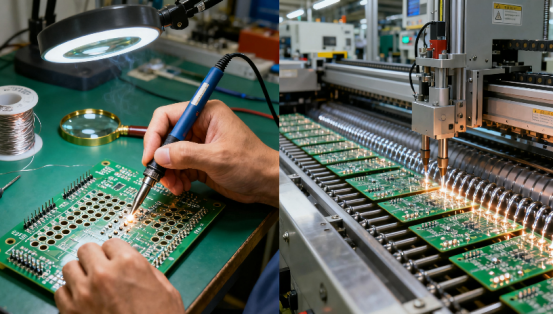

Through Hole PCB Assembly Service – Manual & Wave Soldering Options

In electronics, making a good circuit board is very important. Through hole PCB assembly is one way to put electronic parts onto a board. It helps the parts stay strong and work well for a long time.

In this article, we will talk about the two most common ways to solder these parts: manual soldering (done by hand) and wave soldering (done by a machine).

By reading this, you will learn how each method works and which one is better for your project. This will help engineers and buyers choose the right soldering method for their needs.

Overview of Through Hole PCB Assembly

1. What is Through Hole PCB Assembly

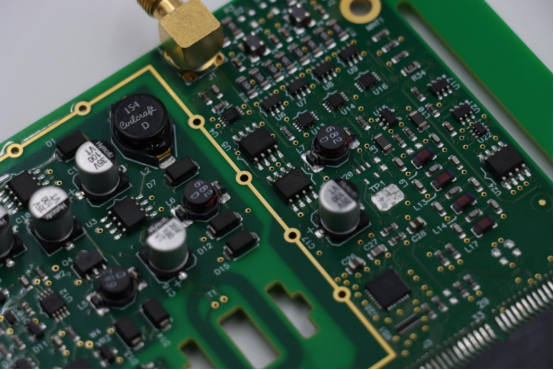

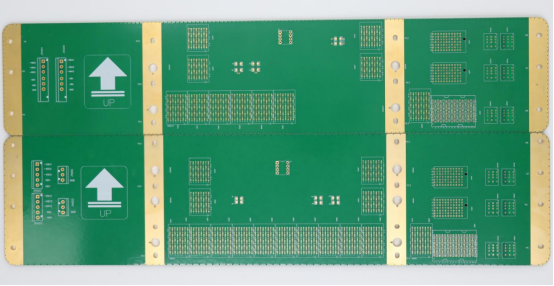

Through hole PCB assembly is a process used to attach electronic components to a circuit board. Each component has small metal legs, called leads, which are inserted into holes that have been drilled in the PCB. Once the leads are in place, they are soldered on the back side of the board. This creates both a strong mechanical connection, keeping the parts firmly attached, and a reliable electrical connection, allowing electricity to flow properly through the circuit.

This method is particularly useful for components that are heavy, large, or carry high current, such as connectors, transformers, and power transistors. The physical strength provided by through hole assembly makes it ideal for devices that may experience vibration or mechanical stress, such as industrial machines and instrumentation equipment.

2. How Through Hole PCB Assembly Works

The assembly process has several important steps:

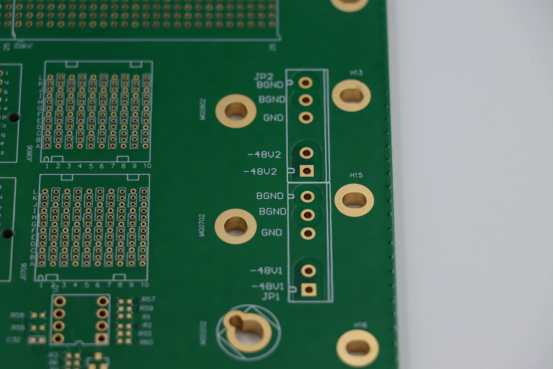

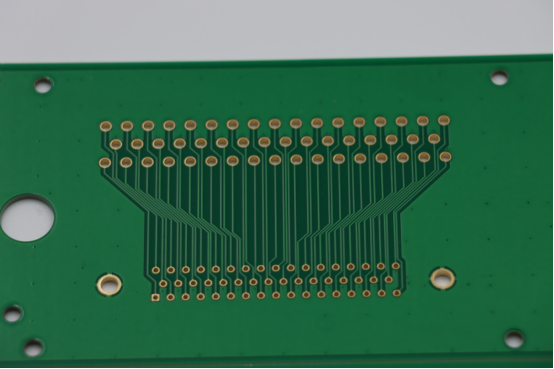

l Drilling the Holes – Holes are precisely drilled on the PCB where each component will go. The size and position of the holes are carefully designed according to the component’s lead dimensions.

l Inserting the Components – The component leads are placed into the drilled holes. Proper alignment is crucial to ensure correct placement and spacing.

l Soldering the Leads – The exposed leads are soldered on the back of the board. This step can be done manually or by machines (like wave soldering), depending on the production scale and complexity of the PCB.

