Quick-Turn PCB vs. Standard PCB: Major Differences Explained

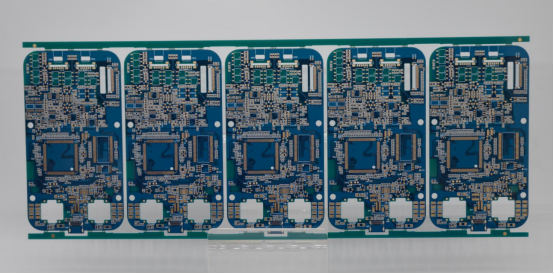

Printed Circuit Boards (PCBs) are a fundamental part of almost every electronic device, from smartphones to industrial equipment. They connect and support the various components inside these devices, making sure everything works as it should. When it comes to creating PCBs, there are two main options: quick-turn PCB and standard PCB.

Quick-turn PCB is designed for speed. They allow you to quickly test new designs or produce small batches, typically within 24 to 48 hours. This makes them ideal for prototypes or projects that need to move fast. On the other hand, standard PCB is built for larger production runs. While they take more time—usually several days to weeks—they offer a lower cost per unit, making them the go-to option for mass production.

In this article, we’ll explore the key differences between these two types of PCBs. We’ll look at things like lead times, costs, material options, and reliability. By the end, you’ll have a better idea of which type suits your needs, whether you’re working on a prototype or preparing for large-scale production.

What Are the Key Differences in Lead Time and Cost?

Quick-turn PCBs offer faster turnaround but come at a higher price, making them ideal for prototypes and small batches. In contrast, standard PCBs have longer lead times but are more cost-effective for large-scale production. Let's dive into how these factors impact your project.

Lead Time Differences Between Quick-turn and Standard PCBs

Quick-turn PCBs:

Quick-turn PCBs are designed for fast delivery, with lead times typically ranging from 24 to 48 hours. This makes them ideal for projects that require rapid prototyping or small-batch production. For example, a startup designing a new smartphone might use quick-turn PCBs to quickly test and refine their product before moving to larger-scale manufacturing. The fast turnaround allows designers to receive their boards, test their designs, and make necessary changes almost immediately.

Standard PCBs:

Standard PCBs, on the other hand, have longer lead times, typically ranging from 7 to 14 days or even longer, depending on the complexity and volume of the order. These are better suited for mass production, where time is less of a concern but cost per unit is crucial. For instance, a company producing hundreds of thousands of consumer electronics may choose standard PCBs to meet the demand for large quantities while minimizing production time for bulk orders. This longer lead time allows for the necessary setup, testing, and production processes, which ensures that the final products meet high-quality standards.

Cost Differences Between Quick-turn and Standard PCBs

Quick-turn PCBs:

The cost of quick-turn PCBs is generally higher due to the speed at which they are produced. The accelerated manufacturing process, including fast sourcing of materials and rapid assembly, adds extra costs. Because these PCBs are typically used for small runs or prototypes, the unit cost per board is higher. This makes quick-turn PCBs a good option when speed and time-to-market are more important than cost. For example, if a tech startup needs a small number of PCBs to test a new product in a short time frame, the higher cost per unit will be justified by the speed at which they can iterate on their design.

Standard PCBs:

Standard PCBs benefit from economies of scale. When producing large quantities, the cost per unit drops significantly. This makes them a more cost-effective solution for high-volume manufacturing. For instance, an electronics company that needs to produce thousands of units of a product will find that using standard PCBs reduces the overall production cost, even though the lead time is longer. By ordering in bulk, companies can spread the setup costs across many units, which lowers the price for each individual PCB.

How Do Material Selection and Design Flexibility Differ?

Quick-turn PCBs are built for speed, which means they come with more limited material options and simpler design capabilities. In contrast, standard PCBs offer a broader selection of materials and allow for more complex, multi-layered designs.

