Potting vs. Conformal Coating: Which Is Better for PCB Protection?

When designing a printed circuit board (PCB), protecting it from environmental hazards like moisture, dust, and mechanical stress is crucial for ensuring long-term reliability. The right protection method can make all the difference, but with so many options available, how do you choose the best one? Potting and conformal coating are two popular methods, each offering unique advantages and limitations. Whether you're designing a rugged industrial sensor or a sleek consumer gadget, understanding the differences between these two protection techniques will help you select the optimal solution for your project’s needs.

What are Potting and Conformal Coating?

When designing and protecting PCBs, two common methods are used: potting and conformal coating. Both techniques offer different types of protection against environmental factors, but they work in unique ways. Let’s explore each method in detail.

Potting: What Is It and How Does It Work?

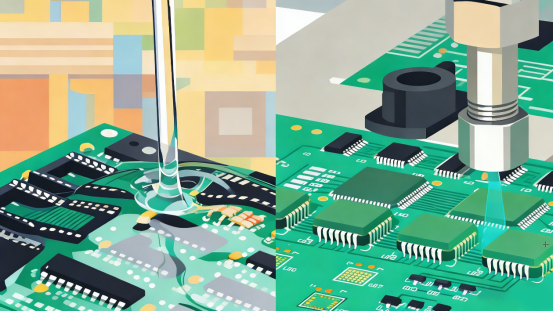

Potting refers to the process of completely encasing a PCB in a thick, solid resin. The resin typically used is epoxy, polyurethane, or silicone. The goal is to create a protective barrier that shields the PCB from harsh environmental conditions, such as moisture, dust, and chemicals, as well as from mechanical stresses like vibration and impact.

In potting, the PCB is submerged into a container filled with resin. Once the resin hardens, it forms a strong and durable shield around the entire board, providing maximum protection. This makes potting ideal for applications where the PCB will be exposed to extreme conditions—such as outdoor sensors, automotive electronics, or industrial machinery.

Real-Life Example: Imagine a PCB used in a car’s engine control unit (ECU). This part is constantly exposed to high temperatures, oils, and vibrations. Potting ensures the PCB remains protected from these harmful factors, preventing malfunctions.

Key Benefits of Potting:

Maximum protection against moisture, dust, chemicals, and vibration.

Provides a rigid, durable barrier that makes the PCB very resistant to physical damage.

Ideal for harsh environments such as automotive, industrial, or marine applications.

However, potting comes with some trade-offs. The added resin makes the PCB bulkier and heavier, which can be an issue for designs that need to be compact. Also, once the PCB is potted, it becomes difficult to repair or replace individual components.

Conformal Coating: What Is It and How Does It Work?

Conformal coating, on the other hand, is a process where a thin, flexible layer of protective material is applied directly onto the surface of a PCB. This coating is usually made from acrylic, silicone, urethane, or parylene. Unlike potting, the goal of conformal coating is not to completely cover the PCB but to create a thin film that conforms to the board’s shape.

This thin protective film shields the PCB from environmental factors like moisture, dust, and minor chemical exposure. It also protects the PCB from mild mechanical stress, such as light vibrations. Conformal coating is often used for consumer electronics and small, portable devices, where minimizing weight and size is important.

Real-Life Example: A PCB inside a smartphone needs to be lightweight, compact, and able to resist occasional spills or dust. Applying a conformal coating provides just enough protection without adding significant weight or size to the device.

Key Benefits of Conformal Coating:

Lightweight and doesn’t add much size or weight to the PCB, making it perfect for small devices.

Allows easy repair and inspection of components since the coating can be removed and reapplied.

Suitable for applications in mild environments like indoor devices, wearables, and home appliances.

However, conformal coating does not offer the same level of protection as potting. It can’t protect against harsh chemicals or extreme mechanical stresses, and it is not waterproof (unless using specific coatings like parylene).

Key Differences Between Potting and Conformal Coating

When it comes to protecting PCBs, both potting and conformal coating offer valuable protection. However, they differ significantly in terms of protection strength, physical structure, repairability, cost, and curing time. Understanding these differences will help you choose the right method for your project’s needs.

Protection Strength

Potting: Potting provides maximum protection. The thick resin completely surrounds the PCB, forming a solid barrier that effectively keeps out moisture, dust, chemicals, and extreme mechanical stresses like vibrations or impacts. This makes potting ideal for environments with high contamination or harsh conditions, such as outdoor sensors, automotive electronics, and industrial machinery.

