Complete Guide to Turnkey PCB Assembly: Benefits and Process

As technology continues to evolve, the need for faster, more reliable production methods has never been greater. Turnkey PCB assembly provides a unique solution, offering a comprehensive approach that handles everything from design to delivery under one roof. This streamlined process eliminates the complexity of dealing with multiple vendors and reduces the time it takes to bring a product to life. By focusing on precision and quality at every stage, turnkey PCB assembly not only accelerates time-to-market but also ensures your product is built to the highest standards. It’s the key to transforming innovative ideas into reality—quickly and efficiently.

Introduction to Turnkey PCB Assembly Services

What is Turnkey PCB Assembly?

Turnkey PCB assembly is an all-inclusive service that manages every step of the printed circuit board (PCB) production process—from the initial design to final delivery. In this model, a single provider handles the entire journey, eliminating the need for multiple vendors and simplifying the complex assembly process.

Key Stages of Turnkey PCB Assembly:

1. Design: The process begins with the creation of a PCB layout, where designers ensure the circuit meets the intended specifications. This stage may include prototyping to verify the design before mass production.

2. Sourcing: Turnkey providers source all the necessary components for the PCB assembly, such as resistors, capacitors, and microchips, often leveraging bulk purchasing to reduce costs.

3. Assembly: Once all components are sourced, the PCB is assembled, typically using methods like surface-mount technology (SMT) or through-hole technology, depending on the design requirements.

4. Testing: After assembly, the board undergoes rigorous testing to ensure it meets functional and quality standards. This often includes Automated Optical Inspection (AOI) and in-circuit testing.

5. Delivery: Finally, the finished PCBs are packaged and shipped to the customer, ready for integration into the final product.

Difference Between Turnkey and Traditional Assembly Models:

In a traditional PCB assembly model, companies may need to coordinate with multiple suppliers for components, assembly, and testing, which can lead to delays, miscommunications, and higher costs. In contrast, turnkey PCB assembly consolidates all these services under one roof, providing a streamlined process that ensures better control over the timeline, quality, and cost of the project.

Why Choose Turnkey PCB Assembly?

Turnkey PCB assembly offers numerous advantages for businesses, particularly when it comes to reducing complexity and improving overall efficiency.

1. Streamlined Project Management:

By outsourcing all steps of the PCB production process to a single provider, businesses can focus on their core operations—such as product development—without worrying about managing multiple suppliers. This reduces the administrative burden, simplifies communication, and ensures better coordination between the different stages of production.

2. Reduced Complexity and Increased Efficiency:

With all aspects of the project handled by one provider, the process becomes much simpler. Companies avoid the need to juggle logistics, track multiple shipments, or deal with different timelines for sourcing, assembly, and testing. This increases efficiency and significantly reduces lead times.

3. Ideal for Various Business Scenarios:

Startups: For startups with limited resources, turnkey PCB assembly provides a cost-effective way to access high-quality production without the overhead of managing multiple suppliers.

Prototyping: Turnkey services are perfect for companies looking to quickly prototype new designs. With a single point of contact for all stages, feedback is faster, and adjustments are easier to implement.

Large-Scale Production: Turnkey solutions also cater to high-volume production needs, where speed and consistency are essential. The ability to scale production without compromising on quality is a major advantage for large businesses.

Overall, turnkey PCB assembly services provide businesses with the flexibility, efficiency, and reliability they need to meet the growing demands of the electronics industry. Whether you are a small startup or a large enterprise, this integrated approach can significantly improve your manufacturing process.

Components and Stages of Turnkey PCB Assembly

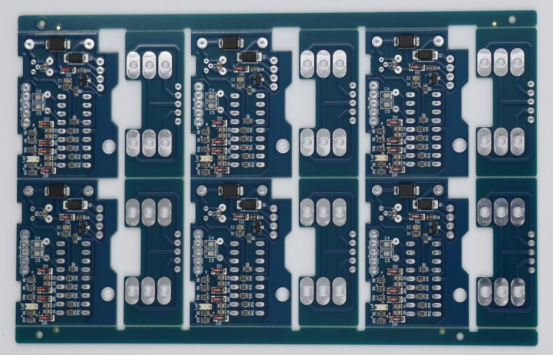

Design and Prototyping

The design and prototyping phase is crucial in the PCB assembly process, setting the foundation for successful production.

