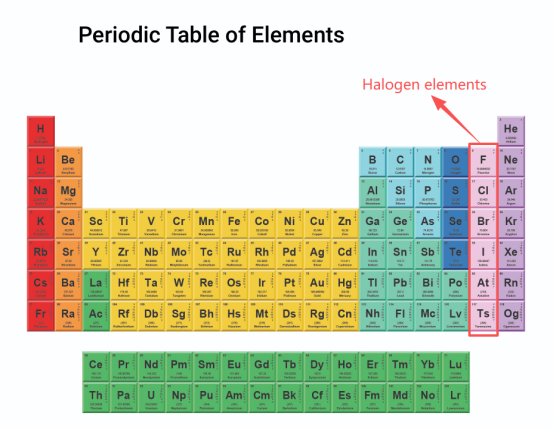

Halogenated vs. Halogen-Free FR-4: Differences and How to Choose for Your PCB?

FR-4 is one of the most commonly used materials in printed circuit boards (PCBs). It is a type of fiberglass that offers excellent electrical insulation and mechanical strength, making it ideal for various electronic devices. However, not all FR-4 materials are the same. The two main types, halogenated and halogen-free FR-4, differ in their chemical composition, environmental impact, and regulatory compliance.

Choosing the right type of FR-4 is crucial for performance, safety, and environmental reasons. Halogenated FR-4 contains halogens like chlorine or bromine, which improve its flame-retardant properties but can pose risks during disposal or recycling. On the other hand, halogen-free FR-4 eliminates these chemicals, making it safer for the environment but typically at a higher cost.

As industries increasingly prioritize sustainability and stricter regulations, it’s essential to understand the differences between these materials. This comparison can guide your decision when selecting the right FR-4 for your specific application, whether it's for consumer electronics, medical devices, or high-performance products.

What is Halogenated FR-4?

Definition and Composition of Halogenated FR-4

Halogenated FR-4 is a type of fiberglass used in PCBs that contains halogen elements, like chlorine or bromine. These halogens are added to improve the flame-retardant properties of the material, helping it resist catching fire when exposed to high temperatures or electrical faults.

The core composition of halogenated FR-4 includes epoxy resin and glass fiber. However, the presence of halogens, especially in the form of flame retardants, distinguishes it from other types of FR-4. These halogens help meet safety standards for fire resistance, but they also have environmental implications during disposal or recycling.

Pros and Cons of Halogenated FR-4

Advantages:

Cost-effectiveness: Halogenated FR-4 is often more affordable than halogen-free alternatives. This is one of the main reasons it remains popular in industries where cost efficiency is a priority.

Widespread use: Due to its cost and flame-retardant properties, halogenated FR-4 is widely used in consumer electronics, automotive systems, and many other sectors.

Good electrical insulation: It provides strong electrical insulation, making it ideal for PCBs that need to maintain stable operation even in high-voltage or high-frequency environments.

Disadvantages:

Environmental concerns: Halogens like chlorine and bromine can be harmful to the environment, especially when the materials are incinerated or improperly disposed of. These substances can release toxic gases, contributing to air pollution.

Health risks: During the manufacturing, disposal, or recycling of halogenated FR-4, harmful chemicals can be released. These pose risks to human health, particularly for workers involved in handling the material.

Applications of Halogenated FR-4

Halogenated FR-4 is commonly used in industries that prioritize cost-effectiveness and flame resistance over environmental impact. Some of the most typical applications include:

Consumer Electronics: It’s widely used in devices like smartphones, computers, and televisions due to its good electrical properties and cost efficiency.

Automotive Industry: Halogenated FR-4 is often found in PCBs for automotive electronics, including systems for controlling lights, airbags, and engine management.

Industrial Equipment: The material is also used in industrial machinery and control systems where high-performance and safety are required.

In these industries, the balance of cost, performance, and flame resistance makes halogenated FR-4 an appealing choice. However, as environmental concerns grow, some companies are starting to shift towards halogen-free alternatives.

What is Halogen-Free FR-4?

Definition and Composition of Halogen-Free FR-4

Halogen-free FR-4 is a type of fiberglass used in PCBs that does not contain halogenated flame retardants, such as chlorine or bromine. In place of these halogens, halogen-free FR-4 relies on alternative flame-retardant materials to achieve the necessary fire resistance. These alternatives include compounds like phosphorous-based or silicon-based flame retardants, which are considered safer for the environment and human health.

The basic composition of halogen-free FR-4 still includes epoxy resin and glass fiber but avoids the use of harmful chemicals associated with halogenated flame retardants. This makes it a more eco-friendly choice while still maintaining good electrical insulation and mechanical strength.

