Applications of Ceramic-Based Aluminum Nitride PCBs Technological Innovations from 5G Base Stations to Aerospace

Ⅰ. High-Power Applications: The Irreplaceability of AlN PCBs

1.1 5G Base Station AAU Modules

Huawei’s 5G Massive MIMO Antenna (Model AAU5613) uses AlN PCBs as core thermal management substrates. Test data reveals:

①Chip junction temperature stabilizes at 85°C under 180W power (vs. >110°C for FR4 substrates).

②Thermal efficiency triples, reducing base station failure rates by 42% (China Mobile 2023 Maintenance Report).

Technical Insights:

AlN substrates (thermal conductivity: 220 W/m·K) directly bond GaN RF chips, achieving 3D heat dissipation via embedded copper pillars (0.3mm diameter), lowering thermal resistance to 0.15°C·cm²/W.

1.2 EV SiC Inverters

In Tesla Model 3 Plaid’s SiC drive module, AlN PCBs deliver critical performance:

①Withstands 600A peak current (vs. 350A limit for Al₂O₃ substrates).

②Power density reaches 45 kW/L (60% higher than IGBT solutions).

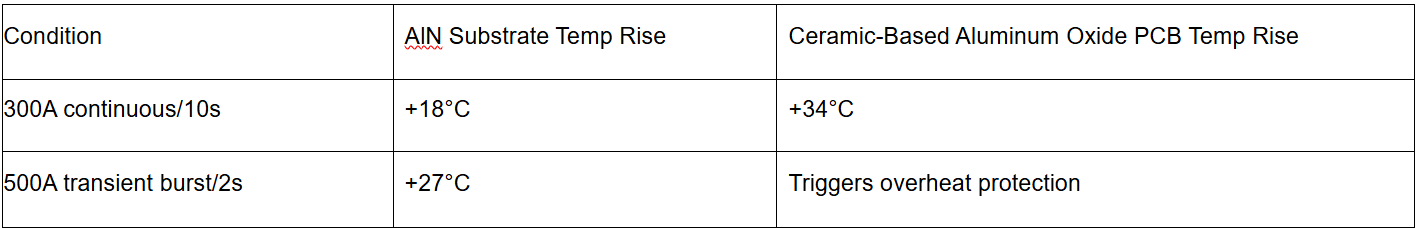

Performance Comparison:

Ⅱ. Extreme Environment Applications: Military & Aerospace Priorities

2.1 Satellite Phased Array Radar

BeiDou-3 navigation satellites use AlN PCBs in Ka-band TR modules, achieving:

①Zero failures over 10 years in vacuum (NASA JPL certified).

②CTE (4.5 ppm/°C) perfectly matches GaAs chips.

2.2 Deep-Well Logging Tools

Schlumberger’s MPR-900 downhole tool breakthroughs:

①Operating temperature upgraded to 225°C (vs. 175°C limit for ceramic-based aluminum oxide PCBs).

②Vibration resistance reaches 20Grms (meets API 16D standards).

Cost Trade-off:

For tools operating below 150°C, ceramic-based aluminum oxide PCBs remain preferred (costing 1/3 of AlN solutions).

Ⅲ. Consumer Electronics Breakthroughs

3.1 UV Laser Beauty Devices

Philips Lumea Prestige IPL’s pulse driver module uses AlN PCBs to achieve:

①<5% light intensity decay after 100,000 flashes (vs. >15% for standard substrates).

②Module thickness reduced to 1.2mm (vs. ≥2.0mm for Al₂O₃ designs).

3.2 Ultra-Thin Laptop Adapters

Dell XPS 13’s 130W GaN adapter innovations:

①Power density hits 8W/cm³ (industry average: 5.2W/cm³).

②Surface temperature <45°C at full load (UL 60950-1 certified).

Ⅳ. When to Choose Ceramic-Based Aluminum Oxide PCBs?

Ceramic-based aluminum oxide PCBs dominate these cost-sensitive scenarios:

1.Industrial Sensors:

①Siemens SITRANS TS500 temperature sensor (-40~150°C range).

②Bulk cost: Al₂O₃ @ ¥38/unit vs. AlN @ ¥120/unit.

LED Automotive Lighting:

①Audi matrix headlight control modules (<20W sustained power).

②Lifetime >50,000 hours (meets ISO 16750 vibration standards).

Medical Monitoring Devices:

①Mindray BeneVision N22 mainboard (IEC 60601-1 EMC certified).

②ESD protection up to 8kV (no need for high-cost AlN solutions).

Ⅴ. Industry Trends & Data Insights

Per Prismark 2024 Report:

①AlN PCB market grows at 21% CAGR (vs. 7% for Al₂O₃ PCBs).

②Price gap narrows: 2023 AlN substrate avg. ¥95/unit (vs. ¥210/unit in 2018).

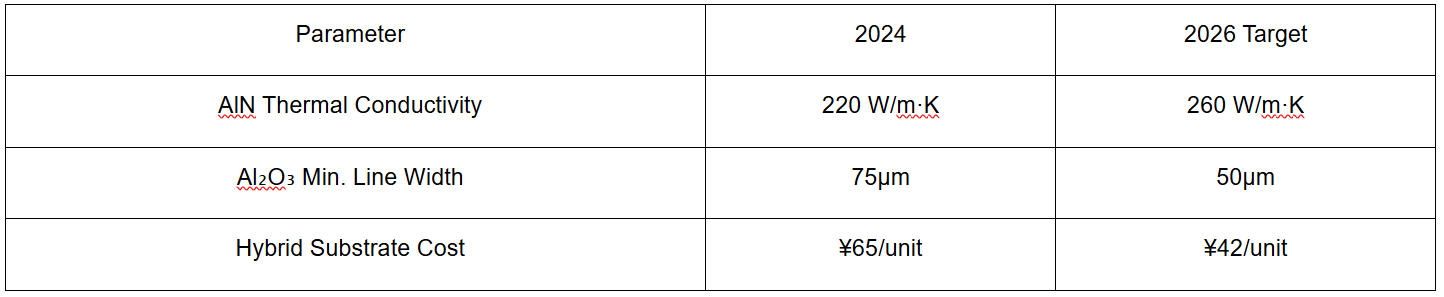

3-Year Technical Forecast:

Conclusion

Ceramic-based aluminum nitride PCBs are redefining high-power electronics, while ceramic-based aluminum oxide PCBs maintain critical roles in mid-to-low-end markets. Engineers must balance lifecycle costs (LCC) and operating conditions to identify the optimal substrate—a "golden ratio" in ceramic PCB selection.

(Data sources: Huawei whitepapers, Tesla supply chain reports, Prismark analysis)

Aluminum Nitride Ceramic-Based PCB The Core Driver of Next-Generation High-Power Electronics