Rigid-Flex PCB Design Guide 5 Core Technologies and 2024 Practical Data Analysis

I. Why Are Rigid-Flex PCBs Revolutionizing Electronic Product Architectures?

According to Prismark's 2024 report, the global rigid-flex PCB market has reached $7.8 billion and is expected to exceed $12 billion by 2028, with an annual growth rate of 13.5%. From pacemakers (as thin as 0.4mm) to SpaceX Starship control systems, rigid-flex PCB design is resolving three major contradictions through its "rigid-flex integration" characteristics:

1.Space Constraints: Saves 40% installation space compared to rigid boards (medical endoscope case study).

2.Reliability Issues: Reduces failure rates by 65% in vibration environments (automotive ECU test data).

3.Cost Efficiency: 22% lower BOM costs through higher integration (drone flight controller example).

II. Three Golden Rules for Material Selection

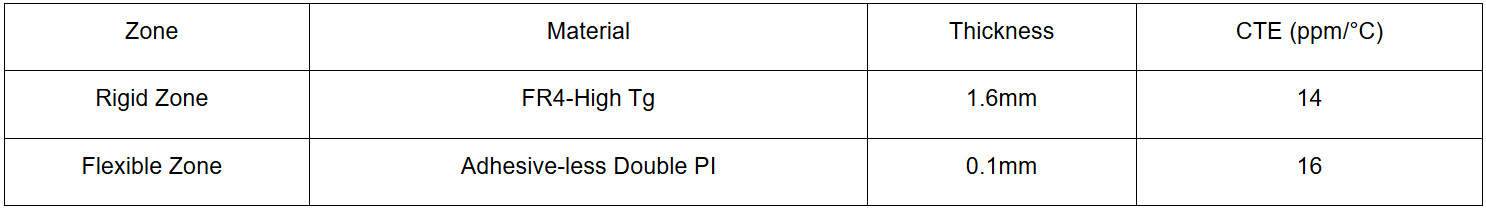

1. Material Matching Formula for Rigid-Flex Transition Zones

2024 Best Practices:

Data Source: Isola Group Material Handbook

2. Copper Foil Selection Guidelines

Dynamic Bending Areas: Rolled copper (50% better fatigue resistance).

High-Current Areas: RTF copper foil (surface roughness ≤3μm).

III. Five Deadly Traps in Rigid-Flex PCB Design

Trap 1: Z-Axis Stress Concentration (Causes 80% Delamination Failures)

Solutions:

①Stepped window design (72% stress reduction).

②45° chamfer in transition zones (IPC-2223B standard).

Trap 2: Incorrect Bending Radius Calculation

2024 Updated Formula:

Case Study:

①Flexible layer 0.1mm + adhesive 0.05mm → R≥0.75mm.

②Violating this rule reduces bending lifespan by 90% (Samsung Lab data).

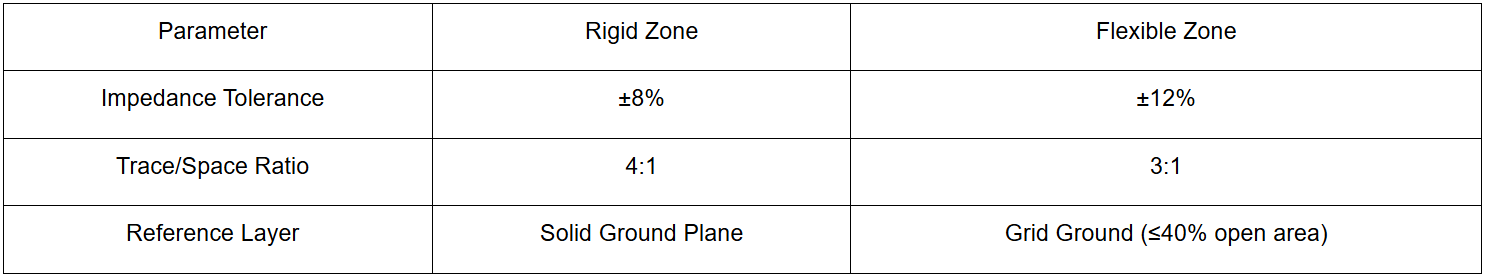

IV. Dual Strategies for Signal Integrity

1. Cross-Zone Transmission Line Design Rules

2. Breakthrough Research: Signal Distortion Compensation Algorithm

(f: Frequency/GHz, θ: Bending angle/degrees)

