The Science Behind PCB Silkscreen How to Choose the Best Color for Your Circuit Board

Introduction

There’s more than meets the eye in a simple color choice.

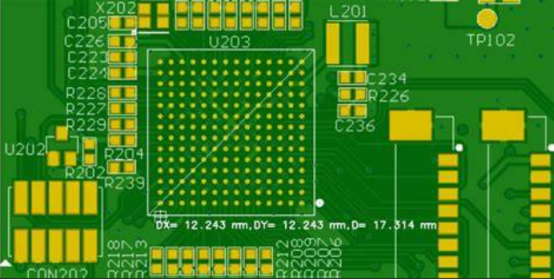

In the world of electronics, the Printed Circuit Board (PCB) is a component we rarely notice, yet it is absolutely vital. When you open any electronic device, the first thing you often see are the texts and symbols on the PCB that mark component locations, orientation, and various information. These markings are the PCB silk screen, displaying component labels (like R1, C2, U3), component designators, polarity markers, test points, version numbers, and even company logos. The silkscreen consists of ink traces applied to the pcb board, providing visual identification and labeling for components and other important information. Their color selection is far from arbitrary; it’s a complex decision combining engineering, ergonomics, and manufacturing processes.

What is a PCB Silk Screen? Why is it So Important?

The PCB silk screen, also known as the legend layer, is a non-conductive ink layer printed on the surface of the circuit board. The silkscreen forms a protective layer over the PCB surface, enhancing durability and resistance to environmental factors. It carries critical information: component labels (like R1, C2, U3), polarity markers that indicate specific polarity for components such as capacitors and diodes, test points, version numbers, and even company logos. Imagine trying to assemble or repair a PCB without any markings – it would be like trying to find a destination in a city without any street signs.

The silk screen layer sits on top of the solder mask – the layer that gives the PCB its main color (usually green). The primary purpose of the silk screen is to guide assembly, ensure correct component placement, and help engineers understand and debug the circuit.

PCB Silkscreen Types and Techniques

The method used to apply the silkscreen layer to a printed circuit board can have a significant impact on the final appearance, durability, and cost of your PCB. There are three main techniques used in the industry: manual screen printing, liquid photo imaging (LPI), and direct legend printing (DLP).

Manual screen printing is the traditional approach, where non-conductive epoxy ink is pushed through a fine mesh screen onto the PCB surface. This method is well-suited for simple designs and larger text, making it a popular choice for prototypes or low-volume production runs. However, it can be less precise for intricate silkscreen markings or fine details.

Liquid photo imaging (LPI) offers higher resolution and is ideal for complex PCB silkscreen design. In this process, a photosensitive liquid epoxy is applied to the PCB, then selectively hardened using UV light through a photomask. The unhardened areas are washed away, leaving behind crisp, high-contrast silkscreen markings. LPI is commonly used in mass production where precision and consistency are essential.

Direct legend printing (DLP), also known as direct legend printing DLP, is the most advanced technique. It uses an inkjet projector to print the silkscreen layer directly onto the PCB surface, guided by CAD data. This method allows for rapid changes, high resolution, and excellent flexibility, making it ideal for complex or high-mix PCB designs. DLP is especially valuable for quick-turn PCB fabrication and when multiple color options or company logos are required.

Choosing the right silkscreen application technique depends on your PCB design requirements, the desired level of detail, and the overall manufacturing process.

Common PCB Silk Screen Colors and Their Properties

White Silk Screen: The Industry Standard

White is the most common silk screen color, especially on dark-colored PCB substrates like green or black. White silk screen creates a sharp contrast against these backgrounds, providing excellent contrast for readability and making text and symbols easy to read. White ink is also widely available and cost-effective, fitting into many PCB silk screen color standards.

The reflective property of white silk screen makes it perform excellently in well-lit environments, which is why most consumer electronics and industrial equipment use white silk screens.

Yellow Silk Screen: The Choice for Special Applications

Yellow is another common choice for screen printing, particularly useful in situations requiring high visibility. Yellow silk screen stands out under various lighting conditions, including low-light environments. This color is often used in automotive or outdoor applications where boards might be inspected under challenging conditions. In addition, yellow PCBs are valued for their heat dissipation and safety benefits, including flame retardant properties, making them suitable for high-power applications.

However, yellow silk screen has a notable drawback: it can have poorer contrast against copper traces and the substrate itself, which might affect readability in some cases.

Black Silk Screen: The Partner for Light-Colored PCBs

Black silk screen is less common but useful on light-colored PCBs, such as white or beige substrates. It provides sharp contrast for easy reading. However, black ink can be harder to see under certain lighting, so it's typically used in controlled environments like labs or for prototypes.

