What Is FR-4? A Complete Guide to the Most Common PCB Substrate

In the world of electronics, every circuit begins with a foundation — and for most, that foundation is FR-4. This versatile fiberglass-reinforced epoxy material has quietly powered everything from smartphones to satellites, offering the strength, insulation, and reliability engineers depend on. Yet behind its familiar name lies a complex balance of chemistry, performance, and design trade-offs that make it both indispensable and, in some cases, limiting. Understanding what FR-4 really is—and why it dominates PCB manufacturing—is key to choosing the right substrate for today’s ever-faster, smaller, and more demanding electronic designs.

Introduction to FR-4

Definition and Overview

FR-4 is a grade of glass-reinforced epoxy laminate that serves as the foundation material for most rigid printed circuit boards (PCBs). The term “FR” stands for Flame Retardant, and the number “4” designates its specific performance level according to material classification standards. In simple terms, FR-4 combines woven fiberglass cloth for strength with epoxy resin for insulation, creating a durable and stable base that can support complex electronic circuits.

Because of its excellent balance of mechanical durability, electrical insulation, and heat resistance, FR-4 has become the industry’s default choice for PCB substrates. Nearly every modern device—from smartphones and routers to industrial controllers—contains FR-4 at its core, making it one of the most widely used materials in electronics manufacturing.

Origin and Standardization

The name “FR-4” originates from the National Electrical Manufacturers Association (NEMA), which established performance and safety standards for electrical laminates. Under NEMA’s classification, FR-4 materials must meet strict criteria for flame retardancy, moisture absorption, and mechanical strength.

It’s important to note that FR-4 is not a brand name but a material grade. This means multiple manufacturers can produce FR-4 laminates as long as they meet the same NEMA specifications. For example, brands such as Isola, Shengyi, and Panasonic each offer FR-4 materials that comply with the same flame-retardant and insulation standards, though they may differ slightly in properties such as glass transition temperature (Tg) or dielectric constant (Dk).

Why FR-4 Matters in PCB Manufacturing

FR-4 remains the most common PCB substrate because it achieves a rare combination of performance, reliability, and affordability. Its glass-fiber reinforcement provides rigidity and dimensional stability, while the epoxy resin ensures excellent electrical insulation and resistance to environmental stress.

This balance allows FR-4 to perform well in a wide range of applications. In consumer electronics, it enables compact, cost-effective circuit designs. In automotive systems, its thermal and mechanical strength support harsh operating environments. In industrial equipment, FR-4’s stability ensures long-term reliability even under continuous heat or vibration.

In short, FR-4 offers the ideal midpoint between basic phenolic boards and high-performance materials like Rogers or polyimide—making it the trusted backbone of modern electronic design.

Composition and Material Properties of FR-4

Core Components

FR-4 is a composite material made from multiple layers that work together to provide mechanical strength and electrical insulation.

Woven Fiberglass Cloth (Reinforcement Layer):

The fiberglass layer gives FR-4 its structural rigidity and resistance to bending or warping. It is made of fine glass fibers woven into a fabric, which evenly distributes mechanical stress and ensures dimensional stability even under temperature changes.

Epoxy Resin (Binding and Insulating Matrix):

The fiberglass is impregnated with epoxy resin, which hardens to form a solid, non-conductive matrix. This resin binds the fibers together and provides excellent electrical insulation, chemical resistance, and moisture protection—key traits for reliable PCB performance.

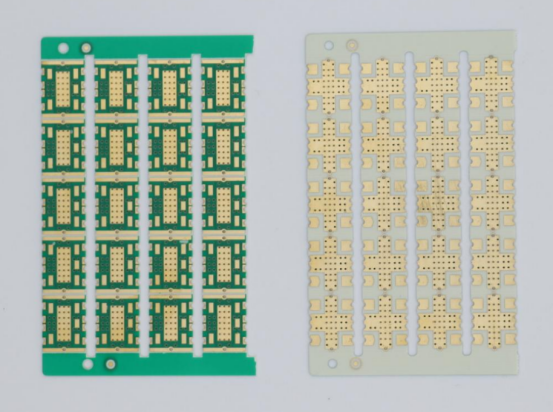

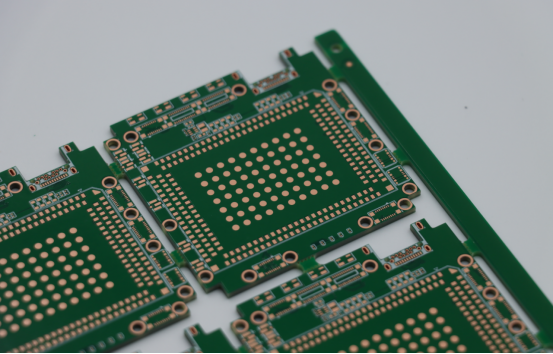

Copper Foil Laminates (Conductive Layers):

In PCB manufacturing, thin sheets of copper foil are laminated to one or both sides of the FR-4 core. These copper layers are later etched to form conductive circuits and vias. The combination of copper and FR-4 creates a strong, multilayer structure capable of supporting complex electronic designs.

