Professional IC Substrate R&D and Manufacturing

AS9100

Aviation-grade standard factoryROHS

Certification Standards25μm

Minimum line width & spacing0.05mm

Minimum laser drilling12-30 days

Sample lead timeWhy Choose Our IC Substrate

We combine advanced technology, strict quality control and customer-centric service to deliver exceptional IC Substrate solutions.

Premium Materials

We stock substrates from leading brands including SYTECH, BT, Mitsubishi, Doushan, Toshiba, LG, Yinghua, ABF to ensure stable performance and adaptability.

Precision Manufacturing

With minimum line width/spacing of 25μm and minimum laser drilling diameter of 0.05mm,

Equipped with LDI exposure machines and high-precision laser drilling.

Full-process QC

Real-time online AOI monitoring throughout the process, 100% inspection of samples with professional IC substrate micro-probe flying probe testers.

Quality Certification

Compliant with AS9100 Aerospace-Grade Quality Management Certification and ROHS environmental standards, ensuring every substrate meets industry highest requirements.

Fast Delivery

Sample lead time only 12-30 days, supporting full-process customization from PCB Prototypes to small-batch production to meet rapid iteration needs.

Expert Team

20-strong R&D team with proven track records in top-tier IC substrate R&D and production, providing one-stop service from technical consultation to customized production.

Our Products of IC Substrate

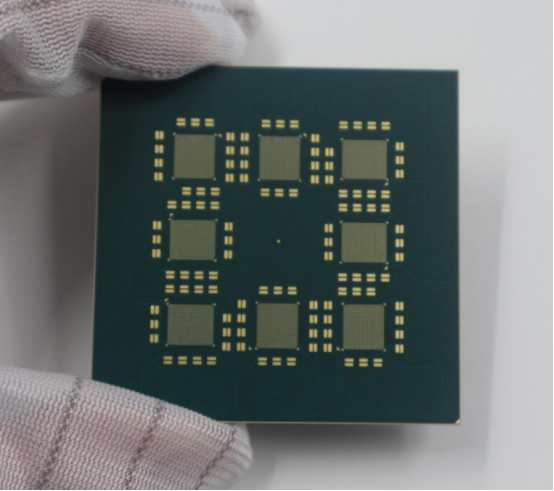

SiP Substrate

System-in-Package (SiP) is currently widely used in various portable communication electronics products.

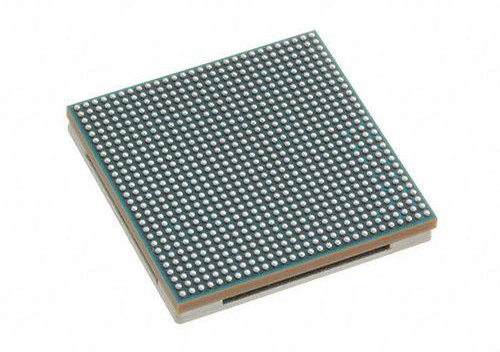

PBGA Substrate

Wire-bond plastic packaging substrates are currently widely used in the packaging of medium/low contact density electronic components such as computer and communication products.

FCCSP Substrate

Widely used in the packaging of low contact density electronic components such as consumer electronics and communication devices, which emphasize lightweight, thinness, compact dimensions and compactness.

FCBGA Substrate

Flip-chip packaging substrates are currently widely used in the packaging of high-speed computing/high contact density electronic components such as computers and communication devices.

Memory Card Substrate

Memory Card Packaging Substrates (MCP Substrates) are currently widely used in various electronic products such as memory cards, computers, mobile phones, storage devices, and servers.

LGA Substrate

Land Grid Array (LGA) is primarily utilized in high-end electronic products centered on semiconductors and chips and demanding high-frequency, high-power, and high-density I/O scenarios.

Product Features / Manufacturing Capabilities

Thickness & Tolerance

Board thickness 0.1~1.2mm, tolerance ±30μm

Small and dense holes

30~150μm hole diameter, hundreds to thousands of micro holes per PCS

Fine line width and spacing

min 25μm

Small pads

Minimum BGA pad diameter: 50μm

Interconnection technology

Buried, blind, and stacked via technologies

Surface treatment

Ni/Au, soft gold, hard gold, Ni/Pd/Au, etc.

Small unit size

≤150×150mm

Dimensional tolerance

min ±50 μm

|

Material

|

SYTECH, BT, Mitsubishi, Doushan, Toshiba, LG, Yinghua, Ajinomoto Buildup Film(ABF) | ||

