The Impact of PCB Stacking on Hole Accuracy and Quality: A Detailed Guide

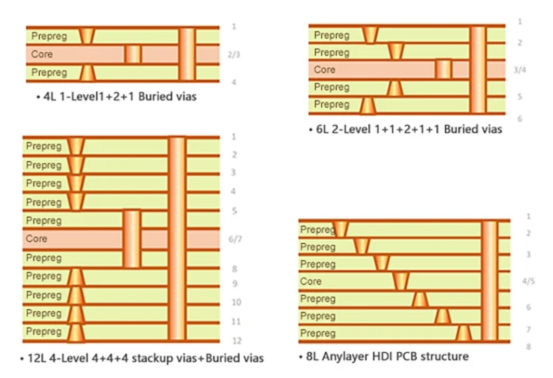

The number of stacked layers in PCB manufacturing has a significant impact on drilling quality, which directly affects the performance and reliability of the final product. As more layers are added, the drilling process becomes more difficult. Uneven resistance from the layers can cause the drill bit to shift, leading to misaligned holes and poor hole walls, which are particularly problematic in high-density interconnect (HDI) boards.

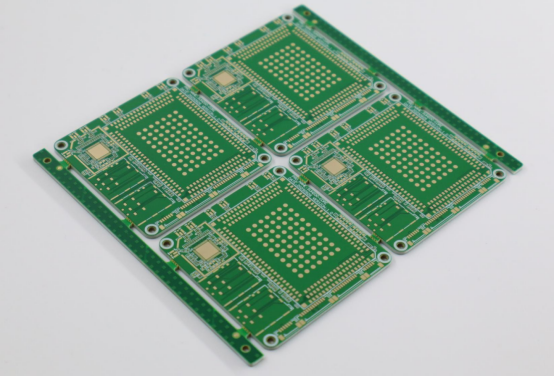

Drilling quality is crucial for ensuring strong electrical connections and effective signal transmission. In HDI boards, which require precise drilling for small, densely packed connections, even the smallest error can lead to failure. Poor drilling can compromise the overall function and durability of the PCB. As designs become more complex and the demand for higher-density boards increases, understanding how stacked layers affect drilling quality is essential for reducing defects and improving the performance of advanced PCBs.

How Does the Number of Stacked Layers Affect Drilling Quality?

As the number of stacked layers in a PCB increases, the drilling process becomes more challenging. The drill bit faces uneven resistance when passing through multiple layers, which can lead to misalignment, poor hole wall quality, and faster drill bit wear. These challenges are especially critical for high-density interconnect (HDI) boards, where precise drilling is essential for ensuring proper performance and reliability. Understanding how stacking layers affects drilling quality is key to producing high-quality PCBs.

How Does an Increased Number of Stacked Layers Affect Hole Position Accuracy?

Hole Position Deviation

As the number of stacked layers in a PCB increases, the drill bit faces uneven resistance while passing through multiple layers. This uneven resistance causes the drill bit to shift slightly or even wobble, leading to inaccuracies in hole placement. The more layers the drill passes through, the harder it becomes to maintain precise positioning. This problem is especially significant in high-density interconnect (HDI) boards, which require precise hole placement due to their dense and intricate design.

For example, when drilling through 12 layers of a PCB, the resistance may vary between each layer, causing slight misalignments in the hole position. In high-density boards, even a small deviation can lead to signal integrity issues or circuit failure, making accuracy a top priority.

What Impact Does an Increased Number of Stacked Layers Have on Hole Wall Quality?

Burrs and Deburring Issues

When drilling through multiple layers, burrs and sharp edges are common at the exit points of the drilled holes, especially in the lower layers. As the drill bit wears down over time, it may have difficulty removing debris effectively, leading to rough edges or burrs that affect the hole walls. These burrs are particularly problematic in the inner layers where high-quality copper connections are critical. Poor hole wall quality can affect the overall performance of the PCB, as poor connections can increase electrical resistance or cause shorts.

