The Complete Guide to LCC Packaging: Key Features, Applications, Benefits, and Challenges

As the need for compact and reliable electronic components intensifies, innovative packaging solutions like the Leadless Chip Carrier (LCC) have gained prominence. LCC is a type of semiconductor package that eliminates the traditional leads, using metal pads on the edges or bottom of a flat, square body instead. This leadless design not only saves space but also enhances durability, making it ideal for applications where reliability is critical. From medical implants to aerospace systems, the LCC packaging provides a robust and efficient solution for industries demanding high performance in challenging environments.

Key Features and Design Characteristics of LCC Packages

Leadless Design

LCC uses a unique design where it eliminates the traditional pins seen in most electronic components. Instead, it has metal pads on the sides or bottom of its flat, square body. This design is stronger and less prone to damage. Traditional leaded packages, like QFP (Quad Flat Package) or DIP (Dual Inline Package), have small pins that can bend or break, especially in rough environments. By removing the pins, LCC packages are more durable and able to withstand physical stress, such as vibration and movement. For example, LCCs are widely used in automotive electronics, where vibrations are common. With no leads to bend, they provide a longer-lasting and more reliable option in demanding conditions.

Flat and Compact Profile

LCC packages are designed to be thin and compact, with a thickness that typically ranges between 1mm to 3mm. This makes them an excellent choice for devices where space is limited, like wearables (e.g., smartwatches) and smartphones. The low profile of LCC packages allows for easier integration into compact systems without taking up too much space. Additionally, their slim design makes them suitable for industries where miniaturization is crucial, such as medical devices and IoT (Internet of Things) sensors. A thinner package also means the device can have a sleeker appearance, which is essential for consumer electronics that prioritize aesthetics.

Material and Enclosure Options

LCC packages are available in both ceramic and plastic materials. Ceramic LCCs are often used in high-performance applications, such as aerospace and medical devices, because they provide better protection against environmental factors like moisture and dust. These packages are airtight, preventing contaminants from affecting the internal components. On the other hand, plastic LCCs are more cost-effective and are typically used in consumer electronics and other less-demanding applications. While plastic LCCs still offer good protection, they are not as resistant to extreme environmental conditions as ceramic options. The choice of material depends on the specific needs of the application: ceramic LCCs are better suited for harsh, high-risk environments, while plastic LCCs are suitable for everyday devices.

Hermetic Sealing for Critical Applications

One of the standout features of certain LCC packages is hermetic sealing. This means that the package is airtight, which prevents moisture, dust, and other contaminants from reaching the sensitive electronics inside. This is particularly important for applications like medical implants (e.g., pacemakers) and aerospace systems, where exposure to the environment could cause failure or health risks. Ceramic LCCs, in particular, are often hermetically sealed, ensuring that the internal chip remains protected from external factors. For instance, a pacemaker that uses a hermetically sealed ceramic LCC package is protected from bodily fluids and external contamination, ensuring its reliable operation inside the human body for years.

Heat Transfer Efficiency

LCC packages are also known for their superior heat dissipation capabilities. The flat, leadless design allows the package to sit directly on the printed circuit board (PCB), which helps transfer heat away from the chip more efficiently. This direct contact improves thermal management, allowing the chip to operate at lower temperatures. Compared to traditional leaded packages, LCCs can transfer heat up to 30% faster, which is crucial for high-performance applications that generate a lot of heat, such as RF (Radio Frequency) devices or high-speed processors. Better heat dissipation ensures that these components run more efficiently and reduces the risk of overheating, improving their overall lifespan and reliability.

Applications of LCC Packages in Different Industries

Aerospace

LCC packages are essential in the aerospace industry, where reliability and performance under extreme conditions are crucial. They are commonly used in satellites, radar systems, and other aerospace components that must function flawlessly in harsh environments, such as extreme temperatures and vacuum conditions.