Pros and Cons of Halogen-Free FR-4

Advantages:

Environmentally Friendly: Halogen-free FR-4 is designed to be safer for the environment. It does not release toxic gases when incinerated, making it easier to dispose of responsibly compared to halogenated materials.

Safer for Handling and Disposal: Without halogens, halogen-free FR-4 is less harmful to workers during production and to the environment during the disposal and recycling process. This makes it a safer material choice for both manufacturers and end-users.

Compliant with Regulations: Halogen-free FR-4 meets various environmental standards, including RoHS (Restriction of Hazardous Substances), which restricts the use of hazardous materials in electronics. This makes it a preferable option for industries that need to comply with global regulations.

Disadvantages:

Typically More Expensive: Halogen-free FR-4 tends to be more costly than its halogenated counterpart, mainly due to the higher price of alternative flame retardants and the more complex production process.

Slightly Less Widespread Availability: Because halogen-free FR-4 is not as commonly used as halogenated FR-4, it may be harder to find in some markets. This can also lead to longer lead times for manufacturers needing to source the material.

Applications of Halogen-Free FR-4

Halogen-free FR-4 is increasingly used in industries where environmental sustainability, health safety, and regulatory compliance are critical. Some common applications include:

Medical Electronics: In medical devices, safety and environmental impact are top priorities. Halogen-free FR-4 is often used in medical PCBs to ensure compliance with safety regulations and to avoid harmful chemicals in devices that come into direct contact with patients.

Aerospace: The aerospace industry requires materials that are not only reliable but also environmentally safe. Halogen-free FR-4 is preferred in this sector due to its safety in handling and disposal, as well as its high-performance capabilities.

Green Electronics: Companies in the green electronics sector, which focuses on sustainable product design, often use halogen-free FR-4 to meet eco-friendly standards and reduce the environmental footprint of their products.

In these industries, halogen-free FR-4 plays a crucial role in ensuring that products are both high-performing and aligned with stringent safety and environmental regulations. It is especially important for businesses that are striving to reduce their ecological impact while maintaining the reliability and performance of their PCBs.

What Are the Key Differences Between Halogenated and Halogen-Free FR-4?

The key differences between halogenated and halogen-free FR-4 are in their chemical makeup, environmental impact, and performance. Halogenated FR-4 contains halogens like chlorine or bromine for flame resistance but can release harmful toxins during disposal. Halogen-free FR-4 uses safer, eco-friendly flame retardants, making it better for the environment and regulatory compliance, though it’s usually more expensive.

Chemical Composition and Flame Retardants

Halogenated FR-4 and halogen-free FR-4 differ mainly in the flame retardants they contain.

Halogenated FR-4 contains halogen elements like chlorine or bromine, which are added to the material to make it flame-resistant. These halogenated compounds work by interfering with the combustion process, slowing down the spread of fire when the material is exposed to heat.

Halogen-free FR-4, as the name suggests, does not use halogenated flame retardants. Instead, it relies on phosphorus-based or silicon-based alternatives to achieve similar flame-retardant properties. These alternatives are generally safer for the environment and human health, as they do not release harmful toxins when the material is burned or disposed of.

While both types of FR-4 offer fire resistance, halogen-free FR-4 avoids the environmental and health risks associated with halogens, which are a key advantage in industries that focus on sustainability.

Environmental Impact

Halogenated FR-4 materials are harmful to the environment, especially when they are disposed of improperly. When incinerated, halogenated materials can release toxic substances, such as dioxins and furans, which are known to be carcinogenic and persistent in the environment. These chemicals can accumulate in ecosystems and pose serious risks to wildlife and human health. Additionally, recycling halogenated materials can be challenging due to the toxic fumes they emit.

On the other hand, halogen-free FR-4 offers environmental benefits. By using non-halogenated flame retardants, it eliminates the risks associated with toxic byproducts during disposal. Halogen-free FR-4 is more eco-friendly and sustainable, helping manufacturers comply with green standards like RoHS (Restriction of Hazardous Substances). RoHS compliance is crucial for reducing the use of harmful materials in electronic products, and halogen-free FR-4 meets these stringent regulations. This makes halogen-free FR-4 the better choice for industries focused on reducing environmental impact and meeting sustainability goals.

Performance Differences

Both halogenated FR-4 and halogen-free FR-4 perform well in most common electronic applications, but their performance can differ under extreme conditions.

Temperature Resistance: Halogenated FR-4 typically has better thermal stability, meaning it can withstand higher temperatures before breaking down. This makes it a popular choice for applications where heat resistance is critical, such as automotive electronics or high-power devices.

