High-Frequency PCB Materials: A Guide to Selecting the Best for Signal Integrity

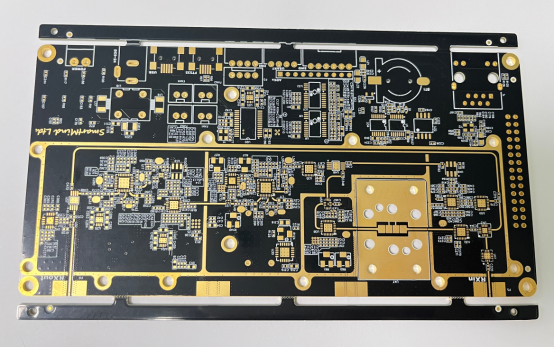

Maintaining signal integrity in high-frequency PCBs is a crucial factor in the performance of modern electronic systems. Whether it's for communications, RF circuits, or aerospace applications, the materials chosen for the PCB directly influence the clarity and reliability of signal transmission. Selecting the right material is key to minimizing signal loss, crosstalk, and interference, which can compromise the overall functionality of the device. This guide explores the most important considerations and provides insight into the best materials available for achieving superior signal integrity in high-frequency applications.

What Are High-Frequency PCB Materials?

High-frequency PCBs (Printed Circuit Boards) are specially designed for applications where signals operate at higher frequencies, typically above 100 MHz. These PCBs are used in systems such as communication devices, RF (Radio Frequency) circuits, and microwave technologies, where maintaining signal integrity is essential. These applications include things like wireless communication systems, radar, satellite equipment, and cell phones.

High-frequency PCBs are required because at higher frequencies, signals are more prone to distortion, loss, and interference. The materials used for these PCBs must have specific properties to minimize such issues and ensure that the signal travels clearly from one point to another. Standard PCB materials like FR-4 are not suitable for high-frequency applications due to their poor performance at higher frequencies.

Real-world example:

In wireless communication, the PCB materials used in smartphones, Wi-Fi routers, and Bluetooth devices need to handle high-frequency signals for transmitting and receiving data. These materials must prevent signal loss and maintain consistent impedance to ensure the device works efficiently without interruptions.

Key Properties of High-Frequency PCB Materials

Selecting the right material for high-frequency PCBs is essential to ensure signal integrity and performance. Key properties like dielectric constant (Dk), dissipation factor (Df), thermal stability, and electrical performance all play a crucial role in minimizing signal loss, maintaining impedance stability, and ensuring reliable operation. Let's take a closer look at these important factors.

1. Dielectric Constant (Dk) and Dissipation Factor (Df)

What is dielectric constant (Dk)?

The dielectric constant (Dk) is a measure of a material’s ability to store electrical energy in an electric field. In high-frequency PCBs, materials with a consistent Dk are essential to control the impedance and maintain signal integrity. A stable Dk helps in ensuring that the signal travels through the PCB with minimal distortion.

What is dissipation factor (Df)?

The dissipation factor (Df) is a measure of how much energy is lost as heat when a signal passes through a material. Lower Df values are preferable for high-frequency PCBs because they result in lower signal loss and reduced heat generation. Materials with a low Df are critical in applications like RF circuits and microwave devices, where signal preservation is key.

2. Thermal Stability and Expansion Coefficients

Why is thermal stability important?

Thermal stability refers to how well a material can maintain its performance and structure under temperature changes. High-frequency PCBs often operate in environments with fluctuating temperatures. Materials that are thermally stable can withstand these changes without warping or losing their electrical properties.

What is the coefficient of thermal expansion (CTE)?

The coefficient of thermal expansion (CTE) measures how much a material expands or contracts with temperature changes. In high-frequency PCBs, it's important that the CTE of the PCB material matches the CTE of other components, such as semiconductor chips and connectors. If the expansion rates don't match, the PCB can warp, causing physical damage and compromising signal integrity.

3. Electrical Performance: Signal Loss and Impedance Stability

Why is electrical performance critical in high-frequency PCBs?

Electrical performance in high-frequency PCBs refers to how well the material allows signals to travel with minimal attenuation, distortion, and reflection. In high-frequency circuits, maintaining signal integrity requires the material to have stable impedance and low signal loss. Impedance mismatch or excessive signal loss can lead to signal reflections, crosstalk, and overall system failure.

Signal loss occurs when the signal weakens as it travels through the PCB material. High-frequency signals are particularly sensitive to this, so materials with low attenuation (signal loss) are critical.

