Aluminum Oxide vs. Aluminum Nitride for Ceramic PCBs: How to Choose?

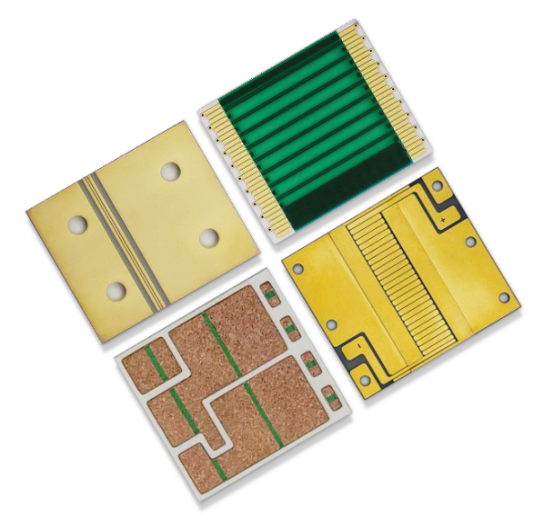

Ceramic PCBs are essential components in modern electronics, offering superior performance in high-temperature, high-power, and high-frequency applications. These PCBs are made from ceramic materials, which provide better heat dissipation, electrical insulation, and mechanical strength compared to traditional PCBs. This makes them ideal for industries like automotive, aerospace, and telecommunications, where reliability and durability are critical.

The material choice in PCB manufacturing is crucial because it directly affects the performance, lifespan, and cost of the final product. For example, selecting the right ceramic material like aluminum oxide or aluminum nitride can make a significant difference in heat management, power efficiency, and overall PCB functionality. By understanding these materials' properties, manufacturers can ensure that their PCBs meet specific requirements for different applications. Whether it's handling high power loads or maintaining stability in extreme conditions, choosing the right material is key to achieving optimal performance and reliability.

Why Is Material Selection Crucial for Ceramic PCBs?

Material selection is crucial for ceramic PCBs because it directly affects their performance, durability, and cost-efficiency. The right material ensures optimal heat dissipation, electrical insulation, and mechanical strength, which are all key to maintaining reliable and long-lasting electronic systems.

Impact on Thermal and Electrical Performance

The choice of material in ceramic PCBs directly impacts their ability to handle heat and electricity, two critical factors in electronics. Materials like aluminum oxide (Al₂O₃) and aluminum nitride (AlN) have different thermal conductivities, meaning they dissipate heat at different rates. For example, aluminum nitride has superior thermal conductivity, which makes it ideal for high-power electronics where managing heat is essential. On the other hand, aluminum oxide provides adequate thermal performance but may not be suitable for very high-temperature environments.

Electrical conductivity also varies between materials. Aluminum oxide is an excellent insulator, preventing electrical interference, while aluminum nitride offers a balance of both thermal conductivity and electrical insulation, making it suitable for circuits that require both heat management and electrical isolation. In simple terms, the right material helps keep the components cool and ensures they work safely without electrical issues.

Cost vs. Performance Trade-offs

Choosing the right material also involves balancing cost and performance. Materials like aluminum oxide are more affordable and are often used in applications where extreme thermal conductivity is not as critical. These cost-effective materials work well for many consumer electronics, such as smartphones or everyday appliances, where performance needs are moderate.

However, for high-performance industries like automotive or aerospace, where components must operate under extreme conditions, the higher cost of materials like aluminum nitride might be justified. Despite being more expensive, aluminum nitride ensures better thermal management, reliability, and overall performance, reducing the risk of overheating and increasing the lifespan of critical electronics. The decision ultimately depends on the application: higher performance may justify higher costs, but for many standard applications, cost-effective materials like aluminum oxide might be sufficient.

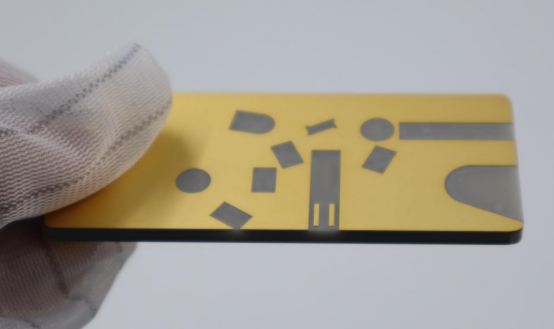

What Is Aluminum Oxide (Al₂O₃) in Ceramic PCBs?