Increased Roughness

With higher stacked layers, the heat generated by the drilling process is not effectively dissipated. The drill bit's reduced efficiency in heat removal can lead to an increase in roughness on the hole walls. High heat levels can also cause materials like epoxy resin or fiberglass to degrade, leading to irregular surface finishes. For instance, if a PCB with 8-10 layers is drilled without proper cooling, the surface roughness of the hole wall may increase, making it harder to solder components properly.

Drill Head Phenomenon

Drilling through multiple layers can sometimes cause the drill bit to experience micro-vibrations at material interfaces, especially between copper and resin layers. These micro-vibrations can lead to the nail-head phenomenon, where irregular copper bumps form inside the hole, disrupting the integrity of the layer and creating inconsistencies in the hole wall. This is particularly problematic in multi-layer PCBs, where precision is key.

How Does an Increased Number of Stacked Layers Affect Drill Bit Life and the Risk of Broken Bits?

Accelerated Drill Wear

As the stack height increases, the total thickness the drill bit has to penetrate also increases. This means the drill bit experiences more wear and tear during each drilling operation. The faster wear can lead to premature failure of the drill bit. The more layers the drill has to pass through, the quicker the bit loses sharpness, leading to inconsistent drilling, poor hole quality, and increased downtime for tool replacement.

For example, when drilling a 12-layer PCB, the drill bit might wear out much faster compared to a 4-layer board, which directly impacts production efficiency and cost.

High Tg Materials and Ceramic Fillers

Some PCB materials, such as those with high glass transition temperature (Tg) or ceramic fillers, present additional challenges. These materials are harder and more abrasive, causing rapid drill bit wear. As the material hardness increases, the drill bit’s lifespan decreases, and the risk of breakage rises. Ceramic-filled boards, commonly used in specialized PCBs, can be particularly difficult to drill due to their hardness, increasing the likelihood of the drill bit breaking and leaving debris inside the hole, leading to defective PCBs.

How to Control Drilling Quality? Key Process Control Points

Controlling drilling quality in PCB manufacturing is essential for ensuring the reliability and performance of the final product. Key factors such as chip removal, heat dissipation, and the use of backing and cover plates all play a significant role in achieving high-quality drilled holes. By optimizing drilling parameters, like feed rate and speed, and employing techniques such as peck drilling and proper plate support, manufacturers can prevent common issues like misalignment, rough hole walls, and tool wear. Understanding and managing these process control points is critical for producing accurate, durable, and reliable PCBs.

How to Optimize Chip Removal and Heat Dissipation Design?

Chip Removal Challenges

As the number of stacked layers increases in PCB manufacturing, chip removal becomes significantly more difficult. When drilling through multiple layers, the debris (chips) produced during the process must travel through all the layers before exiting the hole. The longer path for chip removal increases the risk of clogging, leading to inefficient chip evacuation. This not only reduces drilling accuracy but can also damage the hole walls, affecting overall hole quality.

For example, in a 10-layer PCB, chips can become stuck inside the hole, creating blockages that affect the hole surface and hinder the drilling process. Therefore, optimizing chip removal becomes essential to maintain precision.

Feed Rate and Speed Adjustment: The “Step Drilling” Strategy

One effective way to improve hole wall quality is by adjusting the feed rate and rotational speed using a strategy called "step drilling." In step drilling, the upper layers are drilled at higher speeds and feed rates, while the lower layers are drilled at slower speeds. This ensures that the drill bit can effectively remove chips from the hole without causing too much heat buildup, which helps maintain smooth hole walls.

For instance, drilling a 12-layer PCB might require a higher feed rate for the top 4 layers and slower speeds for the remaining layers to reduce friction and minimize burrs. This approach balances efficiency and hole quality by adapting the drilling conditions to each layer’s needs.

Cooling and Cleaning Strategies: The Role of Peck Drilling

Increasing the number of tool withdrawal cycles, or peck drilling, helps improve cooling and chip removal, but it can lower efficiency. Peck drilling involves drilling in stages, withdrawing the drill bit after each stage to remove debris and cool the drill. While this increases the overall drilling time, it significantly improves hole wall quality and prevents overheating.

For example, in a multi-layer PCB, peck drilling can prevent excessive heat from causing material degradation, ensuring that the hole walls remain smooth and free from damage. Though it reduces speed, this method is essential for maintaining high-quality drilling, especially in thicker boards.

