |

| Mass Production | ≥10 ㎡ | 9 - 11 days | Expedited shipment available in 7 - 8 days |

150 +

Manufacturing Engineer

20,000㎡ +

Monthly Production Capacity

Manufacturing Process Flow

.webp)

1. Cutting Material

.webp)

2. Drilling

.webp)

3. Copper Plating/Electroplating

.webp)

4. Circuit/ETCH

.webp)

5. Stackup

6. Immersion Gold

.webp)

7. Silkscreen

.webp)

8. AOI & Final Test

.webp)

9. Routing and Die Cut

Quality Certification System

We manufacture 100% of our products in accordance with international quality certificates.

IATF 16949

ISO 13485

ISO 9001

ISO 14001

ISO 45001

FAQs of Flexible PCB

Below are the FPC Frequently Asked Questions, if you have any other questions, please feel free to contact us.

Blog & NEWS

We offer an all - inclusive experience. Let us take you on a journey to explore the world of wiring and get you familiar with us.

-

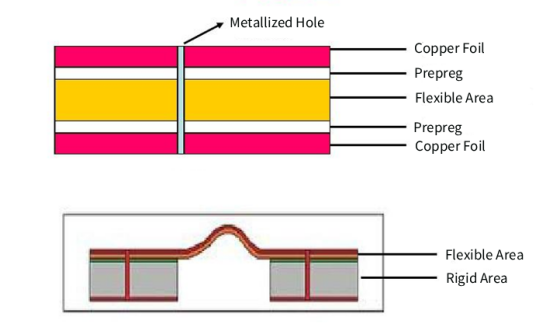

MoreRigid-Flex PCBs: Key Structure and Design Requirements for Reliable ElectronicsRigid-flex PCBs are a vital innovation in modern electronics, merging the flexibility of flexible circuits with the durability of rigid boards. This unique combination allows engineers to design compact, reliable, and versatile devices, fro...Dec 23, 2025

MoreRigid-Flex PCBs: Key Structure and Design Requirements for Reliable ElectronicsRigid-flex PCBs are a vital innovation in modern electronics, merging the flexibility of flexible circuits with the durability of rigid boards. This unique combination allows engineers to design compact, reliable, and versatile devices, fro...Dec 23, 2025 -

MoreFPC Flexible Circuit Boards: Introduction and Differences Between Electrodeposited Copper and Rolled Annealed CopperAt the core layer of flexible printed circuit boards (FPCs), selecting copper foil is akin to encoding the genetic blueprint of the circuit. As the neural pathways for electronic signals, rolled annealed copper (RA) and electrodeposited cop...Jul 2, 2025

MoreFPC Flexible Circuit Boards: Introduction and Differences Between Electrodeposited Copper and Rolled Annealed CopperAt the core layer of flexible printed circuit boards (FPCs), selecting copper foil is akin to encoding the genetic blueprint of the circuit. As the neural pathways for electronic signals, rolled annealed copper (RA) and electrodeposited cop...Jul 2, 2025 -

MoreIntroduction to Various Stiffeners for FPC Flexible Circuit BoardsFlexible Printed circuit stiffeners offering mechanical support to the flexible part of the circuit. This is essential for meeting requirements related to mounting, interfacing (e.g., connectors, gold fingers), soldering (e.g., SMT componen...Jun 30, 2025

MoreIntroduction to Various Stiffeners for FPC Flexible Circuit BoardsFlexible Printed circuit stiffeners offering mechanical support to the flexible part of the circuit. This is essential for meeting requirements related to mounting, interfacing (e.g., connectors, gold fingers), soldering (e.g., SMT componen...Jun 30, 2025

Ready to Solve Your

Flexible PCB Challenges?

Whether you need material selection advice, design optimization, or manufacturing support, our team of experts is ready to help.

Free Design Review

Comprehensive analysis of your FPC design for manufacturability

Custom Solution Proposal

Tailored technical proposal with cost and timeline estimates

Prototype & Testing

Rapid prototyping with full environmental testing capabilities

.webp)

.webp)