LCC packages are designed to withstand temperature ranges from -55°C to 125°C, making them perfect for space applications, where devices experience dramatic temperature fluctuations. For example, in satellites, LCC packages help protect sensitive electronics from the harsh conditions of space, such as intense radiation and extreme temperatures. This ensures that critical components, such as communication systems and sensors, continue to operate reliably for long periods in space.

Medical and Healthcare Devices

In the medical field, LCC packages are widely used in devices like pacemakers, implantable medical devices, and medical imaging tools. The most important feature of LCC packaging in these applications is its hermetic sealing, which prevents harmful contaminants like moisture, dust, and bodily fluids from reaching the sensitive electronics inside.

For instance, pacemakers, which are implanted in the human body, require airtight sealing to protect the electronic components from bodily fluids that could cause malfunctions. The hermetic sealing ensures that the device remains safe and functional over many years. Similarly, portable medical devices like ultrasound machines benefit from LCC packaging because it helps protect them from moisture and dust, which could affect their performance and accuracy.

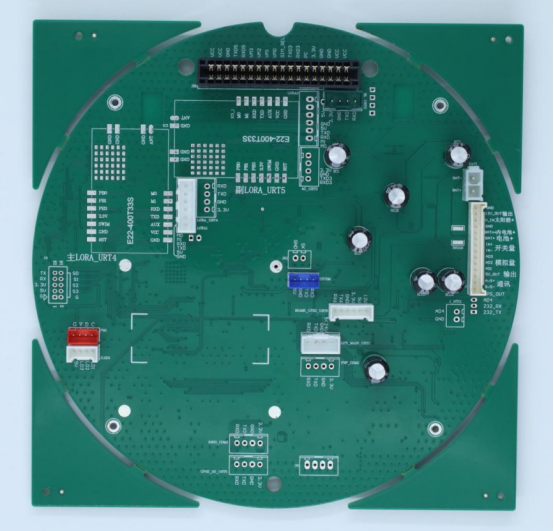

Industrial and IoT Systems

LCC packages are increasingly used in industrial and IoT applications, especially in sensors and devices that must perform in rugged, challenging environments. These environments often include exposure to vibration, dust, moisture, and other harsh conditions, all of which can damage sensitive electronics.

For example, temperature, humidity, and motion sensors used in factories rely on LCC packaging to protect the internal components from environmental stress. These sensors are critical in monitoring and optimizing factory equipment, and the durability of LCC packages ensures they continue to function reliably even in rough conditions. The robust nature of LCCs makes them ideal for use in industrial automation, smart manufacturing, and other IoT applications, where devices need to be both reliable and long-lasting.

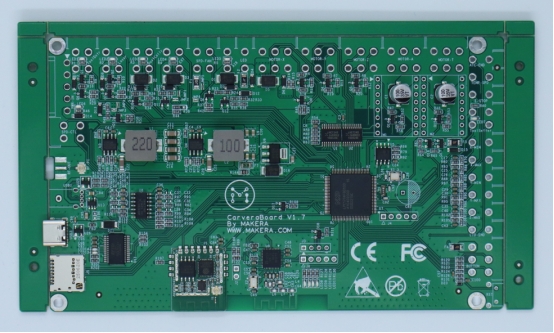

Telecommunications and RF Technology

LCC packages are crucial in the telecommunications sector, particularly for components that handle high-frequency signals, such as those used in 5G base stations and RF (Radio Frequency) transceivers. One of the key advantages of LCC packaging is its ability to minimize signal loss, which is especially important in high-frequency communication systems.

In 5G networks, for instance, LCCs help improve the performance of base stations by ensuring minimal signal degradation, even at high data transmission rates. The compact and leadless design of LCC packages reduces the path for signals, helping to maintain strong, clear communication. Similarly, RF transceivers, which are used in devices like mobile phones, wireless routers, and satellite communication systems, benefit from the low signal loss and high-frequency performance of LCC packaging.

Advantages of LCC Packaging

Space Efficiency

One of the main advantages of LCC packaging is its ability to save space. LCCs offer up to 30% smaller footprint compared to traditional leaded packages, such as QFP or DIP (Dual Inline Package). This makes LCCs ideal for applications where space is limited, such as in consumer devices, wearables, and embedded systems.

