HDI PCB

Highly integrated, Ultra-thin, High-performance

High-Density Interconnect (HDI) PCBs deliver compact, thin and high-performance solutions for modern electronics, enabling smaller, faster and more powerful devices.

1000+ Global Clients Order Our HDI PCBs / Month

+%E6%8B%B7%E8%B4%9D.webp)

HDI Process Capability

4-128 layers PCB manufacturing

HDI Any-Level

Register now

Enjoy special - price orders for HDI PCB prototypes

Core Advantages of Our HDI PCB

We focus on balancing performance, cost and delivery to solve your project challenges.

Cost-Effective Pricing

Competitive prices with reliable quality as the premise — cost control, no performance loss, for R&D prototyping, small-batch & mass production.

-

4-layer(1-level) Blind via PCB: As low as $180 PCB prototype

without Buried via, S<0.3㎡, qty<20pcs -

6-layer(1-level) Blind via PCB: As low as $250 PCB prototype

without Buried via, S<0.3㎡, qty<20pcs

Fast Delivery

Accelerate your product launch with our efficient production capabilities.

- HDI PCBs delivered in as fast as 7 days

- Supports expedited service for urgent projects

- Consistent turnaround for all HDI types

Whether it is 4-layer 1level-HDI PCBs or Any Level HDI PCBs with more than 10 layers, the same fast delivery efficiency as ordinary quick-turn PCBs can be achieved, helping customers accelerate product R&D and market launch.

Strong Process Capability

Stable mass production to cover high-layer and multi-level needs.

- Layer range: 4-layer 1-level to 128-layer Any-level HDI PCBs

- Proficient in core processes

- Mature experience in Any-Layer HDI

Proficient in core processes such as fine circuits, microvias, stacked/staggered vias and Via-in-Pad; with mature experience in Any Level HDI production, meeting the needs of high-density and complex circuit designs.

Our HDI PCB Products

Smaller Denser Thinner

Harness these three advantages in our HDI PCBs to create more compact, high-performance products that give you a competitive edge.

Core Technologies of HDI PCB

High-density interconnection in HDI PCBs relies on Laser drilling, Plated Through Hole, Lamination and fine circuit processes.

Micro-Blind Hole & Buried Hole Technology

Our advanced drilling technologies create precise connections between layers without sacrificing valuable board space.

- Blind Vias

- Buried Vias

-

The main methods for manufacturing blind vias and buried vias are:

Laser Drilling & Mechanical Drilling

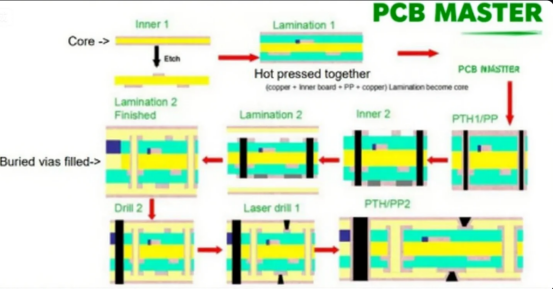

Lamination Technology

Build-up is a core process for constructing micro-blind/buried-blind vias and improving HDI PCB density, with common methods including:

- Build-Up Method

- Sequential Lamination Method

Fine Circuit Manufacturing

Micrometer-level precision with 1.5mil/1.5mil IC substrates for miniaturized electronics.

-

Micrometer-Level Control for HDI PCB Line Width & Spacing

-

Min track/spacing 1.5/1.5mil IC Substrates: Boost Integration, Fit Miniaturized Electronics

Electroplating & Hole-Filling

After the formation of micro-blind vias and circuits, professional electroplating processes are required to ensure electrical conductivity:

- Electroplating Treatment

- Electroplating Hole-Filling

- Quality Assurance

Typical HDI PCB Structures

HDI PCB structures are classified by microvia and lamination levels to match your design requirements.

| Structure Level | Key Features |

|---|---|

| 1-Level HDI | Contains one layer of microvias (usually blind vias) |

| 2-Level HDI | Contains two layers of microvias, which can be stacked or staggered |

| 3-level/High-level HDI | Contains three or more layers of microvias, with a more complex structure |

| Any-Level HDI | Direct interconnection between any two layers can be achieved through laser microvias, making it the highest-density structure |

Quality Inspection Full-Process Control

We implement rigorous testing to guarantee HDI PCB quality, fully compliant with IPC Class 2 and Class 3 standards.

AOI aperture detection

-

Automatically inspects the tool diameter of drilling machines to prevent hole diameter deviation caused by tool wear;

-

AOI equipment scans the substrate after drilling to check for defects such as deviated drilling, missing holes and rough hole walls, preventing drilling issues from entering the next process.

Metallographic Microscope, Plating Thickness Gauge

-

Metallographic Microscope

Analyzes the cross-sectional structure of hole copper and surface copper, verifying plating thickness (ensuring > 20μm) and uniformity.