It's important to note that while a black PCB (solder mask) might create a strong visual effect with black silk screen, this combination is rarely used in practice due to severely impacted readability.

Why is Silk Screen Color Choice So Critical?

Readability and Contrast

The core function of the silk screen color is to provide clear readability. The contrast between the silk screen color and the PCB substrate is the most important factor when choosing a color. Insufficient contrast can lead to assembly errors, repair difficulties, and ultimately increase production costs and time.

Green PCBs (the most common substrate color) pair most clearly with white or yellow silk screens. Blue PCBs are also used in industrial and communication applications for improved contrast and visual inspection. On black PCBs, often used for high-end or aesthetic applications, white silk screen generally stands out more than yellow under most lighting conditions.

Manufacturing Process Considerations

The manufacturing process can differ for silk screen inks of different colors. Standard colors (like white and yellow) are widely used, and most manufacturers typically include them in their baseline pricing. Choosing a non-standard color can increase costs by 10-20%.

Furthermore, the silk screening process itself – whether done via manual screen printing, Liquid Photo Imaging (LPI), or Direct Legend Printing (DLP) – affects the final outcome and cost. For instance, LPI offers higher precision for fine text but might take longer than traditional methods. Other methods, such as inkjet printing and traditional screen printing, are also available, each with their own advantages and disadvantages.

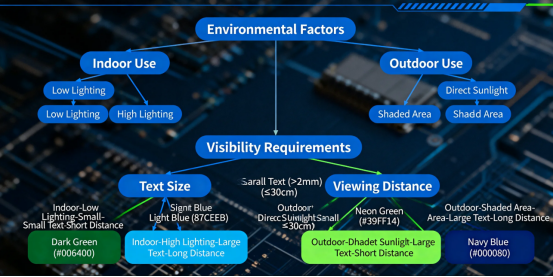

Environmental Suitability

The operating environment of the PCB also influences the choice of silk screen color. In low-light environments, yellow silk screen is often easier to read because yellow reflects light better than white or black. For well-lit environments, like clean room assembly lines, white silk screen usually provides sufficient clarity.

Additionally, the silk screen needs to withstand soldering processes, cleaning agents, and environmental factors like heat or humidity. Exposure to high temperatures, especially above 85°C or in harsh environments such as direct sunlight, can cause silkscreen colors to fade over time. Most manufacturers use non-conductive epoxy-based inks that meet these requirements.

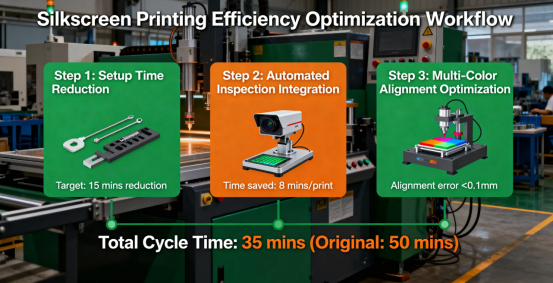

Silkscreen Printing Cost and Efficiency

When planning your PCB fabrication, the cost and efficiency of silkscreen printing are important factors to consider. The choice of silkscreen technique can influence both your budget and your production timeline.

Manual screen printing is generally the most cost-effective option, especially for simple designs and small production runs. Its straightforward process and minimal equipment requirements help keep costs low. However, manual screen printing can be labor-intensive and slower, particularly for complex silkscreen layers or high-volume orders.

Liquid photo imaging (LPI) and direct legend printing (DLP) require more specialized equipment and materials, which can increase the initial cost. However, these methods offer higher resolution and precision, which is crucial for densely packed PCB boards or when fine silkscreen markings are needed. DLP, in particular, stands out for its speed and efficiency, as it prints the silkscreen layer directly onto the PCB surface without additional processing steps. This makes DLP ideal for fast turnaround times and large-scale production.

Ultimately, the best choice depends on your specific needs: for simple, low-cost projects, manual screen printing may suffice, while for high-precision or high-volume manufacturing, LPI or DLP can offer better efficiency and quality.

How to Choose the Best Silk Screen Color for Your PCB?