Impedance stability ensures that the resistance to the signal remains consistent as it moves through the PCB. Variations in impedance can lead to signal reflection, causing data errors or communication failure. High-frequency PCBs must maintain precise impedance to ensure the signal flows without disruption.

Why Is Signal Integrity Crucial in High-Frequency PCB Design?

Signal integrity refers to the quality of an electrical signal as it travels through a PCB. In high-frequency PCBs, maintaining signal integrity is crucial for ensuring that the signal reaches its destination without degradation. If signal integrity is compromised, the result can be poor performance, including data errors, loss of communication, or complete failure of the device. High-frequency signals are particularly susceptible to problems like signal degradation, crosstalk, and noise interference, all of which can negatively impact device performance.

Signal degradation happens when the strength of the signal weakens over time or distance. High-frequency signals are especially prone to this due to factors like material resistance, attenuation, and imperfect transmission paths.

Crosstalk refers to unwanted interference between adjacent signal traces on the PCB. In high-frequency designs, this can cause one signal to unintentionally "leak" into another, creating errors and noise.

Noise interference is any external or internal signal that disturbs the desired signal. High-frequency PCBs can pick up noise from nearby electronic components or the surrounding environment, which can distort or reduce the quality of the signal.

Maintaining good signal integrity ensures that signals are transmitted with minimal distortion, leading to more reliable and efficient performance in high-frequency applications.

What Are the Most Common High-Frequency PCB Materials for Signal Integrity?

The most common high-frequency PCB materials for signal integrity include SYTECH SCGA-500 GF220, AGC TLY-5, ROGERS RT/duroid 5880, WL F4BM220, Zhongying ZYF220D, and WL F4BK225. Each of these materials is designed to minimize signal loss, maintain stable impedance, and offer high thermal stability, making them ideal for RF, microwave, and communication applications.

What is SYTECH SCGA-500 GF220?

SYTECH SCGA-500 GF220 is a PTFE (Polytetrafluoroethylene)-based material reinforced with glass fibers, designed for high-frequency RF circuit applications. It is known for its excellent signal integrity and low dielectric loss, making it ideal for demanding communication and satellite systems.

Key Features:

Dielectric Constant (Dk): 2.20 ± 0.02 @10GHz

Dissipation Factor (Df): 0.0009 @10GHz

Thermal Coefficient of Dk (TcDk): -110 ppm/°C

Moisture Absorption: 0.007%

Flammability Rating: UL 94 V-0

Applications:

Base Station Antennas

Satellite Communications

Phased Array Antennas

Power Amplifiers and LNAs

What is AGC TLY-5?

AGC TLY-5 is a low-Dk, low-Df material primarily used in avionics and high-frequency applications. Its fiberglass reinforcement and low moisture absorption contribute to its dimensional stability, making it ideal for high-precision applications like radar and communication systems.

Key Features:

Dielectric Constant (Dk): 2.20 ± 0.02 @10GHz

Dissipation Factor (Df): 0.0009 @10GHz

Thermal Conductivity: 0.22 W/m·K

Moisture Absorption: 0.02%

Applications:

Automotive Radar (77 GHz)

Satellite Communications

Phased Array Antennas

Power Amplifiers (LNAs, LNBs)

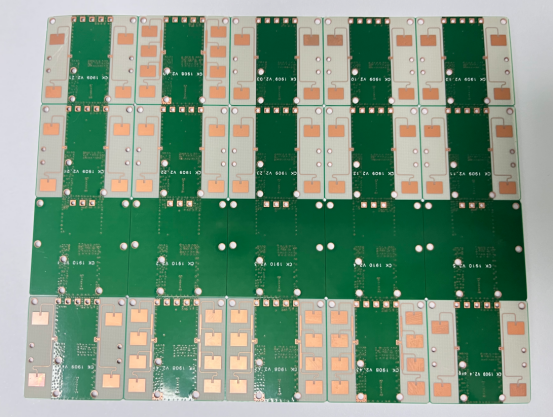

What is ROGERS RT/duroid 5880?

ROGERS RT/duroid 5880 is a PTFE composite material reinforced with glass microfibers. It is widely recognized for its low dielectric constant and low dissipation factor, making it highly suitable for broadband applications.

