Ultra-Long PCBs: Key Factors You Need to Know Before Choosing

Ultra-long PCBs are essential for powering large-scale systems and delivering reliable performance in today’s advanced electronics. Whether it’s for massive LED displays or complex industrial automation, these specialized circuit boards are built to handle the demands of cutting-edge technology. But with so many options to choose from, how do you select the one that’s right for your project?

Choosing the ideal ultra-long PCB involves more than just considering size. It’s about finding the right mix of performance, heat management, and customization that fits your unique needs. From high-power applications to flexible designs, the right PCB can make all the difference. Let’s dive into the key factors that will help you make an informed decision.

Introduction to Ultra-Long PCBs

What Are Ultra-Long PCBs and How Are They Used?

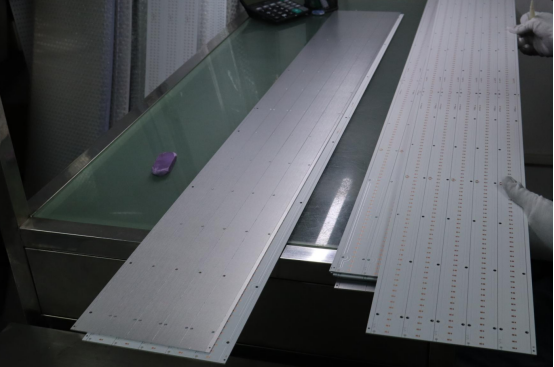

Ultra-long PCBs are circuit boards specifically engineered to handle large, complex designs with extended lengths, typically exceeding 600mm (PCBMASTER manufactures ultra-long PCBs, with some reaching up to 1.8 meters in length). The primary purpose of ultra-long PCBs is to meet the needs of applications where traditional PCBs, with shorter lengths (under 500mm), are insufficient.

Key Applications of Ultra-Long PCBs:

LED Displays: Ultra-long PCBs are commonly used in large LED displays, where long circuit boards help to ensure smooth, continuous signal transmission across the display. The length allows for more LED modules to be connected without interrupting the flow of signals, ensuring better display consistency and reliability.

Industrial Automation: In automated manufacturing systems, ultra-long PCBs simplify wiring by reducing the number of boards and connectors required. This leads to a cleaner, more organized setup that reduces maintenance and troubleshooting

Data Centers: Ultra-long PCBs play an essential role in data centers by managing the power and signal distribution across long racks of servers. With their long form factor, they help minimize signal loss over distance, enhancing overall system stability.

Why Choose Ultra-Long PCBs?

Ultra-long PCBs offer several key advantages that make them a preferred choice in certain high-performance applications.

Reduced Wiring Complexity:

One of the most significant benefits of ultra-long PCBs is that they reduce the need for multiple smaller PCBs and interconnecting cables. In large systems, fewer boards mean less complexity, easier assembly, and a more organized layout. This not only saves space but also reduces the risk of connection failures or signal interruptions that are common with many smaller boards.

Example: In a large LED display setup, a single ultra-long PCB can handle the signal distribution to all modules, eliminating the need for multiple smaller boards that would otherwise need to be connected, tested, and maintained separately.

Enhanced Signal Stability:

Longer PCBs help maintain signal integrity over longer distances by reducing the need for numerous connectors, which can introduce signal loss or interference. In applications like industrial control systems or data centers, maintaining a stable signal across long distances is crucial for ensuring the reliability and performance of the entire system.

Example: In an industrial control system, using ultra-long PCBs reduces the number of joints and connectors needed to transmit data, minimizing potential points of failure and improving the overall signal quality.

Improved Overall Efficiency:

With ultra-long PCBs, systems become more efficient in terms of both design and functionality. By consolidating multiple functions into one large board, these PCBs reduce the physical space required, streamline production processes, and ensure a more stable and consistent performance.

Example: In a data center, ultra-long PCBs help optimize power and signal routing within server racks, reducing clutter and ensuring that data is transmitted efficiently across multiple units.

How to Evaluate if Ultra-Long PCBs Are Right for Your Project

Choosing the right ultra-long PCB for your project involves understanding both the technical requirements and the specific needs of your application. From ensuring the right size to matching performance characteristics like heat dissipation, making the right choice will determine how well your system performs in the long run. Below, we'll walk through the critical steps you need to evaluate if an ultra-long PCB is suitable for your project.