Data Source: Huawei 2012 Labs 2024 Report

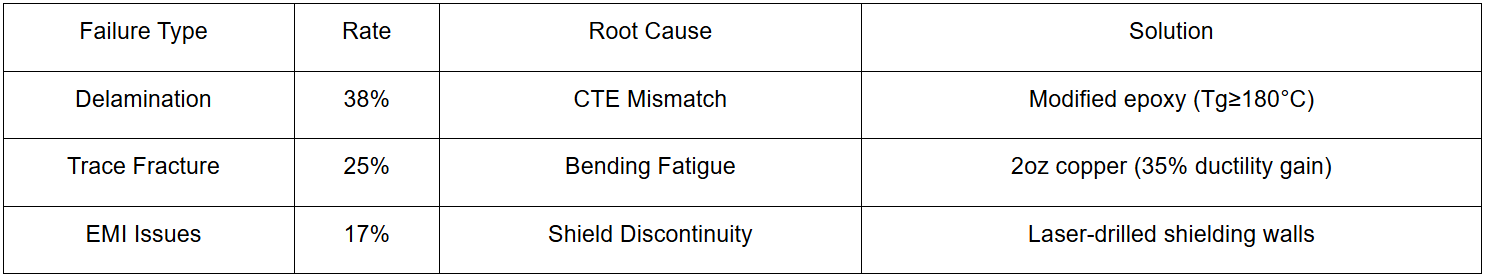

V. 2024 Industry Failure Analysis & Solutions

Data Source: IPC 2024 Failure Statistics

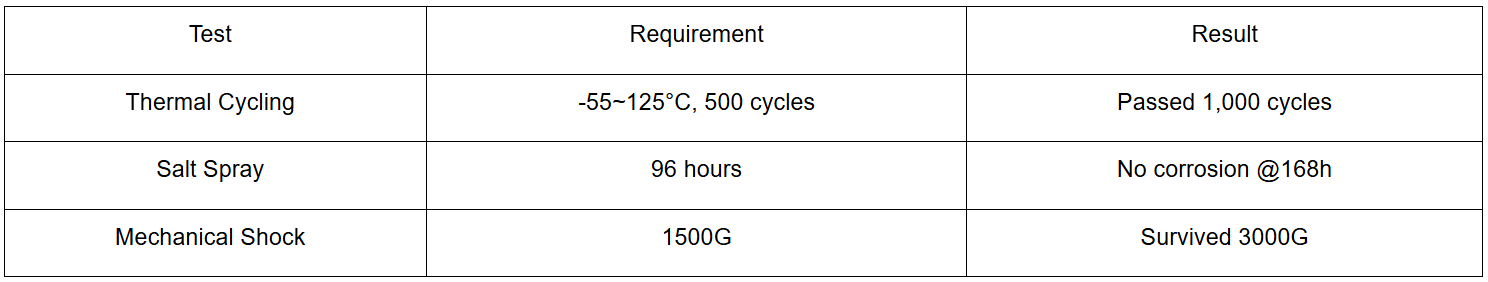

VI. Case Study: Military-Grade Rigid-Flex PCB Design

1. Extreme Environment Test Data

2. Advanced Protection Design

3μm nano-coating (IP68 waterproofing).

Edge gold-plating + laser sealing (leak rate <1×10⁻⁹ Pa·m³/s).

VII. Future Technology Trends

1.3D Heterogeneous Integration:

Via density up to 2,000 holes/cm² (5x improvement).

2.Self-Monitoring Circuits:

Embedded strain sensors (±0.5μm accuracy).

3.Eco-Friendly Substrates:

Bio-based PI materials (60% lower carbon footprint).

2024 Rigid-Flex PCB Design Checklist

1.Are tapered trace widths used in transition zones (≤20%/mm gradient)?

2.Are components smaller than 0402 avoided in dynamic bending areas?

3.Is 360° shielding continuity achieved at rigid-flex junctions?

4.Are test points placed ≥3mm from transition zones?

Data Sources:

1.IPC-2223B Rigid-Flex Design Standard

2.Prismark 2024 Q2 Manufacturing Report

3.Samsung Galaxy Z Fold7 Teardown Analysis

4.Lockheed Martin Military PCB Specifications

Author: Jack Wang