Medical PCB Manufacturer Selection: The Ultimate Guide to Ensuring Quality and Compliance

Selecting the right medical PCB manufacturer is more than just a business decision; it’s a matter of patient safety and regulatory compliance. PCBs, the essential electrical components found in devices like pacemakers, glucose monitors, and diagnostic machines, control critical functions. If these circuits fail, the consequences can be disastrous—ranging from malfunctioning equipment to serious harm to patients.

Imagine your device being used in a life-or-death situation, and a poor-quality PCB causes it to fail. That’s the risk of choosing the wrong manufacturer. Beyond safety, there's the matter of compliance. Regulatory bodies like the FDA and ISO 13485 have strict standards for medical devices, and if your PCB manufacturer doesn’t meet these, your product could face delays, recalls, or even legal action.

Choosing the right medical PCB manufacturer ensures that your device performs as intended, meets all regulatory requirements, and ultimately, keeps patients safe. In this guide, we’ll show you how to select a manufacturer who will help your product succeed, avoiding costly mistakes and ensuring high-quality, reliable PCBs for your device.

What Are the Key Requirements for Medical PCB Manufacturing?

The key requirements for medical PCB manufacturing include ensuring miniaturization, biocompatibility, electromagnetic compatibility (EMC), and long-term durability. These factors are critical for meeting regulatory standards and ensuring patient safety.

What are the Technical Challenges in Designing Medical PCBs?

The main technical challenges in designing medical PCBs include managing miniaturization and complexity, ensuring biocompatibility, meeting EMC standards, and guaranteeing durability and reliability for long-term use.

Miniaturization and Complexity

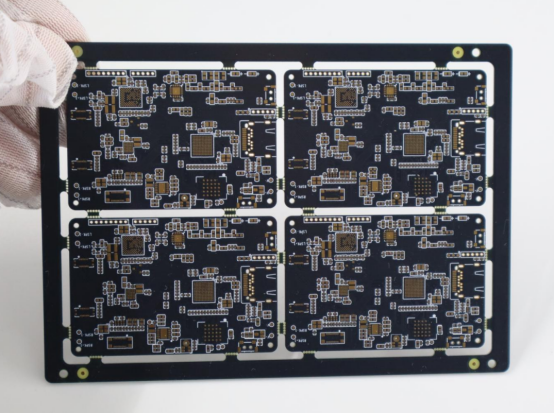

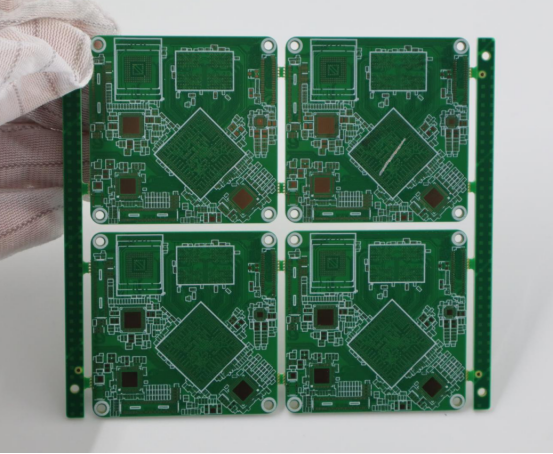

Medical devices require compact, highly functional PCBs. Rigid-flex and multi-layer PCBs help meet these needs by allowing flexible designs and stacking circuits to save space. For example, a wearable heart monitor might use a multi-layer PCB for its small size while maintaining the necessary functions.

Biocompatibility

It’s crucial that medical PCBs use biocompatible materials that don’t react negatively with the human body. Materials like polyimide or ceramic are ideal because they are resistant to body fluids and maintain stability over time. For implantable devices, these materials ensure the PCB doesn’t cause infections or other harmful reactions.

EMC

Medical devices must meet EMC standards to prevent interference with other hospital equipment. IEC 60601 is a key standard, ensuring that devices like pacemakers or MRI machines can function without disrupting other critical systems. Special techniques like shielding and filtering are used to prevent EMI in medical PCBs.

Durability and Reliability

Medical PCBs need to last for 5–10 years without failure. This means they must be made from durable materials that can withstand temperature fluctuations and exposure to body fluids. Additionally, solder joints and components must be resistant to corrosion and degradation over time.

