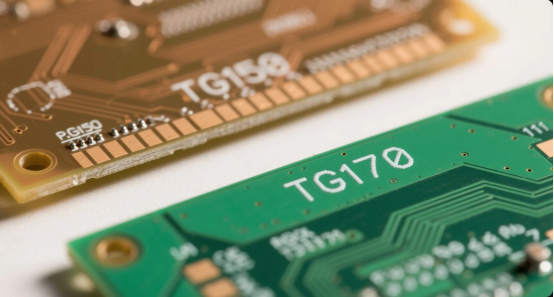

PCB FR-4 TG150 vs. TG170 How to Choose the Right Material for Your Project

Introduction

In the field of electronic manufacturing, selecting the appropriate PCB substrate material is crucial for ensuring product performance and reliability. This article provides an in-depth analysis of the differences between FR-4 TG150 and TG170 materials to help you understand the distinctions and make an informed decision.

In modern electronic product design, printed circuit boards (PCBs) serve as the foundation that connects various electronic components. The performance of a PCB largely depends on its substrate material.

As the most common PCB substrate material, FR-4 is divided into multiple grades based on its glass transition temperature (Tg), with TG150 and TG170 being two common high-performance options. Understanding their differences is essential for designing high-performance and highly reliable electronic products. It is important to focus on the Tg value when selecting materials, as this directly impacts the thermal stability and reliability of the PCB. Notably, a Tg value of 170°C is often considered the threshold for high Tg materials, distinguishing them as suitable for high-temperature applications.

Introduction to PCB Materials

Printed circuit board (PCB) materials form the backbone of every electronic device, directly influencing performance, reliability, and longevity. The most widely used PCB material is FR-4, a glass-reinforced epoxy laminate known for its balance of electrical properties, mechanical strength, and cost-effectiveness. Standard FR-4 typically features a glass transition temperature (Tg) in the range of 130-140°C, making it suitable for many general applications.

However, as electronic devices are pushed to operate at higher working temperatures and in more demanding environments, high Tg materials—those with a Tg value above 170°C—have become increasingly important. These high Tg materials offer superior thermal stability, allowing the circuit board to withstand high temperatures without significant deformation or loss of electrical performance. This makes them ideal for applications where reliability and thermal conductivity are critical, such as automotive, industrial, and high-performance computing.

Beyond FR-4, there are other types of PCB materials available, each with unique advantages. Ceramic PCBs provide excellent thermal conductivity and are used in high-power applications. Metal core PCBs (MCPCB) are favored for their ability to dissipate heat efficiently, while Rogers materials are chosen for their outstanding electrical properties in high-frequency applications.

Selecting the right PCB material involves evaluating several parameters, including Tg value, thermal stability, electrical properties, and cost. The specific requirements of your device—such as operating temperature, mechanical stress, and environmental conditions—will determine which material is most suitable. PCB manufacturers offer a wide range of materials to meet these diverse needs, ensuring that designers can find the optimal solution for their printed circuit board.

A thorough understanding of PCB materials and their properties is essential for engineers and designers aiming to create reliable, high-performance electronic devices. By focusing on the right material for each application, you can enhance the stability, performance, and lifespan of your products.

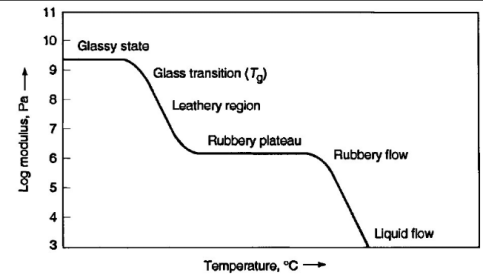

What is Glass Transition Temperature (Tg)?

Glass transition temperature (Tg) refers to the temperature point at which a PCB substrate material transitions from a rigid “glassy state” to a flexible “rubbery state” when heated to high temperatures. This transition temperature is a critical indicator of the thermal resistance of PCB materials. Tg is also a key parameter in PCB material selection, as it directly affects the board's ability to withstand thermal stress.

