SMT PCB Assembly Services | High-Quality Manufacturing Solutions

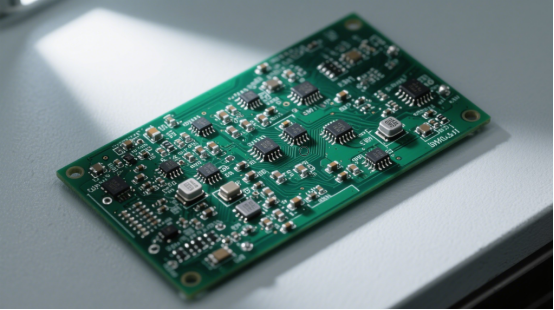

From smartphones and automotive electronics to medical devices and 5G communication systems, there’s one thing they all have in common — SMT PCB Assembly. It’s not just a manufacturing process; it’s the foundation that determines the performance, reliability, and lifespan of modern electronic products.

As devices continue to get smaller, lighter, and more powerful, the demand for precision and quality in PCB assembly has never been higher. To stay competitive, companies need high-quality SMT PCB assembly solutions that ensure consistency, efficiency, and cost-effectiveness.

In this article, we’ll take a closer look at what SMT PCB assembly services are, how the process works, the key benefits, major applications, and how to choose the right partner to help you achieve better product quality, lower costs, and faster time-to-market.

What Is SMT PCB Assembly Service?

1. What Is SMT Technology?

SMT stands for Surface Mount Technology. This is a way of putting electronic parts onto a printed circuit board (PCB).

In the past, parts had long metal legs. These legs had to be pushed through tiny holes in the board and then soldered on the other side. That took time and made the boards bigger.

With SMT, the story is different. The parts are very small and flat. They don’t need long legs or holes. Instead, they sit right on the surface of the PCB. A special silver-colored paste, called solder paste, is printed on the board first. Then the parts are placed on top of that paste. Finally, the board is heated in a special oven, and the paste melts, sticking the parts firmly to the board.

It like baking cookies. You put chocolate chips (the parts) on the cookie dough (the paste on the board). Then you put it in the oven. After baking, the chips are stuck tight to the cookie. That is how SMT works.

2. SMT vs. THT (Through-Hole Technology)

To understand why SMT is special, let’s compare it with the older method, THT (Through-Hole Technology).

Through-Hole (THT)

Each part has long legs, like tiny wires.

The legs go through drilled holes in the board.

Solder is added on the bottom side to hold them.

It makes a strong connection, good for parts that need extra strength, like connectors or big capacitors.

But it takes up more space and slows down production.

Surface Mount (SMT)

The parts are much smaller and have no long legs.

They are placed directly on the surface of the board.

Machines can place thousands of these parts in one minute.

It allows electronics to be smaller, lighter, and faster.

Easy Example:

A big old radio or TV from the 1980s used THT. That’s why they were heavy and bulky.

A modern smartphone, smartwatch, or earbud uses SMT. That’s why they are so small and powerful.

3. Why Is SMT PCB Assembly Important?

SMT PCB Assembly is at the center of today’s electronics industry. Without it, most of the devices we use every day would not exist. Here are the main reasons:

Smaller and Lighter Devices

SMT allows engineers to place more parts in a very small space.

That’s why we can have slim laptops, pocket-sized smartphones, and wearable gadgets.

Faster Production

SMT uses high-speed machines. These machines can place tiny parts at lightning speed, much faster than human hands.

This makes mass production possible, so companies can build millions of devices quickly.

Lower Cost

Because SMT is faster and uses less material, it helps reduce the cost of making PCBs.

Even though the machines are expensive, once they are running, they make boards very efficiently.

Better Performance

SMT parts are closer together on the board, which means signals travel faster and work more reliably.

This is very important for 5G networks, medical devices, and high-speed computers.

Simply put: SMT PCB Assembly is the backbone of modern electronics. It is the reason why your smartphone can fit in your pocket and why medical devices can save lives in hospitals

The Key Process of SMT PCB Assembly

Making an SMT PCB is not just one single action. It is a step-by-step process, and every step must be done carefully to make sure the final board works well. Let’s go through the main steps one by one.