How Does Regulatory Compliance Impact Medical PCB Design?

Regulatory compliance ensures that medical PCBs meet strict safety and quality standards, including certifications like ISO 13485 and FDA registration, as well as adherence to standards like IEC 60601 for EMC and RoHS/REACH for hazardous materials.

ISO 13485 and FDA Registration

Medical PCBs must meet ISO 13485 and FDA regulations to ensure they comply with global safety and quality standards. These certifications guarantee that manufacturers follow rigorous quality management systems. For instance, a heart monitor must be FDA-approved to be sold in the U.S.

EMC Standards

The IEC 60601 standard ensures that medical devices don’t emit harmful electromagnetic interference. Manufacturers must design PCBs that meet this standard, ensuring that devices like a portable ECG machine won’t interfere with sensitive hospital equipment like MRI machines.

Material Restrictions (RoHS/REACH)

Medical PCBs must comply with RoHS and REACH regulations to avoid harmful substances. RoHS restricts materials like lead and mercury, while REACH ensures the chemicals used in the manufacturing process are safe for human health and the environment. For example, a surgical device would use lead-free solder to meet RoHS requirements.

How to Find the Right PCB Manufacturer for Medical Devices?

To find the right PCB manufacturer for medical devices, focus on specialized expertise, industry certifications, and technical capabilities.

What Are the Best Sources for Identifying Qualified Medical PCB Manufacturers?

To identify qualified medical PCB manufacturers, you can explore industry directories, attend trade shows and conferences, and seek referrals from industry peers. These sources will help you find manufacturers who specialize in medical-grade PCBs and meet the necessary regulatory and technical standards.

Industry Directories and Resources

Industry directories like the Medical Device Manufacturers Association (MDMA) or IPC’s medical PCB database are reliable sources to find qualified PCB manufacturers specializing in medical devices. These resources provide a curated list of manufacturers with proven expertise in the medical field.

Trade Shows and Conferences

Attending trade shows like MD&M West or Compamed is an effective way to connect with reputable manufacturers. These events allow you to meet manufacturers face-to-face, learn about their capabilities, and see their products firsthand, which helps you assess their suitability for your medical device project.

Referrals and Client References

Seeking referrals from peers in the medical device industry or reviewing client references can help you identify trustworthy PCB manufacturers. Companies that have already worked with the manufacturer can provide valuable insights into their quality, reliability, and regulatory compliance, making the decision process easier.

What Key Criteria Should You Use for Screening Medical PCB Manufacturers?

When screening PCB manufacturers, focus on their medical device experience, required certifications, and technical capabilities to ensure they meet the specific needs of your medical device.

Medical Device Experience

It’s essential that more than 50% of a manufacturer’s business is dedicated to medical PCBs. This ensures they understand the unique challenges of medical devices, such as strict regulatory requirements and the need for high precision and reliability. For example, a manufacturer with experience in implantable devices will be more knowledgeable about biocompatibility and durability.

Certifications

Make sure the manufacturer holds ISO 13485 certification for medical device quality management and FDA registration for U.S. sales. These certifications are essential to ensure the manufacturer follows stringent standards for medical device production. Additional certifications like IPC-A-610 for electronic assembly can also demonstrate the manufacturer’s commitment to high-quality standards.

Technical Capabilities

Evaluate the manufacturer’s technical capabilities to ensure they can meet the specific needs of your PCB design. This includes their ability to handle rigid-flex or multi-layer designs, as well as their proficiency in advanced testing methods such as automated optical inspection (AOI), X-ray inspection, and functional testing to ensure the PCB meets medical device standards.

What Red Flags Should You Watch Out for When Selecting a Manufacturer?

When selecting a PCB manufacturer, watch for lack of transparency, limited testing capabilities, and an overemphasis on price over quality, which could signal potential risks to your product’s safety and compliance.

Lack of Transparency

A manufacturer that is unwilling to share client references or certifications may not be trustworthy. Transparency is essential in the medical device industry, as it ensures the manufacturer adheres to the necessary standards and regulations. Avoid manufacturers who are hesitant to provide this information.

Limited Testing Capabilities

If a manufacturer does not offer advanced testing capabilities like X-ray inspection or in-circuit testing (ICT), they may not be equipped to detect hidden defects in the PCB. For medical devices, thorough testing is crucial to ensure safety and functionality. Lack of these capabilities could compromise the performance and reliability of the device.