Humidity Resistance: Halogen-free FR-4 performs better in humid or moist environments. The flame-retardants in halogen-free FR-4 are more stable under high humidity, whereas halogenated materials may degrade more easily, affecting the material’s performance and longevity in humid conditions.

Durability and Reliability: Both materials are reliable, but halogen-free FR-4 is gaining ground in high-performance sectors where both reliability and environmental safety are crucial. For example, medical devices and aerospace electronics increasingly prefer halogen-free FR-4 due to its low toxicity and regulatory compliance. However, halogenated FR-4 is still the preferred material in industries where cost and thermal resistance are more important.

Comparison Table: Halogenated vs. Halogen-Free FR-4

| Feature | Halogenated FR-4 | Halogen-Free FR-4 |

| Chemical Composition | Contains halogens like chlorine or bromine | Free from halogens; uses alternative flame retardants (e.g., phosphorus, silicon) |

| Flame Retardants | Halogenated compounds for fire resistance | Non-halogenated compounds for fire resistance |

| Environmental Impact | Can release toxic gases (e.g., dioxins) during disposal | Safer for disposal; no toxic byproducts |

| Health & Safety | Potentially hazardous during production and disposal | Safer for handling and disposal; compliant with RoHS |

| Cost | Typically more affordable | More expensive due to the cost of alternative flame retardants |

| Temperature Resistance | Higher thermal stability, suitable for high-temperature environments | Slightly lower thermal stability |

| Humidity Resistance | Can degrade in humid conditions | Better resistance to moisture and humidity |

| Durability & Reliability | Proven durability in various applications | Gaining traction in high-performance applications, but newer in certain industries |

What Are the Environmental and Regulatory Implications of Using Halogen-Free FR-4?

Halogen-free FR-4 reduces environmental impact by eliminating harmful toxins in disposal and improving recycling safety. It also ensures compliance with key regulations like RoHS and WEEE, making it a more eco-friendly and sustainable choice for electronics manufacturers.

Environmental Benefits of Halogen-Free FR-4

Halogen-free FR-4 materials provide significant environmental benefits compared to their halogenated counterparts. The most notable advantage is that they reduce the ecological footprint of electronics. Halogenated materials can release harmful toxins, such as dioxins and furans, when disposed of improperly or incinerated. These chemicals persist in the environment, contributing to pollution and harming wildlife.

In contrast, halogen-free FR-4 avoids these harmful byproducts. It uses eco-friendly flame retardants that do not release toxic gases, making it safer to dispose of and easier to recycle. This helps in reducing the environmental impact of electronic waste (e-waste), a growing global concern. By switching to halogen-free materials, manufacturers contribute to reducing pollution and supporting sustainable electronics.

Halogen-free FR-4 also plays a role in helping reduce carbon footprints. Since it is safer to handle and recycle, it leads to fewer harmful emissions during the product lifecycle. This makes it an ideal choice for companies striving for greener production practices and environmental responsibility.

Regulatory Compliance

There are several key global regulations that require the use of halogen-free materials, especially in electronics.

RoHS (Restriction of Hazardous Substances): RoHS is a key regulation that restricts the use of certain hazardous substances, including halogens like bromine and chlorine, in electronic products sold within the European Union. The goal is to reduce toxic waste and ensure safer recycling of electronic components. Halogen-free FR-4 complies with RoHS by eliminating these harmful halogenated flame retardants.

WEEE (Waste Electrical and Electronic Equipment Directive): WEEE is a European Union directive that sets goals for the collection, recycling, and recovery of electronic waste. Halogen-free FR-4 helps manufacturers meet WEEE requirements by using materials that are easier to recycle and do not release toxic chemicals when disposed of.

By using halogen-free FR-4, manufacturers can ensure compliance with these regulations, which is crucial for global market access. This reduces the risk of facing penalties or being banned from selling products in markets that strictly enforce environmental standards.

Moreover, compliance with regulations like RoHS and WEEE not only avoids legal issues but also enhances a company's reputation as a sustainable brand. Many consumers and businesses today are increasingly prioritizing eco-friendly products, and adhering to these standards is a competitive advantage.

What Are the Cost Implications of Choosing Halogen-Free FR-4 Over Halogenated FR-4?

Halogen-free FR-4 is more expensive initially due to costlier flame retardants. However, it can be more cost-effective long-term by saving on regulatory fines, disposal costs, and offering environmental benefits, making it a smart choice for sustainable businesses.