Understanding Ultra-Long PCB Size Requirements

Why Size Matters:

The size of your ultra-long PCB directly impacts the functionality and efficiency of your system. Ultra-long PCBs are typically used when a design needs more space for components or requires a longer, uninterrupted signal path. The length of the PCB is usually determined by the scale of the project and how the components will be arranged. Choosing the correct length—such as a 1.8-meter PCB—depends on how much space you need to integrate all necessary components.

For example, in LED displays, a longer PCB can help reduce the number of connections and connectors between the LED modules. The length of the PCB ensures that the signal is transmitted without interruptions, resulting in a seamless display with fewer connection points.

Case Study:

In industrial automation systems, ultra-long PCBs are used to manage long production lines where equipment must be linked with minimal wiring. Choosing the correct size PCB can significantly simplify design by reducing the number of individual boards needed. A 1.8-meter PCB, for instance, can integrate multiple components across a large space, making the system more compact and efficient.

When selecting the size of your ultra-long PCB, always ensure that the chosen length can fit the layout of your system while allowing for all components to be placed in a way that optimizes performance.

Matching Project Needs with Performance Requirements

Ensuring Power and Performance Needs:

It’s crucial that your ultra-long PCB can handle the specific power and performance demands of your project. If you’re dealing with high-power electronic devices, the PCB must be able to manage the heat generated by these components without overheating or causing damage to the circuit. The material and thickness of the PCB will directly affect its ability to support these requirements.

For example, in high-power electronics such as power inverters, the PCB must be designed to manage significant amounts of electrical current. The ability of the PCB to dissipate heat is critical for ensuring long-term reliability and avoiding failure due to thermal stress.

Example of Material Choices:

Aluminum PCBs are often the best choice for high-power applications because they offer superior heat dissipation. If your project involves LED lighting systems or other power-hungry electronics, choosing an aluminum PCB can help manage the heat output effectively.

FR-4 PCBs, on the other hand, are ideal for general-purpose electronics that don’t require advanced heat management. If you’re building something like a consumer electronics device or a simpler industrial control system, FR-4 may be sufficient, offering stability and versatility without needing additional heat management.

By choosing the right material, you ensure that the ultra-long PCB can handle the electrical and thermal demands of your project. This not only improves the lifespan of the PCB but also reduces the risk of overheating or power failure.

Practical Tip:

When selecting a PCB for high-performance or power-intensive applications, always consider the thermal management properties of the material. For low-power applications, FR-4 offers an ideal balance of strength and electrical performance, but for high-power systems, an aluminum-based PCB will be necessary to prevent heat-related failures.

Ultra-Long PCB Material Selection: How to Customize According to Your Project Needs

When selecting the right material for an ultra-long PCB, it’s essential to understand how the material affects the performance, durability, and suitability of your design. Ultra-long PCBs are used in various applications, from high-power electronics to flexible systems, each requiring specific material properties. Here, we'll explore the key materials used in ultra-long PCBs and how to choose the best one based on your project needs.

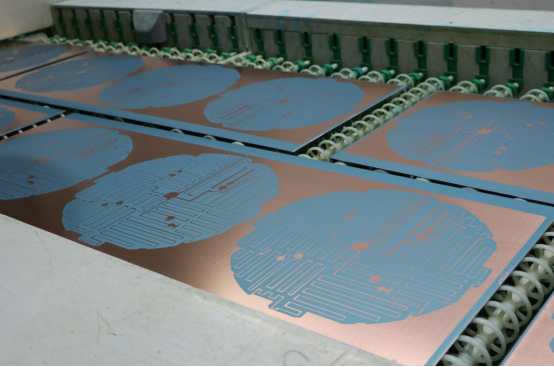

Hard PCB Materials: Choosing Between Aluminum and FR-4

Aluminum PCBs: Ideal for High-Power Applications

Aluminum-based PCBs are highly regarded for their excellent thermal management properties, making them perfect for applications that generate significant heat. These types of PCBs are designed to efficiently dissipate heat, which is essential for ensuring the longevity and reliability of the components on the board.

Common Uses of Aluminum PCBs:

LED Lighting: Aluminum PCBs are frequently used in LED lighting systems because LEDs generate a lot of heat. The aluminum material helps to transfer heat away from the components, preventing overheating and improving the lifespan of the LEDs.

Automotive Electronics: In automotive applications, such as lighting systems and control units, aluminum PCBs provide durability and heat resistance, critical for performance under high-temperature conditions.