Overview of the Design Process:

The process begins with the conceptualization of the PCB layout, where engineers define how the electronic components will be arranged and connected. Tools like CAD (Computer-Aided Design) software are used to create the detailed circuit board design. Once the design is complete, a prototype is developed to test the layout and functionality before moving to full-scale production.

Importance of Early-Stage Prototyping:

Prototyping plays a key role in identifying potential flaws or design issues early in the process. By testing a prototype, designers can verify that the PCB functions as intended, allowing for modifications before committing to large production runs. Early prototypes help reduce the risk of costly errors and delays in later stages.

Example of Design Optimization Using Modular Approaches:

In PCB design, a modular approach allows components to be designed as independent, interchangeable units. For example, using standardized parts like connectors or chips can simplify design changes and reduce rework. If an issue arises during testing, only the affected module may need adjustments, rather than the entire PCB. This approach improves efficiency and speeds up the prototyping process.

Component Sourcing and Procurement

Once the design is finalized, the next step is sourcing the components needed for assembly.

How Turnkey Providers Manage Component Procurement:

Turnkey PCB assembly providers typically handle the entire procurement process, from selecting suppliers to purchasing the necessary parts. This allows for seamless integration and avoids the delays that might occur when businesses need to source components from multiple vendors.

Bulk Purchasing Advantages and Cost Savings:

One of the major benefits of turnkey services is the ability to purchase components in bulk. Bulk purchasing allows turnkey providers to negotiate better prices with suppliers, reducing the overall cost of the components. These savings are passed on to the customer, making the assembly process more cost-effective, particularly for large-volume projects.

Addressing Supply Chain Challenges and Risks in Component Sourcing:

Component sourcing comes with its challenges, including shortages or disruptions in the supply chain. Turnkey providers mitigate these risks by establishing strong relationships with reliable suppliers and maintaining inventory buffers for critical components. Additionally, many turnkey manufacturers have contingency plans in place to quickly adapt to supply chain issues, ensuring that production timelines are met.

Assembly and Manufacturing

The assembly and manufacturing phase is where the design comes to life.

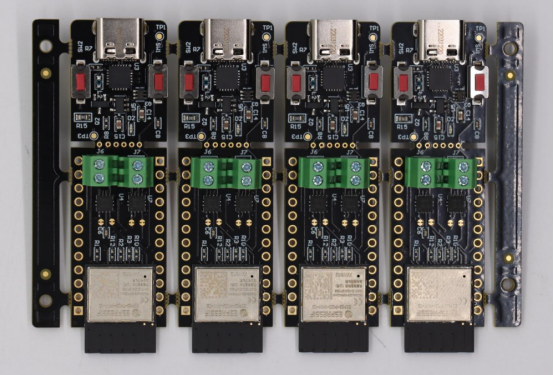

Overview of PCB Assembly Techniques:

There are several techniques used in PCB assembly, the most common being Surface-Mount Technology (SMT) and Through-Hole Technology (THT). SMT is widely used in modern assemblies because it allows for a higher density of components, better performance, and smaller PCBs. Through-hole technology, while older, is still used for certain components that require stronger mechanical connections.

The Role of Automated Machines and Human Expertise:

Automated machines are often used in the assembly process for tasks such as placing components on the board or soldering. However, human expertise is still critical in ensuring that the components are correctly placed and that the assembly meets the required quality standards. Automation improves speed and accuracy, while skilled technicians can handle more complex tasks that machines may not easily manage.

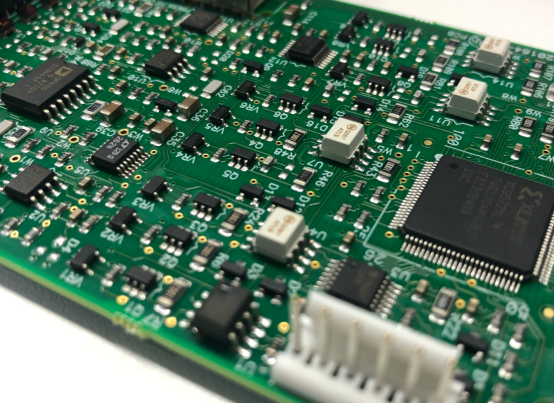

Quality Checks During Assembly:

Throughout the assembly process, quality control is paramount. Turnkey PCB providers implement a combination of visual inspections and automated testing to ensure accuracy. Visual inspection is used to identify any obvious errors, such as misplaced components, while automated systems like Automated Optical Inspection (AOI) check for more subtle issues such as soldering defects or component misalignment.