Example: In a car’s engine bay, where heat, oil, and vibration are common, potting is essential to ensure the PCB continues to function reliably.

Conformal Coating: Conformal coating offers moderate protection. The thin coating covers the surface of the PCB, providing resistance to moisture and dust, but it does not protect against severe chemicals or heavy mechanical impacts. It is suitable for environments that are less demanding, like office settings or consumer electronics.

Example: Smartphones are often coated with conformal coating because they need protection from moisture (like sweat or spills), but not from harsh chemicals or extreme conditions.

Physical Structure

Potting: Potting involves encasing the entire PCB in a thick resin, with a typical thickness ranging from 1mm to 5mm. This results in a rigid, protective shell that completely isolates the PCB from external elements. While this provides strong protection, it also adds bulk to the device. This method is preferred when space is not a concern and maximum durability is needed.

Example: Industrial equipment or marine electronics often use potting because they can afford the extra size and weight for superior protection.

Conformal Coating: In contrast, conformal coating applies a thin, flexible film to the surface of the PCB, usually around 25μm to 100μm thick. This film conforms to the PCB's shape and provides a lighter, more compact protection. Since it’s much thinner than potting, it doesn’t add significant weight or bulk to the device.

Example: Wearable devices like fitness trackers benefit from conformal coating as it allows for protection without compromising the lightweight nature of the device.

Repairability

Potting: Once a PCB is potted, the resin forms a permanent barrier, making repairs very difficult. If a failure occurs, the entire PCB usually needs to be replaced because removing the resin is complicated and often damages the components. Potting is more suitable for applications where the PCB is not expected to require maintenance or repair.

Example: Medical devices that need to function for many years without failure (such as heart rate monitors) might be potted for long-term reliability, even if repairs are not possible.

Conformal Coating: On the other hand, conformal coating is much easier to repair. The coating can be removed by scraping or using solvents like isopropyl alcohol. This allows for easy inspection, maintenance, and component replacement. If an issue arises with a specific component, it can be replaced without having to discard the entire PCB.

Example: Smartphones often use conformal coating because users might need to open up the device for repairs or upgrades, such as changing the battery or replacing a component.

Cost Differences

Potting: Potting tends to be more expensive due to the materials and labor involved in the process. The resin itself is relatively costly, and applying it requires careful, manual work. The cost for potting typically ranges from $2 to $10 per PCB. This higher cost is justified when maximum protection and durability are needed.

Example: Custom industrial sensors, which are produced in smaller quantities but need high reliability, often justify the higher cost of potting.

Conformal Coating: Conformal coating is generally more affordable. The materials are cheaper, and the application process is faster, often using automated spray systems. The cost per PCB usually ranges from $0.5 to $2. This makes it a more cost-effective choice for mass-produced consumer electronics.

Example: Consumer gadgets like smartwatches, which are produced in large quantities, benefit from the low cost of conformal coating.

Curing Time

Potting: Potting requires longer curing times because the resin needs to fully harden to create a durable protective layer. This process typically takes between 2 to 24 hours, depending on the resin type and environmental conditions. This longer curing time can delay production, especially when working with large volumes of PCBs.

Example: For industrial equipment where time is less of a concern, the long curing process is manageable.

Conformal Coating: In contrast, conformal coating cures much faster. Depending on the type of coating, it can take as little as 10 minutes to 2 hours to cure. For UV-cured coatings, the process can be completed even faster. This quick curing time makes conformal coating ideal for high-volume manufacturing, where speed is essential.

Example: In consumer electronics manufacturing, where thousands of devices are produced every day, the fast curing time of conformal coating helps keep production lines moving smoothly.

Comparison Table

| Feature | Potting | Conformal Coating |

| Protection Level | Maximum protection (water, dust, chemicals, vibration) | Moderate protection (water, dust, light chemicals) |

| Physical Structure | Thick resin encasing entire PCB (1–5mm) | Thin, flexible film (25μm–100μm) |

| Repairability | Difficult, often requires full replacement | Easy, can be peeled off and reapplied |

| Cost | $2–$10 per PCB | $0.5–$2 per PCB |

| Curing Time | 2–24 hours | 10 minutes–2 hours |

By understanding these key differences, you can select the protection method that best suits the needs of your PCB project, ensuring both performance and cost-effectiveness. Whether you need the maximum durability of potting or the flexibility and repairability of conformal coating, knowing how each method works will guide you toward the right choice.