For example, in a smartwatch, space is a critical factor. By using an LCC package, manufacturers can save valuable space on the circuit board, allowing for smaller, sleeker designs without compromising performance. This space-saving benefit also makes LCCs perfect for other compact devices like fitness trackers, portable medical devices, and IoT sensors, where the size of components must be minimized without affecting functionality.

Durability and Reliability

LCC packages are known for their durability and reliability, especially in harsh environments. Unlike traditional packages that have pins which can bend or break, LCCs do not have pins. Instead, they use metal pads, which are much more robust. This design makes LCCs more resistant to physical damage, such as bending, which is a common issue with leaded packages in environments where vibration or physical stress is frequent.

For example, LCCs are widely used in automotive applications where high vibrations are common. A sensor in an automotive engine might be exposed to constant vibrations, but with the pinless design of LCCs, the risk of component failure is greatly reduced. Similarly, in aerospace applications, where equipment is exposed to extreme temperatures and vibrations, LCCs provide a more reliable solution, ensuring the integrity of sensitive components.

Signal Integrity and High-Frequency Performance

LCC packages excel in minimizing signal loss, which is especially beneficial in RF and communication devices. The design of LCCs ensures that the signal path is as short as possible, reducing the chances of signal degradation or loss. This is crucial for devices that require high-frequency performance, such as wireless communication systems, 5G base stations, and other data transmission technologies.

For example, in a 5G base station, LCC packaging helps maintain strong, clear signals over long distances and at high frequencies. Because LCCs have a short, direct connection between the chip and the PCB, they reduce signal loss and improve overall communication performance. This makes LCCs ideal for applications in telecommunications, satellite communication, and other industries that rely on high-speed data transfer and low signal loss.

Long-Term Protection for Sensitive Components

Another major advantage of LCC packaging, particularly ceramic LCCs, is their ability to protect sensitive components over time. Ceramic LCCs are hermetically sealed, which means they are airtight and shield the internal chip from harmful environmental factors such as moisture, dust, and chemicals. This protection is essential in applications where reliability is critical, such as in medical devices, aerospace, and industrial sensors.

For example, in medical implants like pacemakers, the hermetic sealing of the LCC package prevents bodily fluids from reaching the electronic components inside. This ensures the device continues to function safely and reliably for many years, even when exposed to the human body’s environment. Similarly, in aerospace systems, ceramic LCCs protect sensitive electronics from the vacuum of space and extreme temperatures, allowing them to perform accurately over long periods in space missions.

Challenges and Limitations of LCC Packaging

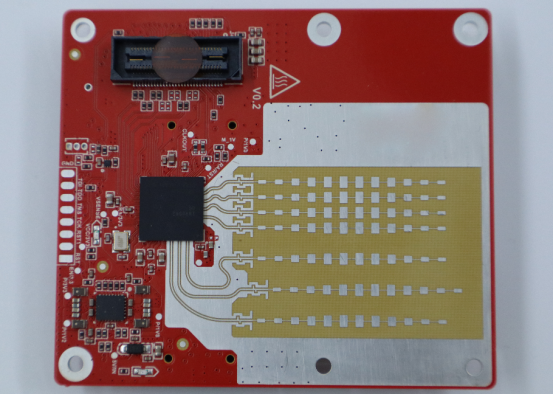

Difficult Inspection and Maintenance

One of the key challenges of LCC packaging is the difficulty in inspecting and maintaining the components once they are assembled. Unlike traditional leaded packages, which have visible pins that can be easily checked, LCC packages have metal pads located on the underside or edges of the package. These pads are hidden once the component is mounted on a PCB , making it hard to visually inspect the solder joints.

To address this, advanced inspection techniques are required, such as X-ray imaging. X-rays can be used to examine the quality of the solder joints and check for potential defects that may not be visible to the naked eye. This added complexity in the inspection process means that specialized equipment and expertise are needed, which can increase the cost and time required for quality control.