How Do the Use of Backing Plates and Cover Plates Affect Drilling Quality?

The Role of Backing Plates

Backing plates provide support to the underside of the PCB during drilling. These plates help to reduce exit burrs and minimize tearing at the hole bottom. When drilling through multiple layers, the bottom layers are often more susceptible to damage, as the drill bit exits the hole. The backing plate acts as a support structure, ensuring that the bottom layer remains intact and free from physical damage, such as torn copper or resin smearing.

For example, in a high-layer PCB, a well-designed backing plate ensures that the drilled hole has smooth edges and that the copper at the bottom layer remains undisturbed, preserving the integrity of the circuit.

The Role of Cover Plates

Cover plates serve to prevent entry burrs and improve hole position accuracy by stabilizing the surface of the PCB during drilling. By covering the topmost layer, the cover plate prevents the drill bit from creating excess burrs when entering the PCB material. This is particularly important for precision drilling, as even slight misalignment at the hole’s entry point can lead to issues like poor contact or soldering problems.

For instance, when drilling a PCB with a very thin top layer, using a cover plate can significantly improve hole position accuracy by providing better stability and preventing surface defects that can arise from the drill bit impacting the top surface.

Impact of Backing Plate Wear on Bottom Layer Accuracy

Over time, backing plates can become worn or damaged, especially when used repeatedly. Worn backing plates may fail to support the PCB properly, leading to imprecise hole locations in the bottom layers. The lack of proper support can result in misaligned holes or increased exit burrs, compromising the overall quality of the PCB.

For example, if a PCB is drilled with a worn backing plate, the drill bit may not exit the hole cleanly, leading to distorted holes in the bottom layers that affect the final product. Regular inspection and replacement of backing plates are crucial to maintaining hole accuracy in multi-layer PCBs.

How to Optimize Drilling Process and Parameters?

Optimizing the drilling process and parameters is key to achieving high-quality PCBs with precise hole placement and smooth hole walls. By adjusting drilling settings based on board material and layer count, upgrading drill bits, and strengthening monitoring techniques, manufacturers can significantly improve drilling performance. Utilizing advanced tools like AI for parameter matching, high-performance tungsten carbide drill bits, and regular process checks with CMM and roughness testers ensures that drilling quality remains consistent, reduces defects, and increases overall production efficiency.

How to Adjust Drilling Parameters Based on Board Material and Layer Count?

AI Parameter Matching

One effective way to optimize drilling parameters is by using AI-driven databases that automatically match the best drilling settings based on the board material and layer count. By feeding data into an AI system, manufacturers can quickly identify the optimal drill speed, feed rate, and tool settings for each specific PCB. This eliminates manual guesswork and ensures that drilling conditions are consistently tailored to the unique requirements of each material and layer configuration.

For example, an AI system may determine that for an 8-layer FR-4 board, a specific feed rate and drill bit size will reduce the risk of hole misalignment and improve hole wall quality. AI-driven parameter matching improves efficiency and ensures that drilling is consistently accurate, especially when dealing with complex and varied materials.

Differences Between FR-4 and Other Materials: Drilling Optimization Strategies

Different PCB materials require different drilling approaches. FR-4, one of the most common PCB materials, is relatively easy to drill but still requires careful management of heat and chip removal. In contrast, materials like high-Tg boards (used for high-temperature applications) or ceramic-filled PCBs are more difficult to drill due to their hardness and abrasiveness. These materials cause faster wear on drill bits and higher friction during the drilling process.

For example, when drilling an FR-4 PCB, the drill speed and feed rate can be higher compared to drilling through high-Tg or ceramic-filled boards. Optimizing drilling parameters for each material ensures better hole quality, reduced tool wear, and fewer defects. Different materials need tailored settings to prevent problems like delamination, excess heat, or poor hole wall quality.

How Do Drill Bit Upgrades Improve Drilling Quality?