-

Plating Thickness Gauge

Monitors the electroplating process in real time to prevent excessively thin/thick plating from affecting electrical performance.

AOI Line&Appearance Inspection

-

AOI After LDI Exposure

Checks for issues such as circuit short circuits, open circuits and line width deviation, ensuring circuit precision.

-

AOI for Finished Product Appearance

Fully scans the substrate surface to detect scratches, stains and component pad defects, ensuring appearance and circuit quality meet delivery standards.

Reliability Testing

-

Key Test Items

Thermal Shock Test (-40℃ ~ 125℃, 1000 cycles), High-Temperature High-Humidity Aging Test;

-

Test Objective & Effect

Simulates harsh operating environments such as automotive electronics and medical equipment, testing the temperature resistance, humidity resistance and vibration resistance of HDI PCBs, verifying the stability of hole wall connections to ensure long-term reliable operation.

X-Ray Inspection

-

Core Function

Penetrates the substrate to inspect the internal connections of buried vias, checking for invisible defects such as voids and cold solder joints; simultaneously inspects the blind via filling rate (requiring ≥95%) to ensure the conductivity and stability of inner-layer interconnections.

Four-Wire Low-Resistance Test (Kelvin Test)

-

Position in Testing Process

A key link in PCB electrical performance testing

-

Testing Principle & Advantage

Through the separated design of "current lines + voltage lines", it eliminates interference from contact resistance/wire resistance, accurately measures low resistance ≤1Ω (e.g., copper foil circuits, blind/buried via conduction paths) and checks for hidden defects such as cold solder joints and thin hole copper, ensuring current transmission reliability.

.webp)

FAQs About HDI PCB

Have more questions? Our technical team is ready to help.

Contact Technical SupportWhy choose PCBMASTER for your blind/buried via PCB project?

PCBMASTER has decades of HDI manufacturing expertise, with advanced precision laser drilling and fully automated testing. Our engineers specialize in blind/buried via technologies, supporting early design phases for seamless concept-to-production transition—delivering high-performance, high-reliability PCBs.

PCBMASTER Blog & NEWS

We offer an all - inclusive experience. Let us take you on a journey to explore the world of wiring and get you familiar with us.

-

MoreEssential Guide to HDI PCB Design and Manufacturing Best PracticesIn the rapidly evolving field of electronic technology, electronic products are advancing rapidly towards miniaturization, high performance, and multifunctionality. From the smartphones and wearable devices we use daily to high-end fields l...Aug 20, 2025

MoreEssential Guide to HDI PCB Design and Manufacturing Best PracticesIn the rapidly evolving field of electronic technology, electronic products are advancing rapidly towards miniaturization, high performance, and multifunctionality. From the smartphones and wearable devices we use daily to high-end fields l...Aug 20, 2025 -

MoreEngineering Guide for HDI FPC Technical Practices in Miniaturization and Reliability BreakthroughsIn today’s electronics industry pursuing extreme thinness and high-density integration, HDI FPC (High-Density Interconnect Flexible Printed Circuit) has become the core enabler for premium electronic devices. This article provides an in-de...Jun 11, 2025

MoreEngineering Guide for HDI FPC Technical Practices in Miniaturization and Reliability BreakthroughsIn today’s electronics industry pursuing extreme thinness and high-density integration, HDI FPC (High-Density Interconnect Flexible Printed Circuit) has become the core enabler for premium electronic devices. This article provides an in-de...Jun 11, 2025 -

MoreThe Future Market of HDI PCBs Technology-Driven Industry TransformationHigh-Density Interconnect (HDI) PCBs, as the core enabler of miniaturization and high performance in the electronics industry, are undergoing unprecedented technological innovation and market expansion. From 5G base stations to foldable sma...Apr 17, 2025

MoreThe Future Market of HDI PCBs Technology-Driven Industry TransformationHigh-Density Interconnect (HDI) PCBs, as the core enabler of miniaturization and high performance in the electronics industry, are undergoing unprecedented technological innovation and market expansion. From 5G base stations to foldable sma...Apr 17, 2025 -

MoreEngineering Characteristics and Technical Practice Guide for HDI (High-Density Interconnect) PCBsⅠ.Current Market Status and Technological Positioning of HDI PCBsAccording to the Prismark Q4 2023 report, the global HDI PCB market has reached $12.7 billion, with a compound annual growth rate (CAGR) of 9.8%. Over 60% of incremental dema...Apr 15, 2025

MoreEngineering Characteristics and Technical Practice Guide for HDI (High-Density Interconnect) PCBsⅠ.Current Market Status and Technological Positioning of HDI PCBsAccording to the Prismark Q4 2023 report, the global HDI PCB market has reached $12.7 billion, with a compound annual growth rate (CAGR) of 9.8%. Over 60% of incremental dema...Apr 15, 2025