Soldering and Assembly Complexity

The soldering process for LCC packages is more challenging compared to traditional packages due to the small size of the pads—typically ranging from 0.2mm to 0.5mm. These tiny pads make it difficult to apply solder manually, as the space between the pads is very limited, increasing the risk of solder bridges or cold joints.

To ensure high-quality assembly, LCC packages require precise reflow ovens and automated soldering systems. Reflow soldering uses controlled heat to melt the solder paste and attach the component to the PCB. However, achieving the correct temperature profile is critical, as too much heat can damage the package, while too little heat can lead to weak solder joints. Automated systems are typically needed to guarantee consistency and minimize defects, which adds to the cost and complexity of assembly.

High Cost of Ceramic LCCs

While LCC packages offer many advantages, they can be more expensive than other packaging types, especially ceramic LCCs. Ceramic packages are often chosen for their superior protection against environmental factors like moisture and extreme temperatures. They are hermetically sealed, which makes them ideal for high-reliability applications such as medical implants, aerospace, and military devices.

However, ceramic LCCs can be up to 2–3 times more expensive than their plastic alternatives, such as QFN (Quad Flat No-lead) packages. The higher cost of ceramic LCCs is mainly due to the materials used and the manufacturing process, which involves more complex techniques, such as the use of specialized ceramics and advanced sealing methods. For applications that do not require the extreme durability of ceramic, plastic LCCs offer a more affordable solution, although they may not provide the same level of protection.

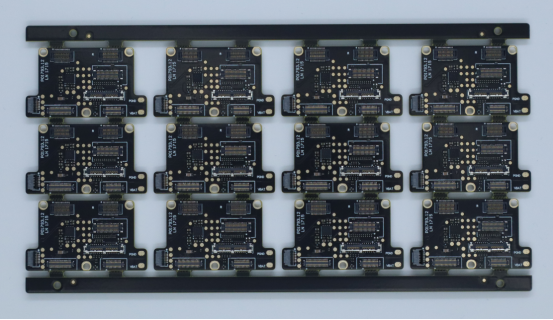

Not Suitable for Hand Assembly

Another limitation of LCC packaging is that it is not suitable for manual assembly. The small pad sizes and precise soldering requirements make LCC packages difficult to handle without specialized equipment. For example, hand soldering, which is often used for smaller production runs or prototypes, is impractical due to the tiny pads that are hard to reach and manipulate by hand.

Industrial manufacturing environments, on the other hand, rely on automated systems for LCC assembly. These systems are designed to handle the precision required for soldering small pads and placing components onto the PCB. As a result, companies must invest in automated assembly lines or advanced robotic equipment, which can be costly and require significant upfront investment.

Comparison of LCC with Other Packaging Types

LCC vs. QFP

Size, Performance, and Footprint Comparison

LCC and QFP are both popular packaging options, but they differ significantly in size and design. LCC packages are typically smaller and more compact than QFPs, with no external leads, giving them up to 30% smaller footprint. This makes LCC a better choice for applications where space is limited, such as in wearable devices or IoT systems. QFP packages, on the other hand, have leads on all four sides, which take up more space on the PCB.

Durability, Thermal Management, and Application Suitability

When it comes to durability, LCCs offer a more robust design due to the absence of leads, which are prone to bending or breaking, especially in high-vibration environments. This makes LCC packages ideal for industries like aerospace, automotive, and medical devices, where reliability and longevity are essential. In contrast, QFPs, with their exposed leads, may not be as durable under harsh conditions.

Thermal management is another area where LCCs have an advantage. The flat design of LCC packages allows for better heat dissipation, as it sits directly on the PCB, transferring heat more efficiently than QFPs. This is crucial for high-performance applications that generate a lot of heat, such as RF devices and power management systems.

In terms of application suitability, LCCs are more suitable for compact, high-reliability applications, while QFPs are often used in larger devices with less stringent space or durability requirements.