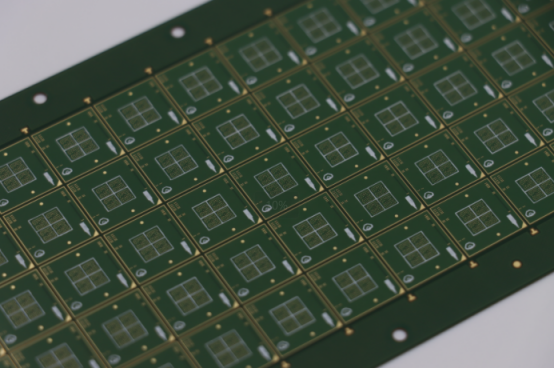

1. PCB Design and BOM Confirmation

Everything starts with a good plan. The PCB design is like a map that shows where every part will go. Along with the design, we also have a BOM (Bill of Materials). This is simply a list of all the parts needed, like resistors, chips, and connectors.

Why it matters for quality:

If the design or BOM has mistakes, the whole board will fail. High-quality solutions always include double-checking the design and BOM before starting production.

Example: Imagine you are cooking. The design is like your recipe, and the BOM is your shopping list. If the recipe is wrong or the list is missing something, the meal won’t turn out right.

2. Solder Paste Printing and SPI Inspection

Before we can place parts, we need something sticky to hold them. That sticky material is solder paste. It looks like gray toothpaste and is made of tiny metal particles mixed with flux (a chemical that helps it stick).

The paste is printed onto the PCB in very exact spots where the parts will go. This is done using a stencil, just like using a stencil to spray paint letters on a wall.

After printing, the board is checked by SPI (Solder Paste Inspection) machines. They use cameras to make sure the right amount of paste is in the right place.

Why it matters for quality:

Too much paste can cause short circuits. Too little paste can cause weak joints. High-quality manufacturing solutions always include 100% SPI checking to avoid these problems.

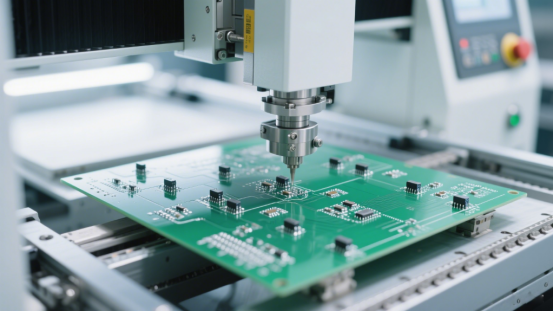

3. Automatic Component Placement (SMT Pick-and-Place)

Now comes the exciting part — putting the parts on the board. This is done by pick-and-place machines. These machines move super fast, like robot arms, picking up tiny parts and setting them exactly where the solder paste is.

Some machines can place tens of thousands of parts in one hour. This step needs to be very precise, because modern parts are so small that even a hair’s width mistake can cause failure.

Why it matters for quality:

A high-quality solution uses advanced machines with accurate vision systems, so every part is placed perfectly.

Example: Think of a bakery where a machine puts chocolate chips on cookies at lightning speed. If the chips land in the wrong spot, the cookie looks bad. On a PCB, if a part is in the wrong spot, the board won’t work at all.

4. Reflow Soldering Process

After the parts are placed, the board goes into a big oven called a reflow oven. Inside, the temperature slowly rises, then reaches a peak, and then cools down. This heat melts the solder paste, and when it cools, the parts are soldered firmly to the board.

This step is very sensitive. If the heating is too fast or too hot, the parts can get damaged. If it is too low, the solder will not melt correctly.

Why it matters for quality:

High-quality manufacturing solutions use precisely controlled heating profiles to make sure every joint is strong and reliable.

5. AOI (Automatic Optical Inspection)

Once the soldering is done, it’s time to check the board. AOI machines use cameras and lights to look at every single joint and part. They check if any part is missing, placed wrong, or has a bad solder joint.

Why it matters for quality:

Human eyes can miss mistakes, but AOI can see even tiny problems. High-quality assembly always uses AOI to catch defects early, before the product goes further.