Testing and Quality Assurance

After assembly, rigorous testing ensures that the PCB functions correctly and meets required standards.

Key Testing Methods:

Automated Optical Inspection (AOI): This method uses cameras and lighting to detect soldering defects, missing components, or misalignment. AOI is a quick and reliable way to catch issues early.

In-Circuit Testing (ICT): ICT tests individual components on the PCB to ensure they are correctly functioning. This method checks for issues like shorts, open circuits, and incorrect component values.

Functional Testing: This type of testing ensures that the PCB performs the functions it was designed for. For instance, it might include testing the PCB in a mock-up of the final product to verify that it works as expected.

Benefits of Integrated Quality Control Measures:

Integrating testing directly into the assembly process allows for immediate identification of defects, reducing rework and delays. It also enhances reliability by ensuring that all components meet high-quality standards before the board leaves the factory.

Example of the Impact of Rigorous Testing on End Product Reliability:

For example, a consumer electronics company may require that their PCBs pass both AOI and ICT tests before being shipped. This rigorous quality assurance process ensures that every unit delivered works as expected, minimizing the risk of product failures and costly recalls.

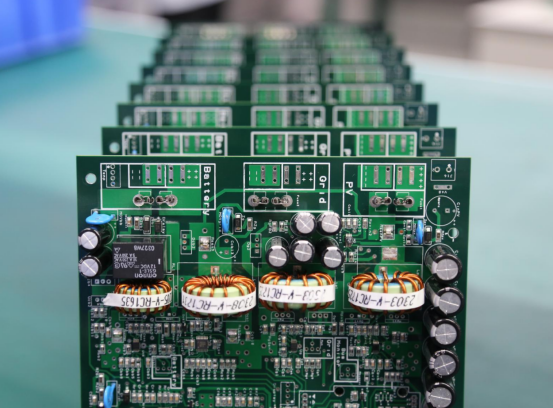

Delivery and Post-Assembly Support

The final stage of the turnkey PCB assembly process involves packaging, logistics, and post-assembly support to ensure the product’s long-term performance.

Packaging, Logistics, and Final Product Shipment:

Once the PCBs pass all tests and are approved for delivery, they are carefully packaged to prevent damage during shipping. Logistics teams coordinate the safe transportation of the boards to the customer. Turnkey providers often offer expedited shipping options to meet tight deadlines.

Ongoing Technical Support After Product Delivery:

Turnkey PCB providers typically offer ongoing technical support even after delivery. This can include troubleshooting, design adjustments, and assistance with integrating the PCB into the final product. Offering post-assembly support ensures that any issues encountered during product use can be quickly addressed.

The Role of Post-Assembly Services in Maintaining Long-Term Product Performance:

Post-assembly services play an important role in maintaining the product's reliability and performance over time. For example, a provider might offer testing services for future batches, updates to the design based on user feedback, or assistance with repairs if defects arise. By offering these services, turnkey PCB providers help companies ensure that their products remain high-performing and compliant with industry standards.

Types of Turnkey PCB Assembly Services

Full Turnkey PCB Assembly

All-Inclusive Services from Design to Delivery:

Full turnkey PCB assembly is an all-encompassing service that manages every aspect of the PCB production process. From the initial design phase to sourcing components, assembly, testing, and final delivery, a single provider handles it all. This integrated approach simplifies the manufacturing process by consolidating tasks into one streamlined service.

Advantages of a Single Provider for the Entire Assembly Process:

Choosing a full turnkey service offers several benefits:

Simplified Management: With only one point of contact, communication is more efficient, and there’s less room for errors or delays caused by coordinating between multiple vendors.

Consistent Quality Control: A single provider ensures that quality standards are maintained throughout the entire process, from design to assembly.

Faster Time-to-Market: With everything managed under one roof, the entire process becomes more efficient, reducing lead times and helping products reach the market faster.

Ideal Applications for Full Turnkey Solutions:

Full turnkey services are especially beneficial for businesses that require a high level of precision and speed. This includes:

Complex Products: High-performance or multi-layered PCBs that require specialized expertise.