Aluminum Oxide (Al₂O₃) is a popular ceramic material used in PCBs for its electrical insulation, mechanical strength, and thermal conductivity. It is cost-effective and commonly used in applications like consumer electronics and automotive systems. While it works well for many standard designs, its heat dissipation is not as efficient as materials like aluminum nitride, making it less suitable for high-power applications.

Advantages of Aluminum Oxide

Reliable Performance in High-Temperature Environments: Aluminum oxide can tolerate temperatures up to 150°C or higher, making it ideal for use in power supplies and other high-temperature applications like LED drivers and automotive electronics.

Cost-Effectiveness: Compared to materials like aluminum nitride, aluminum oxide is much more affordable, making it a popular choice in applications where budget is a concern. It is ideal for general-purpose PCBs in consumer electronics and industrial equipment, where performance requirements are moderate.

Disadvantages of Aluminum Oxide

Limitations in Performance for High-Demand Applications: While aluminum oxide performs well in many applications, its thermal conductivity is lower compared to advanced materials like aluminum nitride. This can limit its effectiveness in situations requiring efficient heat management, such as high-power semiconductors or high-frequency circuits.

Lower Thermal Conductivity: Aluminum oxide’s thermal conductivity, though decent, is not as high as aluminum nitride’s, which makes it less suitable for applications requiring superior heat dissipation, like high-power electronics or laser diodes.

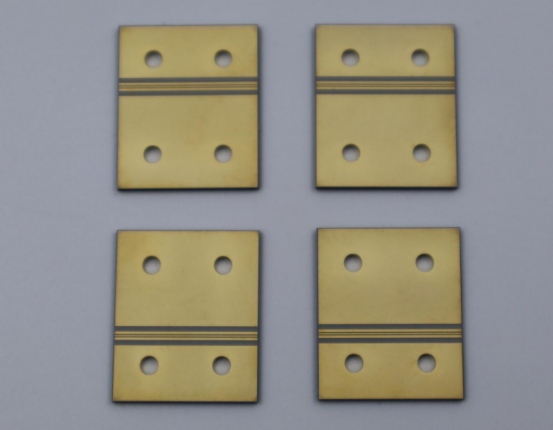

What Is Aluminum Nitride (AlN) in Ceramic PCBs?

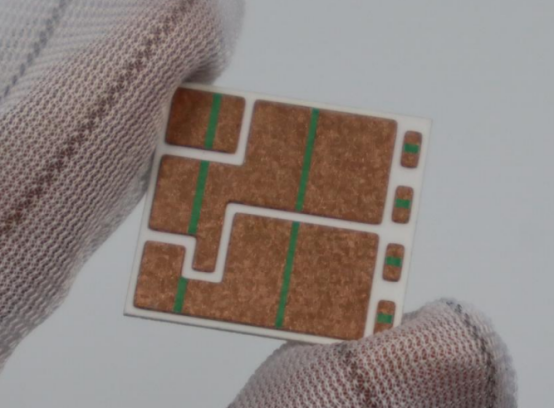

Aluminum Nitride (AlN) is a high-performance ceramic material used in ceramic PCBs for its exceptional thermal conductivity and electrical insulation properties. Unlike other materials like aluminum oxide, AlN efficiently dissipates heat, making it ideal for high-power applications such as power electronics and LED systems. While it offers superior heat management, its higher cost and fragility can make it less suitable for budget-sensitive or mass-market products.

Advantages of Aluminum Nitride

Exceptional Heat Dissipation for High-Power Applications: Aluminum nitride stands out due to its exceptionally high thermal conductivity, which allows it to efficiently dissipate heat in high-power applications. This is crucial in electronics like power amplifiers or automotive systems, where components operate at elevated temperatures. With better heat management, AlN ensures that components do not overheat, improving their lifespan and performance.

Higher Thermal Conductivity Than Aluminum Oxide: Compared to aluminum oxide, aluminum nitride offers significantly higher thermal conductivity, making it a superior choice for applications that demand effective heat management. AlN’s thermal conductivity can be as high as 321 W/m·K, compared to aluminum oxide's 30 W/m·K, making it far more suitable for high-frequency circuits or high-power devices where efficient cooling is critical.

