What Is Polyimide and Why It’s Essential in High-Performance PCBs

In the world of high-performance electronics, not all materials are created equal. Some PCBs endure extreme temperatures, constant vibration, and high-speed signals without breaking a sweat, while others falter under pressure. At the heart of many of these resilient circuits lies a remarkable material: polyimide. Known for its unique combination of flexibility, durability, and thermal stability, polyimide has quietly become a cornerstone in the design of advanced PCBs, enabling innovations that power everything from aerospace systems to wearable devices. Understanding what makes this material so essential can reveal why it’s a game-changer for engineers and designers alike.

Introduction to Polyimide

Definition and Overview

Polyimide is a high-performance polymer widely used in electronics for its exceptional material properties. It belongs to a class of synthetic polymers characterized by imide linkages in their molecular structure, which gives it remarkable thermal and chemical stability. Polyimide can withstand extreme temperatures—often ranging from -269°C to over 400°C—without losing structural integrity.

Beyond heat resistance, polyimide is highly flexible, making it ideal for applications where boards must bend or fold. Its chemical resistance also protects circuits from moisture, acids, and solvents. Compared with traditional PCB materials like FR-4, polyimide offers superior durability and reliability under harsh conditions, which is why it has become a preferred choice for advanced electronics.

Historical Background

Polyimide was first synthesized in the early 20th century, and it gained industrial prominence in the 1960s when engineers discovered its potential for high-temperature applications. Early uses included insulation in aerospace wiring and flexible circuits for electronic devices.

Over time, polyimide’s role expanded into printed circuit board (PCB) manufacturing. Initially, it was used in flexible printed circuits (FPCs) that required extreme bendability. As electronic devices grew smaller and faster, polyimide’s ability to maintain stability under high heat and mechanical stress made it an essential material in multilayer and high-density PCBs. Today, it serves as a backbone for both rigid-flex boards and other high-performance PCB designs.

Importance in Modern Electronics

Polyimide plays a crucial role in modern electronics, particularly in high-density, high-speed, and flexible PCBs. Its combination of flexibility, thermal resilience, and chemical stability allows engineers to design boards that are compact, reliable, and capable of handling complex circuitry.

In aerospace electronics, polyimide PCBs endure extreme temperatures and vibrations while maintaining performance. In the automotive sector, they are used in sensors and high-speed control units exposed to heat and chemicals. Medical devices, including wearable monitors and imaging equipment, also rely on polyimide for its durability and biocompatibility. By supporting both performance and miniaturization, polyimide enables innovations that would be impossible with conventional PCB materials.

Key Properties of Polyimide

Thermal Stability

Polyimide is renowned for its exceptional thermal stability, which makes it suitable for high-performance PCB applications. It can typically operate in temperature ranges from -269°C to over 400°C without losing its structural integrity. This range far exceeds that of traditional PCB materials like FR-4, which usually handle up to around 130°C to 150°C.

The superior thermal stability allows polyimide PCBs to maintain performance in environments with rapid temperature changes or prolonged exposure to heat. For example, aerospace or automotive sensors experience high temperatures during operation, and polyimide ensures the PCB does not warp, delaminate, or degrade. Compared with other polymer substrates, polyimide maintains mechanical and electrical properties even under extreme heat, making it ideal for high-speed and high-density PCB designs.

Mechanical Strength

Polyimide offers a unique combination of tensile strength and flexibility. Its tensile strength enables the PCB to withstand mechanical stress, while its flexibility allows boards to bend or fold without cracking. This is particularly important in flexible and rigid-flex PCBs, where circuits are required to fold around tight spaces or move with the device.

The high mechanical strength directly improves PCB durability in harsh conditions. For example, in automotive electronics, vibrations from engines or movement in tight housings can cause conventional materials to fracture, whereas polyimide-based boards remain intact. Step-by-step, this means the polymer matrix absorbs stress, distributes it across the PCB layers, and prevents localized damage that could lead to circuit failure.

Chemical Resistance

Polyimide is highly resistant to chemicals, including solvents, acids, and moisture. This property is critical for maintaining long-term PCB performance, especially in industrial or automotive environments where exposure to oils, cleaning agents, or humidity is common.