Key Benefits:

Superior heat dissipation

Enhanced reliability in high-power systems

Ideal for high-power LED lights, automotive systems, and power electronics

Example: In an LED streetlight system, aluminum PCBs would be used to ensure that the high-power LEDs do not overheat, which could otherwise lead to premature failure.

FR-4 PCBs: Versatile and Reliable for General Applications

FR-4 is one of the most commonly used materials for PCBs due to its mechanical strength and dielectric properties. It is made from fiberglass reinforced with epoxy resin and is known for its stability and versatility, making it suitable for most general-purpose electronics.

Common Uses of FR-4 PCBs:

Consumer Electronics: FR-4 is widely used in products like computers, smartphones, and household appliances because it provides a good balance of strength, electrical insulation, and cost-effectiveness.

Industrial Control Systems: For industrial applications that don't involve extreme temperatures or power demands, FR-4 provides a reliable and cost-effective solution.

Key Benefits:

Excellent mechanical strength

Good dielectric properties

Versatile and suitable for a wide range of applications

Example: In a home appliance control system, FR-4 PCBs are often used because they offer strong electrical insulation while being cost-efficient for general electronics.

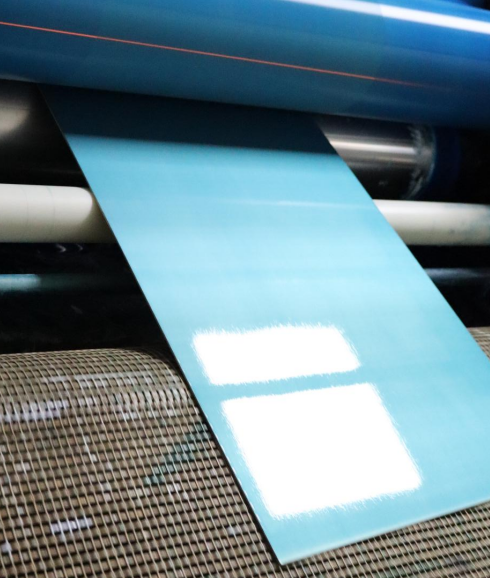

Flexible Materials: The Advantages of Polyimide (PI)

Polyimide (PI) Material: Ideal for Flexible and Long-Scale Applications

Polyimide (PI) is a highly flexible material that offers outstanding performance in applications that require the PCB to bend or flex. It is especially useful when designing circuits for systems that need to conform to unique shapes or fit in tight spaces.

What Makes Polyimide Special?

Polyimide can handle flexing and bending without breaking or losing its electrical properties, making it the go-to material for flexible circuits. It can extend up to 2.5 meters in length, making it ideal for ultra-long PCBs used in flexible designs.

Common Uses of Polyimide PCBs:

Wearable Electronics: In devices like smartwatches or fitness trackers, polyimide PCBs are used to create flexible, durable circuits that can bend with the device's shape.

Aerospace Applications: Polyimide is commonly used in aerospace for flexible interconnects and systems where weight and space are crucial, and bending capabilities are required.

Key Benefits:

High flexibility for bending designs

Excellent thermal and electrical properties

Can be used for long-scale applications, extending up to 2.5 meters

Example: In a wearable fitness device, polyimide PCBs allow the circuit board to conform to the device’s shape, ensuring durability and flexibility for the user.

Customization of Materials: PCBMASTER's Tailored Solutions

Custom PCB Materials for Specific Application Needs

At PCBMASTER, we understand that no two projects are the same. Different applications have unique demands, whether it’s for managing heat, offering flexibility, or ensuring superior electrical performance. That’s why we offer fully customizable materials, allowing you to choose the right type of PCB to match your exact requirements.

How We Customize PCB Materials:

Heat Dissipation Needs: If your project involves high-power electronics or devices that generate significant heat, we can provide aluminum-based PCBs or other materials specifically designed to manage heat effectively. Our custom solutions ensure that the PCB material can efficiently dissipate heat to protect sensitive components.

Flexibility Requirements: For applications that require flexible circuit boards, such as wearable electronics or complex designs with limited space, we offer polyimide (PI) PCBs. These materials can stretch up to 2.5 meters and bend without compromising the PCB’s performance, making them perfect for flexible designs.

General Applications: For applications in moderate environments, FR-4-based PCBs offer strong mechanical strength and reliable electrical insulation. These PCBs are ideal for general electronics and industrial systems, providing durability and stability without the need for extreme heat resistance.

