TG260 Halogen-Free Material: Durable, Heat-Resistant Solution for High-Tech Devices

As technology continues to evolve, the materials used in high-tech devices need to offer more than just basic functionality. TG260 halogen-free material stands out as a reliable option, known for its heat resistance, durability, and environmentally friendly properties. This material is increasingly being used in electronics where performance under stress and long-term reliability are crucial.

What is TG260 Halogen-Free Material?

TG260 halogen-free material refers to a type of high-performance material that combines two important properties: a high glass transition temperature (TG) of 260°C and the absence of halogen elements. This combination makes it especially suitable for use in electronics that need to withstand high temperatures while being environmentally safe.

What does TG260 mean?

TG260 indicates that the material has a glass transition temperature (TG) of 260°C, which means it can resist thermal stress and high temperatures without compromising its structure. In simpler terms, TG260 materials can maintain their shape and performance even in environments where heat levels are extreme, making them ideal for applications like automotive electronics, aerospace components, and high-performance circuit boards.

What does Halogen-Free mean?

A halogen-free material is one that does not contain halogen elements, such as chlorine, bromine, fluorine, or iodine. These halogen elements are often used in traditional materials for flame retardance, but they can release toxic gases when exposed to heat or disposed of improperly. Halogen-free materials, like those with the TG260 characteristic, eliminate this risk, making them safer and more environmentally friendly. This makes them increasingly important in meeting global environmental regulations such as RoHS and WEEE, which restrict the use of harmful substances in electronic devices.

What are the Key Benefits of Using TG260 Halogen-Free Materials?

TG260 halogen-free materials offer several key advantages that make them highly suitable for modern electronics. These benefits include superior durability, heat resistance, and environmental safety, all of which are essential for high-performance devices in demanding industries like automotive, aerospace, and consumer electronics.

Why is TG260 considered a durable material in harsh environments?

TG260 materials is considered a durable material in harsh environments due to its ability to resist mechanical wear and maintain its performance under extreme conditions.

Mechanical strength: TG260 materials have excellent mechanical strength, allowing them to withstand physical stress without cracking, warping, or breaking. This is especially crucial for devices exposed to continuous handling, impacts, or vibrations.

Resistance to wear: The material's resistance to abrasion and wear makes it ideal for use in environments where components are subject to repeated movements or friction, such as automotive sensors or machine components.

Protection in extreme conditions: TG260 materials provides protection against extreme conditions like high pressures and fluctuating temperatures. Whether a device is exposed to high-pressure environments in aerospace applications or to extreme temperature variations in automotive electronics, TG260 materials' durability ensures consistent performance over time.

For instance, in the automotive industry, TG260 materials is used in components that must withstand constant vibrations, heat fluctuations, and exposure to harsh chemicals, ensuring the longevity and reliability of key electronic parts.

How does TG260 materials provide superior heat resistance for modern electronics?

TG260 materials provide exceptional heat resistance, making it ideal for modern electronics that operate in high-temperature environments. This is due to its high glass transition temperature (TG) of 260°C.

Glass transition temperature (TG) of 260°C and its implications: The glass transition temperature is the temperature at which a material transitions from a rigid, glassy state to a more flexible, rubbery state. A high TG, like 260°C, means that TG260 materials can maintain its structural integrity and performance at higher temperatures compared to materials with a lower TG. This allows devices made from TG260 materials to operate reliably in high-temperature environments without risk of material degradation, warping, or failure.

High heat tolerance in various applications: In automotive, aerospace, and high-performance electronics, components are often exposed to extreme heat. For example, in electric vehicles (EVs), battery management systems must withstand high temperatures, and TG260 materials are used to ensure the thermal stability of these critical components. Similarly, aerospace components often need to operate in environments where temperatures can fluctuate significantly, and TG260 materials’ high heat tolerance ensures reliability and performance in such conditions.

TG260 materials' heat resistance is a major reason why it is used in applications that require long-term stability under thermal stress, helping to prevent failures in devices that would otherwise be vulnerable to overheating.

How does TG260 materials contribute to environmental and health safety?

TG260 materials are not only a high-performance material but also a healthier and safer choice due to its halogen-free nature.