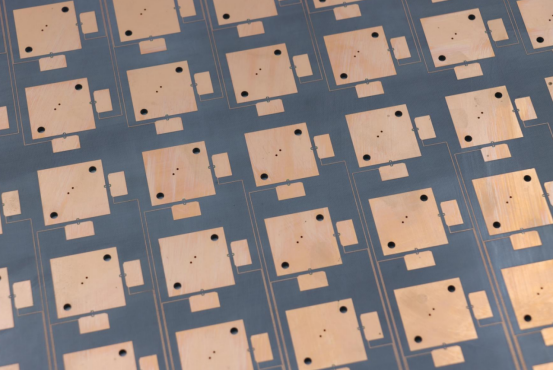

Material Selection Differences Between Quick-turn and Standard PCBs

Quick-turn PCBs:

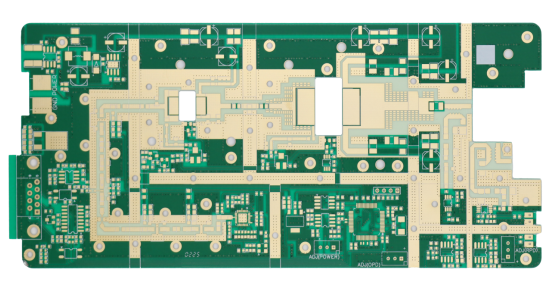

Due to the need for fast production, quick-turn PCBs have more limited material options. The primary goal is speed, so manufacturers focus on materials that are readily available and easy to process quickly. This means that quick-turn PCBs typically use basic materials like standard FR4 (a common fiberglass-based material) that can be processed in a short time. These materials are well-suited for simple designs, such as single-layer or low-complexity multi-layer boards. For example, a startup creating a prototype might choose a quick-turn PCB because it allows them to quickly test their design without worrying about specialized materials.

Standard PCBs:

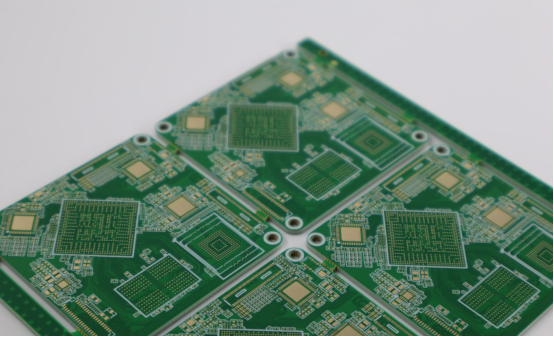

In contrast, standard PCBs offer a much wider range of material choices, allowing for customization based on specific project needs. Standard PCBs can be made from specialized materials, including high-temperature laminates, flexible materials, and high-frequency materials like Teflon. These materials enable more complex designs, such as multi-layer boards and boards requiring advanced thermal or electrical properties. For instance, a company producing PCBs for automotive applications might opt for specialized materials that can withstand high temperatures and harsh environments, which wouldn’t be feasible with quick-turn boards.

Design Flexibility Differences Between Quick-turn and Standard PCBs

Quick-turn PCBs:

Because quick-turn PCBs prioritize speed over complexity, they are typically limited to simpler designs. These boards often consist of single-layer or few-layer layouts. The simpler the design, the faster the manufacturing process can be. For example, a basic proof-of-concept prototype for a new gadget might only require a single-layer PCB. However, as the design becomes more complex, with more layers or tighter tolerances, the production time increases, making it more challenging to meet the quick turnaround requirement. This is why quick-turn PCBs are not typically suitable for intricate designs with high-density interconnections (HDI) or multi-layer setups.

Standard PCBs:

On the other hand, standard PCBs are ideal for more complex, long-term projects that require greater design flexibility. These boards can handle multi-layer designs, allowing for intricate circuit paths, high-density interconnections (HDI), and better signal integrity. Companies that need boards with complex routing, high-speed signals, or additional layers for functionality often choose standard PCBs. For instance, a tech company designing a high-performance computer motherboard would need a standard PCB to accommodate the complex design requirements of the product.

What Are the Differences in Quality and Reliability?