3. Difference from Surface Mount Technology (SMT)

Through hole assembly provides extra stability and mechanical strength compared with surface mount technology (SMT), where components are placed directly on the surface of the board. While SMT is faster and allows for more compact designs, through hole assembly is preferred for large, heavy, or high-current components.

4. Applications of Through Hole PCB Assembly

Through hole PCB assembly is widely used in electronics where durability and reliable connections are critical:

l Industrial Control Systems – Machines and factory equipment that need robust boards.

l Instrumentation Devices – Equipment that measures or monitors electricity, temperature, or pressure.

l Power Modules – Parts that carry higher current and require strong mechanical support.

It is suitable for both small batch production, like prototypes or testing boards, and large batch production, ensuring that each soldered connection is strong and long-lasting.

Manual Soldering Options

1. What is Manual Soldering?

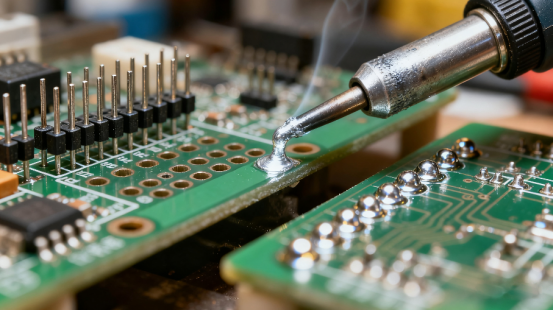

Manual soldering is a way to join electronic components to a PCB by hand. A skilled worker uses a soldering iron and solder wire to heat the component leads and the PCB pads so that the solder melts and forms a solid electrical connection.

This method allows precise control over each connection, making it ideal for small, delicate, or specialized components that need careful handling.

2. The Manual Soldering Process

The process involves a few key steps:

l Preparing the PCB and components – Make sure the board and component leads are clean and free of dust or oil.

l Heating the soldering iron – The worker heats the iron to the proper temperature, usually around 350°C (660°F) for most electronics.

l Applying solder – The soldering iron touches both the component lead and the PCB pad. Solder wire is fed onto the joint until it melts and forms a smooth, shiny connection.

l Inspecting the joint – Each soldered joint is checked to ensure it is fully connected and there are no cold joints or gaps.

The tools used include a soldering iron, solder wire, flux (to help the solder flow), and sometimes a magnifying glass for small components.

3. Advantages and Disadvantages of Manual Soldering

Advantages:

l Very flexible, can solder components in tight or awkward spaces.

l Ideal for small batch production and prototypes.

l Can handle precision components that are difficult for machines.

Disadvantages:

l Slow process, not efficient for large quantities.

l Higher labor cost, since each joint is done by hand.

l Requires skilled workers to ensure good quality.

4. Applications of Manual Soldering

Manual soldering is most suitable for:

l Prototype development – Testing new designs before mass production.

l Small batch production – When only a few boards are needed.

l Specialized components – Large, fragile, or unusual parts that machines cannot handle easily.

It is often used together with other assembly methods in a hybrid production process, where critical or unique components are soldered by hand, and standard parts may be soldered by machines.

Wave Soldering Options

1. What is Wave Soldering?

Wave soldering is a method used to solder many electronic components to a PCB at once using a machine. Instead of soldering each joint by hand, the board passes over a “wave” of molten solder, which touches all the component leads at the same time and makes strong electrical connections.

This method is ideal for large-scale production where efficiency and consistency are important.

2. The Wave Soldering Process

The process involves several key steps:

l Preheating the PCB – The board is gently heated before soldering. This helps prevent thermal shock and improves solder flow.

l Applying flux – A chemical called flux is applied to the PCB to clean surfaces and help the solder stick.

l Passing through the wave – The PCB moves over a molten solder wave. The solder touches all the leads and pads, forming solid connections.

l Cooling and inspection – The board is cooled down, and solder joints are checked for defects.

The equipment includes a wave soldering machine, flux applicator, and a conveyor system to move the boards through the machine.

3. Advantages and Disadvantages of Wave Soldering

Advantages:

l High efficiency – Many components are soldered at once.

l Consistent solder joints – Less variation compared with manual soldering.

l Suitable for large batches – Perfect for mass production of standard boards.

Disadvantages:

l High equipment cost – Machines and maintenance are expensive.

l Not suitable for surface mount (SMT) components – Only works for through hole parts.

l Less flexible for unusual or fragile components compared with hand soldering.

4. Applications of Wave Soldering

Wave soldering is commonly used for:

l Batch production – When many boards need to be made quickly.

l Standard components – Common resistors, capacitors, and connectors.

l Large PCBs – Boards that have many through hole components.

It is often used in factories for medium to high volume production, where efficiency, consistency, and reliable soldering are the top priorities.

Comparing Manual Soldering and Wave Soldering

When choosing a soldering method for through hole PCB assembly, it is important to understand the differences between manual soldering and wave soldering. Each method has its strengths and weaknesses, depending on the product requirements.