Disadvantages of Aluminum Nitride

Higher Cost Than Aluminum Oxide: One of the key drawbacks of aluminum nitride is its higher cost compared to materials like aluminum oxide. The manufacturing process for aluminum nitride is more complex and expensive, which raises its overall cost. While AlN offers superior performance, this higher cost can be a deciding factor when designing products where budget is a primary concern.

More Fragile and Difficult to Manufacture: Aluminum nitride is also more fragile than aluminum oxide, making it difficult to manufacture and process. The material is more prone to cracking under stress, which can lead to challenges in production and increased waste. Additionally, the precision required in cutting and shaping AlN can add to its production cost, further complicating its use in large-scale or mass-market products.

How Do Aluminum Oxide and Aluminum Nitride Compare in Key Performance Metrics?

When choosing between aluminum oxide (Al₂O₃) and aluminum nitride (AlN) for ceramic PCBs, understanding how they compare in key performance metrics is essential. These materials differ significantly in terms of thermal conductivity, electrical insulation, mechanical strength, and manufacturing complexity, all of which impact their suitability for various applications. By examining these differences, you can determine which material is best suited for your specific needs, whether it’s for high-power electronics, consumer devices, or cost-sensitive projects.

Thermal Conductivity

Aluminum Oxide (Al₂O₃) has moderate thermal conductivity compared to other ceramics. It typically 30 W/m·K, making it suitable for standard applications where heat dissipation is important but not extreme. For example, aluminum oxide is often used in consumer electronics or low-power devices, where the heat load is manageable.

Aluminum Nitride (AlN), on the other hand, offers superior thermal conductivity, typically 321 W/m·K. This makes it highly effective at managing heat in high-power applications, such as power semiconductors, LED drivers, and automotive electronics, where efficient heat dissipation is crucial for performance and longevity.

Implications for PCB Performance:

AlN’s higher thermal conductivity ensures better heat dissipation, which is especially important in high-power electronics. In contrast, Al₂O₃ is suitable for lower-power devices where heat management needs are less critical.

Electrical Insulation

Aluminum Oxide (Al₂O₃) is an excellent electrical insulator, offering high resistance to electrical currents. This makes it suitable for applications where electrical isolation between components is essential, such as in power supplies and telecommunication circuits.

Aluminum Nitride (AlN) also provides electrical insulation, but its performance in this area is very similar to aluminum oxide. While both materials prevent electrical interference, AlN is often chosen for its combined thermal conductivity and electrical insulation properties, especially in high-power applications that also require heat management.

Implications for PCB Performance:

Both materials offer excellent electrical insulation, but AlN is favored in high-performance applications where both heat dissipation and electrical isolation are critical, such as in semiconductors and high-frequency devices.

Mechanical Strength

Aluminum Oxide (Al₂O₃) has strong mechanical properties, making it durable and capable of withstanding physical stresses. It is highly resistant to wear and tear, which is beneficial for general-purpose PCBs used in less demanding environments.

Aluminum Nitride (AlN) is more brittle and can be prone to cracking under stress. While it has sufficient mechanical strength for many applications, it is less durable in environments where high physical stress or impacts are common.

Implications for PCB Durability:

Al₂O₃’s tougher mechanical strength makes it more suitable for high-vibration environments or where physical durability is a priority. In contrast, AlN’s fragility can limit its use in harsh environments but is acceptable in controlled, low-stress applications where heat dissipation is more critical than mechanical robustness.

Manufacturing Process and Complexity

Aluminum Oxide (Al₂O₃) is easier to manufacture compared to aluminum nitride. It is widely available, and the manufacturing process is straightforward, which makes it more cost-effective. The simplicity of working with aluminum oxide also leads to lower production costs, which is why it’s commonly used in mass-market electronics.

Aluminum Nitride (AlN) is more complex and expensive to manufacture due to its higher purity requirements and the more intricate processing techniques involved. The material is also fragile, making it harder to handle and shape, which can increase manufacturing costs and time.

Implications for Cost and Production:

While Al₂O₃ offers cost-efficiency and easier processing, AlN’s higher manufacturing complexity and cost are justified in applications that demand superior thermal management and performance. Al₂O₃ is ideal for budget-sensitive projects, while AlN is best for high-end, specialized applications.