Price Comparison of Halogenated vs. Halogen-Free FR-4

Halogen-free FR-4 is generally more expensive than halogenated FR-4 due to the cost of alternative flame retardants. Halogenated FR-4 uses chlorine or bromine-based compounds, which are typically less expensive and more readily available. These halogenated materials have been in use for a longer time, and their manufacturing processes are well-established, keeping costs lower.

In contrast, halogen-free FR-4 relies on phosphorus-based or silicon-based flame retardants, which are often more costly. These materials are not as widely produced as halogenated compounds, and their production processes can be more complex. Additionally, the demand for halogen-free FR-4 is still growing, which can result in higher prices due to limited supply.

Overall, the raw material costs and specialized manufacturing processes for halogen-free FR-4 contribute to its higher price compared to traditional halogenated FR-4.

Cost-Effectiveness in the Long Run

Although halogen-free FR-4 has a higher initial cost, it can be more cost-effective in the long run due to several factors.

Regulatory Compliance: Halogen-free FR-4 helps manufacturers meet global environmental regulations like RoHS and WEEE, which restrict the use of hazardous substances in electronic products. By using halogen-free materials, manufacturers avoid potential penalties or fines for non-compliance with these regulations, which can be costly.

Lower Disposal Costs: Halogen-free FR-4 is safer and easier to recycle compared to halogenated materials, which release toxic gases during incineration. As a result, disposal costs are lower, especially in regions with strict e-waste recycling laws. This reduces the overall environmental cost of the product lifecycle.

Environmental Impact: With growing demand for sustainable products, companies that choose halogen-free FR-4 may benefit from an enhanced brand reputation and the ability to market their products as more eco-friendly. This can lead to higher consumer demand and, ultimately, higher sales.

For industries prioritizing sustainability and regulatory compliance, the higher upfront cost of halogen-free FR-4 is often offset by the long-term savings and benefits.

How Do You Choose Between Halogenated and Halogen-Free FR-4 for Your PCB?

Choosing between halogenated and halogen-free FR-4 depends on factors like cost, regulatory needs, performance, and environmental impact. Halogen-free FR-4 is better for sustainability and compliance, while halogenated FR-4 offers better thermal stability and lower cost. Consider your project’s priorities to make the best choice.

Factors to Consider When Choosing FR-4 Material

Cost vs. Environmental Impact

When deciding between halogenated and halogen-free FR-4, it’s important to balance cost with environmental impact. Halogenated FR-4 is generally more affordable due to the lower cost of halogen-based flame retardants. However, halogen-free FR-4 is more expensive but provides eco-friendly benefits by reducing harmful toxic emissions and ensuring compliance with green regulations like RoHS and WEEE. If your business values sustainability or is working towards reducing its carbon footprint, the extra investment in halogen-free FR-4 might be worth it in the long term, even though it may increase your initial material costs.

Industry Requirements and Regulations

Industry standards like RoHS (Restriction of Hazardous Substances) and UL certifications can greatly influence your choice. If your PCB needs to meet RoHS compliance, which limits the use of hazardous substances (including halogens), then halogen-free FR-4 is a necessary choice. Similarly, certain sectors (e.g., medical, aerospace, or green electronics) may require halogen-free materials to meet regulatory requirements or safety standards. Always ensure your material choice aligns with the standards required for your specific industry to avoid compliance issues and potential legal complications.

End-Product Performance

The performance of your end product is a critical factor in choosing between halogenated and halogen-free FR-4. Halogenated FR-4 generally offers superior thermal stability and can handle high temperatures better than halogen-free FR-4. If your product operates in extreme environments or requires high-temperature performance, halogenated FR-4 may be more suitable. On the other hand, halogen-free FR-4 tends to perform better in moisture and humidity-prone environments and is a reliable choice for products used in medical devices, consumer electronics, or automotive applications where safety and sustainability are key.

Manufacturing Considerations

The choice of material can impact your PCB manufacturing process. Halogenated FR-4 is typically easier to process due to its well-established manufacturing methods and compatibility with existing equipment. It’s widely available, and most manufacturers are experienced with it. However, halogen-free FR-4 may require specialized processing techniques, including more precise temperature control during production to avoid material degradation. Additionally, the higher cost and more limited supply of halogen-free FR-4 could lead to longer lead times or a need for customized equipment. Consider your production capacity and timelines before making a decision.

Step-by-Step Guide to Making the Right Choice

Step 1: Identify the Primary Application and Industry Standards

Begin by understanding your PCB’s primary application. Is it used in a medical device, consumer electronics, or automotive system? Different industries have varying requirements when it comes to regulatory compliance and safety standards. Check if your industry mandates the use of halogen-free materials (for example, RoHS compliance in Europe). This step will help you determine if you must use halogen-free FR-4.