Tight Timelines: Businesses needing to meet strict deadlines, such as those in the consumer electronics or medical device sectors, where quick product rollouts are crucial.

Partial Turnkey PCB Assembly

Clients’ Role in Supplying Some Components or Managing Certain Phases:

Partial turnkey PCB assembly allows businesses to retain control over certain aspects of the production process. For example, companies may choose to supply specific components, such as custom parts, while outsourcing the rest of the assembly process (e.g., design, standard components, testing, and delivery). This model offers a more flexible approach compared to full turnkey services.

Pros and Cons Compared to Full Turnkey Solutions:

Pros:

Cost Savings: By sourcing certain components themselves, businesses can reduce costs, particularly for components they already have in stock.

Control: Companies maintain more control over specific aspects of the production, such as choosing suppliers for certain components or managing inventory.

Cons:

Increased Complexity: Managing part of the supply chain means dealing with multiple vendors, which can add complexity and potential for delays.

Longer Lead Times: Since clients are involved in sourcing some components, there may be longer wait times if parts are unavailable or delayed.

Example of Businesses that Might Choose Partial Turnkey Services:

Companies with Existing Component Stock: Businesses that already have stockpiles of components or prefer to source specific parts directly from their suppliers.

Custom Product Manufacturers: Companies making products that require highly specialized components, such as custom-designed chips or sensors, which they may want to handle separately.

Consignment PCB Assembly

Definition and Comparison to Turnkey Services:

Consignment PCB assembly is a model where businesses supply their own components to the assembly provider. The assembly company then assembles the boards using the client’s components, testing them, and delivering the completed PCBs. Unlike full turnkey services, where the provider handles component procurement, consignment assembly places the responsibility of sourcing materials on the client.

When Businesses May Opt for Consignment Assembly Instead of Turnkey Solutions:

Businesses may choose consignment PCB assembly when they have existing inventory, specific suppliers they trust, or cost-saving strategies tied to bulk purchasing. This model is also useful when businesses have strict requirements for certain components and prefer to control the procurement process.

Benefits and Drawbacks of Consignment Models for Businesses:

Benefits:

Cost Control: By providing their own components, businesses can take advantage of lower component prices or bulk purchasing discounts.

Supply Chain Flexibility: Businesses have more flexibility in choosing suppliers, which can be important for sourcing specialized or hard-to-find components.

Drawbacks:

Increased Risk of Component Shortages: If the client fails to procure the correct parts or experiences delays, production can be stalled.

Greater Responsibility: Businesses must manage the procurement, quality, and storage of components, adding more responsibilities to their workflow.

Consignment PCB assembly may be ideal for businesses with established supply chains or those looking for greater flexibility in sourcing components but comes with the added responsibility of component management.

Key Benefits of Turnkey PCB Assembly Services

Cost Savings and Economies of Scale

How Turnkey Services Reduce Overall Costs Through Bulk Purchasing and Streamlined Production:

Turnkey PCB assembly services provide significant cost savings by offering bulk purchasing advantages. Since providers manage the entire assembly process, they can buy components in large quantities, securing better pricing from suppliers. This reduction in component costs directly lowers the overall manufacturing expenses for businesses. Additionally, turnkey services streamline production by consolidating tasks like design, sourcing, and testing, reducing overhead costs associated with managing multiple vendors.

Example of Cost-Saving Opportunities in Large-Volume Production Runs:

For instance, a company producing thousands of consumer electronics might opt for turnkey PCB assembly to take advantage of economies of scale. By sourcing components in bulk, the turnkey provider can pass on discounts, significantly lowering the cost per unit. For businesses in industries like consumer electronics, automotive, or medical devices, this cost efficiency is particularly important as high-volume production demands keeping costs manageable while maintaining product quality.

Faster Time-to-Market

How Turnkey Solutions Accelerate Production Timelines by Consolidating Tasks Under One Provider:

One of the key benefits of turnkey PCB assembly is the acceleration of production timelines. With a single provider handling all stages of the PCB process—from design and component procurement to assembly and testing—the entire project moves faster. There are fewer delays due to the need for coordination between multiple vendors, and decisions can be made quickly since everything is managed under one roof.