Key Features:

Dielectric Constant (Dk): 2.20 ± 0.02 @10GHz

Dissipation Factor (Df): 0.0009 @10GHz

Moisture Absorption: Low

Thermal Stability: High

Applications:

Satellite Communications

5G Systems

Radar Applications

High-Speed Data Transmission

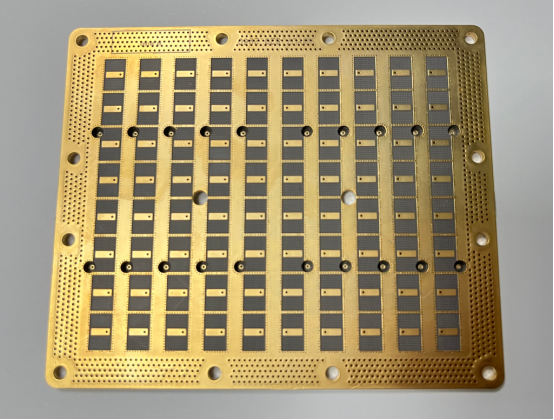

What is WL F4BM220?

WL F4BM220 is a PTFE-based laminate reinforced with fiberglass, offering low dielectric loss and high stability. It is ideal for RF and microwave applications where consistent electrical performance is critical.

Key Features:

Dielectric Constant (Dk): 2.2 ± 0.04 @10GHz

Dissipation Factor (Df): 0.001 @10GHz

Thermal Stability: -142 ppm/°C

Moisture Absorption: ≤ 0.08%

Applications:

Phase Shifters

Satellite Communication Systems

RF Power Dividers/Couplers

Radar Systems

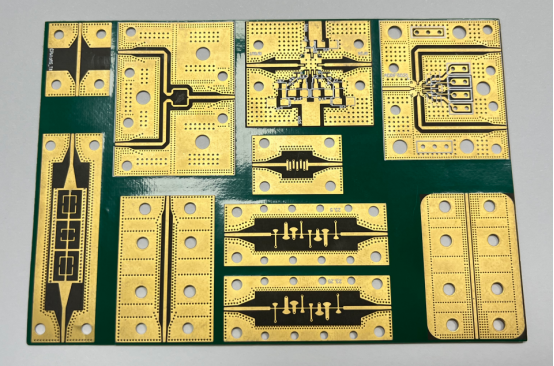

What is Zhongying ZYF220D?

Zhongying ZYF220D is a PTFE-based material reinforced with glass fiber, known for its excellent dielectric performance and low moisture absorption. It is especially suited for high-frequency applications requiring low loss and stable performance.

Key Features:

Dielectric Constant (Dk): 2.20 ± 0.02 @10GHz

Dissipation Factor (Df): 0.0009 @10GHz

Thermal Conductivity: 0.26 W/m·K

Moisture Absorption: 0.02%

Applications:

Radar Systems

Aerospace

Phased Array Antennas

Satellite Communications

What is WL F4BK225?

WL F4BK225 is another PTFE-based laminate reinforced with glass fibers, designed for high-frequency applications. It offers a slightly higher dielectric constant compared to other materials, making it suitable for aerospace applications.

Key Features:

Dielectric Constant (Dk): 2.25

Dissipation Factor (Df): 0.0015

Flame Rating: UL 94V-0

Applications:

Aerospace

Base Station Antennas

Satellite Communications

Filters and Couplers

Comparison Table

Material Dk @ 10GHz Df @ 10GHz Key Applications SYTECH SCGA-500 GF220 2.20 ± 0.02 0.0009 RF, Microwave, Satellite Systems, Antennas AGC TLY-5 2.20 ± 0.02 0.0009 Automotive Radar, Satellite, Power Amplifiers ROGERS RT/duroid 5880 2.20 ± 0.02 0.0009 Satellite, 5G, Radar, Data Transmission WL F4BM220 2.2 ± 0.04 0.001 RF Power Dividers, Satellite, Radar Zhongying ZYF220D 2.20 ± 0.02 0.0009 Radar, Aerospace, Phased Array Antennas WL F4BK225 2.25 0.0015 Aerospace, Base Stations, Filters

How to Select the Appropriate High-Frequency PCB Material for Signal Integrity Based on Your Specific Needs

Selecting the right high-frequency PCB material is crucial for maintaining signal integrity and ensuring reliable performance in demanding applications. The choice of material depends on factors such as the operating frequency, environmental conditions, signal stability, and budget constraints. By understanding key properties like dielectric constant (Dk), dissipation factor (Df), thermal stability, and fabrication requirements, you can make an informed decision that balances performance and cost for your specific needs.

1. Determine Your Application’s Frequency Range

Why is the frequency range important?

The frequency at which your PCB operates will significantly influence the type of material you should choose. Materials with lower dielectric constants (Dk) are typically better for higher frequencies as they reduce signal loss and maintain better signal integrity.