Step 2: Evaluate Environmental and Regulatory Requirements

Next, evaluate the environmental standards and regulatory compliance for your product. If your company needs to meet green certifications or sustainability goals, halogen-free FR-4 is the better option. Similarly, check if your product must comply with RoHS or other regulations that restrict harmful substances. Understanding these requirements will ensure your PCB meets legal and ethical standards.

Step 3: Consider Material Performance and Cost Implications

Assess the performance needs of your PCB. Does it need to withstand high temperatures or humidity? Compare the costs of halogenated vs. halogen-free FR-4, factoring in both the upfront material cost and the long-term environmental and regulatory benefits. Although halogen-free FR-4 might have a higher initial cost, it may be more cost-effective in the long run due to regulatory savings and lower disposal costs.

Step 4: Make an Informed Decision Based on Sustainability, Performance, and Budget

After evaluating all factors, make your decision based on a balance of performance requirements, sustainability goals, and budget. If environmental impact and regulatory compliance are top priorities, halogen-free FR-4 is the best choice. However, if performance under high-temperature conditions and cost are more important, halogenated FR-4 may be more suitable for your needs.

Conclusion

The choice between halogenated and halogen-free FR-4 depends on several key factors, including application, cost, sustainability, and regulatory requirements. Halogenated FR-4 is more cost-effective and offers better thermal stability, making it ideal for high-temperature applications. However, if environmental impact and compliance with green standards like RoHS are a priority, halogen-free FR-4 is the better choice, as it eliminates toxic materials and supports sustainable practices.

Ultimately, your decision should be based on the specific performance needs of your PCB and the industry standards you must meet. Whether you need high durability, environmental safety, or cost efficiency, make sure to evaluate your unique requirements carefully.

At PCBMASTER, we provide both halogenated and halogen-free PCBs, tailored to meet your specific needs, ensuring top-quality solutions for your projects.

FAQs

What is the main difference between halogenated and halogen-free FR-4?

The core difference lies in the chemical composition. Halogenated FR-4 contains halogen elements like bromine or chlorine as flame retardants, which help slow down combustion. In contrast, halogen-free FR-4 uses alternative flame retardants such as phosphorus or silicon to achieve flame resistance. From an environmental impact standpoint, halogenated FR-4 can release toxic chemicals like dioxins when burned, while halogen-free FR-4 is more eco-friendly, as it avoids harmful byproducts during disposal and recycling.

Which industries should use halogen-free FR-4?

Halogen-free FR-4 is preferred in industries that prioritize environmental safety and regulatory compliance, such as:

Medical Devices: Halogen-free FR-4 is ideal for medical electronics, where safety and compliance with RoHS are critical.

Aerospace: The aerospace industry requires high-performance materials that are not only safe but can also withstand demanding environmental conditions.

Green Electronics: Consumer electronics focused on sustainability and meeting environmental standards (e.g., WEEE, RoHS) prefer halogen-free materials for their eco-friendly characteristics.

These industries demand non-toxic, sustainable materials to meet strict environmental regulations and safety standards.

Is halogenated FR-4 cheaper than halogen-free FR-4?

Yes, halogenated FR-4 is typically cheaper than halogen-free FR-4. This is primarily because halogenated flame retardants like bromine and chlorine are less expensive and more widely produced, with well-established manufacturing processes. On the other hand, halogen-free FR-4 uses more costly alternative flame retardants (such as phosphorus or silicon-based compounds) that are less commonly available and require more specialized production, leading to higher material costs.

Can halogen-free FR-4 withstand high temperatures like halogenated FR-4?

Halogen-free FR-4 generally has lower thermal stability compared to halogenated FR-4. Halogenated FR-4 tends to perform better in high-temperature environments due to the stronger flame-retardant properties of halogen compounds. However, halogen-free FR-4 can still withstand moderate heat but may not perform as well in extreme temperature conditions (e.g., high-power electronics or automotive applications) that demand very high heat resistance. If temperature tolerance is a key requirement, halogenated FR-4 is typically the better option.

Is halogen-free FR-4 required by law?

Yes, in certain regions, halogen-free FR-4 is mandated by law due to regulatory requirements like RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment). The RoHS directive restricts the use of hazardous substances, including bromine and chlorine, in electrical and electronic equipment sold within the European Union. This makes halogen-free FR-4 a requirement for many electronic devices sold in these regions. While not all regions have strict laws, industries with high environmental standards often require halogen-free materials to ensure compliance and safety.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!