How to Choose Between Potting and Conformal Coating Based on Environment, Mechanical Stress, Space/Weight Limitations, Repairability, and Cost

When selecting the right protection method for a PCB (Printed Circuit Board), several factors must be considered. These include the environment in which the PCB will be used, the amount of mechanical stress it will face, space and weight restrictions, whether repairs might be necessary, and the project’s overall cost and production volume. By understanding how each factor influences the decision, you can choose the best protection method for your device.

Environmental Factors: Does Your PCB Face Extreme Conditions?

Potting for Harsh Environments:

If your PCB will be exposed to extreme temperatures, chemicals, or moisture—such as in outdoor sensors, industrial equipment, or automotive applications—potting is the best choice. Potting creates a thick resin barrier that protects the PCB from moisture, dust, chemicals, and vibration. This is ideal for environments where the PCB is exposed to harsh elements.

Example: A PCB used in an outdoor weather station or a vehicle’s engine control unit (ECU) needs potting to resist extreme temperatures, rain, snow, or oil.

Conformal Coating for Indoor Devices:

For devices operating in milder conditions, like smartphones, smart home devices, or other indoor electronics, conformal coating is sufficient. It protects against light moisture and dust but won’t shield the PCB from heavy chemicals or extreme weather conditions. Conformal coating is perfect for environments where the risks are minimal.

Example: A smart thermostat installed in a home only needs protection from occasional dust and moisture, making conformal coating the ideal choice.

Mechanical Stress: How Much Vibration, Shock, or Pressure Will the PCB Experience?

Potting for High Stress:

If the PCB is expected to endure strong vibrations, shocks, or mechanical pressure—such as in heavy machinery, automotive electronics, or industrial equipment—potting is necessary. The thick resin provides added protection and helps absorb shocks, preventing components from being damaged or displaced. Potting can also protect the PCB from pressure changes or mechanical stresses that could cause damage over time.

Example: A PCB inside a construction tool or industrial sensor is constantly subjected to shocks and vibrations. Potting ensures the PCB components stay secure and function reliably.

Conformal Coating for Light Stress:

For devices that only experience mild vibration or no significant physical impact—such as smartphones, smartwatches, or office equipment—conformal coating provides adequate protection. It shields the PCB from dust and light moisture but doesn’t need to absorb shocks or heavy mechanical pressure. Conformal coating is thin, lightweight, and flexible, offering protection without adding extra bulk.

Example: A smartwatch experiences light vibration when worn, but the conformal coating is enough to protect it from everyday conditions without adding weight or size.

Space and Weight Limitations: How Compact is Your Device?

Conformal Coating for Small and Lightweight Devices:

When working with small, compact devices—such as wearables, IoT sensors, or portable electronics—conformal coating is the clear choice. Its thin, flexible film adds little to no weight or size, making it perfect for devices where space and weight are critical.

Example: A fitness tracker or a hearing aid requires minimal space, and the lightweight nature of conformal coating makes it an ideal protection method without affecting the device's portability.

Potting for Larger Devices:

For larger devices, such as industrial sensors, external equipment, or products where space and weight are not as critical, potting can be used. Although potting adds bulk and weight, it’s a good option for devices that need the highest level of protection but can afford to increase in size or weight.

Example: Industrial control systems, where space and weight are not as critical, can benefit from the robust protection offered by potting without concerns about the added bulk.

Repairability: Will the PCB Need to Be Repaired or Upgraded?

Conformal Coating for Easy Repairs:

If the PCB is part of a device that might require repairs, upgrades, or routine inspections, conformal coating is the better choice. The coating can be easily removed using solvents or scraping methods, allowing technicians to access and replace damaged components without damaging the PCB itself. This is especially important for consumer electronics and devices that are expected to be maintained or updated over time.

Example: In smartphones, components like batteries or screens might need replacement. With conformal coating, technicians can remove the coating, make repairs, and reapply it.

Potting for Non-Repairable Devices:

For devices that are unlikely to need repairs or for those that will be used in remote or difficult-to-access locations—such as disposable industrial sensors or aerospace electronics—potting is more suitable. Once the PCB is potted, the resin hardens and prevents any repairs. This makes potting ideal for long-term reliability, where repairs are not feasible.

Example: A PCB used in a remote solar power system might be potted because it won’t need maintenance, and the focus is on long-lasting protection against the elements.

Cost and Production Volume: How Many PCBs Are You Producing?

Conformal Coating for High-Volume Production:

For mass production of consumer electronics, where cost and speed are important, conformal coating is the more economical option. The application process is fast and can be automated, making it ideal for high-volume production. Additionally, the lower material costs of conformal coating make it more suitable for large-scale manufacturing of affordable products.