Key Physical and Mechanical Properties

FR-4 is valued for its mechanical strength and stability.

Density and Tensile Strength:

With a typical density of around 1.85–1.9 g/cm³, FR-4 is lightweight yet strong. Its tensile strength (300–450 MPa) ensures that PCBs can withstand mechanical stress during manufacturing and operation.

Glass Transition Temperature (Tg):

Tg represents the temperature at which the epoxy transitions from a rigid to a flexible state. Standard FR-4 typically has a Tg between 135°C and 150°C, while high-Tg FR-4 can exceed 170°C, improving thermal stability for high-power or multilayer boards.

Dimensional Stability and Moisture Absorption:

FR-4 maintains its shape and size under heat or humidity. Its low moisture absorption rate (usually below 0.15%) helps prevent expansion and signal loss, which is essential for precision applications like HDI and multilayer PCBs.

Electrical Characteristics

The electrical properties of FR-4 determine how well it insulates and transmits signals.

Dielectric Constant (Dk):

FR-4 typically has a Dk value of 4.2–4.8 at 1 MHz, meaning it offers good insulation and predictable signal transmission. Lower Dk values result in faster signal propagation, which is why low-loss FR-4 variants are preferred for high-speed digital circuits.

Dissipation Factor (Df):

The Df, or loss tangent, measures how much signal energy is lost as heat. Standard FR-4 has a Df of 0.015–0.020, while advanced low-loss types can reach 0.005 or less, reducing signal attenuation in high-frequency applications.

Surface and Volume Resistivity:

FR-4 provides high surface resistivity (≥10⁸ MΩ) and volume resistivity (≥10¹³ Ω·cm), ensuring minimal leakage currents and stable performance in humid or high-voltage environments.

Thermal Properties

FR-4’s ability to handle heat directly impacts its reliability and performance.

Heat Resistance and Decomposition Temperature (Td):

The Td, typically around 300°C, marks the temperature at which the epoxy resin begins to chemically decompose. Operating below this threshold ensures long-term stability.

Coefficient of Thermal Expansion (CTE):

The CTE measures how much the material expands when heated. FR-4’s CTE is around 14–17 ppm/°C in the X/Y plane, closely matching copper’s, which helps prevent delamination during soldering.

Example – FR-4 vs High-Tg Materials:

Standard FR-4 (Tg ≈ 135–150°C) may soften under prolonged heat, while high-Tg FR-4 (>170°C) or advanced laminates (Tg >200°C) maintain integrity during lead-free soldering or high-temperature reflow processes.

Flame Retardancy

One of FR-4’s defining traits is its self-extinguishing flame resistance.

UL94 V-0 Rating:

FR-4 materials are certified under the UL94 V-0 standard, which means that when exposed to flame, they extinguish within 10 seconds and do not produce flaming drips. This property is vital for meeting safety standards in consumer and industrial electronics.

Brominated Epoxy System:

The flame retardancy primarily comes from brominated compounds in the epoxy resin. During combustion, bromine atoms release radicals that inhibit the oxidation process, effectively slowing or stopping the fire’s spread.

This combination of fiberglass strength, epoxy insulation, and flame-retardant chemistry makes FR-4 one of the most reliable and versatile materials in PCB production, balancing performance, safety, and manufacturability across a wide range of electronic applications.

Types of FR-4 Materials

Not all FR-4 laminates are created equal. Over time, manufacturers have developed several variants of FR-4 to meet different electrical, thermal, and environmental requirements. Understanding these types helps engineers choose the right substrate for each PCB design.

Standard FR-4

Standard FR-4 is the most widely used version, designed for general-purpose and low-frequency electronic applications. It offers a good balance of strength, insulation, and cost-effectiveness, making it suitable for consumer devices, office equipment, and simple industrial circuits.

Typical properties: Tg between 130°C and 150°C, dielectric constant (Dk) around 4.5.

Applications: Power supplies, LED drivers, control panels, and other products where thermal and signal demands are moderate.

Because it’s affordable and easy to process, standard FR-4 remains the go-to choice for most everyday PCB manufacturing.

High-Tg FR-4

High-Tg FR-4 materials are engineered for environments where higher operating temperatures or mechanical stress are common. “Tg” stands for glass transition temperature, the point where the material shifts from rigid to soft.

Key feature: A Tg value of 170°C or higher, providing better thermal and mechanical stability than standard FR-4.

Advantages: Improved resistance to delamination and deformation during lead-free soldering or reflow processes.

Applications: Automotive control systems, power modules, and multilayer PCBs in industrial automation or aerospace electronics.

For example, Isola 370HR and Panasonic R-1755V are high-Tg FR-4 materials often chosen for multilayer or high-power designs, where maintaining dimensional stability under heat is critical.

Halogen-Free FR-4

Halogen-free FR-4 is an environmentally friendly alternative to conventional FR-4. It eliminates bromine- and chlorine-based flame retardants, which can produce toxic gases when burned.

Compliance: Meets RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives.

How it works: Flame retardancy is achieved through phosphorus- or nitrogen-based compounds instead of halogens.