Eliminating toxic halogens in the manufacturing process: Traditional materials often use halogen elements like bromine and chlorine to improve fire resistance. However, when these materials burn or degrade, they can release toxic gases that are harmful to human health and the environment. TG260 halogen-free materials do not contain these harmful elements, significantly reducing the risks associated with material breakdown or disposal.

Non-toxic and safer for end-users, particularly in consumer electronics: By being halogen-free, TG260 materials reduce the risk of releasing toxic fumes in high-heat conditions, which is particularly important in consumer electronics such as smartphones, laptops, and wearables. This ensures that these devices are safer to use, especially when heated or disposed of improperly.

For example, in consumer electronics, where devices are often discarded after use, TG260 halogen-free materials make the recycling process safer, reducing the environmental impact of e-waste and contributing to a greener future.

Where is TG260 Halogen-Free Material Applied in High-Tech Devices?

TG260 halogen-free material is used in high-tech devices that require heat resistance, durability, and environmental safety. It is commonly applied in consumer electronics, automotive sensors, and aerospace components, where reliable performance in extreme conditions is essential.

Which high-tech devices benefit the most from TG260 Halogen-Free materials?

TG260 halogen-free materials are essential in high-tech devices that require durability, heat resistance, and environmental safety. Several industries are adopting TG260 materials for its ability to perform reliably under harsh conditions.

Use cases in consumer electronics (smartphones, laptops, wearables): In the consumer electronics sector, smartphones, laptops, and wearables benefit greatly from TG260 materials. These devices often face high temperatures due to long usage periods. TG260 materials’ thermal stability helps prevent overheating, ensuring the longevity and consistent performance of internal components like circuit boards. In wearables, which are constantly exposed to movement and moisture, TG260 materials enhance durability and heat resistance, making it an ideal material for devices like fitness trackers and smartwatches.

Applications in the automotive industry (electric vehicles, sensors): The automotive industry has seen a significant rise in the use of electric vehicles (EVs), which require materials that can withstand high temperatures, vibrations, and exposure to chemicals. TG260 materials are used in sensors and connectors in electric vehicles, ensuring reliable performance in the harshest conditions. For example, EV battery management systems rely on TG260 materials to ensure that components operate optimally, even in extreme environments, without degradation over time.

Aerospace technologies (durability in extreme conditions): Aerospace components also benefit from TG260materials' high thermal resistance and mechanical durability. Components exposed to extreme temperature fluctuations and high-altitude conditions, such as aerospace sensors, require materials with TG260 to maintain performance without failure. TG260 materials’ heat resistance ensures that electronics in aerospace devices can perform reliably under pressure and in changing environments.