The protective performance works in layers: the polyimide substrate forms a barrier around copper traces, preventing corrosion and degradation. Any solder mask or protective coating applied on top further enhances this resistance. Step-by-step, the polyimide layer shields the conductive pathways, while the coatings prevent chemical penetration, ensuring stable electrical and mechanical properties over time.

Electrical Insulation

Polyimide also excels as an electrical insulator. It has a low dielectric constant and a low loss tangent, which means it minimizes signal loss and maintains signal integrity in high-speed circuits. These properties are essential for high-frequency PCBs used in modern electronics, including telecommunications, automotive sensors, and aerospace systems.

By providing stable insulation, polyimide reduces crosstalk between adjacent traces and prevents unwanted electromagnetic interference (EMI). This ensures that high-speed signals travel with minimal attenuation, supporting reliable performance in dense, multilayer PCB designs.

Polyimide in PCB Applications

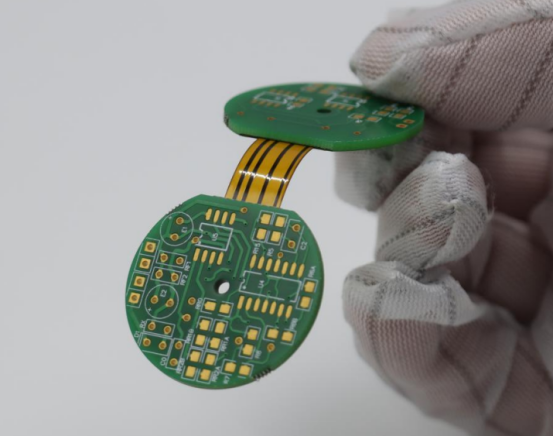

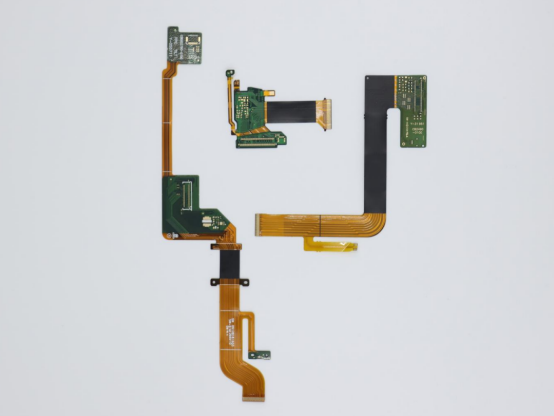

Flexible PCBs (FPCs)

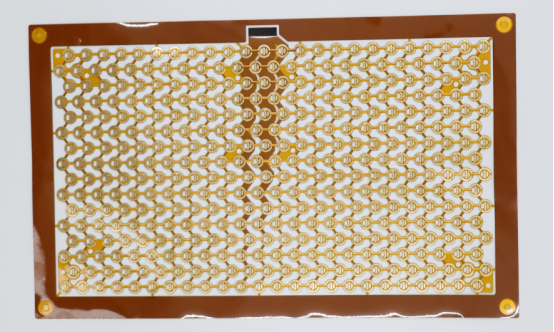

Polyimide is the backbone of flexible PCBs, enabling circuits that can bend, fold, or twist without breaking. Its inherent flexibility allows electronic designers to create compact, lightweight boards that fit into unconventional shapes.

For example, wearable devices like smartwatches and fitness trackers rely on polyimide-based FPCs to wrap around wrists or fold within small housings. Similarly, smartphones use flexible PCBs to connect screens, cameras, and other components without adding bulk. Compared with rigid FR-4 boards, polyimide FPCs handle repeated mechanical stress while maintaining electrical performance.