Quick-turn PCBs prioritize fast production, which can sometimes lead to compromises in quality and long-term reliability. In contrast, standard PCBs are designed with higher quality controls and better reliability for long-term use.

Quality Differences Between Quick-turn and Standard PCBs

Quick-turn PCBs:

Due to the fast production process, quick-turn PCBs may involve some trade-offs in quality. The rush to meet tight deadlines can sometimes result in slight imperfections, such as minor inconsistencies in the soldering or material imperfections. These boards are designed primarily for prototyping and verification, where speed is the priority over flawless quality. For example, if you're testing a new product design, a quick-turn PCB allows you to quickly iterate and make changes, even if the quality is not perfect for long-term use. These minor quality issues are generally acceptable for low-volume runs and initial testing but may not meet the standards required for high-performance applications.

Standard PCBs:

In contrast, standard PCBs undergo more rigorous quality control processes. Since these boards are typically used for large-scale production, manufacturers ensure that each board meets strict quality standards. These standards cover everything from the material quality to the precision of the manufacturing process. For instance, standard PCBs are often used in industries like automotive, medical, and aerospace, where product reliability is critical. These applications demand high-quality PCBs that can withstand harsh conditions and perform consistently over time.

Reliability Differences Between Quick-turn and Standard PCBs

Quick-turn PCBs:

The reliability of quick-turn PCBs is generally lower than that of standard PCBs. Since these boards are produced quickly and with fewer quality checks, they are more prone to defects that can affect long-term performance. For example, a quick-turn PCB used in a consumer electronics prototype might work fine in the short term, but it may fail in more demanding environments or under heavy use. As such, quick-turn PCBs are not suitable for high-reliability applications where long-term durability and consistent performance are critical.

Standard PCBs:

Standard PCBs, on the other hand, are designed for high-reliability applications. These boards are built to last and perform consistently over long periods, making them suitable for industries that require robust performance under demanding conditions. Whether it’s for consumer electronics, medical devices, or industrial machinery, standard PCBs are engineered to handle high temperatures, stress, and constant use. The higher reliability of standard PCBs is one of the main reasons they are preferred for mass production, where long-term product durability is essential.

What Are the Drawbacks of Quick-turn and Standard PCBs?

Quick-turn PCBs offer speed but come with higher unit costs, limited material options, and potential quality compromises. They are not ideal for large-scale production or products that require high long-term reliability. Standard PCBs have longer lead times and are less flexible for rapid prototyping, making them unsuitable for projects that need fast iterations or small batch production. Additionally, they can be more expensive for low-volume orders.

Challenges of Quick-turn PCBs

High Unit Cost and Limited Material/Design Choices:

One of the main drawbacks of quick-turn PCBs is their higher cost per unit. Because these boards are produced quickly, they often come with a premium price tag. The fast production process also limits the materials and design options available. For example, if you need a PCB with specific properties, like heat resistance or flexible materials, quick-turn options may not be the best choice. These limitations can make quick-turn PCBs unsuitable for projects that require specialized materials or intricate designs.

Not Suitable for Mass Production or High-Reliability Products:

Quick-turn PCBs are ideal for prototyping or small batch runs, but they are not suited for large-scale production. The high cost and production time involved make them inefficient for high-volume orders. Additionally, these PCBs often lack the reliability needed for long-term use. For example, if you’re designing a product that will be used in harsh environments or require extensive durability, quick-turn PCBs may not meet the necessary reliability standards.

Challenges of Standard PCBs

Longer Lead Time and Higher Cost for Small Batches:

Standard PCBs typically have longer lead times, which means the time between placing an order and receiving the final product can range from a few days to weeks. This can be a disadvantage for projects that require faster results. Furthermore, when ordering small batches, the unit cost of standard PCBs is higher compared to quick-turn boards. For instance, if you only need a small number of units for a prototype, the time and cost involved in creating a standard PCB may not be cost-effective.