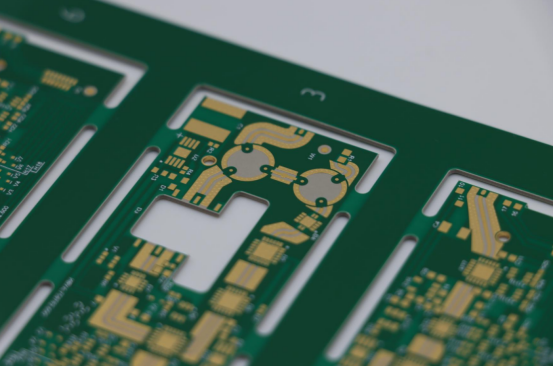

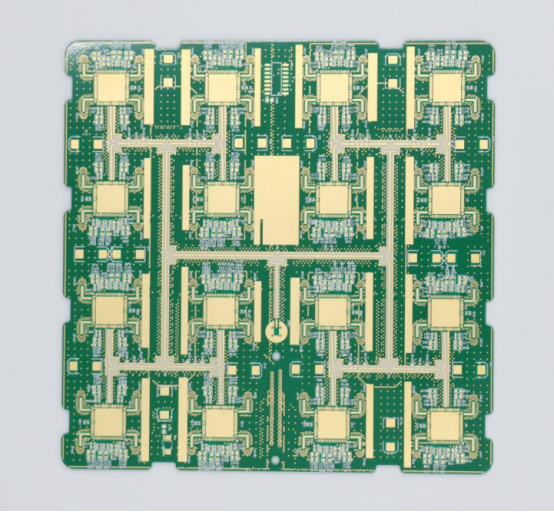

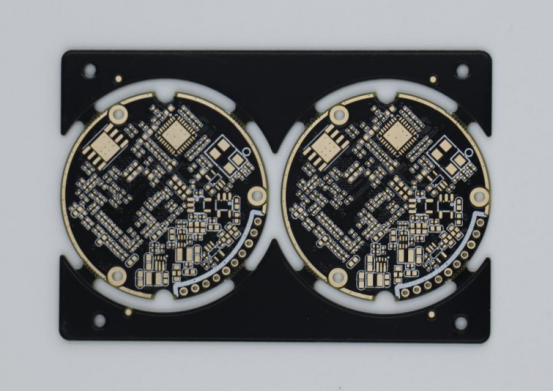

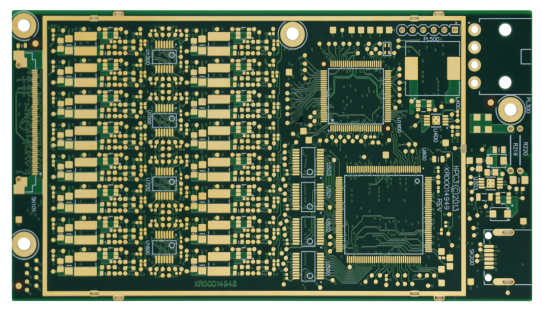

How does TG260 materials enhance the performance of printed circuit boards (PCBs)?

TG260 halogen-free materials offer significant advantages in printed circuit board (PCB) manufacturing, making them ideal for modern electronics that demand high performance and long-term stability.

Advantages of TG260 materials in PCB manufacturing (low thermal expansion, high dielectric strength): One of the key benefits of TG260 materials in PCB manufacturing is its low thermal expansion. This ensures that circuit boards maintain their shape and performance under varying temperature conditions. Additionally, TG260 materials have high dielectric strength, providing excellent electrical insulation. This helps prevent short circuits and ensures that the PCBs remain functional and safe, even under extreme conditions.

Long-term performance in high-density PCBs for cutting-edge tech: As electronics become more compact and complex, high-density PCBs are necessary to fit more components into smaller spaces. TG260 materials’ thermal stability and mechanical durability make it a great material choice for high-density PCBs, which are crucial in smartphones, wearables, and IoT devices. These devices require reliable performance over time, and TG260 materials ensure that PCBs remain operational even in the face of temperature fluctuations and high power densities.

Conclusion: Why Choose TG260 Halogen-Free Material for Your Next High-Tech Device?

TG260 halogen-free material offers a combination of superior heat resistance, mechanical durability, and environmental safety, making it an ideal choice for electronics manufacturers. Its high glass transition temperature (260°C) ensures reliability in extreme heat conditions, while its halogen-free nature makes it safer for both users and the environment. This material excels in automotive, aerospace, and consumer electronics, where long-term performance and sustainability are key.

For your next high-performance, eco-friendly device, consider exploring TG260 halogen-free material. Its combination of heat resistance, durability, and environmental safety makes it a strong option for a variety of applications. At PCBMASTER, we offer a range of materials, including TG260 halogen-free material, to match your specific needs. With years of expertise in the industry, we can help you find the ideal material for your project, ensuring the best performance and sustainability.

FAQs

What is the difference between TG260 Halogen-Free material and other halogen-free materials?

TG260 halogen-free refers to materials that have a glass transition temperature (TG) of 260°C and are halogen-free. The key distinction lies in the thermal resistance and environmental friendliness:

Heat Resistance: Materials with TG260 are specifically designed to withstand high temperatures, with a glass transition temperature of 260°C. This is higher than many other halogen-free materials, which tend to have lower TGs. As a result, TG260 materials are more suitable for applications that require higher thermal stability.

Environmental Safety: While all halogen-free materials eliminate the use of harmful halogens, TG260 halogen-free materials stand out due to their combination of high thermal resistance and environmental benefits. The absence of halogens makes them safer in terms of disposal and emissions, while the high heat resistance makes them ideal for high-performance applications.