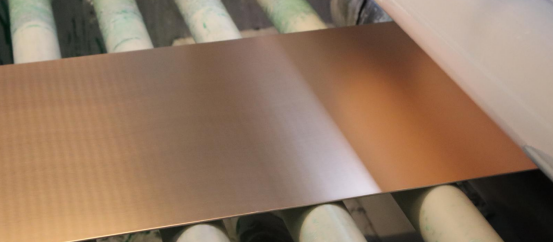

How to Choose the Right Thickness and Structure for Ultra-Long PCBs

Choosing the right thickness and structural design for your ultra-long PCB is crucial to ensuring its performance, durability, and suitability for your specific application. The thickness and structure influence factors such as heat dissipation, mechanical strength, and flexibility, all of which impact the overall functionality of your project. Below, we’ll explore how to select the right thickness and structure based on your project’s needs.

Different Thicknesses and Their Impact on Your Project

Thin PCBs (0.4mm to 1.0mm):

Thin PCBs are ideal for lightweight and flexible designs. They are often used in applications where space is tight, or a compact form factor is required. Thin PCBs are also suitable for projects that need flexible layouts, such as wearables or flexible displays.

Best for: Consumer electronics, flexible devices, and compact systems.

Example: In a smartwatch, a thin PCB allows the device to maintain a lightweight and slim profile while still providing the necessary functionality.

Medium Thickness PCBs (1.0mm to 3.0mm):

Medium thickness PCBs are versatile and commonly used in industrial applications. They offer a balance between mechanical strength and electrical performance, making them suitable for most types of standard electronic systems. Medium-thickness boards are a good choice when you need strength without compromising too much on weight or space.

Best for: Industrial control systems, consumer electronics, and low-power devices.

Example: In home appliances like microwaves or refrigerators, medium-thickness PCBs provide enough strength to handle the components and wiring while keeping the system lightweight and efficient.

Thick PCBs (3.0mm to 5.0mm):

Thicker PCBs are designed to handle high-power applications that generate significant heat. These PCBs are ideal for systems like electric vehicles (EVs), power inverters, and other high-power electronics that require excellent heat dissipation.

Best for: High-power electronics, power distribution systems, and heat-sensitive applications.

Example: A power inverter uses thick PCBs to ensure that the board can handle high current and dissipate heat efficiently, preventing the system from overheating.

Structural Design and Layout Considerations

How to Choose the Right Multi-Layer or Rigid-Flex Design:

The structure of the PCB plays an important role in ensuring the board can handle complex designs, signal integrity, and space constraints. For ultra-long PCBs, you may need to choose between a multi-layer design or a rigid-flex configuration, depending on the complexity of the circuit and the physical requirements of your application.

Multi-layer PCBs: These are essential for dense, high-performance circuits. Multiple layers allow for more complex routing and better signal integrity, which is necessary for high-frequency or high-speed applications.

Rigid-flex PCBs: This design combines rigid and flexible sections to offer both durability and flexibility. Rigid-flex designs are ideal for space-constrained applications where the PCB needs to fit into a compact or irregular shape.

Case Study:

In automotive electronics, multi-layer PCBs are often used to handle the complex circuits in systems like engine control units (ECUs). These multi-layer boards allow for more efficient use of space, while ensuring signal integrity and mechanical stability even in high-vibration environments.

By selecting the correct structure, you can ensure your ultra-long PCB performs optimally and fits seamlessly into your design.

PCBMASTER’s Customization Services

Tailored Solutions for Your PCB Needs:

At PCBMASTER, we offer comprehensive customization services to meet the unique demands of your project. We understand that every application has specific needs, and we’re ready to help you select the perfect thickness and structural design to match those requirements.

Custom Thickness: Whether you need a thinner PCB for flexibility or a thicker one for heat dissipation, we can tailor the thickness to your exact specifications.

Custom Layouts: We offer multi-layer and rigid-flex designs to meet the complexity of your circuit layout, ensuring that your ultra-long PCB will perform optimally in its intended environment.

Example:

If you’re working on a high-power automotive application, we can create a thick, multi-layer PCB with heat-resistant materials that can handle the extreme conditions inside the engine control unit, ensuring reliable performance in challenging environments.