Simply put, Tg represents the maximum temperature at which the base material maintains its rigidity and remains in a rigid state. When the environmental temperature exceeds the material’s Tg value, the PCB begins to enter a softened state, and its mechanical strength and electrical properties significantly deteriorate. Therefore, a higher Tg value generally indicates better heat resistance and dimensional stability. Exceeding the Tg value can impair the function of the PCB, especially in high-temperature applications where operational stability is critical.

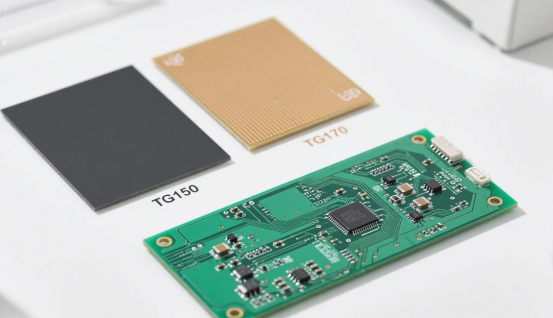

Overview of FR-4 TG150 Material

FR-4 TG150 is a PCB substrate material with a medium glass transition temperature, typically around 150°C. Composed of woven fiberglass and epoxy resin, it offers better heat resistance, moisture resistance, and chemical resistance than standard FR-4 materials (which typically have a Tg of 130). In addition, FR-4 TG150 is flame resistant, providing self-extinguishing properties that are important for safety and compliance with flame retardant standards.

TG150 material maintains more stable performance in high-temperature, high-humidity, and corrosive environments, making it suitable for applications with higher requirements than standard consumer electronics. It strikes a balance between performance and cost, making it an ideal choice for many industrial-grade and automotive-grade applications.

Overview of FR-4 TG170 Material

FR-4 TG170 is a high glass transition temperature PCB substrate material with a Tg value exceeding 170°C. As a high Tg material, it is especially suitable for high-temperature applications where thermal stability and reliability are critical, such as in industrial, automotive, or LED environments. This material maintains better mechanical strength and electrical performance stability under extreme temperature conditions.

TG170 material offers exceptional heat resistance, moisture resistance, chemical resistance, and dimensional stability, maintaining stable performance even under the high-temperature conditions of lead-free soldering processes. This makes it the preferred material for high-reliability applications.

Performance Comparison: TG150 vs. TG170

To better illustrate the differences between these two materials, here are the details of their main performance parameters:

| Performance Indicator | FR-4 TG150 | FR-4 TG170 |

|---|---|---|

| Glass Transition Temperature | ≈150°C | ≥170°C |

| Heat Resistance | Good | Excellent |

| Moisture Resistance | Good | Excellent |

| Chemical Resistance | Good | Excellent |

| Dimensional Stability | Fairly Good | Better |

| Mechanical Strength (at high temp) | Fairly Good | Better |

| Electrical Performance Stability | Fairly Good | Better |

| Processing Difficulty | Moderate | Higher |

| Cost | Moderate | Higher |

As evident from the comparison, TG170 outperforms TG150 in almost all performance indicators, but this also means higher processing difficulties and costs.

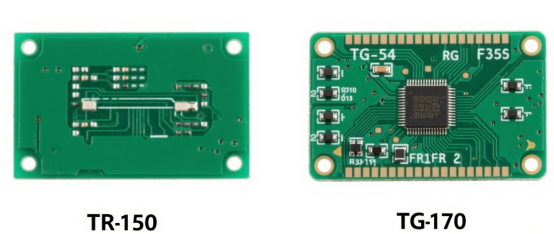

Differences in Application Areas

Typical Applications of TG150

TG150 material is suitable for applications that require performance above standard FR-4 but don’t need extreme temperature capabilities, including:

·Industrial control equipment: Suitable for most industrial environments, capable of withstanding certain temperature fluctuations and harsh conditions.

·Automotive electronics: Used in non-critical automotive electronic systems that can tolerate some heat in engine compartments.

·Communication equipment: Used in mid-range communication devices, providing better signal integrity and stability.

·High-performance computing equipment: Suitable for computing devices that require extended operation, offering better thermal stability.

TG150 is often chosen by customers in these industries who need a balance of performance and cost, ensuring their specific requirements are met without unnecessary expense.