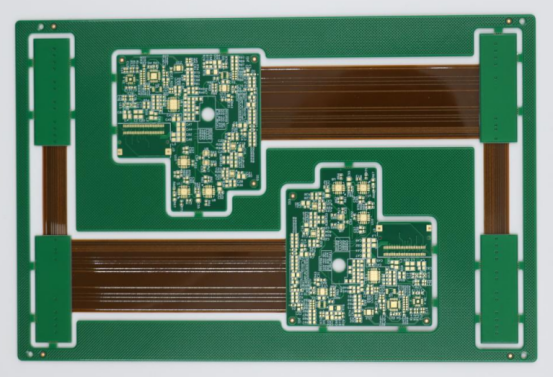

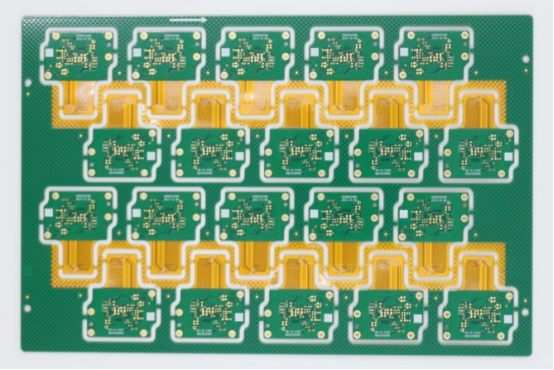

Rigid-Flex PCBs

Rigid-flex PCBs combine the best of two worlds: rigid FR-4 layers for structural support and polyimide flexible layers for movement and bending. This hybrid design allows high-density circuits to occupy minimal space while remaining durable.

Step-by-step, a typical rigid-flex PCB includes:

1. Rigid sections made of FR-4 for mounting heavy components.

2. Flexible polyimide layers connecting rigid sections, allowing bending or folding.

3. Copper traces embedded within both rigid and flexible layers for electrical continuity.

This structure is widely used in compact devices where reliability and space optimization are critical, such as medical imaging equipment and advanced consumer electronics.

High-Frequency and High-Speed PCBs

Polyimide plays a critical role in high-frequency and high-speed PCBs by minimizing signal loss and reducing electromagnetic interference (EMI). Its low dielectric constant and thermal stability ensure that signals maintain integrity even at gigahertz frequencies.

Compared with other substrates like standard FR-4 or epoxy resins, polyimide offers superior performance in high-speed applications. For instance, polyimide PCBs are preferred in 5G communication hardware and high-speed data processing units because they reduce crosstalk and signal attenuation, supporting reliable high-frequency operation.

High-Temperature and Harsh Environment PCBs

Polyimide PCBs excel in high-temperature and harsh environmental conditions due to their thermal resilience, mechanical strength, and chemical resistance. They are commonly used in aerospace, automotive, and industrial electronics, where boards must endure extreme heat, vibration, or exposure to moisture and chemicals.

Real-world examples include:

Aerospace sensors that operate reliably at elevated temperatures during flight.

Automotive engine control units exposed to heat and vibration.

Industrial machinery where chemical exposure is frequent, such as in factory automation systems.

In each case, polyimide ensures the PCB maintains structural integrity, signal reliability, and long-term durability, outperforming conventional materials.

Manufacturing Considerations with Polyimide

Laminate Types

Polyimide is available in various laminates to suit different PCB designs. Common polyimide laminates include single-sided, double-sided, and multilayer variants, with thicknesses typically ranging from 12 µm to over 125 µm depending on the application.

Single-sided laminates consist of a polyimide substrate with copper on one side, suitable for simple circuits or flexible extensions.

Double-sided laminates have copper on both sides, allowing more complex circuit routing while retaining flexibility.

Multilayer laminates combine several polyimide and copper layers, enabling high-density circuits for compact and high-performance electronics.

Compared with standard FR-4 laminates, polyimide laminates offer superior thermal and chemical resistance, making them more reliable in challenging environments.

Fabrication Challenges

Working with polyimide introduces unique fabrication challenges. Etching, drilling, and layer adhesion require careful handling due to the material’s flexibility and chemical properties.

Etching: Polyimide’s chemical resistance can slow down standard etching processes. Using optimized etchants and controlled temperature ensures precise patterning.

Drilling: Small vias may delaminate or deform if improper drill speeds or bit types are used. High-precision drills and stepwise feed rates help prevent damage.

Adhesion: Polyimide layers sometimes exhibit weaker bonding with copper or other substrates. Applying surface treatments or adhesive primers improves layer adhesion.

Step-by-step best practices:

1. Pre-treat polyimide surfaces for better copper adhesion.

2. Use optimized etching chemicals and temperatures for clean traces.

3. Apply controlled drilling techniques to avoid delamination.

4. Conduct post-fabrication inspections to ensure structural integrity and electrical continuity.

Surface Finishes and Compatibility

Surface finishes on polyimide PCBs affect solderability, long-term reliability, and component mounting. Common finishes include ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), and OSP (Organic Solderability Preservative).