1. Comparison Table

Feature Manual Soldering Wave Soldering Efficiency Low – each joint is done by hand High – many joints soldered at once Cost Higher labor cost Higher equipment cost, lower labor

Suitable Batch Size

Small batches and prototypes

Medium to large batches

Precision

High – precise for delicate parts

Medium – good for standard components

Process Complexity

Simple tools, requires skilled worker

Complex machine setup and maintenance

| Feature | Manual Soldering | Wave Soldering |

|---|---|---|

| Efficiency | Low – each joint is done by hand | High – many joints soldered at once |

| Cost | Higher labor cost | Higher equipment cost, lower labor |

Suitable Batch Size | Small batches and prototypes | Medium to large batches |

Precision | High – precise for delicate parts | Medium – good for standard components |

Process Complexity | Simple tools, requires skilled worker | Complex machine setup and maintenance |

2. How to Choose the Right Soldering Method

l For prototypes or small production runs – Manual soldering is usually better because it is flexible and can handle unusual or delicate components.

l For large-scale production – Wave soldering is more efficient and consistent, saving time and labor costs.

l For components that are heavy or carry high current – Both methods work, but wave soldering ensures uniform soldering across many joints quickly.

l For specialized or fragile parts – Manual soldering is safer because a skilled worker can carefully control the heat and solder placement.

By considering production volume, component type, cost, and required precision, you can select the soldering method that fits your PCB assembly needs.

Key Factors in Choosing Through Hole PCB Assembly Services

When selecting a through hole PCB assembly service, it is important to consider several key factors to ensure you get high-quality boards, on time, and at a reasonable cost.

1. Quality Control

Quality is the most important factor in PCB assembly. A reliable service provider follows IPC standards, which are industry rules for soldering quality and board reliability.

They also perform solder joint inspection to check that each connection is strong and electrically correct. Some factories have online inspection systems, which automatically monitor the soldering process in real-time to catch any defects before the boards leave the production line.

2. Lead Time and Production Capacity

Different soldering methods affect the production speed.

l Manual soldering – slower, because each joint is done by hand. Suitable for prototypes or small batch orders.

l Wave soldering – much faster, can handle medium to large batches efficiently.

When choosing a service, check if the supplier can meet your required delivery time and has enough production capacity for your order size.

3. Cost Considerations

Cost is not just about the price per board. You should also consider:

l Material costs – including PCB material, solder, flux, and components.

l Labor costs – manual soldering requires skilled workers, which is more expensive.

l Equipment depreciation – machines like wave soldering systems are costly to buy and maintain, and this cost is spread over production.

A good service provider balances quality, speed, and cost, helping you get reliable PCBs without overspending.

Conclusion

In through hole PCB assembly, both manual soldering and wave soldering have their own strengths. Manual soldering is flexible and precise, perfect for prototypes, small batches, or delicate components. Wave soldering is fast and consistent, ideal for large batches and standard components.

The best soldering method depends on your product needs, production volume, and component types. Choosing the right method ensures strong, reliable connections and a successful PCB assembly.

For the best results, it is recommended to work with a professional PCB assembly service like PCBMASTER, which can provide customized solutions for both manual and wave soldering, meeting your quality, efficiency, and budget requirements.

FAQs

1. Can I mix manual soldering and wave soldering on the same PCB?

Yes, you can use both methods on the same board. This is called a hybrid assembly process. Usually, delicate or unusual components are soldered by hand, while standard parts go through the wave soldering machine. This approach helps save time and cost while ensuring that sensitive components are handled carefully.

2. How do I know if my PCB components are suitable for through hole assembly?

Components suitable for through hole assembly usually have leads or pins that can go through holes in the PCB. Heavy, large, or high-current parts are especially good for this method because the mechanical support is stronger than surface mounting. If a component is very small or flat, it may be better suited for surface mount technology (SMT) instead.

3. How can I prevent damage to small components during manual soldering?

To protect small or delicate components:

l Use the correct temperature on the soldering iron, not too hot.

l Apply flux to help solder flow smoothly.

l Hold the component carefully with tweezers or a fixture.

l Avoid touching the component body with the soldering iron.

These steps prevent overheating and ensure a clean, strong solder joint.

4. Is wave soldering safe for boards with both through hole and surface mount components?

Wave soldering alone can damage SMT components because the molten solder can touch them. However, this problem can be solved with protective masking or selective wave soldering. Masking uses special covers to protect SMT parts, and selective wave soldering machines only apply solder to the desired through hole areas. This allows mixed boards to be soldered safely.

5. How do I choose between different PCB assembly service providers?

When choosing a PCB assembly service:

l Check their experience with through hole and hybrid assembly.

l Ask about their inspection methods to ensure solder quality.

l Confirm their production capacity matches your order size.

l Compare pricing, but also consider quality and delivery reliability.

Look for services that provide technical support for special component handling or custom requirements.