Applications: Consumer electronics, medical devices, and export products where environmental regulations are strict.

Example materials: Shengyi S1155 or ITEQ IT-150G halogen-free FR-4 laminates.

This type supports the electronics industry’s shift toward greener, sustainable PCB materials without significantly compromising mechanical or electrical performance.

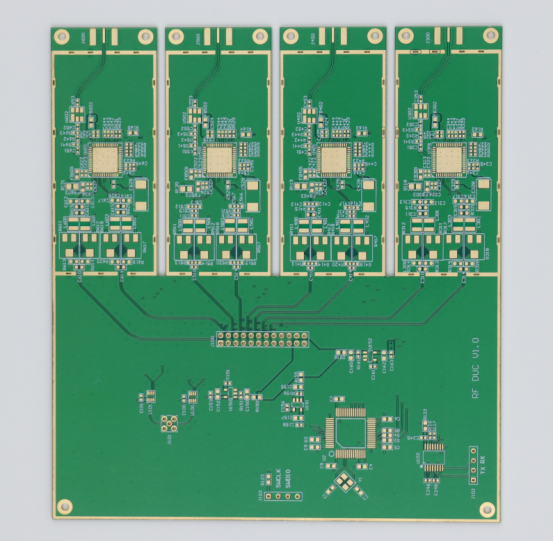

Low-Loss FR-4

Low-loss FR-4 is optimized for high-speed digital or high-frequency circuits, where minimizing signal loss is crucial. As signal frequencies rise, standard FR-4’s dielectric properties cause attenuation and timing errors—low-loss variants solve this problem.

Key electrical properties:

- Lower dielectric constant (Dk ≈ 3.6–3.9)

- Reduced dissipation factor (Df ≤ 0.008)

Result: Better signal integrity, reduced crosstalk, and improved high-speed transmission.

Applications: Servers, 5G communication boards, high-frequency backplanes, and data processing systems.

Examples: Isola FR408HR, ITEQ IT-180A, and Taiyo TU-872 are common low-loss FR-4 materials designed for advanced multilayer PCBs.

Compared to traditional FR-4, low-loss materials offer superior performance for GHz-level signals, bridging the gap between standard laminates and specialized high-frequency materials like Rogers.

Each type of FR-4 serves a distinct purpose—from cost-effective general use to high-speed, high-reliability, or eco-conscious designs. Selecting the right one depends on factors like operating temperature, frequency range, and environmental standards, ensuring that the final PCB meets both performance and compliance goals.

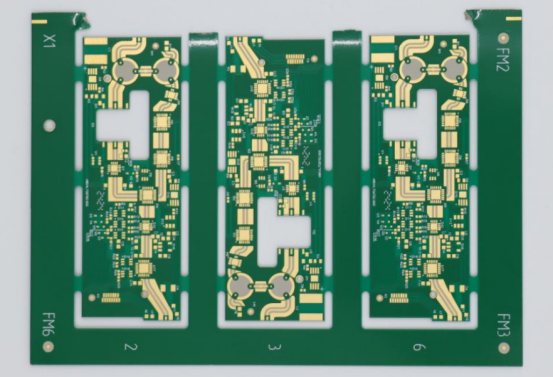

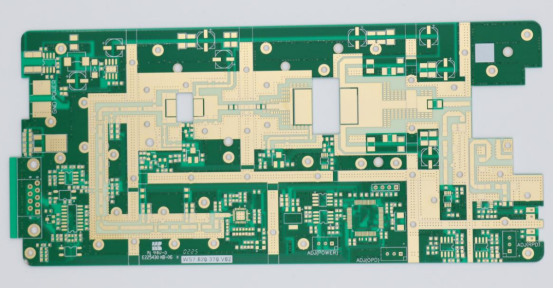

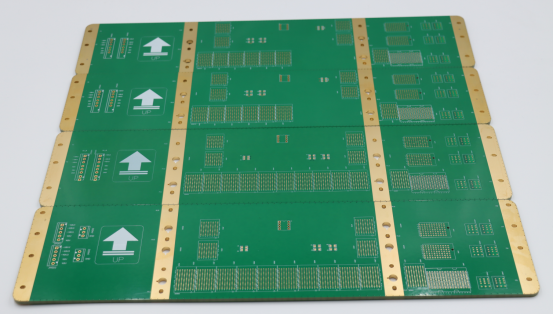

How FR-4 Is Used in PCB Manufacturing

FR-4 is more than just a substrate material—it is the structural and electrical backbone of modern printed circuit boards. From the inner dielectric layers to the final surface finish, FR-4 plays a vital role in ensuring performance, reliability, and manufacturability.

Role in Layer Stack-Up

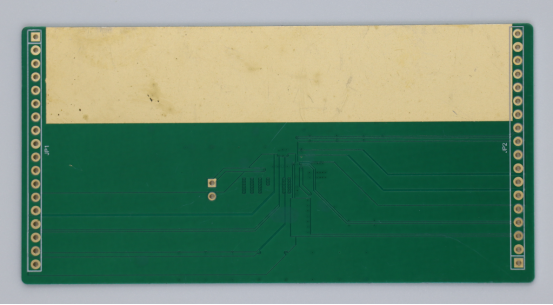

In PCB manufacturing, FR-4 acts as the dielectric core that separates conductive copper layers. Its primary function is to insulate electrical signals while maintaining mechanical rigidity.