Price Over Quality

Focusing solely on cost can lead to serious long-term risks. While cheaper manufacturers may offer lower prices, they often cut corners on quality, which could result in non-compliance, product recalls, or other costly issues. Prioritize manufacturers that offer a balance of quality and cost-effectiveness.

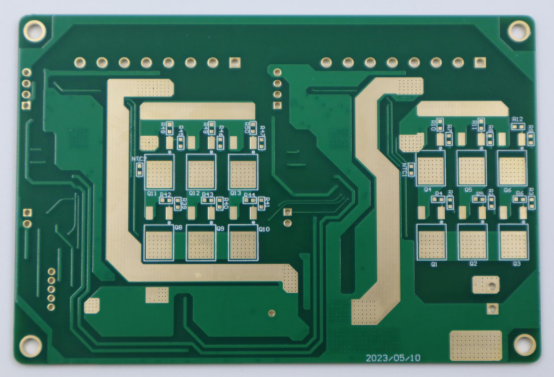

PCBMASTER: A Trusted Solution for Medical PCBs

PCBMASTER is a leading provider of high-quality medical PCBs, offering advanced manufacturing capabilities and compliance with all necessary industry standards. With a focus on precision, reliability, and regulatory compliance, PCBMASTER ensures your medical devices meet the highest standards of safety and performance. Whether you need multi-layer PCBs, rigid-flex designs, or advanced testing services, PCBMASTER provides tailored solutions to support your product’s success in the market.

How to Evaluate a Manufacturer’s Technical Capabilities for Medical PCBs?

To evaluate a manufacturer’s technical capabilities for medical PCBs, focus on their expertise in material selection, precision design, and compliance with EMC standards.

What Specialized Skills Should You Look for in a Medical PCB Manufacturer?

You should look for manufacturers skilled in using biocompatible materials, precision design techniques, and EMC shielding. These skills are crucial to ensure the PCB is safe, reliable, and compliant with medical industry standards.

Material Expertise

The manufacturer must have a deep understanding of biocompatible and sterilization-resistant materials, such as polyimide and ceramics, to ensure the PCB's functionality in medical devices. These materials must withstand sterilization processes and be safe for contact with the human body. Their knowledge of these materials ensures that the PCB will maintain integrity over time without compromising patient safety.

Precision and Miniaturization

Manufacturers should be proficient in Laser Direct Imaging (LDI) to create fine-pitch traces and microvias. This technology is essential for producing high-precision, miniaturized designs required for medical devices like wearables, implantables, and diagnostic tools. Precision ensures that even the most complex medical devices can fit within the tight spaces required by their design, without losing performance.

EMC Shielding and Testing

To meet IEC 60601 and other EMC standards, manufacturers must integrate EMC shielding methods, such as copper pours or metal enclosures. These techniques prevent electromagnetic interference (EMI), which could disrupt the functioning of medical devices or nearby equipment. Manufacturers should also perform EMC testing to verify that their designs are compliant with safety regulations, preventing risks like data corruption or device malfunctions in medical settings.

How Does a Manufacturer Ensure Quality Control for Medical PCBs?

A reliable manufacturer should have strict quality control processes in place, including multi-stage inspection, traceability systems, and continuous improvement models.

Multi-Stage Inspection

Manufacturers must use multiple inspection methods, such as In-Circuit Testing (ICT), Automated Optical Inspection (AOI), X-ray inspection, and functional testing. These tests help identify electrical faults, visual defects, and hidden issues in the PCB, ensuring that only high-quality, fully functional PCBs are used in medical devices. Each inspection stage plays a critical role in ensuring the PCB's reliability and safety.

Traceability Systems

A strong traceability system is vital for tracking each PCB’s production journey, from raw material to finished product. This system helps verify that the PCB meets all FDA and ISO 13485 compliance requirements and facilitates efficient recalls if needed. It also ensures full accountability, as every step of the production process is documented and traceable.

Continuous Improvement Models

Manufacturers should implement continuous improvement models like DMAIC (Define, Measure, Analyze, Improve, Control) to refine their processes over time. By using this approach, manufacturers can identify inefficiencies, reduce defects, and ensure that every batch of medical PCBs meets the highest standards for quality and consistency.