Tungsten Carbide Drill Bits with Nano Coating

Upgrading drill bits to tungsten carbide (WC) with nano-coating significantly improves drilling performance and longevity. Tungsten carbide is a highly durable material that resists wear and heat, which is essential for drilling through multi-layer PCBs or harder materials like high-Tg or ceramic-filled boards. Nano-coating further enhances the drill’s surface properties, reducing friction and preventing heat build-up.

For instance, using a tungsten carbide drill bit with nano-coating can increase tool life and maintain consistent drilling quality, even with tough materials. This upgrade reduces the frequency of tool changes, cutting down downtime and improving production efficiency. It also results in smoother hole walls with fewer burrs, as the coating helps the drill bit glide through materials more easily.

Step Drill Design: Application in High Layer Count Boards

Step drills, designed with varying diameters along the shaft, are increasingly used in multi-layer boards to minimize drill bit deflection and ensure precise hole placement. These specialized bits help reduce the risk of edge chipping or exit burrs by maintaining the drill's stability across multiple layers.

For example, when drilling through a 12-layer PCB, a step drill with a tapered design ensures that the bit doesn't shift or wobble as it penetrates each layer. This reduces the risk of creating rough hole walls or damaging the bottom layers. Using step drills in high-layer count boards leads to better hole quality, reduced tool wear, and increased drilling accuracy.

How to Strengthen Process Monitoring for Improved Quality Control?

CMM (Coordinate Measuring Machine) for Hole Diameter Measurement

Regularly using a CMM to measure hole diameter is essential for maintaining hole accuracy, especially in multi-layer PCBs. The CMM provides precise, automated measurements of each hole’s dimensions, ensuring that they meet the design specifications. Regular inspections help detect small variations in hole placement early, preventing larger issues like misaligned vias or poor electrical connections.

For instance, periodic CMM measurements can catch small discrepancies in hole size that might otherwise go unnoticed, leading to significant quality improvements over time. This continuous monitoring allows manufacturers to adjust parameters immediately, ensuring consistent production of high-quality PCBs.

Hole Wall Roughness Testing: Using Roughness Testers to Verify Thermal Impact Depth

Another important quality control method is using a roughness tester to measure the surface quality of drilled holes. These testers can assess the roughness depth of the hole walls, which is especially critical for evaluating thermal damage caused by excessive drilling heat. Thermal damage can lead to poor adhesion between layers or degrade material properties, impacting overall PCB performance.

For example, a roughness tester can detect increased surface roughness due to heat buildup in a high-layer PCB, allowing for adjustments in drilling parameters, such as feed rate or cooling methods. By verifying hole wall smoothness and ensuring that thermal damage is minimized, manufacturers can improve the reliability and longevity of the finished PCB.

How to Balance Layer Count and Drilling Quality: Finding the Optimal Solution

Balancing layer count and drilling quality is crucial for producing high-performance PCBs, especially as layer counts increase. As the number of layers rises, the drilling process becomes more challenging, leading to potential issues like misalignment, poor hole walls, and faster tool wear. Finding the optimal solution involves understanding the non-linear relationship between layer count and drilling quality, improving equipment precision, and fine-tuning process controls. Through methods like Design of Experiments (DOE) and real-time monitoring systems, manufacturers can optimize drilling parameters to achieve the best balance between quality and cost.

What is the Non-Linear Relationship Between Layer Count and Drilling Quality?

Theoretical Analysis: Why Layer Count and Drilling Quality Have a Non-Linear Inverse Relationship

The relationship between the number of stacked layers (layer count) and drilling quality is non-linear and negative. As the number of layers increases, the drill bit experiences uneven resistance from each layer. This irregular resistance leads to drill deflection, misalignment, and uneven hole walls. However, this effect is not linear—doubling the number of layers doesn’t necessarily double the difficulty or the defects. The impact increases exponentially as more layers are stacked, especially in high-density interconnect (HDI) boards. At a certain point, drilling quality deteriorates faster due to compounded factors such as drill bit wear, heat generation, and chip removal difficulties.

For example, drilling through 8 layers might result in minor misalignment, but drilling through 16 layers could cause significant quality issues, as the resistance from each additional layer worsens the drill's precision. The key takeaway is that the negative effects on drilling quality grow faster than the layer count.