Not Ideal for Rapid Iterations or Prototyping:

Standard PCBs are not designed for rapid iteration, making them less suitable for prototyping or projects that require frequent changes. If you need to quickly test and modify your design, a quick-turn PCB would be a better choice. Standard PCBs require more time to produce, which can delay the development cycle if your project demands continuous design updates.

Which Applications Are Best Suited for Quick-turn and Standard PCBs?

Quick-turn PCBs are ideal for fast prototyping and small-batch production, while standard PCBs are better for high-volume, cost-effective manufacturing.

Applications for Quick-turn PCBs

Prototyping and Small-batch Production:

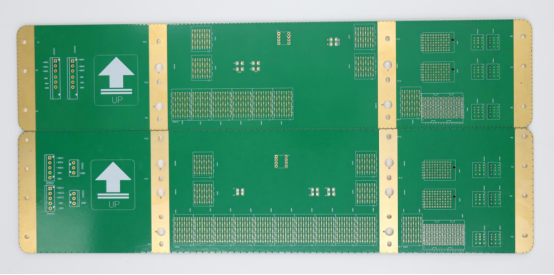

Quick-turn PCBs are perfect for prototyping and small-batch production. Since these boards can be manufactured in a short time, they are ideal for testing and refining new ideas before moving into mass production. For example, if an electronics startup is designing a new gadget, they can use quick-turn PCBs to rapidly produce prototypes and test them in real-world conditions, making design adjustments along the way.

Industries Requiring Fast Feedback and Iteration:

Quick-turn PCBs are particularly useful in industries like electronics startups, research and development teams, and companies that need rapid feedback and iterative testing. These industries often have evolving designs and require a fast turnaround to adjust to new insights or market demands. For instance, a team designing a new wearable technology might use quick-turn PCBs to quickly build prototypes, test them for functionality, and make fast design improvements based on testing results.

Applications for Standard PCBs

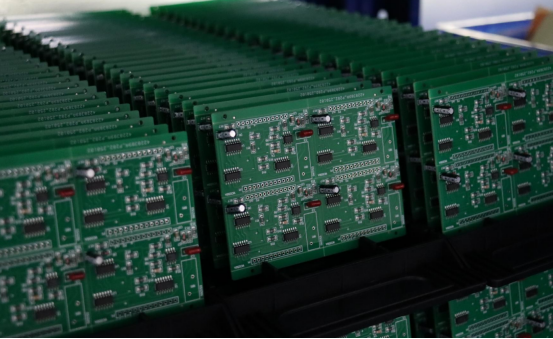

High-volume Consumer Electronics:

Standard PCBs are best for applications requiring mass production, such as in consumer electronics. Products like smartphones, televisions, and other electronic devices benefit from the low-cost per unit offered by standard PCBs. The ability to produce large quantities with consistent quality makes standard PCBs the go-to choice for these types of applications. For example, a company that manufactures thousands of smartphones would use standard PCBs to keep production costs low while ensuring each unit meets quality standards.

Automotive and Industrial Equipment:

Another key application for standard PCBs is in industries like automotive and industrial equipment, where high performance and durability are required. In these sectors, PCBs must operate reliably in challenging environments, such as high temperatures and vibrations. Standard PCBs are built for these types of conditions, providing the reliability needed for components in vehicles or heavy machinery. For example, a car manufacturer would use standard PCBs for engine control units (ECUs) to ensure they can withstand extreme conditions and function over long periods without failure.

Cost-effective Large-scale Manufacturing:

Standard PCBs are designed for large-scale production, making them ideal for applications where cost efficiency and consistent performance are key priorities. They are highly suitable for industries where the need for mass production outweighs the demand for rapid development. For instance, manufacturers of home appliances may use standard PCBs for washing machines or refrigerators, where the goal is to produce large quantities at a low cost while maintaining high reliability.

Conclusion

quick-turn PCBs and standard PCBs serve different purposes depending on your project’s requirements. Quick-turn PCBs are ideal for rapid prototyping, testing, and small-batch production, but they come with higher costs and limited design options. Standard PCBs, on the other hand, are better suited for high-volume production, offering cost efficiency and reliability but with longer lead times and less flexibility for quick iterations.