Impact of Reduced Lead Times on Product Launch and Competitiveness in Fast-Paced Industries:

In fast-moving industries like consumer electronics, time-to-market is crucial. Turnkey solutions significantly reduce lead times, enabling businesses to launch products faster and stay ahead of competitors. For example, a company developing a new smartphone might need to bring its PCB assembly from concept to production in just a few months to meet market demands. With turnkey services, the business can bypass many of the delays associated with multiple suppliers, ensuring that the product reaches consumers before competitors' similar offerings.

Enhanced Quality Control

Integrated Testing and Inspection Protocols for Superior Product Quality:

Turnkey PCB assembly integrates comprehensive quality control measures throughout the manufacturing process. These include Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and Functional Testing. By combining these advanced testing methods, turnkey providers can catch issues early, ensuring that only high-quality PCBs are delivered. Automated systems perform consistent inspections, while human oversight ensures that complex issues are addressed.

Comparison Between Traditional Multi-Vendor Models and Turnkey Quality Assurance:

In a traditional multi-vendor assembly model, managing quality assurance can be challenging. Different vendors may use varying testing methods, leading to inconsistencies and gaps in quality checks. In contrast, a turnkey solution consolidates all testing and inspection under one provider, ensuring standardized quality control. This unified approach results in higher product reliability and fewer defects, reducing the risk of costly recalls or customer complaints.

Simplified Supply Chain Management

How Turnkey Assembly Minimizes Supply Chain Complexities and Reduces the Need for Multiple Vendors:

Turnkey PCB assembly services significantly simplify supply chain management by reducing the number of suppliers involved in the process. Since a single provider handles all stages—component sourcing, assembly, and testing—companies do not need to coordinate with multiple vendors. This minimizes the complexity of managing multiple supply chains, reducing the chances of miscommunication, delays, or parts shortages.

Real-World Examples of How Turnkey Assembly Simplifies Procurement and Logistics:

For example, a company in the automotive industry may require custom PCBs for its electronic systems. By choosing a turnkey provider, the company avoids managing separate contracts for components, assembly, and testing. The turnkey provider sources all components, assembles the PCBs, and conducts testing, delivering the finished product directly to the company. This not only speeds up the production process but also eliminates the logistical headaches of dealing with several suppliers, reducing shipping costs and lead times.

Challenges in Turnkey PCB Assembly and How to Overcome Them

Supply Chain and Component Availability

Potential Risks Such as Component Shortages or Disruptions:

One of the primary challenges in turnkey PCB assembly is the risk of supply chain disruptions. Factors such as raw material shortages, geopolitical issues, or logistical delays can result in component shortages that impact production timelines. For instance, the global chip shortage has affected industries from automotive to consumer electronics, leading to delays in PCB production and assembly.

Strategies for Mitigating Supply Chain Risks:

To overcome these challenges, businesses can implement strategies to reduce supply chain risks:

Diversifying Suppliers: Working with multiple suppliers across different regions ensures that if one supplier faces issues, alternatives are readily available. This helps minimize the impact of disruptions on production.

On-Demand Production: Utilizing on-demand or just-in-time production allows businesses to manage component inventory more efficiently, reducing the risks associated with holding excessive stock or facing sudden shortages.

Establishing Buffer Stocks: Maintaining a small buffer of critical components can provide a safety net in case of sudden disruptions or shortages.

By diversifying suppliers and employing flexible production methods, companies can mitigate the impact of supply chain challenges on their turnkey PCB assembly projects.

Design Changes and Flexibility

Managing Last-Minute Design Changes and the Impact on Production Schedules:

In PCB assembly, last-minute design changes are common, especially in fast-paced industries where product requirements evolve quickly. These changes can disrupt the production process, leading to delays or increased costs. For example, a new component might be added to the design, requiring sourcing, testing, and integration, which can affect the overall timeline.

How Effective Communication with Turnkey Providers Ensures Smooth Adaptation to Changes:

The key to handling design changes effectively is clear and constant communication with the turnkey provider. Establishing a transparent and collaborative relationship helps ensure that design modifications are quickly understood and integrated without significantly impacting production schedules.

Real-Time Updates: Keeping the provider informed of changes in real time can help them adjust component sourcing, assembly schedules, and testing processes to accommodate new requirements.

Prototyping and Testing: If design changes are significant, creating prototypes early in the process allows the team to test and validate modifications before scaling up production.