A typical multilayer PCB stack-up follows these steps:

1. Core Layer Formation: Manufacturers start with an FR-4 sheet laminated with copper foil on both sides.

2. Inner Layer Etching: Copper is patterned to create circuit traces.

3. Prepreg Application: Layers of FR-4 prepreg (uncured fiberglass impregnated with epoxy) are stacked between etched cores.

4. Lamination: Heat and pressure are applied, curing the prepreg and bonding all layers into a single solid structure.

This process allows engineers to create complex multilayer designs (e.g., 8-layer or 16-layer PCBs) while maintaining precise dielectric spacing. The FR-4’s stability ensures that signal layers remain aligned and insulated, even in high-density interconnect (HDI) applications.

Drilling and Plating Process

Once the multilayer stack is cured, the next stage involves drilling vias—tiny holes that allow electrical connections between layers.

Drilling: CNC or laser drills bore through FR-4 to create via holes, typically ranging from 0.1 mm to 0.3 mm in diameter. Because FR-4 is tough and rigid, it resists deformation during drilling but can also accelerate drill bit wear due to its fiberglass reinforcement. Manufacturers often use carbide or diamond-coated bits to maintain accuracy.

Desmearing and Plating: After drilling, chemical desmear processes remove epoxy residue, exposing clean copper. The holes are then copper-plated, forming conductive pathways that connect different layers.

FR-4’s mechanical strength ensures hole wall integrity and reliable copper adhesion, which are essential for long-term PCB durability, especially in high-vibration or high-thermal-cycle environments.

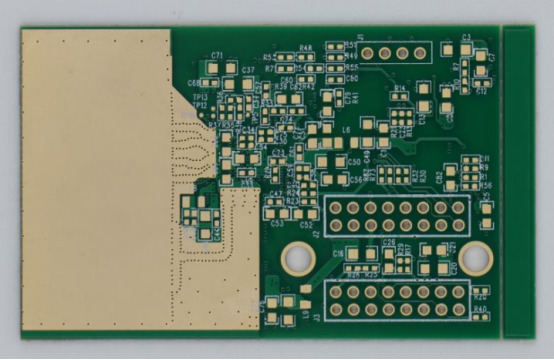

Surface Finishing Compatibility

The final stage in PCB production involves applying a surface finish to protect exposed copper pads and ensure good solderability. FR-4 substrates are compatible with nearly all standard PCB finishes, including:

ENIG (Electroless Nickel Immersion Gold): Provides excellent flatness and oxidation resistance—ideal for high-reliability and fine-pitch FR-4 PCBs.

HASL (Hot Air Solder Leveling): A cost-effective option suitable for general-purpose FR-4 boards.

OSP (Organic Solderability Preservative): Environmentally friendly and commonly used in low-cost, high-volume production.

Immersion Silver or Tin: Preferred for boards requiring strong electrical conductivity with smooth surfaces.

For high-performance FR-4 laminates, ENIG and Immersion Silver finishes are often chosen because they maintain signal integrity and prevent oxidation over long service periods.

Design Considerations

Designing a PCB with FR-4 involves balancing mechanical, thermal, and electrical parameters to achieve optimal performance.

Trace Width and Spacing: FR-4’s dielectric constant (~4.2–4.8) affects impedance control. Designers calculate trace width and spacing precisely to ensure signal integrity, particularly in high-speed or differential pair routing.

Thermal Expansion Matching: FR-4’s coefficient of thermal expansion (CTE) is close to that of copper, reducing the risk of layer separation during soldering or thermal cycling.

Signal Integrity at High Frequencies: As frequencies exceed 3–5 GHz, signal loss increases due to FR-4’s dielectric properties. Engineers may switch to low-loss FR-4 or hybrid stack-ups (combining FR-4 with high-frequency materials) to maintain clean signal transmission.

Proper design and material selection allow FR-4 PCBs to achieve high reliability and performance across a wide range of electronic applications—from compact consumer devices to mission-critical industrial systems.

In essence, FR-4 serves as both the structural skeleton and the electrical insulator of PCBs. Its versatility in lamination, drilling, finishing, and design makes it the cornerstone of modern circuit manufacturing—balancing durability, manufacturability, and electrical performance in a single material system.

Advantages and Limitations of FR-4

FR-4 has remained the most widely used PCB material for decades because it strikes a strong balance between mechanical reliability, electrical insulation, and manufacturing cost. However, like all materials, it has limits that make it unsuitable for certain high-performance or high-frequency applications.

Advantages

1. Excellent Mechanical Stability and Moisture Resistance

FR-4’s fiberglass-reinforced epoxy structure gives it superior rigidity and dimensional stability. It resists bending and maintains its shape even under mechanical or thermal stress. Its low moisture absorption rate (typically below 0.15%) helps prevent warping and electrical leakage, making it dependable in humid or variable environments.