6. Functional Testing and Final Assembly

Finally, the board is tested to make sure it really works. This can include simple electrical checks, or more complex tests where the board is powered on and connected to other parts of a system.

After passing all the tests, the PCB may be joined with cases, displays, or connectors, depending on the product. Now it is ready to be shipped.

Why it matters for quality:

High-quality solutions never skip testing. Every finished board should prove that it can work safely and reliably before it leaves the factory.

Example: Just like checking if a car engine starts before selling the car, testing ensures the PCB works before delivering it to the customer.

Why Choose High-Quality SMT PCB Assembly Solutions?

Choosing high-quality SMT PCB assembly solutions is not just about making a board that works—it’s about making it reliable, fast, and cost-effective. Let’s look at the main reasons.

1. Improve PCB Performance (Signal Integrity & Electrical Reliability)

A PCB is like the “highway” for electricity. If the paths are not smooth, signals can slow down or get lost. High-quality SMT assembly ensures:

Clean, precise solder joints so electricity flows without interruption.

Accurate placement of tiny parts, avoiding shorts or weak connections.

Stable performance over time, so devices last longer.

Example: Think of it like water pipes. If pipes are full of leaks or clogs, water doesn’t flow properly. High-quality assembly makes the “electricity pipes” strong and smooth.

2. Support High-Density & Miniaturized Designs

Modern devices need lots of parts in very small spaces:

Smartphones, smartwatches, and 5G modules are tiny but powerful.

Medical electronics like portable monitors or implants are very small but must be precise.

High-quality SMT assembly can place thousands of tiny components accurately in tight spaces. This allows engineers to build smaller, lighter, and more advanced devices.

3. Reduce Defects and Increase Yield

“Yield” means how many boards come out working correctly. A poor assembly process can create defective boards, which waste money and time.

High-quality SMT assembly focuses on:

Accurate solder paste printing

Precise component placement

Careful reflow soldering

Thorough inspections

All these steps reduce errors and increase the number of boards that pass tests the first time.

Example: Imagine baking 100 cookies. A high-quality process ensures 95–100 cookies turn out perfect, instead of only 70.

4. Shorten Delivery Time & Support Rapid Prototyping and Mass Production

High-quality SMT assembly solutions use advanced machines and efficient workflows. This means:

Quick prototyping for testing new designs.

Fast mass production to meet market demands.

Reduced delays caused by errors or rework.

Companies can launch products faster and stay ahead of competitors.

5. Balance Cost and Quality

At first, high-quality assembly may seem more expensive. But in the long run, it saves money because:

Fewer defective boards → less waste

Fewer repairs → lower maintenance costs

Consistent quality → higher customer satisfaction

In other words, spending a little more up front prevents big problems and extra costs later.

Applications of SMT PCB Assembly

SMT PCB assembly is used everywhere in modern electronics. From the phones in our pockets to the cars on the street, these tiny boards make devices work. Let’s look at the main areas where SMT PCB assembly is very important.

1. Communication & 5G Devices

Modern communication devices, like smartphones, routers, and 5G modules, rely on SMT PCBs.

These devices need high-speed signals that travel fast and without interruption.

SMT allows engineers to place very tiny parts close together, which helps signals move quickly.

Without SMT, devices like your smartphone would be bigger, slower, and less reliable.

Example: The tiny PCB inside a 5G phone is packed with chips and resistors, all assembled with SMT technology.

2. Automotive Electronics & New Energy

Cars today are full of electronics: engine control units, sensors, battery management systems, and electric vehicle controllers.

SMT PCB assembly helps make compact, reliable boards that survive heat, vibration, and long-term use.

It allows the production of boards for electric vehicles and advanced driver-assistance systems.

Example: The PCB that controls an electric car’s battery is made with SMT parts. High-quality assembly ensures the battery system works safely for years.

3. Medical Devices

Medical electronics need to be small, precise, and reliable, because lives depend on them.

SMT PCBs are used in devices like portable monitors, ECG machines, insulin pumps, and implants.

They allow for miniaturization, so devices are comfortable and easy to use.

High-quality assembly ensures no failures, which is critical in healthcare.