Durability: Compared to other halogen-free materials, TG260-based materials generally offer superior mechanical strength and long-term durability, especially in harsh operating conditions like high temperatures and mechanical stress.

How does TG260 material impact the cost of manufacturing high-tech devices?

Using TG260 halogen-free material can influence the cost of manufacturing high-tech devices in the following ways:

Material Cost: TG260 halogen-free materials can be more expensive than other halogen-free materials, due to their high-performance characteristics. This is particularly true for materials with higher glass transition temperatures and greater heat resistance. As a result, the raw material cost might be higher compared to standard halogen-free resins or other lower-performance alternatives.

Manufacturing Complexity: The complexity of manufacturing with TG260 materials might also increase, particularly if the material requires specialized processes to achieve its high heat resistance and mechanical durability.

Cost vs. Performance: While TG260-based materials may involve higher upfront costs, the long-term benefits—such as enhanced reliability, reduced maintenance, and improved durability—make them a cost-effective solution for industries where performance is paramount. In high-performance applications like electric vehicles or aerospace, the investment in TG260 materials is justified by the reduction in potential failures or downtime.

Can TG260 material be used for flexible electronics or is it only for rigid materials?

TG260 halogen-free material is generally more suitable for rigid applications due to its high glass transition temperature and mechanical properties, which make it ideal for applications that require thermal stability and rigidity. However, it can still be used in some semi-flexible applications with certain limitations.

Suitability for Flexible Electronics: TG260 material is not typically used in highly flexible electronics like wearable devices, smart fabrics, or bendable circuits. Its rigid nature and focus on thermal stability make it less ideal for applications that require frequent bending or flexing.

Semi-flexible Use: TG260 materials can be used in semi-flexible applications that do not require extensive bending but still need high heat resistance and mechanical durability. For example, flexible PCBs used in some wearables or foldable electronics might use TG260 material for specific rigid components within the design.

Alternative Materials: For highly flexible electronics, materials like polyimides, liquid crystal polymers (LCPs), or silicone-based resins are more appropriate due to their ability to provide both flexibility and thermal resistance.

What industries are adopting TG260 halogen-free material the fastest?

The industries adopting TG260 halogen-free materials the fastest are those that require high-performance and environmentally safe materials, such as:

Automotive Industry: The automotive sector, particularly in electric vehicles (EVs), is rapidly adopting TG260 materials for battery management systems, connectors, and sensors. The high thermal resistance of TG260 material ensures that components can withstand high temperatures and mechanical stress, which are common in electric and autonomous vehicles.

Aerospace: Aerospace companies are increasingly using TG260-based materials for electronics and sensors in spacecraft, satellites, and aircraft. The material’s ability to perform in extreme temperature fluctuations and high-stress environments makes it ideal for the aerospace industry.

Consumer Electronics: High-end consumer electronics, including smartphones, laptops, and wearables, are incorporating TG260 material for components that require reliable performance in small spaces and under high heat. The growing demand for eco-friendly and high-performance materials is driving the adoption of TG260 material in high-tech consumer devices.

Is TG260 materials compatible with all types of printed circuit board (PCB) designs?

TG260 halogen-free material is compatible with a variety of PCB designs, particularly those that require high-temperature resistance and mechanical durability.

High-Density PCBs: TG260 material is well-suited for high-density PCBs, where space is tight, and components need to operate reliably in high heat. Its high thermal resistance ensures that PCBs can handle power dissipation and thermal stress without failing, making it ideal for advanced electronics like smartphones and electric vehicle electronics.

Various PCB Designs: TG260 material can be used in single-layer, multi-layer, or rigid-flex PCBs, providing high thermal stability and electrical insulation. It ensures that these PCBs maintain performance and reliability over time, even in harsh operating conditions.

Limitations for Flexible PCBs: While TG260 material is compatible with rigid and semi-flexible PCBs, it may not be the best choice for highly flexible PCBs that require constant bending or folding. For those applications, more flexible materials like polyimides are often preferred.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!