How Do Manufacturers Validate Their Processes for Regulatory Compliance?

Manufacturers must validate their processes to meet FDA and ISO requirements and provide adequate support for regulatory audits.

Manufacturing Process Validation (MPV)

For Class III medical devices, MPV is essential to ensure that the manufacturing process is capable of consistently producing high-quality PCBs. MPV confirms that the equipment, materials, and production methods used by the manufacturer meet FDA standards for consistency and safety. It ensures that each PCB is produced with the necessary precision and reliability.

Audit Support and Documentation

A reputable manufacturer should provide audit support and comprehensive documentation to assist with FDA audits and regulatory submissions. This includes process validation records, quality control documentation, and material certifications. By offering full support, the manufacturer ensures compliance with industry standards, making it easier for medical devices to gain regulatory approval and enter the market quickly.

How Do You Build a Long-Term, Effective Relationship with Your Medical PCB Manufacturer?

Building a long-term relationship with a medical PCB manufacturer goes beyond simply placing orders. It's about establishing trust, clear communication, and shared goals.

How Do You Assess Manufacturer Communication and Support?

Clear communication and dedicated support are vital for a smooth working relationship with your manufacturer. You need to ensure that the manufacturer provides dedicated points of contact, keeps you updated regularly, and collaborates to resolve challenges efficiently.

Dedicated Points of Contact

Having a designated project manager or contact person ensures consistent communication throughout the manufacturing process. This point of contact helps streamline information flow, addressing questions, concerns, or any issues that arise quickly. It fosters transparency and ensures the project stays on track with minimal delays.

Regular Updates

Manufacturers should keep you informed about progress, testing outcomes, and potential issues. Regular updates help you manage expectations and adjust plans accordingly. For example, if a delay occurs due to supply chain issues or technical challenges, timely updates allow you to plan accordingly and mitigate the impact on your project.

Collaborative Problem-Solving

A manufacturer that collaborates with you to solve design or compliance issues is a valuable partner. For instance, if a medical device faces challenges with regulatory standards, a manufacturer with strong problem-solving capabilities will work with you to find solutions. This could mean tweaking the design, adjusting materials, or addressing manufacturing obstacles to ensure compliance and product success.

Why Is It Important to Visit the Manufacturer’s Facility?

Visiting the manufacturer’s facility allows you to assess production standards, equipment quality, and team expertise in person. It also gives you a better understanding of the manufacturer’s commitment to quality and compliance, ensuring they meet medical industry requirements.

Facility and Cleanroom Standards

Inspecting the cleanliness and organization of a manufacturer’s facility helps you gauge their commitment to high production standards. Cleanrooms are essential in medical PCB production to avoid contamination. You should look for facilities with proper cleanliness protocols and storage conditions for biocompatible materials, as well as tools for safe handling.

Equipment Investment

Advanced manufacturing equipment is a key indicator of a manufacturer’s ability to meet medical PCB standards. Machines such as Laser Direct Imaging (LDI) for precision, automated testing stations, and other state-of-the-art tools demonstrate that the manufacturer is investing in the right technologies. These tools ensure that your medical PCBs meet the rigorous standards needed for medical devices.

Team Expertise

Meeting the manufacturer’s quality control and engineering team is essential to understanding their capabilities. Discussing testing processes and certifications in person will give you confidence that the team has the experience and expertise to handle the specific challenges of medical device production. It also helps you assess their commitment to continuous improvement and adherence to regulatory standards.

What Are the Key Points to Address in the Contract Negotiation?

A well-structured contract ensures clear expectations and protects both parties in the manufacturing process. Key areas to address include regulatory responsibilities, intellectual property protection, and quality guarantees to avoid future disputes or issues.

Regulatory Responsibilities

In the contract, clarify the manufacturer’s role in meeting FDA requirements and supporting regulatory audits. The manufacturer should be responsible for managing compliance, providing necessary documentation like process validation records, and ensuring that your product meets all legal standards. This reduces your risks when going through regulatory approval.

IP Protection

Protecting your intellectual property (IP) is crucial in the medical device industry. Your contract should include clauses that guarantee the confidentiality of your PCB designs and proprietary data. NDAs (Non-Disclosure Agreements) and terms protecting your intellectual property ensure that your designs are not copied or shared without authorization, safeguarding your competitive edge.