2. Balanced Cost and Performance

One of FR-4’s greatest advantages is its cost-to-performance ratio. It offers sufficient strength, insulation, and thermal endurance for most PCB designs at a fraction of the price of advanced materials like Rogers, polyimide, or metal-core laminates. This makes it ideal for consumer electronics, automotive controls, and industrial systems where reliability and affordability are equally important.

3. Compatibility with Common PCB Processes

FR-4 works seamlessly with standard drilling, plating, and lamination techniques used in PCB fabrication. It also supports a wide range of surface finishes (ENIG, HASL, OSP, etc.) and soldering processes, including lead-free reflow. Because it’s widely available from multiple suppliers, FR-4 ensures consistent material quality and global manufacturing compatibility.

Limitations

1. Poor Performance at Very High Frequencies

FR-4’s dielectric constant (Dk ≈ 4.2–4.8) and dissipation factor (Df ≈ 0.015–0.020) make it unsuitable for circuits operating above 3–5 GHz. At these frequencies, signal losses and impedance variations become significant, leading to signal distortion and timing errors. High-speed applications like 5G antennas or microwave amplifiers therefore require low-loss laminates such as Rogers or PTFE-based materials.

2. Limited Thermal Conductivity

FR-4 has low thermal conductivity (≈0.3 W/m·K), which limits its ability to dissipate heat effectively. In high-power or LED applications, this can cause hotspots and shorten component lifespan. Materials like aluminum-core PCBs or ceramic substrates perform better in thermal management due to their higher conductivity and heat-spreading capability.

3. Moderate Temperature Resistance

Although high-Tg FR-4 variants can endure elevated temperatures, standard grades begin to soften near 135–150°C. Prolonged exposure to high heat can lead to delamination or dielectric breakdown, making FR-4 unsuitable for extreme thermal cycles.

When Not to Use FR-4

FR-4 performs well in most general-purpose designs, but it should be avoided in high-frequency or extreme-environment applications.

High-Speed RF and Microwave Circuits:

FR-4’s higher dielectric losses lead to poor signal transmission above several gigahertz. RF and microwave designs for radar, communication, or satellite systems are better served by Rogers, Taconic, or PTFE-based substrates with stable dielectric properties.

Harsh or High-Temperature Environments:

In aerospace, or automotive power modules, FR-4 may not withstand sustained heat, vibration, or chemical exposure. Metal-core or ceramic-based PCBs offer higher thermal stability and mechanical resilience in such conditions.

Power Electronics and LED Lighting:

When thermal dissipation is critical, FR-4’s limited conductivity can lead to component degradation. Aluminum-backed PCBs or IMS (Insulated Metal Substrate) boards are preferred alternatives.

In summary, FR-4 remains the standard PCB material for most electronic applications due to its versatility, affordability, and manufacturability. However, designers must recognize its electrical and thermal boundaries—selecting alternative materials when the circuit demands ultra-high frequency performance, superior heat management, or exposure to extreme conditions.

FR-4 vs. Other PCB Materials

While FR-4 is the industry standard for most printed circuit boards, engineers often compare it to polyimide, Rogers, and metal-core substrates when designing for specific performance needs. Each material has its strengths and trade-offs in terms of thermal endurance, electrical performance, and cost efficiency.

FR-4 vs. Polyimide

Polyimide PCBs are known for their exceptional thermal stability and flexibility, making them ideal for flex and rigid-flex circuits used in aerospace, and automotive applications.

Polyimide materials can withstand continuous operating temperatures above 200°C, far exceeding the typical FR-4 range of 130–180°C. This makes them more suitable for high-temperature soldering, thermal cycling, and harsh environments.

However, this performance comes at a cost — polyimide laminates are significantly more expensive and may absorb more moisture than standard FR-4. For general-purpose or cost-sensitive designs, FR-4 remains the more economical choice with adequate thermal and mechanical reliability for most industrial and consumer electronics.

In short:

Use FR-4 for cost-effective, rigid boards with moderate temperature needs.

Use Polyimide when durability, flexibility, and heat tolerance are critical.

FR-4 vs. Rogers

Rogers laminates are engineered for RF and microwave applications, offering low dielectric constant (Dk ≈ 2.9–3.5) and very low dissipation factor (Df < 0.004). This means less signal loss, better impedance control, and improved phase stability at high frequencies.

By contrast, FR-4 has a higher Dk (≈ 4.2–4.8) and Df (≈ 0.015–0.020), which cause signal degradation above 3–5 GHz. As a result, Rogers materials are preferred in 5G antennas, radar systems, and high-speed RF circuits, where performance outweighs cost considerations.

Rogers laminates are also more consistent across temperature ranges, minimizing frequency drift — an area where FR-4 struggles due to its dielectric variability.

In short:

Use FR-4 for digital, low-to-mid frequency designs.

Use Rogers for high-frequency, RF, or microwave circuits requiring superior signal integrity.