ENIG provides a flat, corrosion-resistant surface ideal for fine-pitch components.

HASL offers a cost-effective solution but can add uneven thickness on polyimide boards.

OSP is suitable for short-term applications but may degrade faster under heat or moisture.

Choosing the right finish ensures reliable solder joints and extends PCB lifespan. For example, ENIG is often preferred for high-density, high-frequency polyimide PCBs because it maintains surface flatness and resists corrosion better than HASL.

Advantages of Polyimide in High-Performance PCBs

Reliability in Extreme Conditions

Polyimide PCBs are highly reliable in extreme environments due to their heat resistance, mechanical strength, and chemical stability. They can operate continuously at high temperatures, withstand vibrations, and resist exposure to moisture, acids, and solvents.

For example, in aerospace electronics, polyimide-based sensors and control circuits function reliably at elevated temperatures and under constant vibration. In automotive applications, engine control units and advanced sensors use polyimide PCBs to endure heat from engines and chemical exposure from fuels or fluids. This level of reliability ensures long-term performance where conventional materials, such as FR-4, may fail.

Miniaturization and Design Flexibility

Polyimide enables the creation of thinner, lighter, and more complex PCB designs. Its flexibility allows boards to bend or fold, reducing the space needed for connections and components.

Compared with FR-4 or other thermoset materials, polyimide allows higher layer density and more compact routing without sacrificing durability. This advantage is especially important in wearable electronics, smartphones, and high-density industrial devices. By supporting miniaturization, polyimide helps engineers design efficient, space-saving circuits while maintaining structural and electrical integrity.

Signal Integrity and Performance

Maintaining signal integrity is critical in high-speed and high-frequency PCB designs, and polyimide excels in this area. Its low dielectric constant and stable electrical properties reduce signal loss, crosstalk, and electromagnetic interference (EMI).

For example, polyimide PCBs in 5G communication modules or high-speed data processing systems deliver consistent signal performance even at gigahertz frequencies. Compared with traditional substrates like FR-4, polyimide ensures that high-speed signals travel with minimal attenuation, supporting reliable operation in dense multilayer layouts.

Cost Considerations and Trade-Offs

Material and Manufacturing Costs

Polyimide PCBs generally have higher material and manufacturing costs compared with standard FR-4 boards. Polyimide resin and laminates are more expensive due to their advanced chemical properties and thermal performance. Additionally, processing steps such as etching, drilling, and layer adhesion require more precise control, which increases fabrication costs.

For example, a multilayer polyimide PCB can cost 2–3 times more than an equivalent FR-4 board, but this premium reflects the material’s ability to perform reliably under extreme temperatures, mechanical stress, and chemical exposure.

Design and Processing Complexity

Using polyimide introduces trade-offs between performance and fabrication complexity. Its flexibility and chemical resistance, while advantageous for high-performance designs, make standard processes like drilling, etching, and surface finishing more challenging.

Step-by-step considerations for design and processing include:

Layer alignment must be precise to avoid misregistration in multilayer boards.

Etching and drilling require optimized parameters to prevent delamination or deformation.

Surface treatment is often needed to ensure proper copper adhesion and solderability.

These complexities mean that designers and manufacturers must balance performance benefits against increased time and technical effort during production.

ROI and Long-Term Benefits

Despite higher upfront costs, polyimide PCBs offer strong return on investment (ROI) through extended lifespan, reduced maintenance, and consistent reliability in demanding applications.

For instance, in automotive sensors or industrial machinery, polyimide boards can operate for years in high-temperature or chemically aggressive environments without failure. Over the product lifecycle, this durability reduces downtime, replacement costs, and warranty claims, making polyimide an economically advantageous choice for high-performance applications.

Future Trends and Innovations

Advanced Polyimide Formulations

Polyimide materials are evolving with advanced formulations designed to meet the demands of next-generation electronics. High-temperature grades can withstand sustained exposure above 400°C, making them suitable for extreme environments such as aerospace electronics and industrial machinery. Flame-retardant variants enhance safety by reducing the risk of ignition in high-power applications.

