Alumina Ceramic PCB vs. Aluminum Nitride Ceramic PCB Core Types, PCB Fabrication Processes, and Industry Applications

Ⅰ. Alumina Ceramic PCB vs. Aluminum Nitride Ceramic PCB: Type and Performance Comparison

1. Alumina Ceramic PCB (Al₂O₃)

① Single-Layer Alumina Ceramic Substrate: Suitable for simple circuit designs, with a thermal conductivity of 20–27 W/m·K, high electrical insulation, and cost-effectiveness.

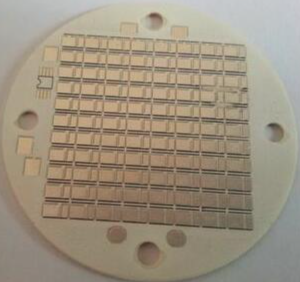

② Multilayer Alumina Ceramic Substrate: Supports complex circuit integration via lamination and microvia technology, widely used in consumer electronics and industrial control systems.

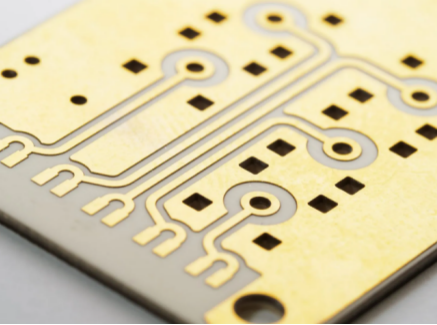

③ Metallized Alumina Ceramic Substrate: Surface copper/silver plating process, designed for high-power LED packaging and power module heat dissipation.

Aluminum Nitride Ceramic PCB (AlN)

① Single-Layer Aluminum Nitride Ceramic Substrate: Thermal conductivity of 180–220 W/m·K, low dielectric constant, ideal for high-frequency communication and 5G base station RF components.

② Multilayer Aluminum Nitride Ceramic Substrate: High-density wiring capability, meeting demands for radar systems and satellite communication in high-frequency scenarios.

③ Metallized Aluminum Nitride Ceramic Substrate: Ultra-high thermal conductivity, suitable for extreme heat dissipation in IGBT modules and laser diode packaging.

Performance Comparison:

Thermal Conductivity: Aluminum Nitride Ceramic Substrate (180–220 W/m·K) significantly outperforms Alumina Ceramic Substrate (20–27 W/m·K).

Warpage: Both ≤3‰ (0.3mm per 100mm), ensuring flatness and processing stability.

Copper Bond Strength: Both Alumina and Aluminum Nitride substrates ≥10 N/cm², guaranteeing long-term circuit reliability.

Ⅱ. Comprehensive Analysis of Alumina/Aluminum Nitride Ceramic PCB Fabrication Processes

1. Substrate Selection: High-purity Alumina or Aluminum Nitride ceramic substrates are precision-cut to standard dimensions (114×114mm to 190×140mm).

2. Metallization: Chemical plating (DPC) or high-temperature bonding (DBC) processes form a copper layer on Alumina/Aluminum Nitride substrates.

3. Patterning and Etching: Photolithography transfers circuit patterns precisely; redundant metal is etched to ensure line accuracy.

4. Drilling and Interconnection: Laser drilling enables microvia interconnection, supporting complex circuit designs in multilayer Alumina/Aluminum Nitride PCBs.

5. Surface Treatment: Gold plating/anti-oxidation processes enhance corrosion resistance and solderability.

6. Assembly and Testing: Automated SMT assembly and rigorous electrical/thermal performance testing for Alumina and Aluminum Nitride PCBs.

Ⅲ. Core Applications of Alumina Ceramic PCBs and Aluminum Nitride Ceramic PCBs

1.High-Power Electronic Packaging:

Alumina Ceramic PCBs: Widely used in LED lighting and home appliance control modules.

Aluminum Nitride Ceramic PCBs: Specialized in IGBT modules and new energy vehicle electronic control systems.

2.High-Frequency Communication Equipment:

Aluminum Nitride Ceramic PCBs: 5G base station filters and RF power amplifiers.

Alumina Ceramic PCBs: Mid-to-low frequency microwave circuits and sensor signal processing.

3.Industrial High-Temperature Scenarios:

Alumina Ceramic PCBs: High-temperature furnace tubes and chemical sensor carriers.

Aluminum Nitride Ceramic PCBs: Heat dissipation substrates for semiconductor manufacturing equipment.

4.Optoelectronic Field:

Aluminum Nitride Ceramic PCBs: Laser diode packaging for improved heat dissipation and lifespan.

Alumina Ceramic PCBs: General-purpose optoelectronic module substrates.

Ⅳ. PCBMASTER – Technical Advantages of Alumina and Aluminum Nitride Ceramic Substrates

Full Specification Support: Customizable Alumina and Aluminum Nitride substrates (thickness: 0.2–2.0mm, sizes up to 190×140mm).

Advanced Process Coverage: DPC (Direct Plated Copper), DBC (High-Temperature Bonding), and LTCC (Silver Paste Circuitry) technologies for diverse applications.

Strict Quality Control: Warpage ≤3‰, copper bond strength ≥10 N/cm², compliant with ISO certification standards.