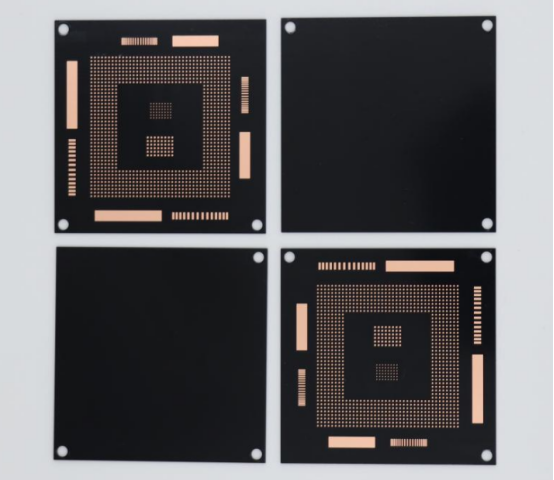

FR-4 vs. Metal-Core PCBs (MCPCBs)

Metal-core PCBs, usually built on aluminum or copper bases, are designed for efficient heat dissipation in power electronics and LED lighting. Their thermal conductivity (1–5 W/m·K or higher) far surpasses FR-4’s ~0.3 W/m·K, allowing heat to transfer away from components quickly and improving reliability.

While FR-4 is lighter and easier to process, it struggles with thermal buildup in high-current circuits. MCPCBs, on the other hand, are heavier and costlier to machine but excel in applications requiring active thermal management, such as automotive lighting, motor drives, and power converters.

In short:

Choose FR-4 for standard low-power designs.

Choose Metal-core materials for high-power or heat-intensive applications.

Comparison Table: FR-4 vs. Polyimide vs. Rogers vs. Metal-Core

Property

FR-4

Polyimide

Rogers

Metal-Core PCB

Thermal Stability (Tg)

130–180°C

>200°C

200–280°C

25–100°C (metal base conducts heat)

Thermal Conductivity

~0.3 W/m·K

~0.4 W/m·K

~0.6 W/m·K

1–5+ W/m·K

Dielectric Constant (Dk)

4.2–4.8

3.4–4.2

2.9–3.5

N/A (metal substrate)

Dissipation Factor (Df)

0.015–0.020

0.010–0.015

0.001–0.004

N/A

Flexibility

Rigid

Flexible or rigid-flex

Rigid

Rigid

Moisture Resistance

Excellent

Moderate

Excellent

Excellent

Cost Level

Low

High

High

Medium–High

Best For

General-purpose PCBs

High-temp / flexible circuits

RF, microwave, 5G boards

Power, LED, and thermal control boards

Property | FR-4 | Polyimide | Rogers | Metal-Core PCB |

|---|---|---|---|---|

Thermal Stability (Tg) | 130–180°C | >200°C | 200–280°C | 25–100°C (metal base conducts heat) |

Thermal Conductivity | ~0.3 W/m·K | ~0.4 W/m·K | ~0.6 W/m·K | 1–5+ W/m·K |

Dielectric Constant (Dk) | 4.2–4.8 | 3.4–4.2 | 2.9–3.5 | N/A (metal substrate) |

Dissipation Factor (Df) | 0.015–0.020 | 0.010–0.015 | 0.001–0.004 | N/A |

Flexibility | Rigid | Flexible or rigid-flex | Rigid | Rigid |

Moisture Resistance | Excellent | Moderate | Excellent | Excellent |

Cost Level | Low | High | High | Medium–High |

Best For | General-purpose PCBs | High-temp / flexible circuits | RF, microwave, 5G boards | Power, LED, and thermal control boards |

FR-4 remains the most widely used and cost-effective PCB base material, ideal for standard applications. However, polyimide excels in flexible and high-heat environments, Rogers leads in high-frequency signal performance, and metal-core PCBs dominate thermal management scenarios.

Selecting the right substrate ultimately depends on your design’s frequency range, thermal load, and cost priorities.

Selecting the Right FR-4 Material

Choosing the correct FR-4 laminate is a critical step in PCB design. The right material ensures reliability, signal integrity, and thermal performance while keeping costs under control. Engineers should consider several key factors when selecting an FR-4 grade.

Factors to Consider

Operating Temperature:

Determine the maximum temperature the PCB will experience during operation and soldering. Standard FR-4 is suitable for temperatures up to 130–150°C, while high-Tg FR-4 can withstand 170°C or higher, making it better for automotive, industrial, or multilayer designs.

Signal Frequency and Speed:

High-speed digital circuits or RF signals demand FR-4 with low dielectric loss. Low-loss FR-4 reduces signal attenuation and crosstalk, which is critical for communication boards, server backplanes, and high-speed computing applications.