How to Ensure the Quality and Stability of Ultra-Long PCBs

Ensuring the quality and stability of ultra-long PCBs is critical for their successful application in high-performance and high-reliability systems. These boards are used in demanding environments, and any failure in their quality can lead to system malfunctions or even safety hazards. To maintain top performance, PCBMASTER follows strict quality control processes and employs advanced manufacturing technologies.

Strict Quality Control Standards

How does PCBMASTER ensure each ultra-long PCB meets strict quality standards?

At PCBMASTER, quality is our top priority. We understand that ultra-long PCBs need to meet high standards of reliability and performance to work effectively in critical applications. Therefore, we implement rigorous quality control procedures throughout the manufacturing process. Every PCB undergoes a series of detailed inspections and tests to ensure it meets the required specifications for performance, durability, and safety.

Key Quality Control Processes:

AOI (Automated Optical Inspection): AOI systems are used to detect any defects in the PCB layout, including missing components, incorrect placements, or faulty connections. This inspection ensures that the PCB is free of errors before moving on to the next stage of production.

Flatness Check: Ultra-long PCBs are susceptible to warping, which can lead to performance issues. We perform flatness checks to ensure that each PCB remains perfectly flat, with a warpage tolerance of less than ±0.1mm per 100mm. This is essential for maintaining the structural integrity and functionality of the PCB, especially in large-scale applications like LED displays or industrial automation systems.

Electrical Testing: Each PCB undergoes electrical testing to verify that all connections are functional and that there are no short circuits or open circuits. This helps confirm that the PCB can reliably handle the power and signals required by the end device.

Example: In a data center power distribution system, maintaining the integrity of ultra-long PCBs is crucial to avoid signal loss or system failures. The AOI and flatness checks help ensure that the PCBs are free from defects and that they can deliver stable performance under high demands.

High-Precision Manufacturing Technology

Why is high-precision manufacturing technology especially important for ultra-long PCBs? How do we ensure accuracy and stability?

Ultra-long PCBs require high precision due to their extended size and the need to maintain consistent electrical and mechanical performance across the entire board. The larger the PCB, the more challenging it becomes to maintain uniformity in the manufacturing process. Therefore, high-precision technology is critical to ensuring that the PCB functions as expected in demanding applications.

At PCBMASTER, we use advanced manufacturing equipment and techniques to ensure that each ultra-long PCB is produced with the utmost precision. This technology ensures that the board’s size, layout, and components meet the design specifications, and it helps avoid common issues like misalignment, dimensional inaccuracies, or uneven signal distribution.

How We Ensure Precision:

Advanced CNC Machines: We use high-precision CNC (Computer Numerical Control) machines to cut, drill, and route the PCB. These machines are programmed with high accuracy, ensuring that the dimensions of the ultra-long PCB are precise, even for boards that extend up to 1.8 meters.

Laser Direct Imaging (LDI): For complex designs and fine details, LDI technology is used to create accurate patterns on the PCB. This laser-based imaging process ensures that the PCB’s circuit pattern is precisely transferred to the board, which is crucial for high-speed applications.

Automated Assembly and Soldering: With the help of robotic systems, the components are placed with millimeter-level precision. The soldering process is automated, ensuring consistent quality and preventing human errors.

Case Study:

In an automotive control system, precision is crucial for ensuring the PCB can handle the high-power requirements and maintain signal integrity. Using CNC machines and LDI technology, PCBMASTER can produce ultra-long PCBs with tight tolerances, ensuring reliable performance in this demanding environment.

Why Lead Time and Production Efficiency Are Crucial

When it comes to ultra-long PCBs, delivery time and production efficiency can make or break a project. Timely production and rapid prototyping are essential to meet strict deadlines, minimize risks, and ensure the final product is up to expectations. At PCBMASTER, we understand the importance of both speed and quality in our manufacturing process, offering fast sample production and efficient large-scale manufacturing to keep your project on track.

Sample Production and Approval Cycle

What is PCBMASTER’s sample production cycle?

PCBMASTER offers a fast sample production cycle of 3-5 days, allowing you to quickly assess the quality and performance of your ultra-long PCB before mass production. This short turnaround time ensures that you can move from design to prototype without unnecessary delays, helping you stay on schedule.

How can clients confirm performance through samples and reduce risk in final production?

The sample phase is a critical step in ensuring the PCB design meets the necessary requirements. By reviewing and testing the samples, you can verify that all components function properly and that the design aligns with expectations. This step helps to detect any issues early on, reducing the risk of errors during mass production. It also provides an opportunity for you to make any necessary adjustments to the design, ensuring the final product is reliable and high-quality.