By having a flexible process in place and maintaining open communication, businesses can better manage design changes without disrupting the production flow.

Maintaining High Quality Standards

The Importance of Consistent Quality Control Throughout the Assembly Process:

Maintaining high-quality standards is critical in turnkey PCB assembly. Consistent quality control ensures that the final product meets the required performance specifications and is free from defects. Poor quality can lead to costly product recalls, damage to brand reputation, and customer dissatisfaction. Turnkey providers implement strict quality control protocols at every stage of the assembly process, from component sourcing to final testing.

Example of Advanced Testing Methods Like X-Ray Inspection and AOI in Preventing Defects:

To prevent defects, turnkey PCB assembly providers often use advanced inspection technologies:

Automated Optical Inspection (AOI): AOI is used to inspect the surface of the PCB for defects such as misaligned components or soldering issues. This automated process helps ensure consistent quality across large production runs.

X-Ray Inspection: X-ray technology is used to inspect the internal layers of PCBs, particularly for hidden defects such as solder joints or connections that cannot be easily detected by visual inspection. This method ensures that even the most complex multi-layer PCBs are free of defects.

These advanced testing methods enhance the overall reliability of the final product, ensuring that the assembled PCBs perform as intended.

Handling High-Volume Orders

How Turnkey Providers Manage Scalability to Accommodate Both Small and Large Production Runs:

Turnkey PCB assembly services are designed to scale to meet the needs of both small and large production runs. Providers use advanced automation and efficient workflow management to handle high-volume orders without compromising on quality. Whether producing prototypes or large batches, turnkey providers adjust their processes to ensure the production line is optimized for efficiency and accuracy.

The Balance Between Volume Production and Custom, High-Precision Needs:

While turnkey services excel in managing high-volume production, they must also balance the need for customization and high-precision requirements. Some industries, such as medical devices or aerospace, require highly specialized PCBs that demand tight tolerances and customized components. In such cases, the turnkey provider must use specialized techniques, such as precision surface mount technology (SMT) or rigid-flex PCB assembly, to meet these high-precision needs without compromising the scalability of the production process.

By combining advanced automation with expertise in handling custom designs, turnkey providers can manage high-volume production while ensuring that the unique needs of each project are met.

How to Choose the Right Turnkey PCB Assembly Provider

Assessing Experience and Capabilities

The Importance of Choosing a Provider with Proven Expertise and Technical Skills:

When selecting a turnkey PCB assembly provider, it's crucial to prioritize experience and technical expertise. Providers with a proven track record are better equipped to handle the complexities of design, production, and testing, ensuring that your PCB meets all required specifications. They also bring insights gained from years of working across different industries, helping to navigate challenges unique to each sector, such as consumer electronics, automotive, or medical devices.

What to Look for in a Provider’s Portfolio:

To evaluate a provider’s capabilities, check their portfolio for:

Case Studies: Successful projects that demonstrate the provider's ability to meet tight deadlines, manage complex designs, and deliver high-quality products.

Industry Specialization: Experience in your specific industry is a significant advantage. Providers with expertise in your field are more likely to understand regulatory requirements and technical demands, ensuring smoother execution.

A provider with a strong portfolio and specialized experience can effectively manage your project, from the initial design phase to final production.

Evaluating Equipment and Facilities

The Significance of Advanced Manufacturing Facilities for Ensuring High-Quality Output:

The quality of the end product relies heavily on the equipment and facilities used in production. Advanced manufacturing facilities with automated systems ensure precise assembly, maintain consistency, and improve overall production efficiency. A provider with up-to-date equipment can handle complex designs and high-volume orders while adhering to strict quality standards.

Key Equipment to Look for in Turnkey Providers:

Surface Mount Technology (SMT) Lines: Essential for high-precision assembly, SMT lines enable efficient mounting of components directly onto the PCB surface. Automated systems are crucial for ensuring consistent and fast production, especially for high-volume orders.

Automated Optical Inspection (AOI) Systems: AOI machines automatically check for defects, ensuring components are placed correctly and soldered properly. This reduces human error and ensures the integrity of each PCB.

X-Ray Inspection Systems: Used for detecting hidden defects, such as faulty solder joints or internal component issues, X-ray inspection is vital for complex assemblies with components like BGAs (Ball Grid Arrays).