LCC vs. QFN

Structural Differences and Packaging Approaches

LCC and QFN packages share similarities in that both use leadless designs, but they differ in structure. LCCs typically have metal pads on the bottom or edges, while QFNs use pads located on the underside of the package. QFNs have a similar size and form factor as LCCs but often have more robust connections, especially for high-frequency applications.

QFNs are more common in standard consumer electronics because they provide easy mounting and reliable solder joints due to their flat structure. LCCs, however, are often used in more specialized applications where durability, heat transfer, and signal integrity are more critical.

Suitability for High-Frequency and High-Reliability Applications

When it comes to high-frequency and high-reliability applications, LCC packages are the preferred choice. The flat profile and direct contact with the PCB allow for superior heat management and reduced signal loss, making LCCs ideal for RF devices, aerospace, and medical implants.

In contrast, while QFNs are suitable for general consumer electronics, they may not offer the same level of durability or thermal management needed in high-performance or extreme environment applications. For instance, LCCs are better suited for medical devices like pacemakers and aerospace components where hermetic sealing and long-term reliability are critical.

Comparison Table

Feature LCC QFP QFN Size/Footprint 30% smaller footprint than QFP Larger footprint due to external leads Similar size to LCC, but leads are on the bottom Durability High durability, no leads to bend or break Leads can bend, less durable in harsh environments Moderate durability, no leads but requires precision soldering Thermal Management Excellent heat dissipation, direct PCB contact Moderate, less efficient than LCC Good heat management, but not as efficient as LCC Signal Integrity High, minimal signal loss Moderate, leads can introduce signal loss High, good for high-frequency applications Application Suitability Ideal for compact, high-reliability, and harsh environments (medical, aerospace) Used in larger consumer devices where space is not a primary concern Suitable for general electronics, but not ideal for extreme conditions Assembly Complexity Requires specialized automated assembly Easier to assemble, manual soldering possible Requires precision assembly and automated systems

Conclusion

LCC packaging offers significant advantages in terms of durability, space efficiency, and thermal management, making it ideal for high-performance applications in sectors like aerospace, medical devices, and telecommunications. While there are challenges such as inspection difficulties and assembly complexity, the benefits of LCC packaging make it a top choice for many demanding industries.

For those looking to source high-quality PCBs and integrate LCC packages seamlessly, PCBMASTER is a trusted supplier. As an expert in PCB manufacturing, PCBMASTER provides reliable, precise, and durable solutions that help ensure your LCC components perform at their best in any application.

FAQs

What makes LCC packaging ideal for harsh environments?

LCC packages are designed for extreme durability, offering high resistance to moisture, vibration, and temperature fluctuations. These features make LCC packaging highly suitable for demanding applications in industries like aerospace, military, and medical fields, where components must perform reliably under challenging conditions.

Why is LCC packaging more expensive than traditional leaded packages?

Ceramic LCCs are more expensive than traditional leaded packages due to the advanced materials and manufacturing processes involved. Ceramic offers superior protection, including hermetic sealing, which is essential for applications requiring high reliability, such as medical implants and aerospace systems. The precision required in producing ceramic LCCs contributes to the higher cost compared to plastic alternatives.

Can LCC packages be manually soldered?

No, LCC packages typically require automated soldering techniques. The small pad sizes (ranging from 0.2mm to 0.5mm) make manual soldering impractical, as it would be too difficult to apply solder accurately. Automated systems, such as reflow ovens, are necessary to ensure proper soldering and avoid defects.

What are the main benefits of ceramic LCCs over plastic LCCs?

Ceramic LCCs provide superior hermetic sealing, which is crucial for protecting sensitive electronics from moisture, dust, and other contaminants. This makes them ideal for high-reliability applications, such as medical implants or aerospace systems, where environmental protection is essential for long-term functionality.

Are there alternatives to LCC packaging for space-constrained devices?

Yes, alternatives like QFN and WLCSP (Wafer-Level Chip Scale Package) are also used in compact designs. However, LCC packaging offers unique advantages in durability, thermal management, and signal integrity, making it a preferred choice in applications where reliability in harsh environments is a key requirement.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!