What to look for:

For applications like RF (radio frequency) communication or microwave systems, materials with a low and stable Dk are necessary to minimize signal degradation. For example, ROGERS RT/duroid 5880 (Dk = 2.2) works well for high-frequency systems like satellites and radars, while materials like WL F4BM220 (Dk = 2.2) are commonly used in 5G base stations.

2. Assess the Required Signal Integrity and Impedance Stability

Why does signal integrity matter?

Signal integrity ensures that the signal remains clear and strong as it travels through the PCB. Impedance stability is key in high-frequency circuits, as any variation can cause signal reflections, resulting in data loss or poor system performance.

What to look for:

Materials with low dissipation factors (Df) and consistent dielectric properties are ideal. For instance, AGC TLY-5 (Df = 0.0009) is known for excellent signal preservation, making it ideal for applications where signal clarity is critical, like satellite communications.

3. Consider Environmental Conditions and Thermal Stability

Why is environmental stability critical?

High-frequency PCBs are often used in extreme environmental conditions where temperature, humidity, and even chemical exposure can fluctuate. The material must maintain its performance and structural integrity in these conditions.

What to look for:

Materials with low moisture absorption and high thermal stability are essential. For example, SYTECH SCGA-500 GF220 (moisture absorption: 0.007%) has low moisture absorption, ensuring that it performs consistently even in humid environments. Similarly, materials with low Coefficient of Thermal Expansion (CTE) help prevent warping and damage under temperature changes.

4. Balance Performance with Cost-Effectiveness

Why is cost a factor in material selection?

High-frequency PCB materials can vary significantly in price. While materials like ROGERS RT/duroid 5880 offer exceptional performance, they can be more expensive. Depending on your application’s budget and performance requirements, you may need to make trade-offs between cost and performance.

What to look for:

For applications where extreme performance is not critical, more affordable materials like WL F4BK225 (Dk = 2.25, Df = 0.0015) may offer a good balance of performance and cost. For budget-conscious designs, materials like Zhongying ZYF220D (Dk = 2.2, Df = 0.0009) are reliable options that offer high performance without the premium price tag.

5. Consider Fabrication Requirements and Ease of Processing

Why is fabrication and ease of processing important?

The material you select should not only perform well but also be easy to fabricate and process during PCB production. Difficult-to-process materials can increase production costs and time.

What to look for:

Materials like AGC TLY-5, which can be easily laser-ablated and machined, are preferable for applications that require precise manufacturing processes. Choosing a material that is easy to process ensures faster turnaround times and reduces potential errors during PCB assembly.

6. Evaluate the Need for Mechanical Flexibility

Why does mechanical flexibility matter?

Some high-frequency applications require materials that offer mechanical flexibility, especially in designs where bending or movement is necessary. Rigid materials may not be suitable for all use cases.

What to look for:

Materials like AGC TLY-5 and its variant TLY-3FF are designed to offer higher mechanical flexibility while maintaining low Df. This is ideal for applications in automotive or flexible antenna systems where slight bending or movement is required without compromising signal performance.

7. Availability and Lead Time for Material Supply

Why does material availability matter?

In high-frequency PCB design, the availability of materials can directly affect production timelines. Delays in sourcing materials can lead to delays in project completion, especially in industries with tight schedules.

What to look for:

Materials like ROGERS RT/duroid 5880 and SYTECH SCGA-500 GF220 are widely used and readily available, ensuring that your project won’t be delayed due to material shortages. Always check with suppliers for lead times to ensure timely delivery.

Conclusion

Selecting the best high-frequency PCB material is essential for ensuring optimal signal integrity and system performance. Key factors like dielectric constant (Dk), dissipation factor (Df), thermal stability, and environmental resistance must be carefully considered based on your application’s needs. Materials with low Dk and Df, such as ROGERS RT/duroid 5880 or SYTECH SCGA-500 GF220, are ideal for high-frequency systems where signal preservation is critical. Additionally, balancing cost and performance is vital for applications with tighter budgets, where alternatives like WL F4BM220 can provide reliable results at a more affordable price point.

Ultimately, choosing the right material involves understanding both your technical requirements and financial considerations. At PCBMASTER, a seasoned PCB supplier, we specialize in offering high-quality PCB solutions tailored to your specific needs. Whether you require high-performance materials for aerospace, telecommunications, or consumer electronics, we can help you select the ideal product to meet your exact specifications. Our experience and customer-focused approach ensure that you get the best value without compromising on quality.