How Can Equipment Precision and Process Control Improve the Balance?

The Role of Equipment Precision and Process Control

Improving the balance between layer count and drilling quality requires enhancing both equipment precision and process control. High-precision drilling machines can reduce drill bit deflection and improve hole alignment, even when drilling through multiple layers. Additionally, fine-tuning drilling parameters, such as speed, feed rate, and cooling methods, helps control temperature and tool wear, which are critical factors at higher layer counts. By optimizing these parameters, manufacturers can achieve a better balance, minimizing the negative effects of additional layers on drilling quality.

For example, using high-quality drill bits (like tungsten carbide with a nano-coating) and adjusting the feed rate during the drilling process can help mitigate the increased challenges posed by a high layer count. The use of advanced cooling systems and chip removal mechanisms can also help manage heat and debris, which is particularly important when drilling through many layers.

How to Optimize the "Quality-Cost" Balance Using Design of Experiments (DOE)?

Design of Experiments (DOE) Method: Finding the Optimal Solution for Different Layer Counts

Design of Experiments (DOE) is a powerful method for determining the optimal drilling parameters at different layer counts. Through systematic testing and experimentation, DOE helps identify the most effective combinations of drilling speed, feed rate, cooling techniques, and tool types for each specific layer count. By adjusting these factors and observing their effects on drilling quality and cost, manufacturers can find the ideal balance for their production needs.

For example, a DOE study might reveal that for a 4-layer PCB, higher feed rates can be used without compromising quality, but for a 12-layer PCB, slower feed rates and additional cooling are required to maintain hole accuracy and surface smoothness. This method helps manufacturers optimize both quality and cost by reducing the time spent on trial and error.

How Can Real-Time Warning Systems Help Monitor Drilling Parameter Drift?

Application of Real-Time Monitoring Systems: Warning Drifting Parameters

Real-time monitoring systems play a critical role in maintaining drilling quality during production. These systems track drilling parameters such as speed, temperature, and tool wear in real-time, alerting operators when parameters begin to drift from the optimal range. Early detection of parameter drift allows manufacturers to make immediate adjustments, preventing drilling defects like misalignment or rough hole walls.

For example, a real-time system can monitor the drill bit’s wear level and automatically adjust the feed rate or speed when the bit starts to lose sharpness. This helps maintain consistent drilling quality, even as the process progresses, ensuring that layer count does not negatively impact hole precision. Regular use of real-time monitoring can significantly improve the overall quality of drilled holes and reduce production defects.

Conclusion

The number of stacked layers in PCB manufacturing directly impacts drilling quality, with challenges such as misalignment, rough hole walls, and increased drill wear becoming more pronounced as layer counts rise. Optimizing process controls and utilizing advanced drill bit technologies, such as tungsten carbide and step drills, are essential to maintaining high-quality standards. By fine-tuning drilling parameters and using real-time monitoring systems, manufacturers can achieve a balance between layer count, drilling quality, and production efficiency. Looking ahead, innovations like AI-driven optimization, better cooling techniques, and advanced drill materials will continue to improve drilling precision. As the demand for more complex PCBs grows, companies like PCBMASTER, a seasoned PCB supplier, are at the forefront of adopting these cutting-edge technologies to enhance production capabilities and meet the evolving needs of the industry.

FAQs

1. Why Is the Hole Quality of the Bottom Layer Worse When Stacking PCB Layers? How Can It Be Improved?

Reasons:

The hole quality of the bottom layer in a multi-layer PCB tends to be the worst due to a combination of factors: drill bit wear, difficult chip removal, and insufficient support. As the drill passes through each additional layer, it wears down more, causing increased resistance and leading to poor hole formation. Furthermore, when drilling through multiple layers, the chips produced by the drilling process have to travel a longer path to exit the hole, which increases the likelihood of chip clogging and rough hole walls. Additionally, the lack of adequate support beneath the bottom layer can cause tear-out and deformation of the copper and resin.