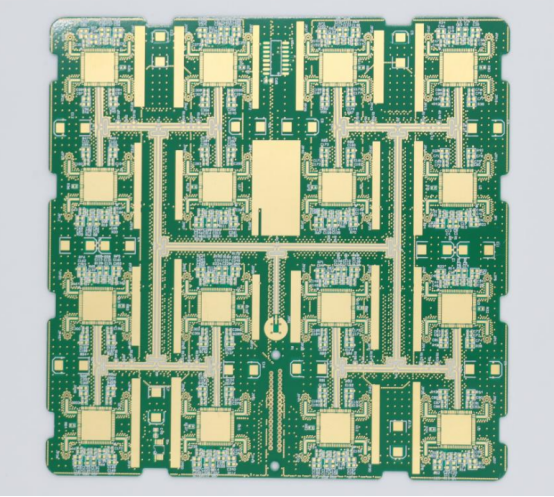

Layer Count:

Multilayer boards (8 layers or more) require FR-4 with high dimensional stability to maintain layer alignment during lamination. High-Tg or reinforced FR-4 variants perform better in complex multilayer stack-ups.

Mechanical and Electrical Requirements:

Consider factors like CTE (coefficient of thermal expansion), tensile strength, and moisture resistance to ensure the FR-4 substrate can handle the expected mechanical stress and environmental conditions.

Matching FR-4 Type to Application

Consumer Electronics:

Standard FR-4 is sufficient for smartphones, household appliances, and general-purpose electronics, providing a good balance between cost and performance.

Automotive and Industrial Applications:

High-Tg FR-4 ensures reliability under high temperatures, vibration, and mechanical stress, making it ideal for engine control units, power electronics, and industrial machinery.

Communication and Server Boards:

Low-loss FR-4 is preferred for high-frequency and high-speed digital designs, such as network switches, data centers, and 5G communication boards, where signal integrity and minimal dielectric loss are critical.

Manufacturer Recommendations

Several widely used FR-4 materials are recommended by PCB manufacturers based on performance and reliability:

Isola 370HR: High-Tg FR-4, suitable for multilayer PCBs and industrial applications.

Shengyi S1000-2: Standard FR-4 with consistent electrical properties for general-purpose designs.

Panasonic R-1755V: High-performance FR-4 with good thermal stability and dimensional control for automotive and industrial boards.

These examples illustrate how different FR-4 variants are optimized for specific applications, helping engineers make informed material choices.

Cost vs. Performance Trade-Off

Upgrading from standard FR-4 to high-Tg or low-loss FR-4 is justified when the design demands higher thermal endurance, signal performance, or multilayer stability.

For low-cost consumer electronics, standard FR-4 is sufficient.

For high-reliability automotive, industrial, or high-speed server boards, the investment in advanced FR-4 materials ensures long-term performance, reduced failure rates, and regulatory compliance.

In practice, engineers balance material cost, PCB complexity, and operating environment to select the FR-4 type that provides the best performance-to-price ratio for the project.

Environmental and Regulatory Considerations

FR-4 materials are not only selected for performance but also increasingly for environmental compliance and sustainability. Understanding regulatory standards and ecological impacts is essential for manufacturers and designers aiming for responsible PCB production.

RoHS and REACH Compliance

RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) set limits on certain hazardous substances in electronics.

RoHS restricts halogens, lead, cadmium, mercury, and other toxic metals commonly used in PCB laminates and soldering.

REACH regulates chemical substances across the European Union, requiring detailed reporting and control of hazardous compounds.

Using FR-4 materials that comply with RoHS and REACH ensures safe electronics for consumers and industry while meeting legal obligations for global markets. For instance, halogen-free FR-4 laminates are often chosen to satisfy RoHS-compliant manufacturing processes.

Halogen-Free Standards

Halogen-free FR-4 eliminates bromine and chlorine compounds traditionally used for flame retardancy. Compliance is verified through standards such as:

IEC 61249-2-21: Specifies requirements for halogen-free laminates used in PCB manufacturing, including chemical composition and flame retardancy.

UL94 Ratings (V-0, V-1, etc.): Ensure that halogen-free FR-4 maintains adequate flame resistance while reducing toxic gas emissions during combustion.

These standards allow manufacturers to produce safer, environmentally conscious boards without compromising mechanical or electrical performance.

Recyclability and Sustainability Trends

Recycling FR-4 is challenging because it is a composite of fiberglass and epoxy resin, which are difficult to separate. Traditional recycling methods often require high energy or produce waste residues.

Challenges: FR-4 cannot easily be remolded or reused as a primary material, limiting its recyclability compared to pure metals or thermoplastics.

Emerging solutions: Bio-based epoxy resins and partially recyclable FR-4 alternatives are being developed to reduce environmental impact. These materials aim to retain FR-4’s mechanical stability and flame retardancy while lowering carbon footprint and toxic waste.

By selecting halogen-free and bio-based FR-4 laminates, designers and manufacturers can align PCB production with sustainability initiatives, green electronics certifications, and circular economy principles.

In summary, environmental and regulatory considerations are integral to modern FR-4 selection. Compliance with RoHS, REACH, and halogen-free standards, along with awareness of recyclability challenges, ensures that FR-4 PCBs meet global safety, environmental, and sustainability requirements while maintaining high performance.

Future Trends in FR-4 Technology

FR-4 has long been the backbone of PCB manufacturing, but as electronics evolve, the material itself is undergoing innovations to meet higher performance demands. Emerging trends focus on resin improvements, integration with advanced PCB technologies, and market adaptability.

