Rigid-Flex PCB

Rigid Stability, Flexible Versatility

Freeing Up Circuit DesignWant to design thinner, lighter, more reliable products? Start with a rigid-flex PCB. From design, prototyping to mass production: full-process control, deliveries meet standards.

Professional Manufacturing

Mass-production capability for 2-30 layer rigid-flex PCBs, supports HDI 1-3Level & special processes(impedance, blind/buried vias, step and page-type design, etc.)

Cost Advantage

Integrated structural solution reduces connection points and effectively lowers overall costs.

High Reliability

First-pass yield: 99.6%; the product withstands 1M bends, maintains electrical performance, meets long-term reliability.

Ultra-Thin & Light

Space & weight savings – 3D folding design cuts device size by ↓30%-50%, weight by ↓20%-30%, suits irregular spaces, meets complex structural & functional needs.

What is Rigid-Flex PCB?

Rigid-Flex PCB is a composite circuit carrier formed by integrating rigid PCBs (for component support) and flexible PCBs (for bendable connections) through precision processes, eliminating connection risks associated with traditional wires or connectors.

PCBMASTER owns a professional factory specializing in FPC / RIGID-FLEX PCB manufacturing. The factory overview is as follows:

8000+ ㎡

The Areas

5000+ ㎡

Production Capacity/Mo.

200+

Employees

20+

Senior Engineers

Featured Products We Made

Rigid-Flex PCBs are widely used across high-end industries where space, reliability and flexibility are critical. From consumer electronics to aerospace, these hybrid boards enable compact, lightweight and high-performance designs.

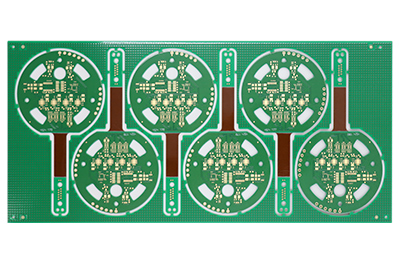

4-Layer(1-Level) HDI Rigid-Flex

- Material: FR-4 + Panasonic-Pl

- Layers: 4 Layers

- Thickness: 1.2mm

- Track/Spacing: 3/3mil

- Surface finish: Immersion gold(ENIG)

- Special technology: Rigid-Flex.HDI(1-Level)

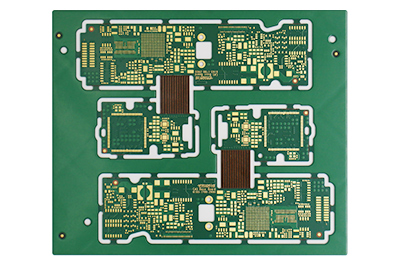

10-Layer Rigid-Flex PCB

- Material: IT-180A + Dupont-PI

- Layers: 10 Layers

- Thickness: 1.6mm

- Track/Spacing: 2.5/2.5mil

- Surface finish: Immersion gold(ENIG)

- Special technology: Rigid-Flex.Dispensing glue.Impedance

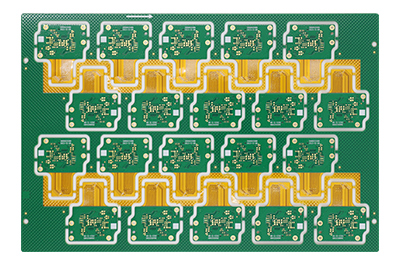

8-Layer HDI Rigid-Flex PCB

- Material: S1000-2M + Polyimide(SY)

- Layers: 8L(2R+4F+2R)

- Thickness: 1.03mm 土10%

- Track/Spacing: 3/4mil

- Surface finish: Immersion gold(ENIG)

- Special technology: 2-Level HDI.Multi - Layered Laser Decapping.HI-POT

Rigid-Flex PCB Capabilities

PCBMASTER's Rigid-Flex PCB process capabilities combine precision engineering and advanced materials to deliver reliable, high-performance boards. Our expertise ensures consistent quality across complex multilayer and ultra-thin flexible designs.