Example: In the production of thousands of smartphones, conformal coating provides cost-effective protection for PCBs without significantly impacting the overall price of the device.

Potting for Low-Volume, High-Reliability Projects:

For low-volume projects that require high reliability, such as medical devices, aerospace electronics, or custom industrial equipment, potting may be worth the additional cost. While potting is more expensive due to the materials and labor involved, it provides superior protection, making it ideal for mission-critical devices where reliability and longevity are more important than cost.

Example: In medical devices like pacemakers or in space-bound equipment, where failure is not an option, the higher cost of potting is justified for the level of protection it offers.

Summary: How to Choose the Right Protection Method

To summarize, the choice between potting and conformal coating depends on the following factors:

Environment: Potting for harsh environments (extreme temperatures, chemicals, water); conformal coating for indoor, milder conditions.

Mechanical Stress: Potting for high vibration, shock, or pressure; conformal coating for light stress.

Space and Weight: Conformal coating for compact, lightweight devices; potting for larger devices where size and weight are less of a concern.

Repairability: Conformal coating for devices needing repairs or upgrades; potting for long-lasting, non-repairable systems.

Cost and Production Volume: Conformal coating for high-volume, low-cost production; potting for low-volume, high-reliability projects.

By carefully evaluating these factors, you can make a well-informed decision that balances protection, cost, and practicality for your specific application.

Conclusions

Choosing between potting and conformal coating ultimately depends on the unique requirements of your project, whether it's environmental protection, mechanical stress resistance, space constraints, or repairability. By understanding the key differences and evaluating your specific needs, you can ensure your PCB is properly protected and optimized for performance.

For reliable, high-quality PCBs, PCBMASTER is a trusted supplier that can guide you through the selection of the best protection method for your application. With a wide range of solutions tailored to meet the demands of various industries, PCBMASTER ensures your designs are safe, durable, and ready to perform in the toughest environments. Let their expertise support your next project and keep your devices running smoothly, no matter the conditions.

FAQs

Can Potting Improve Thermal Management for PCBs?

Yes, potting can help improve heat dissipation, especially in high-power electronics. By using thermally conductive resins, such as those filled with aluminum oxide, potting can transfer heat away from hot components like voltage regulators. This helps in managing heat more effectively and prevents overheating, which is crucial in power-hungry devices. Example: Power electronics, such as power supplies or motor controllers, often use thermally conductive potting to ensure reliable performance under high temperatures.

Is Conformal Coating Waterproof?

Generally, most conformal coatings are only splash-proof and offer protection up to IP54, meaning they can resist light moisture but not submersion in water. However, parylene coating can meet IP67 standards, providing full waterproofing protection. If waterproofing is critical, parylene is the ideal choice, especially for devices exposed to more extreme environments like marine electronics or outdoor sensors. Example: Consumer devices like smartphones might use conformal coating for basic water resistance, while underwater sensors would require parylene for full waterproofing.

Can Potting and Conformal Coating Be Used Together?

Yes, in some specific cases, potting and conformal coating can be used together. This is typically when different parts of the PCB require different levels of protection. For example, potting can be used for sensitive areas like sensors or circuits that need full protection, while conformal coating can be applied to connectors or other components that may need easy access for repairs or upgrades. This hybrid approach offers flexibility in ensuring both maximum protection and ease of maintenance.

Example: An industrial sensor might be potted to protect it from chemicals and moisture, while the connectors could be conformally coated to allow easy servicing.

What is the Lifespan of Potting and Conformal Coating?

Potting typically lasts 10 to 20 years, making it ideal for long-term applications like automotive or aerospace systems where the device needs to function reliably for many years without failure.

Conformal Coating has a shorter lifespan, usually 5 to 10 years, and is more suitable for consumer electronics or devices that are not exposed to extreme conditions.

Example: A long-term device like a medical sensor used in a hospital might benefit from potting, while a smartphone or laptop, which has a shorter expected lifespan, is better protected with conformal coating.

Should I Choose Potting or Conformal Coating for Medical Devices?

Implantable devices (e.g., pacemakers) should use parylene conformal coating because it is biocompatible, thin, and durable, offering reliable protection while being safe for use in the human body.

Portable devices (e.g., ultrasound probes) can benefit from potting, especially if they are exposed to moisture or harsh cleaning chemicals. Potting provides higher protection against such factors, ensuring the device continues to perform safely and effectively over time.

Example: A portable medical sensor that is often exposed to disinfectants may be potted, whereas an implanted device like a pacemaker would use parylene for protection.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!