Improvement Measures:

To improve the hole quality of the bottom layer, new or high-quality backing plates should be used. This provides better support during drilling, reducing the likelihood of tear-outs or burrs at the hole exit. Optimizing drilling parameters like feed rate, rotational speed, and cooling settings also helps minimize heat buildup and tool wear, improving overall hole quality. Additionally, employing a peck drilling strategy, which involves withdrawing the drill bit periodically, can help improve chip removal and reduce the chances of debris buildup.

2. How to Control Burrs and Edge Flaps During Drilling?

Reason Analysis:

Burrs and edge flaps (or fuzzing) are common issues in PCB drilling, particularly in multi-layer boards. These defects occur due to the high friction and heat generated during drilling, especially when the drill bit exits the material. When drilling through multiple layers, the friction at each layer causes the drill bit to push material out, resulting in raised edges or small particles that can interfere with electrical connections. The drill bit’s wear and misalignment can also cause uneven drilling at the hole entry or exit points, leading to these defects.

Optimization Methods:

To minimize burrs and edge flaps, the feed rate and rotational speed should be carefully adjusted. Slower feed rates can reduce friction and heat, resulting in smoother edges. Additionally, using cover plates can help reduce the occurrence of burrs at the entry point, while backing plates provide support at the exit, reducing tear-out. Ensuring proper chip removal through better vacuum or air blow systems is also critical in minimizing debris that could cause burrs. Lastly, using higher-quality drill bits with coatings like nano-coating can help reduce friction and improve overall hole smoothness.

3. How to Extend Drill Bit Life After Increasing Layer Count?

Reason Analysis:

As the number of stacked layers increases, the total thickness the drill bit has to penetrate also increases. This causes the drill bit to experience more wear and tear, especially when working with high-Tg materials or ceramic-filled PCBs, which are more abrasive and difficult to drill. The increased wear on the drill bit results in reduced accuracy, higher chances of bit breakage, and poor hole quality over time. This effect is more pronounced when dealing with materials that are harder or more heat-sensitive.

Measures to Extend Life:

To extend the life of the drill bit, high-performance drill bit materials such as tungsten carbide with nano-coating should be used. These materials resist wear and heat better, allowing for longer operational life and more consistent drilling. Optimizing the cooling and heat dissipation systems is also essential, as excessive heat is a leading cause of drill wear. Using peck drilling techniques can help reduce heat buildup by periodically withdrawing the drill, allowing it to cool. Regularly replacing or sharpening drill bits is another practical measure to ensure consistent drilling quality.

4. How to Improve Hole Position Accuracy, Especially in HDI Boards?

Methods to Improve Precision:

Improving hole position accuracy, particularly in HDI (High-Density Interconnect) boards, requires precise control over the drilling process. First, optimizing drilling parameters is key. This includes adjusting feed rate, rotational speed, and drill bit size based on the layer count and material type to ensure uniform pressure and resistance across all layers. Improving chip removal systems ensures that debris doesn’t affect the hole position by obstructing the drill bit. Regular hole position monitoring, using CMM (Coordinate Measuring Machines) or laser-based measurement tools, helps ensure hole placement remains within design specifications.

Additionally, using cover plates can help improve hole accuracy at the entry point by stabilizing the surface during drilling, preventing displacement that could cause misalignment. Step drills can also be employed for high-density boards to reduce drill bit deflection and increase overall precision.

5. How to Adjust Drilling Process According to Different Material Characteristics?

Material Differences:

Different PCB materials require distinct adjustments in drilling parameters. For instance, FR-4 is a relatively easy material to drill compared to more challenging materials like high-Tg boards, ceramic-filled boards, or metal-core PCBs. These tougher materials produce more heat and cause faster drill wear, so the drilling parameters must be adjusted accordingly.

Adjusting Parameters:

For materials like FR-4, the standard feed rates and rotational speeds work well, but for harder materials like high-Tg or ceramic-filled PCBs, slower feed rates and lower rotational speeds are recommended to reduce heat and prevent drill wear. Also, adjusting cooling strategies (such as using liquid cooling or air jets) is essential for tougher materials to manage the additional heat produced. Step drills and tungsten carbide drill bits with nano-coating are highly recommended for challenging materials, as they provide better heat resistance and durability. For each material, manufacturers should test various drilling settings to find the optimal combination for quality and efficiency.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!