Quality Guarantees

A contract should specify clear quality targets, such as maximum defect rates and procedures for handling defective products. For example, including a guarantee of less than 100 parts per million (ppm) defects ensures that the manufacturer delivers high-quality PCBs. Additionally, include terms for addressing issues like non-conforming products or delays, ensuring that you can hold the manufacturer accountable to high standards.

Conclusion: Ensuring Long-Term Success with the Right PCB Manufacturer

Choosing the right PCB manufacturer for medical devices is critical to ensuring both safety and long-term success. Start by evaluating key criteria like technical expertise, regulatory compliance, and manufacturing capabilities. A trusted partner should have a deep understanding of medical industry standards and be committed to quality, from material selection to production processes. The manufacturer should also offer transparency, support, and the ability to handle complex designs and testing requirements. Maintaining a relationship with a manufacturer focused on continuous improvement, safety, and compliance is essential for consistent, high-quality results. With a reliable partner, you can navigate the challenges of medical device production with confidence, ensuring your products meet both regulatory requirements and market expectations. PCBMASTER is a top choice for medical PCB manufacturing, offering expertise in advanced designs, quality control, and regulatory compliance to support your device's success

FAQs

What are the most important certifications for a medical PCB manufacturer?

The most important certifications for a medical PCB manufacturer are ISO 13485 and FDA registration. ISO 13485 ensures that the manufacturer follows stringent quality management systems specifically for medical devices, guaranteeing safety and consistency in the production process. FDA registration is essential for manufacturers selling products in the U.S. It confirms compliance with FDA regulations, demonstrating that the manufacturer adheres to necessary standards for medical device safety and effectiveness. Both certifications are critical to ensuring that the manufacturer meets global medical device quality requirements.

How do I ensure that the manufacturer has the right experience with my type of medical device?

To ensure that the manufacturer has the right experience for your specific medical device, look for manufacturers with a strong track record in medical-grade PCBs and relevant device types, such as implantable devices, wearables, or diagnostic equipment. Ask for examples of similar projects they have handled and request case studies or references from previous clients. It's also helpful to evaluate the manufacturer's experience with regulatory compliance, especially if your device requires specific certifications like FDA approval or adherence to ISO 13485 standards.

What kind of testing is required for medical PCBs to meet regulatory standards?

To meet regulatory standards, medical PCBs must undergo several critical testing methods:

In-Circuit Testing (ICT): Detects electrical faults such as short circuits, open circuits, or incorrect components on the PCB.

Automated Optical Inspection (AOI): Inspects the board visually for manufacturing defects like misalignment, soldering issues, and component placement errors.

X-ray Inspection: Used to check the internal layers of the PCB for hidden defects, such as solder joint issues that are not visible on the surface.

Functional Testing: Verifies that the PCB performs its intended functions under normal operational conditions.

These tests are essential to meet safety, performance, and regulatory standards, including IEC 60601 (for electromagnetic compatibility) and RoHS (for hazardous materials).

Can a manufacturer help with FDA approval and regulatory submissions?

Yes, a qualified PCB manufacturer can provide significant support during the FDA approval and regulatory submission processes. They can assist by offering necessary documentation, such as test reports, process validation records, and material certifications, which are required for regulatory reviews. Additionally, they should be familiar with FDA 21 CFR Part 820 and other relevant regulations to ensure that the manufacturing process aligns with the standards. A good manufacturer can also help with audit support, making the approval process smoother and faster.

How do I evaluate if a PCB manufacturer is offering value beyond just the quote price?

When evaluating a PCB manufacturer, it's crucial to look beyond the initial quote and consider the following factors:

Quality Assurance: Ensure the manufacturer follows ISO 13485 and other relevant certifications, offering high-quality, compliant PCBs.

Support and Communication: Evaluate the level of customer support, including the manufacturer’s willingness to provide regular updates, troubleshooting, and documentation.

Technical Expertise: Look for a manufacturer with experience in your specific type of medical device and advanced technical capabilities for handling complex PCB designs.

Long-Term Costs and Reliability: Consider the long-term value of choosing a manufacturer that offers consistent quality, regulatory compliance, and after-sales support, as these will help avoid costly issues down the line, such as product recalls or regulatory fines.

By considering these aspects, you can ensure that the manufacturer you choose delivers lasting value, not just an attractive initial price.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!