These technologies allow for better control over quality and faster turnaround times, ensuring that each PCB meets the required specifications.

Importance of Customer Support and Communication

How Strong Customer Support Enhances Project Management and Troubleshooting:

Customer support plays a pivotal role in managing turnkey PCB assembly projects. A strong support system ensures that issues are resolved quickly, design changes are incorporated smoothly, and the project progresses without delays. Providers with responsive customer service teams can offer timely advice and solutions, helping to keep your project on track.

Ensuring Clear Communication Channels to Prevent Delays and Misunderstandings:

Effective communication is critical to preventing misunderstandings and delays in the production process. Clear communication channels help ensure that the project’s requirements are thoroughly understood and followed. Regular updates, prompt responses to inquiries, and the ability to quickly adapt to changes will all contribute to a smoother workflow and timely delivery.

Maintaining open lines of communication ensures that any potential problems are addressed early, keeping your project on schedule.

Comparing Pricing and Service Options

Factors That Influence Pricing in Turnkey PCB Assembly:

Several factors contribute to the pricing of turnkey PCB assembly, including:

Order Volume: Larger production runs typically offer cost savings due to economies of scale.

Design Complexity: Complex PCB designs, such as multi-layer or high-frequency boards, will often require more time, specialized materials, and advanced manufacturing techniques, raising costs.

Lead Time: If you need a quick turnaround, expedited production and shipping can add to the cost.

How to Weigh Cost Against Quality and Service Level:

While it’s important to keep costs in check, the lowest price doesn’t always guarantee the best value. When comparing prices, consider the level of service and quality offered by the provider. A cheaper service might cut corners on quality control or customer support, leading to higher long-term costs due to defects or delays. Balancing cost with the provider’s reputation for quality and reliability ensures you get the best value for your investment.

Company Recommendation: PCBMASTER

When choosing a turnkey PCB assembly provider, it's crucial to partner with a company that not only meets your technical requirements but also offers excellent support throughout the process. For businesses seeking both reliability and expertise, PCBMASTER stands out.

With over 15 years of experience, PCBMASTER offers a full range of services, from PCB design to assembly and component sourcing. Their six highly automated facilities ensure that every project is completed with precision, and their adherence to ISO 9001, IATF 16949, and UL certifications guarantees high-quality standards.

The company’s flexible shipping options and 99% on-time delivery rate provide additional peace of mind for businesses working with tight deadlines. Their transparent pricing and 24/7 customer support make managing projects seamless, offering a comprehensive solution for both small and large orders.

For those looking for a trusted, all-in-one PCB partner, PCBMASTER offers a proven track record and the expertise needed to ensure success.

Applications of Turnkey PCB Assembly Across Industries

Consumer Electronics

Turnkey PCB assembly plays a crucial role in the fast-paced consumer electronics industry, where rapid product development and time-to-market are essential. By outsourcing the entire PCB assembly process to a single provider, companies can streamline their design, prototyping, and manufacturing stages, enabling quicker product launches.

For example, smartphones and smart wearables heavily rely on complex PCBs with high precision. Turnkey services allow manufacturers to meet the evolving demands of innovation by ensuring high-quality, reliable assemblies that are ready for mass production. The integration of assembly, testing, and sourcing in one package also reduces lead times and minimizes production delays, keeping products ahead of the competition.

Medical Devices

In the medical device sector, turnkey PCB assembly is vital for ensuring compliance with strict industry regulations and safety standards. Medical devices require PCBs that are not only highly reliable but also capable of performing in critical environments. The turnkey model helps companies adhere to medical-grade standards while managing the complexity of designs.

Challenges in medical PCB assembly include maintaining compliance with FDA regulations and ensuring biocompatibility and safety. Turnkey providers help mitigate these challenges by offering comprehensive solutions that include strict quality checks and testing methods, ensuring the end product is both safe and effective for use in sensitive medical environments.

Automotive Industry

The automotive industry increasingly relies on high-performance PCBs for advanced electronics, such as in-vehicle infotainment systems and sensor technologies. These components require durable and highly reliable PCBs that can withstand harsh conditions like temperature fluctuations and vibrations. Turnkey PCB assembly ensures that automotive manufacturers receive high-quality, high-performance PCBs ready for integration into critical systems.