| Capability | Details |

|---|---|

| Number of Layers | 2-30 Layers |

| Polyimide Base Material | Polyimide(PI), PET, Polyester-Flex |

| Rigid Base Materials | FR-4, Metal Base, High Speed, High Frequency (Supplier: Rogers, ISOLA, Nelco, Taconic, SYTECH etc.) |

| FPC Thickness | 0.025-0.6mm |

| Rigid Thickness | 0.3-8mm |

| Thickness tolerance | ±0.1mm (T≤1.0mm);±10%(1.0>T<2.0) ±0.2(2.0>T<3.0);±0.5(T≥3.0) |

| Min Track / Spacing | 2.5/2.5mil |

| Min Hole Size (diameter) | 0.075mm(Laser), 0.15mm(Mechanical) |

| Capability | Details |

|---|---|

| Hole to window min | 30 mil |

| Coverlay (Flex Part) | Yellow Coverlay, Black Coverlay, White Coverlay, |

| Silkscreen Color | Yellow, Red, White, Black, Etc. |

| Surface Finish | OSP, Plated Gold, Immersion Gold, Immersion Silver, Immersion Tin, etc. |

| Finished inner Copper | min 0.5oZ |

| Finished Out Copper | min 0.5oZ |

| Stiffener Material | FR4, Cu, Al, Steel, PI, PET and Ceramic etc. |

| Assembly Techniques | Surface Mount Assembly (SMT), Through-Hole Assembly, Press-fit Assembly, Bonding, Flex PCB Assembly, Rigid-Flex PCB Assembly |

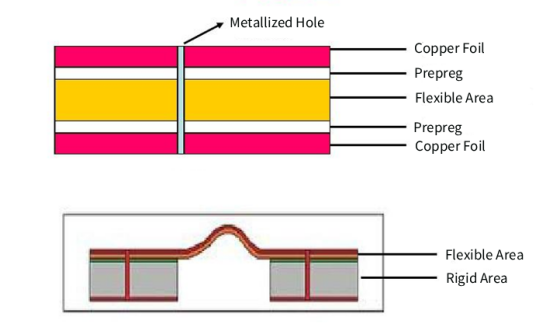

Structure of Rigid-Flex PCBs

Rigid-Flex PCBs are typically made of flexible Polyimide (PI) and rigid FR4. PCBMASTER is not limited to the combination of rigid FR4 and flexible PI; it can also incorporate various materials (FR4, Rogers materials, aluminum, copper, Polyimide, Polytetrafluoroethylene/PTFE, etc.) to meet specific requirements such as high frequency, high speed and mixed signals.

Core Production Process

PCBMASTER specializes in Rigid-Flex PCB manufacturing. Leveraging precision lamination processes, laser drilling technology and controlled-depth cutting solutions, we create high-reliability products that operate stably in extreme environments. We provide one-stop Rigid-Flex PCB solutions from design to delivery, accelerating the implementation of your innovative designs.

Our Rigid-Flex PCB core production process combines state-of-the-art equipment, precision techniques and strict quality control to ensure each board meets the highest standards of reliability and performance.

1. Precise Material Selection and Preprocessing

High-grade rigid copper-clad laminates (FR-4, metal base, high-frequency & high-speed materials) and flexible Polyimide (PI) substrates are strictly selected. Impurities are removed through professional cleaning processes, laying a solid foundation for the excellent electrical and mechanical performance of Rigid-Flex PCBs.

2. High-Precision Inner Layer Circuit Processing

Laser Direct Imaging (LDI) technology is used to fabricate and etch micron-level circuits on rigid and flexible substrates respectively, ensuring the accuracy of inner-layer circuits and providing reliable support for subsequent interlayer interconnection.

3. Core Stacking & Seamless Lamination Process

As a key link in Rigid-Flex PCB manufacturing, the flexible core is accurately embedded into the rigid multi-layer board structure via a fully automatic alignment system. Through high-temperature, high-pressure vacuum lamination, seamless connection between rigid and flexible areas is achieved, forming an integrated stable structure and ensuring the product's bending performance.

4. Laser Microvia Drilling Technology

High-precision laser drilling equipment is used to fabricate micro through-holes and blind holes, accurately connecting circuit channels across layers. This enables efficient interlayer interconnection of Rigid-Flex PCBs and ensures stable signal transmission in complex circuits.