Comparison Table

Metric Aluminum Oxide (Al₂O₃) Aluminum Nitride (AlN) Thermal Conductivity Moderate (30 W/m·K) High (321 W/m·K) Electrical Insulation Excellent Excellent Mechanical Strength Strong, durable Brittle, more fragile Manufacturing Process Easier, cost-effective Complex, higher cost Best Use General-purpose, lower power devices High-power, high-performance devices

Which Applications Benefit from Aluminum Oxide (Al₂O₃) in Ceramic PCBs?

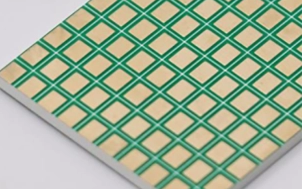

Aluminum oxide (Al₂O₃) is widely used in ceramic PCBs for applications that require reliable performance at a lower cost. It is particularly well-suited for standard consumer electronics and low to mid-power devices where thermal management needs are moderate. This material provides a good balance of electrical insulation and thermal conductivity, making it ideal for everyday devices that don’t demand high-end thermal solutions.

Standard Consumer Electronics

Aluminum oxide (Al₂O₃) PCBs are ideal for standard consumer electronics because they offer the right balance of electrical insulation and thermal conductivity for everyday devices. In products like smartphones, tablets, and home appliances, where the heat load is moderate, aluminum oxide provides sufficient heat dissipation to maintain reliable operation. These devices typically don’t require extreme thermal performance, making aluminum oxide a cost-effective choice for manufacturers.

For example, power supplies or voltage regulators in common electronics can easily use aluminum oxide PCBs, as they offer a reliable solution without the need for high-end materials like aluminum nitride. In these applications, thermal conductivity of around 30 W/m·K is sufficient, ensuring the device remains cool enough during normal operation, without increasing production costs unnecessarily.

Low to Mid-Power Electronics

In low to mid-power electronics, where heat generation is less intense and cost is a major factor, aluminum oxide is often the material of choice. Applications like LED lighting, audio equipment, and small motors benefit from aluminum oxide’s reliable performance without the need for expensive, high-performance materials. Since these devices don’t generate extreme heat, aluminum oxide provides enough thermal dissipation while keeping manufacturing costs low.

For example, in LED drivers used for indoor lighting, aluminum oxide PCBs can manage the relatively low thermal load and provide sufficient insulation for the circuit components, making them an economical solution for lighting systems in homes and businesses. By using aluminum oxide, manufacturers can reduce production costs while still meeting the thermal and electrical needs of the application.

Which Applications Benefit from Aluminum Nitride (AlN) in Ceramic PCBs?

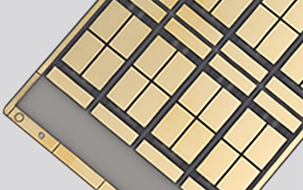

Aluminum Nitride (AlN) is the preferred material for high-performance, high-power applications due to its exceptional thermal conductivity and electrical insulation. It is especially valuable in industries like automotive and aerospace, where efficient heat dissipation and reliable performance under extreme conditions are crucial.

High-Power Electronics

Aluminum Nitride (AlN) is ideal for high-performance, high-power applications due to its exceptionally high thermal conductivity. This material can efficiently manage the heat generated by powerful electronic components, making it perfect for power amplifiers, power converters, and high-power semiconductors. For example, LED drivers and power transistors that handle large amounts of current and generate significant heat rely on AlN PCBs to prevent overheating and ensure the device remains operational under demanding conditions.

AlN’s superior thermal management allows it to dissipate heat more effectively than materials like aluminum oxide (Al₂O₃), which is crucial for high-power devices. In these applications, effective heat dissipation ensures the longevity and reliability of components. Without AlN’s thermal properties, components would likely fail due to excessive heat, leading to reduced efficiency and performance.

Automotive and Aerospace Electronics

In industries like automotive and aerospace, where electronic systems are exposed to extreme temperatures and high power loads, Aluminum Nitride is the go-to material for heat management. These sectors require materials that not only handle high temperatures but also maintain electrical insulation under stress, which AlN does exceptionally well.

In automotive electronics, AlN is used in components like engine control units (ECUs), electric vehicle (EV) power management systems, and battery controllers. These systems often experience rapid temperature fluctuations and heavy power demands, making efficient heat dissipation a critical factor. Similarly, in aerospace, AlN is used in power electronics for satellites, navigation systems, and communication devices, where reliability and thermal efficiency are essential for operation in extreme environments.

In both cases, AlN's combination of high thermal conductivity and electrical insulation ensures that the systems perform efficiently, maintain stability, and avoid failure, even in the harshest conditions.