Advancements in Resin Systems

Next-generation FR-4 laminates are being developed with enhanced epoxy resin formulations that provide:

Lower dissipation factor (Df): Reduces signal loss, which is critical for high-speed digital, 5G, and HDI PCBs.

Higher glass transition temperature (Tg): Improves thermal stability, allowing boards to withstand lead-free soldering processes, high-power components, and automotive/industrial heat cycles.

For example, manufacturers are producing FR-4 laminates with Df < 0.008 and Tg > 180°C, bridging the gap between standard FR-4 and more expensive high-frequency materials. These innovations make FR-4 viable for next-generation high-speed applications without drastically increasing costs.

Integration with Advanced PCB Technologies

Modern FR-4 laminates are increasingly compatible with advanced PCB design techniques, including:

Embedded Components: Integrating resistors, capacitors, or ICs within the FR-4 substrate to save space and improve signal performance.

Via-in-Pad Technology: Enables higher component density by plating through small vias directly under component pads, benefiting from FR-4’s mechanical stability.

Hybrid Laminates: Combining FR-4 with high-frequency or metal-core layers for multifunctional boards that balance signal integrity, thermal management, and cost.

This flexibility ensures FR-4 remains relevant even as PCBs grow more complex in smartphones, IoT devices, automotive electronics, and 5G infrastructure.

Market Outlook

Despite the rise of specialized substrates, FR-4 continues to dominate due to its cost-effectiveness, reliability, and process compatibility. Key market trends include:

Continued demand for multilayer HDI boards in consumer electronics and servers.

Expansion in automotive and industrial electronics, where high-Tg FR-4 ensures thermal and mechanical reliability.

Incremental adoption of low-loss and hybrid FR-4 variants, which extend performance into higher-frequency applications without fully replacing traditional FR-4.

In summary, FR-4 is not being replaced but evolving alongside emerging technologies, offering improved electrical, thermal, and mechanical properties that keep it competitive in an increasingly high-speed and high-density electronics market.

Conclusion

FR-4 has earned its place as the most widely used PCB substrate thanks to its reliable combination of mechanical strength, electrical insulation, and cost-effectiveness. From consumer electronics to automotive systems and industrial devices, FR-4 provides a versatile foundation that supports a wide range of applications while remaining compatible with standard PCB manufacturing processes.

While advanced materials like polyimide, Rogers, or metal-core laminates offer specialized advantages, FR-4 continues to strike a practical balance between performance and affordability. Innovations in high-Tg, low-loss, and halogen-free FR-4 variants are extending its relevance, enabling designers to meet the demands of high-speed, multilayer, and environmentally conscious PCB designs without significantly increasing costs.

For engineers and manufacturers seeking high-quality PCBs, PCBMASTER offers a wide selection of FR-4 and alternative substrate materials, providing solutions that match various electrical, thermal, and mechanical requirements. By leveraging these materials, designers can optimize their boards for reliability, efficiency, and long-term performance, ensuring that FR-4 remains a cornerstone of modern electronics.

FAQs

What does “FR-4” stand for in PCB manufacturing?

FR-4 stands for Flame Retardant 4, a glass-reinforced epoxy laminate used as the standard substrate for rigid printed circuit boards (PCBs). It combines woven fiberglass for mechanical strength with epoxy resin for electrical insulation and flame resistance. The “4” indicates a material grade rather than a specific brand, defining its performance according to industry standards.

How do I choose between standard and high-Tg FR-4 materials?

The choice depends on operating temperature, layer count, and application requirements. Standard FR-4 is suitable for general-purpose electronics with moderate temperatures and lower layer counts. High-Tg FR-4 is designed for high-temperature or multilayer PCBs, with a glass transition temperature typically above 170°C, providing better thermal stability, dimensional control, and reliability for automotive, industrial, or multilayer designs.

Is FR-4 suitable for high-frequency or high-speed designs?

Standard FR-4 has a dielectric constant (Dk) around 4.2–4.8 and a dissipation factor (Df ≈ 0.015–0.020), which can cause signal loss or timing errors at frequencies above 3–5 GHz. For high-speed digital circuits or RF/microwave applications, low-loss FR-4 variants or specialized materials like Rogers are preferred to maintain signal integrity.

What are the main differences between FR-4 and Rogers PCB materials?

Rogers laminates are optimized for high-frequency performance, offering lower dielectric constants (Dk ≈ 2.9–3.5) and very low dissipation factors (Df < 0.004) compared to FR-4. This reduces signal attenuation and crosstalk, making Rogers ideal for RF, microwave, and high-speed circuits. FR-4, by contrast, is more cost-effective and widely available, making it suitable for general-purpose or lower-frequency applications.

Are halogen-free FR-4 boards more environmentally friendly?

Yes. Halogen-free FR-4 eliminates bromine and chlorine compounds traditionally used for flame retardancy, reducing toxic gas emissions during manufacturing or combustion. These boards comply with RoHS and WEEE standards, making them a greener alternative while still maintaining mechanical stability, electrical insulation, and flame resistance.