Consider the PCB Substrate Color

The first step to achieving optimal readability is considering the relationship between the silk screen ink color and the PCB substrate color. Here are some proven combinations:

·Green PCB: White or yellow silk screen (best contrast)

·Black PCB: White silk screen (maximum contrast)

·Blue PCB: White silk screen (good contrast; blue substrate is often used in specialized applications, such as industrial or military contexts, to improve visual contrast and readability)

·White PCB: Black silk screen (sharp contrast)

·Red PCB: White or black silk screen (depending on the shade)

Evaluate the Application Scenario

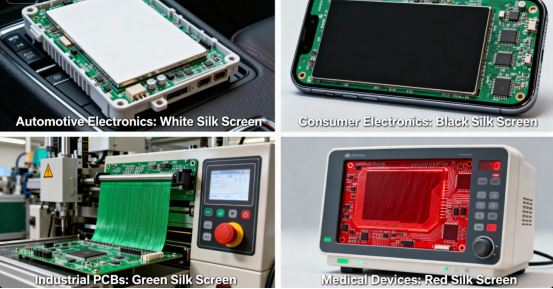

Different applications have unique needs:

·Consumer Electronics: Often use white silk screen for its clean, professional look and cost-effectiveness.

·Automotive Electronics: Boards are often exposed to vibration and extreme temperatures; durable yellow silk screen might be preferred for its visibility during field repairs.

·Industrial Equipment: May require high-contrast combinations, like white silk screen on a dark green substrate.

·Medical Devices: Often require permanent markings, sometimes using laser engraving instead of ink.

Balance Aesthetics with Functionality

While aesthetics are an important consideration, functionality and readability should always be the primary concern. In some high-end products, designers might choose a silk screen color that matches the product’s color scheme, but they must ensure readability isn’t sacrificed. Purple PCBs, for example, offer unique visual appeal and can provide better contrast for component identification in certain applications; however, they may make solder joint inspection more difficult and are less commonly available as a non-standard color option.

For most applications, a conservative color choice (like a light silk screen on a dark substrate) is usually the safest bet.

Quality Control and Inspection

Ensuring the quality of the silkscreen layer is a vital part of the PCB manufacturing process. A well-executed silkscreen not only improves the appearance of your PCB but also plays a crucial role in assembly and maintenance.

Manufacturers use a combination of visual inspection and automated optical inspection (AOI) systems to check for defects in the silkscreen layer. Common issues include misaligned text, blurry or incomplete printing, and incorrect color application. These defects can lead to assembly errors or make it difficult to identify components and reference indicators during the assembly process.

To maintain high standards, PCB manufacturers follow industry guidelines, such as those set by the Institute of Printed Circuits (IPC), ensuring that every silkscreen layer meets strict specifications for clarity, durability, and accuracy. By prioritizing quality control at every stage of the manufacturing process, companies can deliver PCBs that are reliable, easy to assemble, and meet the demands of modern electronic devices.

Best Practices for PCB Silk Screen Design

Beyond color selection, effective silk screen design requires attention to the following:

·Font and Size: Recommended font height is 0.8mm to 1.2mm (prioritizing readability). The ratio of character height to stroke width should generally be ≥6:1 for clarity.

·Placement Avoidance: Silk screen should not cover pads, vias, or test points. Typically, a clearance of at least 6 mils is required.

·Direction Consistency: Keep the orientation of all text consistent (e.g., all left-to-right or all top-to-bottom).

·Key Information Marking: Include crucial markers like pin 1 indicators for chips, polarity symbols ("+" or "-"), and interface functions.

·Simplify Content: Only include necessary information to avoid cluttering the board with unnecessary text or logos.

Future Developments in PCB Silkscreen

The world of PCB silkscreening is evolving rapidly, driven by advances in technology and the increasing complexity of modern circuit boards. One major trend is the shift toward environmentally friendly materials, such as lead-free and halogen-free inks, which offer improved safety and sustainability while meeting global regulatory requirements.

Another exciting development is the integration of silkscreen printing with other manufacturing processes, like 3D printing and surface mount technology (SMT). This integration enables the creation of more compact and sophisticated PCB designs, enhancing both functionality and performance.

Looking ahead, artificial intelligence (AI) and machine learning (ML) are poised to revolutionize PCB design and silkscreen application. These technologies can optimize the placement of silkscreen markings, predict potential assembly errors, and streamline the entire manufacturing process, resulting in higher quality and more efficient production.

As PCB design continues to advance, expect silkscreen technology to keep pace, offering new possibilities for customization, precision, and sustainability in the world of printed circuit boards.

Conclusion

While a small detail, the PCB silk screen color is an important element in electronic design. Choosing the right silk screen color not only enhances the board's manufacturability and maintainability but can also impact the product's overall quality and user experience.

Whether you choose the common white silk screen or opt for yellow or another color for a special application, the key is to ensure optimal readability and contrast. By considering factors like substrate color, lighting conditions, and application needs, you can design circuit boards that are easier to assemble, inspect, and maintain.

Next time you open an electronic device, take a moment to notice the PCB's silk screen color – you'll discover that behind this humble color choice lies profound engineering wisdom.

Do you have any unique experiences or questions regarding PCB silk screen colors? Feel free to share your thoughts in the comments section!