Step-by-Step Guide: Choosing the Right Material for Your PCB Design

Choosing the right material for your PCB design is crucial for ensuring optimal performance, durability, and cost-effectiveness. Whether you’re deciding between aluminum oxide (Al₂O₃) and aluminum nitride (AlN), it's important to consider factors like thermal requirements, mechanical stress, budget constraints, and industry standards.

1. Assess the Power and Heat Requirements

Determine the heat dissipation needs for your PCB application.

The first step in choosing the right material for your PCB is understanding how much heat your device will generate during operation. Different electronic components produce varying amounts of heat, and choosing the right material ensures your PCB can handle this heat effectively.

If your application involves high-power electronics, such as power converters, LED drivers, or automotive systems, you will need a material with high thermal conductivity, like aluminum nitride (AlN). AlN can dissipate heat efficiently, ensuring your device doesn’t overheat.

For low-power devices, such as consumer electronics or small motors, a material like aluminum oxide (Al₂O₃) might suffice. It offers moderate thermal conductivity at a lower cost, making it a good choice for applications with less intense heat generation.

Example: If you're designing a PCB for a power amplifier used in a sound system, you would likely need AlN for optimal heat dissipation, as these systems produce significant heat during operation.

2. Evaluate Mechanical Stress and Durability

Consider if your PCB will be exposed to high mechanical stresses.

Mechanical stress can come from physical impacts, vibrations, or harsh environmental conditions. Understanding the mechanical demands of your application is key to selecting the right material.

Aluminum oxide (Al₂O₃) is more durable and resistant to mechanical stress. It’s a good choice for applications in environments with vibrations, such as automotive electronics or consumer electronics that may experience regular handling.

Aluminum nitride (AlN) is more brittle and can be prone to cracking under stress. It’s better suited for controlled environments where high mechanical durability is less of a concern, like high-performance computing or aerospace electronics.

Example: If you’re designing a PCB for a robotic arm used in a factory, which experiences vibrations and physical impacts, Al₂O₃ would be a better choice for its durability.

3. Balance Budget and Performance

Decide based on the trade-off between cost and performance based on application.

While aluminum oxide (Al₂O₃) is more affordable, it might not provide the superior thermal performance needed for high-end applications. On the other hand, aluminum nitride (AlN) offers exceptional thermal conductivity but comes at a higher cost.

For budget-sensitive applications, such as consumer electronics or low-power devices, Al₂O₃ offers a cost-effective solution without compromising too much on performance.

For high-performance applications, such as automotive power systems or high-frequency devices, the higher initial cost of AlN is justified by its thermal efficiency, electrical insulation, and long-term reliability.

Example: If you're designing a smartphone PCB, where cost is a critical factor but thermal management is moderate, Al₂O₃ would likely be your best option. For a high-end power module, AlN would be more suitable despite the higher cost.

4. Consult Industry Standards and Manufacturer Guidelines

Refer to relevant industry standards for high-performance PCB materials.

Before finalizing your material choice, it’s essential to check any industry standards or manufacturer guidelines. These guidelines ensure your design meets safety, performance, and compliance requirements, particularly for specialized industries like automotive, aerospace, and medical devices.

For instance, automotive electronics are subject to strict guidelines for heat dissipation and durability, so materials like AlN might be specified to meet these standards.

Similarly, aerospace PCBs might require materials with higher thermal conductivity and mechanical strength to withstand extreme conditions.

Example: For medical devices like pacemakers or heart monitors, it's crucial to follow specific regulatory guidelines on thermal management and electrical insulation, which might lead to choosing a material like AlN for its reliability in high-power applications.

Conclusion

the choice between aluminum oxide (Al₂O₃) and aluminum nitride (AlN) largely depends on the specific needs of your application. Al₂O₃ offers a cost-effective solution for low to mid-power applications with moderate heat dissipation requirements, making it ideal for consumer electronics and basic electronic components. On the other hand, AlN stands out for high-power and high-performance applications where superior thermal conductivity and electrical insulation are crucial, such as in automotive and aerospace electronics.

Choosing the right material is a decision that balances performance and cost based on your project’s requirements. Whether you prioritize thermal efficiency or need a budget-friendly option, understanding these key differences will help guide your choice.