|---|---|---|---|

| MASS Production | Samples Production | ||

| Layer | 2-10 layers | 2-12 layers | |

| Min Drilling | 50um | 50um | |

| Bonding Finger | Min.Pitch | 105um | 95um |

| Min.Width | 35um | 35um | |

| Circuit Line | Min.Pitch | 95um | 25um |

| Min.Width | 25um | 25um | |

| Min.Spacing | 25um | 25um | |

| Min.Welding ring | 80um | 80um | |

| Min.Thickness | 2L | 100um | 100um |

| 4L | 300um | 200um | |

| 6L | 400um | 300um | |

| 10L | 800um | / | |

| 12L | 1000um | / | |

| Line to PAD/EDGE | 100um | 75um | |

| Solder mask | Solder DAM | 50um | 50um |

| Solder PAD | 80um | 70um | |

| Thickness | 20+/-5um | 20+/-5um | |

| Flatness | 5um | 5um | |

| Surface Finish | Hard Gold | Ni:5-15μm Au:0.2-0.5μm | Ni:5-15μm Au:0.2-2μm |

| Soft Gold | Ni:5-15μm Au:0.3-0.8μm | Ni:5-15μm Au:0.3-2μm | |

| ENEPIG-WB | Ni:3-8μm, Pd:0.1-0.2μm Au:0.1-0.2μm | Ni:3-8μm, Pd:0.1-0.2μm Au:0.1-2μm | |

| ENEPIG-SMT | Ni:3-8μm, Pd:0.05-0.15μm Au:0.05-0.15μm | Ni:3-8μm, Pd:0.05-0.15μm Au:0.05-2μm | |

| OSP | OSP:0.1-0.3μm | OSP:0.1-0.3μm | |

Process Flow

Blog & NEWS

-

Tg 230℃ vs. Tg 250℃ for BT Materials in IC Substrates: Which is Better for Your Application?IC substrates are the foundation of modern electronic devices, providing crucial connections and support for integrated circuits (ICs). Without these substrates, electronic components would lack the structural integrity necessary for proper...Jan 23, 2026More

Tg 230℃ vs. Tg 250℃ for BT Materials in IC Substrates: Which is Better for Your Application?IC substrates are the foundation of modern electronic devices, providing crucial connections and support for integrated circuits (ICs). Without these substrates, electronic components would lack the structural integrity necessary for proper...Jan 23, 2026More -

IC Packaging Substrate Technology for Engineers: A Comprehensive GuideIn the wave of upgrades towards higher density and miniaturization in the electronics industry, the performance of integrated circuits (ICs) relies heavily on the support of the packaging process. As a critical interface between the bare ch...Jan 15, 2026More

IC Packaging Substrate Technology for Engineers: A Comprehensive GuideIn the wave of upgrades towards higher density and miniaturization in the electronics industry, the performance of integrated circuits (ICs) relies heavily on the support of the packaging process. As a critical interface between the bare ch...Jan 15, 2026More -

Ultimate Guide to IC Packaging Substrates Manufacturing: HDI PCB & Fine Line ProcessIntroduction1. Definition of ICAn IC (Integrated Circuit) is a miniature electronic device or component. Using specific manufacturing processes, all the necessary elements of a circuit—such as transistors, diodes, resistors, capacitors, an...Nov 11, 2025More

Ultimate Guide to IC Packaging Substrates Manufacturing: HDI PCB & Fine Line ProcessIntroduction1. Definition of ICAn IC (Integrated Circuit) is a miniature electronic device or component. Using specific manufacturing processes, all the necessary elements of a circuit—such as transistors, diodes, resistors, capacitors, an...Nov 11, 2025More -

The Best PCB Packaging Box Solutions for Safe Shipping and StorageIntroductionIn the field of electronics manufacturing, a high-quality PCB packaging box is not only a protector of products but also a reflection of a company’s professional image.This article serves as a comprehensive guide to PCB packagi...Oct 25, 2025More

The Best PCB Packaging Box Solutions for Safe Shipping and StorageIntroductionIn the field of electronics manufacturing, a high-quality PCB packaging box is not only a protector of products but also a reflection of a company’s professional image.This article serves as a comprehensive guide to PCB packagi...Oct 25, 2025More

Technical Challenges

Ultra-thin core board processing control technology

Ultra-thin core boards are prone to warpage and expansion/contraction issues. Breakthroughs are required in process technologies such as deformation/expansion-contraction control, lamination structure design, board expansion-contraction management, lamination parameters optimization, and interlayer alignment systems. This ensures effective control of warpage and lamination thickness for ultra-thin core boards.

Micro via processing technology

Including laser drilling capability for micro blind vias, mechanical drilling capability for micro through vias, via filling technology, and stacked via technology.

Ultra-fine circuit fabrication technology

Including copper reduction capability, circuit compensation control, plating uniformity control, and etching uniformity control.

Interlayer alignment technology

Including multi-layer lamination technology, LDI (Laser Direct Imaging) alignment exposure technology, and positioning reference technology.

Solder mask fabrication technology

Including solder mask plugging (for blind vias and through vias), solder mask alignment accuracy, and solder mask flatness.

Surface finish technology

Including electroplated soft thick gold, electroplated hard thick gold, and electroless nickel palladium gold (ENEPIG), with requirements for pad flatness and fine-grained crystallization.

Testing and inspection technology

Testing of micro bonding pads requires the support of high-precision AOI (Automatic Optical Inspection) equipment and micro-probe flying probe testers for continuity testing. Meanwhile, an AOI repair process must be established to avoid quality issues caused by micro-defects.

Have any questions? Our technical team is ready to help.