Example: A tiny PCB in a wearable heart monitor is built with SMT parts, so it can fit on your wrist and give accurate readings.

4. Industrial Control & Automation

Factories and industrial machines use SMT PCBs for automation systems, robotics, and control panels.

SMT allows for compact and reliable boards that can handle harsh environments.

Machines in factories need electronics that work 24/7 without failure.

Example: The PCB controlling a robotic arm in a car factory is assembled with SMT technology to ensure precision and reliability.

5. Consumer Electronics

Almost every modern gadget uses SMT PCBs: laptops, tablets, smartwatches, cameras, and gaming consoles.

SMT allows small, lightweight, and powerful designs.

High-quality assembly ensures products work correctly, reducing returns and complaints.

Example: A smartwatch PCB is so small that it can fit in a thin strap, but it still has dozens of tiny parts working together perfectly.

How to Choose an SMT PCB Assembly Supplier

Choosing the right SMT PCB assembly supplier is very important. A good supplier can help you get high-quality boards, on time, and at a fair price. Here are the main things to look for.

1. Check Production Equipment and Process Capability

A supplier must have modern machines and skilled workers to make high-quality boards.

Pick-and-place machines for precise part placement.

Reflow ovens for strong, reliable soldering.

Inspection equipment like AOI and X-ray machines to catch mistakes.

Suppliers with advanced equipment can handle small, complicated boards and large, high-volume production.

2. Look for Quality Certifications

Certifications show that the supplier meets international standards.

ISO 9001 – general quality management.

IATF 16949 – for automotive electronics.

UL – safety certification for electronic products.

Choosing a certified supplier ensures consistent quality and safety.

3. Check Delivery Capability

You need a supplier that can deliver boards on time, no matter the order size:

Small batch production – for prototypes or testing new designs.

Large batch production – for mass production.

Fast turn services – if you need boards quickly.

High-quality suppliers plan carefully and use efficient processes to avoid delays.

4. Look for After-Sales and Technical Support

A supplier should help you after the boards are delivered.

Technical support for assembly questions or troubleshooting.

Quick response if a problem happens.

Advice on improving design for better assembly quality.

Good support ensures your project stays on track and avoids costly mistakes.

Summary: A supplier that meets all these criteria guarantees high-quality, reliable boards, faster time-to-market, and peace of mind. For example PCB MASTER, it is a reputable SMT PCB assembly supplier that offers high-quality services, fast delivery, and professional support.

Conclusion

In short, the heart of SMT PCB Assembly services is providing high-quality manufacturing solutions. Every step—from design and solder paste printing to component placement, soldering, and testing—must be done carefully to make sure your electronic boards work reliably and last a long time.

Choosing a reliable supplier is just as important as the technology itself. The right supplier ensures precision, consistency, and fast delivery, so you don’t waste time or money fixing mistakes.

If you want your projects to succeed, it’s time to partner with a professional SMT PCB Assembly provider. A trusted supplier, like PCB MASTER, can deliver high-quality boards, provide expert support, and help you bring your products to market faster and with confidence.

FAQs

1. How long does it usually take to get SMT PCB boards made?

The production time for SMT PCB boards depends on the complexity and quantity of your order. For small prototypes, it can take just a few days because there are fewer boards to make and test. For large production runs, it may take a few weeks because each board goes through careful steps like solder paste printing, placement, soldering, inspection, and testing. Choosing a supplier with efficient machines and processes can make the process faster without losing quality.

2. Can SMT PCB Assembly handle very tiny parts?

Yes! One of the main advantages of SMT is that it can place very small components, sometimes smaller than a grain of rice, on the PCB. High-quality assembly machines use precision vision systems to pick up and place these tiny parts accurately. This is important for modern devices like smartphones, wearable devices, and medical electronics, where space is limited but performance must be high.

3. What happens if a part is placed incorrectly on the PCB?

If a part is in the wrong place, the board might not work at all. That’s why SMT assembly includes multiple quality checks:

AOI (Automatic Optical Inspection) cameras check every part for position and solder quality.

Functional testing ensures the board works as expected before it leaves the factory.

High-quality suppliers catch mistakes early so you don’t have to deal with broken boards later. This saves time, money, and frustration.