If you're unsure which material best fits your needs, expert guidance is essential. PCBMASTER is a trusted PCB supplier that can help you select the right material based on your unique requirements. With years of experience, we offer tailored solutions to ensure your PCBs meet both performance and cost expectations.

FAQs

What’s the main difference between aluminum oxide and aluminum nitride for ceramic PCBs?

The key differences between aluminum oxide (Al₂O₃) and aluminum nitride (AlN) for ceramic PCBs can be summarized in terms of thermal conductivity, cost, and application suitability:

Thermal Conductivity: AlN has a much higher thermal conductivity (321 W/m·K) compared to Al₂O₃ (30 W/m·K), making it better suited for applications where efficient heat dissipation is critical, such as high-power electronics.

Cost: Al₂O₃ is more affordable than AlN, making it a cost-effective choice for low to mid-power applications.

Application Suitability: AlN is ideal for high-performance and high-power devices (e.g., power semiconductors, automotive electronics), while Al₂O₃ is suitable for standard consumer electronics and applications with moderate heat generation.

Can aluminum oxide be used for high-power electronics?

Aluminum oxide (Al₂O₃) can technically be used for high-power electronics, but it’s not the best material for these applications. Al₂O₃ offers moderate thermal conductivity, which means it might not handle the high heat generated by power-hungry components as efficiently as aluminum nitride (AlN). In high-power applications like power amplifiers, LED drivers, or automotive systems, the ability to dissipate heat quickly is crucial to prevent component failure and maintain efficiency. AlN is typically the preferred material in these cases due to its superior heat dissipation. However, for low to mid-power applications, Al₂O₃ can be sufficient, offering a more cost-effective solution without compromising performance too much.

Is aluminum nitride worth the extra cost for my PCB project?

Whether aluminum nitride (AlN) is worth the extra cost depends on the specific needs of your PCB project:

Yes, it’s worth the cost if your application involves high-performance and high-power components that generate significant heat. AlN’s superior thermal conductivity and electrical insulation make it ideal for environments like automotive electronics, aerospace, and power electronics, where heat management is crucial for reliability and performance.

No, it might not be necessary if you are working on low to mid-power electronics, where moderate thermal conductivity is sufficient, and cost is a more important factor. In such cases, aluminum oxide (Al₂O₃) would provide good value without the higher cost of AlN.

In essence, the extra cost of AlN is justified for applications requiring superior heat dissipation, but for cost-sensitive projects, Al₂O₃ can offer an acceptable alternative.

How do I choose the right material if I’m working with a limited budget?

If you’re working with a limited budget, here’s how to choose between aluminum oxide (Al₂O₃) and aluminum nitride (AlN):

1. Assess Thermal Requirements:

If moderate heat dissipation is enough for your application (e.g., consumer electronics, low-power circuits), Al₂O₃ is an excellent, cost-effective choice.

If your design involves high-power electronics (e.g., power supplies, LED drivers), where efficient heat management is critical, AlN might be necessary despite its higher cost.

2. Consider Mechanical Stress:

Al₂O₃ is stronger and more durable, making it suitable for applications with physical stress or vibrations, like in automotive or consumer electronics.

If your application doesn’t face significant physical stress, AlN can be used, but its higher price might not justify the benefits for lower-end designs.

3. Evaluate Long-Term Savings:

While AlN is more expensive upfront, its superior thermal performance can help reduce failures over time, making it worthwhile for high-end applications where reliability is key.

Ultimately, if your project doesn't require the highest performance, Al₂O₃ offers a budget-friendly option without compromising the essential thermal and mechanical properties.

Can aluminum oxide and aluminum nitride be combined in a single PCB design?

Yes, aluminum oxide (Al₂O₃) and aluminum nitride (AlN) can be combined in a single PCB design for applications that require a hybrid approach to thermal and mechanical performance.

In some advanced PCB designs, Al₂O₃ can be used in parts of the PCB that require mechanical strength and cost-effectiveness, while AlN can be applied where high thermal conductivity is crucial.

This hybrid design approach allows for optimized performance across the entire system by leveraging the strengths of both materials in the appropriate sections of the PCB.

Example: In a high-power LED system, AlN can be used for the high-power components to efficiently manage heat, while Al₂O₃ might be used in non-critical areas to keep costs lower. This approach allows for a cost-effective solution without sacrificing performance in critical areas.

Combining these materials can provide a balance between thermal management, durability, and cost, making it a flexible solution for diverse applications.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!