5. Hole Metallization & Uniform Electroplating

Through chemical copper deposition and high-precision copper electroplating processes, a uniform and dense conductive layer is formed on the inner wall of drilled holes. This builds a solid interlayer conductive channel, enhancing the current-carrying capacity and connection reliability of Rigid-Flex PCBs.

6. Outer Layer Circuit & Flexible Solder Mask Treatment

After fabricating the outer-layer circuits, special flexible solder mask ink is sprayed. This not only provides insulation protection for the circuits but also does not affect the dynamic bending performance of flexible areas, balancing protection and flexibility.

7. Precise Controlled-Depth Contour Cutting

Advanced laser cutting technology are used to precisely process the board outline and control the cutting depth of flexible areas, avoiding stress damage in the bending zones.

8. Comprehensive Testing & Zero-Defect Inspection

100% electrical performance testing (Flying Probe Testing / Fixture Testing) and Automatic Optical Inspection (AOI) are conducted on each Rigid-Flex PCB. Strict quality control ensures zero-defect delivery, meeting the rigorous requirements of various high-end fields.

FAQs About Rigid-Flex PCB

Have more questions? Our technical team is ready to help.

Contact Technical SupportPCBMASTER Blog & NEWS

-

Rigid-Flex PCBs: Key Structure and Design Requirements for Reliable ElectronicsRigid-flex PCBs are a vital innovation in modern electronics, merging the flexibility of flexible circuits with the durability of rigid boards. This unique combination allows engineers to design compact, reliable, and versatile devices, fro...Dec 23, 2025More

Rigid-Flex PCBs: Key Structure and Design Requirements for Reliable ElectronicsRigid-flex PCBs are a vital innovation in modern electronics, merging the flexibility of flexible circuits with the durability of rigid boards. This unique combination allows engineers to design compact, reliable, and versatile devices, fro...Dec 23, 2025More -

Rigid-Flex PCB Design Guide 5 Core Technologies and 2024 Practical Data AnalysisI. Why Are Rigid-Flex PCBs Revolutionizing Electronic Product Architectures?According to Prismark's 2024 report, the global rigid-flex PCB market has reached $7.8 billion and is expected to exceed $12 billion by 2028, with an annual growth ...May 21, 2025More

Rigid-Flex PCB Design Guide 5 Core Technologies and 2024 Practical Data AnalysisI. Why Are Rigid-Flex PCBs Revolutionizing Electronic Product Architectures?According to Prismark's 2024 report, the global rigid-flex PCB market has reached $7.8 billion and is expected to exceed $12 billion by 2028, with an annual growth ...May 21, 2025More -

PCBMASTER shares with you the practical design of flexible-rigid printed circuit boards in medical devices!Industry Demand Case Study:Implantable devices like pacemakers require PCBs to withstand >500,000 bends over 10 years with a thickness ≤0.4mm. Traditional designs showed a 23% failure rate, making rigid-flex PCBs the breakthrough solution....Mar 3, 2025More

PCBMASTER shares with you the practical design of flexible-rigid printed circuit boards in medical devices!Industry Demand Case Study:Implantable devices like pacemakers require PCBs to withstand >500,000 bends over 10 years with a thickness ≤0.4mm. Traditional designs showed a 23% failure rate, making rigid-flex PCBs the breakthrough solution....Mar 3, 2025More -

PCBMASTER Shares with You Which Is More Cost-Effective in IoT Product Development, HDI or Rigid-Flex PCBWith the rapid popularization of Internet of Things (IoT) devices, the design of electronic products is increasingly trending towards miniaturization, multi - functionality, and high reliability. As a core component of IoT devices, the choi...Feb 27, 2025More

PCBMASTER Shares with You Which Is More Cost-Effective in IoT Product Development, HDI or Rigid-Flex PCBWith the rapid popularization of Internet of Things (IoT) devices, the design of electronic products is increasingly trending towards miniaturization, multi - functionality, and high reliability. As a core component of IoT devices, the choi...Feb 27, 2025More