Example:

If you’re designing a large-scale LED display, the sample PCB allows you to test the layout and signal routing. Testing the sample ensures that the long PCB will work seamlessly across the full display area, eliminating potential risks during the full production run.

Large-Scale Production Timeframe

What is the typical production time for ultra-long PCBs?

The production time for ultra-long PCBs generally ranges from 10-15 days, depending on the complexity of the design and the number of units required. At PCBMASTER, we ensure that our production processes are streamlined, allowing us to deliver high-quality ultra-long PCBs within this timeframe.

How do we ensure on-time delivery to meet project schedules?

Meeting tight project deadlines is crucial in today’s fast-paced industries. By maintaining an efficient manufacturing process and using advanced equipment, PCBMASTER is able to deliver ultra-long PCBs on time without sacrificing quality. Our team carefully plans production schedules to align with your project timelines, ensuring that your order is completed and delivered on schedule.

Example:

For a telecommunications project, meeting the production deadline is essential to avoid delays in system setup. PCBMASTER’s efficient production line ensures that the ultra-long PCBs are manufactured and shipped on time, allowing you to keep your project on track.

Handling Urgent Orders: Flexible Production Scheduling

How does PCBMASTER handle urgent orders?

At PCBMASTER, we understand that sometimes deadlines are tighter than expected. To meet urgent orders, we offer flexible production arrangements to expedite the process. Whether it's speeding up sample creation or accelerating mass production, our team works closely with you to adjust schedules and prioritize urgent orders. This allows us to deliver the required PCBs faster while still maintaining the highest quality standards.

Example:

For an automotive manufacturer facing unexpected production delays, PCBMASTER can fast-track an order for ultra-long PCBs, ensuring that they are delivered within a shortened timeframe without compromising quality.

What Are the Customization Advantages of PCBMASTER's Ultra-Long PCBs?

When working on projects that require ultra-long PCBs, having a manufacturer that can adapt to your specific needs is essential. PCBMASTER offers a range of customization options that allow you to tailor ultra-long PCBs to your exact specifications. From design to production, our services ensure that your PCBs meet both performance and budget requirements. Below are the key customization advantages that PCBMASTER provides for ultra-long PCBs.

Tailored Design Services

What makes PCBMASTER’s design services unique?

At PCBMASTER, we offer end-to-end customization from design to production. This means that we work closely with you to create ultra-long PCBs that are precisely tailored to your project’s needs. Whether it’s adjusting the size, selecting the right materials, or fine-tuning the thickness, our design team ensures that every aspect of the PCB is customized to fit your application.

Custom Dimensions: Ultra-long PCBs can be adjusted to meet specific length requirements, whether it's for a 1.8-meter LED display or a long power distribution system.

Material Selection: Depending on your project, we offer a range of materials such as FR-4 for general electronics, aluminum-based PCBs for high-power applications, and flexible materials for complex, space-constrained designs.

How do we incorporate customer feedback into the design process?

One of the key aspects of our design service is the constant communication with our clients. As your project progresses, we actively collect feedback and make any necessary adjustments to the design to ensure that every detail meets your performance and application requirements. This ensures that the final product aligns with your expectations, reducing the risk of errors in the manufacturing process.

Example:

In a telecommunications network, precise PCB dimensions and materials are crucial for signal stability. PCBMASTER works with clients to adjust the design to their specifications, ensuring that the ultra-long PCB is optimized for signal routing and power distribution.

Highly Flexible Production Capabilities

How does PCBMASTER handle different production volumes?

One of PCBMASTER’s standout features is our ability to accommodate both high-volume and low-volume production runs. Whether you need a mass production of ultra-long PCBs for large-scale industrial systems or small batch custom PCBs for a specialized prototype, we have the flexibility to meet your needs.

High-Volume Production: We ensure that larger orders are completed efficiently while maintaining high-quality standards. Our advanced production lines can handle bulk production without sacrificing precision or performance.

Low-Volume Custom Production: For smaller, specialized projects or prototypes, we can quickly adjust production schedules and deliver custom ultra-long PCBs with unique specifications.

This flexibility helps you meet tight deadlines and specialized requirements without compromising on quality, whether your project demands 100 or 10,000 PCBs.