FAQs

1. What is the most important property of high-frequency PCB materials?

The dielectric constant (Dk) and dissipation factor (Df) are the most important properties for high-frequency PCB materials. The dielectric constant determines how well a material can store electrical energy within an electric field, which directly impacts the impedance of the PCB traces. A stable Dk ensures consistent impedance, reducing the likelihood of signal reflection or loss.

The dissipation factor (Df) measures how much energy is lost as heat when an electrical signal travels through the material. Lower Df values are essential for minimizing signal loss, especially at high frequencies. Materials with low Df help ensure that the signal maintains its strength and integrity, reducing distortion and ensuring accurate data transmission. Materials with both low Dk and Df are therefore ideal for high-frequency applications such as RF circuits, satellite communications, and microwave devices.

2. Can FR-4 be used for high-frequency PCBs?

While FR-4 is a commonly used material for low to medium-frequency PCBs, it is not recommended for high-frequency applications. The reason is that FR-4 has relatively higher values for both dielectric constant (Dk) and dissipation factor (Df) compared to other materials designed specifically for high-frequency use. These higher values can lead to signal loss, impedance mismatch, and poor signal integrity, particularly at frequencies above 1 GHz.

For applications that require reliable performance at high frequencies (such as RF communication, radar, or satellite systems), specialized materials like PTFE or Rogers materials (e.g., RT/duroid) are more suitable due to their much lower Dk and Df values, which help minimize signal degradation.

3. How does Rogers material compare to PTFE for signal integrity?

Both Rogers materials and PTFE are excellent choices for high-frequency PCBs, but they have different strengths.

Rogers materials (such as RT/duroid 5880) are designed to offer consistent low Dk and low Df across a wide frequency range, making them suitable for many high-frequency applications like RF circuits and satellite communications. These materials are well-regarded for their stable electrical properties and low signal loss over a wide frequency spectrum, which translates to better signal integrity and reliable performance in challenging environments.

PTFE materials, on the other hand, are often used when extreme low-loss performance is required, especially in microwave and millimeter-wave frequencies. PTFE has a very low Df, making it ideal for applications where signal loss must be minimized as much as possible. However, PTFE can be more expensive than Rogers materials and may require more precise handling and manufacturing techniques.

In summary, Rogers materials offer great performance at a more balanced price point, while PTFE excels in ultra-low-loss applications, particularly at very high frequencies, but at a higher cost.

4. How do environmental factors affect signal integrity in high-frequency PCBs?

Environmental factors like temperature, humidity, and mechanical stress can have a significant impact on signal integrity in high-frequency PCBs. Here’s how:

Temperature: Changes in temperature can affect the dielectric constant (Dk) and dissipation factor (Df) of PCB materials. High-frequency PCB materials often experience changes in these properties as temperature fluctuates, leading to impaired signal integrity or unstable impedance. Materials with low temperature coefficient of Dk (TcDk), like ROGERS RT/duroid, are designed to maintain their properties even in extreme temperature conditions.

Humidity: Moisture absorption can cause materials to swell, altering their dielectric properties and leading to signal loss and impedance instability. Therefore, materials with low moisture absorption (such as SYTECH SCGA-500 GF220, which absorbs only 0.007% moisture) are preferred in humid environments.

Mechanical Stress: Physical stresses such as bending or thermal cycling can affect the coefficient of thermal expansion (CTE) of PCB materials. When the expansion rates of the PCB material and other components (such as chips or connectors) don’t match, it can cause warping and cracks, leading to signal degradation or PCB failure.

In high-frequency designs, selecting materials that can withstand environmental variations and maintain stable electrical properties is essential for ensuring long-term reliability and signal quality.

5. What is the role of impedance control in high-frequency PCB design?

Impedance control is a critical factor in high-frequency PCB design because it ensures the signal travels smoothly across the PCB traces without reflections or signal loss. Impedance is the resistance a signal encounters as it travels through the traces, and any variation in impedance can cause part of the signal to reflect back, resulting in signal distortion, data errors, or even system failure.

To maintain consistent impedance, it’s essential to select PCB materials with stable dielectric properties and precise manufacturing controls. The trace width and spacing also play a role in controlling impedance. By carefully controlling these factors, designers can ensure that signals are transmitted with minimal loss, preserving the integrity of the data and ensuring the system operates as intended.

In high-frequency applications like RF communication, radar systems, and satellite communications, precise impedance control is crucial for achieving optimal performance and reducing the likelihood of errors or failures.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!