Here’s a quick comparison to highlight the key differences between quick-turn and standard PCBs:

| Feature | Quick-turn PCBs | Standard PCBs |

| Lead Time | 24-48 hours | 7-14 days (or more, depending on complexity) |

| Cost | Higher unit cost due to fast production | Lower unit cost for high-volume production |

| Material Options | Limited to basic, readily available materials | Wide range of materials, including specialized options |

| Design Complexity | Suitable for simple designs (single-layer or few layers) | Supports complex designs (multi-layer, HDI) |

| Reliability | Lower reliability for long-term use | Higher reliability, suitable for long-term applications |

| Applications | Prototyping, small-batch production, R&D | Mass production, consumer electronics, automotive, industrial |

| Flexibility for Iteration | Highly flexible, ideal for rapid prototyping and testing | Less flexible, slower iteration process due to longer lead times |

| Production Scale | Best for low-volume or small runs | Ideal for large-scale manufacturing |

To help you choose the right PCB for your needs, consider your project’s timeline, budget, and design complexity. If you need fast results for testing or prototyping, quick-turn PCBs are the way to go. For mass production or high-reliability applications, standard PCBs will provide better value.

No matter which type of PCB best suits your needs, working with an experienced supplier can make all the difference. At PCBMASTER, we specialize in both quick-turn and standard PCBs, offering high-quality products and expert support for your projects. Whether you're developing a prototype or scaling up for mass production, we are here to help you achieve the best results.

FAQs about Quick-Turn PCBs and Standard PCBs

What Types of Projects Are Best Suited for Quick-turn PCBs?

Quick-turn PCBs are perfect for projects that need fast prototype validation, design revisions, and small batch production. They are often used in early-stage development and experimental projects, especially by startups and R&D teams. For example, if you're a startup working on a new product and need to quickly test and adjust your design, quick-turn PCBs are an ideal choice. They allow teams to build prototypes quickly, test functionality, and make design changes based on real-world feedback.

What Is the Quality of Quick-turn PCBs?

Since quick-turn PCBs are produced in a short time, there can sometimes be slight compromises in quality. The fast turnaround can lead to minor imperfections in processes like soldering or lamination. However, these small quality differences usually aren’t a problem for most prototyping and testing needs. If you’re validating a new design or conducting preliminary tests, quick-turn PCBs are generally good enough for the job. That said, if you need high-precision or long-term stability, you may need to consider alternatives.

Are Standard PCBs Suitable for Rapid Iteration Projects?

Standard PCBs are not the best choice for rapid iteration projects because they typically have longer lead times—usually anywhere from 7 to 14 days, or more depending on the complexity. If your project requires frequent design changes and quick validation, standard PCBs may slow down the process. For example, if you’re designing a new product that needs continuous testing and modification, quick-turn PCBs are much more suitable as they allow faster feedback and iterations. Standard PCBs are better for projects that are past the prototyping phase and are moving into long-term production.

How Much More Expensive Are Quick-turn PCBs Compared to Standard PCBs?

Quick-turn PCBs are generally more expensive per unit than standard PCBs. The main reason for this is the faster production process, which requires manufacturers to expedite production, often through overtime or specialized methods. While this is necessary for getting prototypes or small batches out quickly, it does increase the cost. In contrast, standard PCBs can benefit from bulk production, which drives the cost down significantly per unit. If you’re planning to produce a large volume of products, standard PCBs will be more cost-effective.

Can the Same Materials Be Used for Both Quick-turn and Standard PCBs?

While some materials can be used in both quick-turn PCBs and standard PCBs, quick-turn PCBs generally have more limited material options. This is because the fast production times require materials that are readily available and can be processed quickly, like standard FR4 or basic copper-clad laminates. If your project requires more specialized materials, such as high-frequency or flexible substrates, standard PCBs offer a much wider range of material choices to meet specific performance needs. Therefore, quick-turn PCBs are typically limited to more standard, off-the-shelf materials that are faster to procure and work with.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!