Example:

If you're launching a new smart home product that requires a specialized ultra-long PCB for a custom circuit design, PCBMASTER can produce a small batch for testing and further iterations before scaling up to larger quantities.

Professional Technical Support and After-Sales Service

How does PCBMASTER provide ongoing technical support?

Our commitment to customer satisfaction extends beyond the production phase. At PCBMASTER, we provide comprehensive technical support throughout your entire project, from initial design to final application. Our technical team is available to help you with any design challenges, performance questions, or troubleshooting during production. Whether you need help with design optimization, material selection, or manufacturing concerns, we are here to provide expert guidance.

How do we ensure timely assistance during the usage phase?

Even after the PCB has been delivered, we provide after-sales support to address any issues that may arise during the installation or operational phase. Whether it's assistance with installation, performance optimization, or problem-solving related to the PCB's functionality, PCBMASTER is dedicated to ensuring that your product works flawlessly.

Example:

For a medical device manufacturer, precise PCB design and performance are crucial. If any issues arise after installation, our team is ready to provide swift support to resolve the issue, ensuring minimal downtime and maintaining the reliability of the device.

Conclusion

Ultra-long PCBs offer significant advantages for projects that require large, complex designs. By choosing the right ultra-long PCB, you can greatly enhance project efficiency, reduce wiring complexity, and improve overall performance. These specialized PCBs are particularly valuable in applications like large LED displays, industrial automation, and high-power systems, where traditional shorter boards simply can’t meet the demands. Their customizability ensures they align perfectly with specific project needs, from size to material choice, delivering reliable and optimized results.

If you’re ready to take your project to the next level with a tailored ultra-long PCB, contact PCBMASTER today. Our team of experts is ready to assist you with professional design, fast production, and comprehensive support to ensure your project succeeds. Let’s discuss how our custom solutions can fit your unique needs and help you achieve the best possible results. Reach out now to get started!

FAQs about Ultra-Long PCBs

1. What is the maximum length PCBMASTER can customize for ultra-long PCBs?

PCBMASTER can customize ultra-long PCBs up to 1.8 meters in length, making them suitable for large-scale projects where traditional PCBs fall short. This capability allows us to support a wide range of applications, including massive LED displays, industrial automation systems, and complex communication devices. Whether you need a precise, extended circuit board for power distribution or signal transmission, our ultra-long PCBs can meet the unique needs of your project.

2. What is the difference between aluminum PCBs and FR-4 PCBs?

The choice between aluminum PCBs and FR-4 PCBs depends on the specific demands of your application:

Aluminum PCBs are ideal for high-power and heat-sensitive applications. They offer excellent heat dissipation, making them perfect for projects such as LED lighting, automotive electronics, and power inverters. The aluminum base helps manage heat more effectively, preventing overheating of components.

FR-4 PCBs, on the other hand, are widely used in general electronics due to their mechanical strength and electrical insulating properties. They provide good stability in most applications like consumer electronics, telecommunications, and computer systems.

Choosing the right material will depend on factors such as heat management needs, electrical performance, and environmental conditions.

3. What is the typical production cycle for ultra-long PCBs?

The production cycle for ultra-long PCBs at PCBMASTER is structured to ensure quality and timely delivery:

Prototype production typically takes 3-5 days, allowing you to verify design specifications and functionality before moving to mass production.

Mass production usually takes around 10-15 days, depending on the complexity of the design and quantity. PCBMASTER ensures on-time delivery and can handle both small and large production runs efficiently, meeting tight deadlines while maintaining quality.

4. Can the thickness and material of ultra-long PCBs be customized?

Yes, PCBMASTER provides comprehensive customization options for both thickness and materials of ultra-long PCBs. Depending on your project’s specific needs, we can adjust the thickness of the PCB to ensure the right balance of mechanical strength, thermal conductivity, and flexibility.

We offer a wide range of materials, including aluminum, FR-4, and polyimide (for flexible designs), allowing you to tailor the PCB to meet your exact specifications, whether for high-power applications, flexible circuits, or standard electronics.

5. Does PCBMASTER offer expedited production services?

Yes, PCBMASTER offers expedited production services for urgent projects. If you need ultra-long PCBs quickly, we can adjust our production schedule to meet tight deadlines. Our team works efficiently to ensure that your project is completed on time, even for urgent orders. Whether it's a prototype or a mass production order, we are committed to delivering the required PCBs as quickly as possible, without compromising on quality.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!