For example, driver assistance systems and autonomous vehicles depend on sensors, cameras, and real-time data processing, all of which require robust PCB designs. By choosing a turnkey solution, automotive companies can ensure that the PCBs meet stringent industry standards while reducing development time and costs.

Industrial Electronics

Turnkey PCB assembly also plays a key role in industrial electronics, where automation, robotics, and control systems demand high-precision, reliable PCBs. These systems operate in environments where failure is not an option, such as factories and power plants.

The turnkey approach supports manufacturers by providing access to a streamlined process that includes sourcing, assembly, and quality control. For example, automation systems require PCBs that can manage complex signals and heavy loads without compromising performance. By leveraging turnkey services, industrial electronics companies can ensure that their PCBs meet the high standards required for long-term, reliable use in demanding industrial environments.

Turnkey PCB assembly is increasingly essential in a variety of industries due to its ability to streamline production, ensure high-quality output, and meet industry-specific requirements. Whether it’s for consumer electronics, medical devices, automotive applications, or industrial control systems, turnkey solutions offer significant benefits by simplifying the process, reducing time-to-market, and ensuring compliance with regulatory standards.

Conclusion

Turnkey PCB assembly is a smart choice for businesses looking to save costs, accelerate production, and maintain high-quality standards. By streamlining the entire process from design to delivery, it reduces complexity and ensures faster time-to-market. As industries evolve and demand for advanced electronics grows, turnkey solutions will continue to play a critical role in keeping companies competitive and responsive to global market needs.

FAQs

1. What is the difference between full turnkey and partial turnkey PCB assembly?

Full Turnkey PCB Assembly: This service covers every step of the process from design, component sourcing, assembly, testing, and delivery. It’s an all-in-one solution where the provider handles everything, saving you time and effort by managing the entire production flow.

Partial Turnkey PCB Assembly: In this model, the client supplies some components or manages certain phases of the process, while the provider handles others. For example, you may handle component sourcing yourself while the provider assembles and tests the boards. This option is ideal if you already have some resources in place or want more control over certain aspects.

2. How can turnkey PCB assembly reduce time-to-market for my product?

Turnkey PCB assembly streamlines the entire process by consolidating multiple stages—design, sourcing, assembly, testing, and delivery—under one provider. This eliminates delays caused by coordination between different vendors, speeding up production timelines. Additionally, having a single point of contact ensures faster decision-making, and the provider's established processes and resources allow for quicker prototyping and mass production, helping your product reach the market faster.

3. What are the main benefits of using a turnkey PCB assembly provider instead of managing the process in-house?

Using a turnkey provider offers several advantages:

Cost Efficiency: You save on internal resources and infrastructure, as the provider handles everything.

Expertise: Turnkey providers have specialized knowledge and equipment, ensuring high-quality results.

Reduced Complexity: You avoid the hassle of managing multiple vendors and processes, which simplifies the supply chain.

Faster Production: With experience and automation, turnkey providers can execute the entire assembly process more quickly.

For businesses without in-house PCB assembly expertise, opting for a turnkey provider can significantly reduce the risk of errors and increase operational efficiency.

4. How do I ensure the quality of PCBs produced through a turnkey assembly service?

To ensure high-quality PCBs, choose a turnkey provider that offers:

Rigorous Testing: Look for providers that use advanced testing methods like Automated Optical Inspection (AOI) and X-ray inspection to detect defects.

Certifications: Providers should have quality certifications such as ISO 9001 or IATF 16949, ensuring they adhere to industry standards.

Full Transparency: Ask for detailed reports on quality control procedures, testing results, and batch traceability.

Reputation and Experience: Choose a provider with a proven track record and experience in producing high-quality products for your specific industry.

5. What factors should I consider when choosing a turnkey PCB assembly provider for my project?

When selecting a provider, consider:

Experience and Expertise: Look for a provider with experience in your industry and the specific type of PCB you need.

Capabilities: Ensure they have the necessary equipment and facilities to handle your project, including the ability to scale production if needed.

Quality Assurance: Check for robust quality control processes and industry certifications.

Communication: Choose a provider that offers excellent customer support, with clear communication and transparency throughout the process.

Cost and Value: While cost is important, ensure the provider offers good value by balancing price with quality and service.

By considering these factors, you can find a provider that aligns with your needs and ensures a successful assembly process.