These advanced formulations expand the range of applications for polyimide PCBs while maintaining the material’s flexibility, chemical resistance, and electrical insulation properties. Compared with standard polyimide laminates, these specialized variants allow designers to tackle challenges in environments where both performance and safety are critical.

Emerging Applications

Polyimide continues to enable innovations in emerging electronic technologies. In 5G communications, polyimide PCBs support high-speed signal integrity and minimize electromagnetic interference (EMI) in multilayer designs. AI hardware, including processors and accelerators, benefits from polyimide’s thermal stability and high-density routing capabilities.

Wearable electronics also rely on polyimide’s flexibility and durability. Devices such as smart glasses, fitness trackers, and medical monitors use polyimide-based flexible PCBs to achieve compact, lightweight, and bendable circuits. Compared with conventional PCB materials, polyimide allows engineers to develop smaller, more reliable, and higher-performance devices.

Sustainable and Eco-Friendly Polyimides

The push for sustainability has reached PCB manufacturing, and polyimide materials are adapting accordingly. Recyclable or low-emission polyimide laminates reduce environmental impact during production and disposal. Manufacturers are also developing processes that minimize chemical waste and energy consumption, making polyimide a greener choice for high-performance electronics.

Step-by-step, these innovations include: selecting low-emission resins, optimizing fabrication processes to reduce solvent use, and designing PCBs that can be more easily recycled at the end of their lifecycle. As a result, eco-friendly polyimide solutions help companies meet both performance and environmental goals without compromising reliability.

Conclusion

Polyimide continues to play a critical role in high-performance PCBs, providing flexibility, durability, and excellent signal integrity for a wide range of applications. From wearable electronics to high-speed industrial and automotive systems, its unique properties support compact, reliable, and innovative PCB designs.

For engineers and designers looking to harness these benefits, PCBMASTER offers fast and dependable solutions for rigid-flex and high-density interconnect (HDI) boards. With delivery in as little as 7 days for 10-layer first-order rigid-flex PCBs, support for 6–20 layers, and high-quality materials from DuPont, Panasonic, and New Gao, PCBMASTER ensures your advanced polyimide PCB projects meet both performance and schedule requirements. The service even accommodates ultra-thin flexible sections down to 0.8 mm, making it easier than ever to bring complex PCB designs to life.

FAQs

How does polyimide compare to FR-4 for flexible PCBs?

Polyimide is far more flexible than FR-4, making it ideal for bendable or foldable circuits used in flexible PCBs (FPCs). Unlike FR-4, which is rigid and can crack under bending, polyimide can repeatedly flex without damage. Additionally, polyimide offers superior thermal stability and chemical resistance, making it better suited for high-performance, compact, and high-density designs.

What temperature ranges can polyimide PCBs withstand?

Polyimide PCBs can typically operate in temperatures ranging from -269°C to over 400°C. This broad range allows them to maintain structural integrity and performance in extreme heat or cold environments, far exceeding the limits of standard FR-4 boards, which generally handle up to around 130–150°C.

Can polyimide be used in high-frequency RF applications?

Yes. Polyimide is well-suited for high-frequency and high-speed RF applications because of its low dielectric constant and low loss tangent. These properties minimize signal loss, reduce crosstalk, and maintain signal integrity, which is crucial for devices like 5G modules, high-speed processors, and communication hardware.

What are the main challenges when manufacturing polyimide PCBs?

Manufacturing polyimide PCBs involves some unique challenges:

Etching: Polyimide’s chemical resistance can make standard etching slower or less precise.

Drilling: Small vias or holes may delaminate or deform if drill speed and bit type are not optimized.

Layer adhesion: Polyimide layers can bond less strongly with copper or other substrates, requiring surface treatments or adhesive primers.

Step-by-step solutions include pre-treating surfaces, using controlled etching and drilling processes, and conducting thorough post-fabrication inspections to ensure quality.

Why is polyimide preferred in aerospace and automotive electronics?

Polyimide is preferred because of its high thermal stability, mechanical strength, and chemical resistance. In aerospace, it can withstand extreme temperatures and vibrations, ensuring sensors and control circuits remain reliable. In automotive applications, polyimide boards tolerate heat from engines, vibration, and exposure to fluids, providing durability and long-term performance that standard materials like FR-4 cannot match.