Typical Applications of TG170

TG170 material is designed for extreme environments and high-end applications, primarily including:

·High-layer count printed circuit boards (10 layers or more): Provides better dimensional stability and thermal reliability.

·Automotive electronic control systems: Used in high-temperature critical areas such as engine control units.

·Aerospace electronic equipment: Capable of withstanding extreme temperature variations and harsh environmental conditions.

·High-end communication equipment: Such as routers, base stations, and other devices requiring long-term high reliability.

·Military equipment: Meets the stringent requirements for reliability and environmental adaptability in military applications.

·Medical electronic devices: Used in critical medical equipment like life support systems, ensuring extremely high reliability.

TG170 is often selected to meet stringent customer requirements in high-reliability and mission-critical applications, ensuring the material aligns with specific customer specifications for thermal and mechanical performance.

Processing Considerations and Cost Factors

When choosing between TG150 and TG170, processing technology and cost factors must also be considered:

TG150 has relatively mature processing technology with good compatibility with standard FR-4 processes. It has moderate processing difficulty and costs more than standard FR-4 but less than TG170. The choice of material can also impact the quality and reliability of the assembly process, as certain materials may facilitate better component placement and thermal management during assembly.

TG170 has higher processing requirements, needing higher lamination temperatures and pressures, with stricter demands on processing equipment and conditions. Increasing the Tg value, as with TG170, can increase processing complexity and require more advanced manufacturing controls. Additionally, TG170 material itself is more expensive, and the greater processing difficulty leads to significantly higher overall costs compared to TG150.

When deciding which material to use, it’s essential to balance performance requirements with budget constraints. If TG150 already meets application needs, choosing TG170 might result in unnecessary cost waste. Selecting the appropriate material can also help reduce unnecessary costs or risks associated with over-specification.

PCB Manufacturing Process

The PCB manufacturing process is a multi-stage journey that transforms a design concept into a reliable, high-quality printed circuit board. It begins with the design phase, where engineers create detailed layouts that account for component placement, routing, and crucial factors like thermal management and electrical performance. The choice of PCB material at this stage is vital, as it influences not only the board’s properties but also the entire manufacturing workflow.

Once the design is finalized, the prototyping stage allows for the creation of sample boards. This step is essential for testing and validating the design, ensuring that the selected materials—especially high Tg materials—perform as expected under real-world conditions. Prototyping helps identify any issues early, reducing the risk of costly errors in mass production.

The production stage involves large-scale manufacturing using processes such as etching, drilling, and soldering. High Tg materials require careful handling and precise processing to maintain their thermal stability and mechanical integrity. For example, these materials may need higher lamination temperatures and specialized equipment to ensure the finished PCB meets stringent reliability standards.

Throughout the manufacturing process, rigorous testing and inspection are conducted to verify the board’s electrical properties, mechanical strength, and overall quality. A reputable PCB manufacturer will have robust quality control systems in place, ensuring that every board meets the required specifications and industry standards.

Flexibility and fast delivery are also key considerations. The ability to quickly adapt to design changes or material substitutions can significantly speed up development cycles and help bring products to market faster. By understanding the intricacies of the PCB manufacturing process and working closely with experienced manufacturers, designers can ensure that their boards are produced efficiently, reliably, and to the highest quality standards.

How to Choose: TG150 or TG170?

When selecting PCB materials, consider the following factors:

1. Operating environment temperature and working temperature: If the product operates in high-temperature environments (such as automotive electronics near engines), it is important to ensure that the PCB's working temperature is significantly lower than its Tg for thermal stability and reliability. In such cases, TG170 might be necessary. If operating and working temperatures are lower, TG150 may be sufficient.

2. Soldering process: If using lead-free soldering processes (where reflow temperatures can reach 260°C), TG170 provides better reliability.

3. Layer count and complexity: High-layer count PCBs (8 layers or more) typically require TG170 to ensure dimensional stability and reliability during the lamination process.

4. Reliability requirements: Aerospace, medical, and military applications typically require the highest level of reliability and will choose TG170 even at higher costs.

5. Budget constraints: While meeting performance requirements, consider cost-effectiveness and choose the most economical material.

In addition to Tg, consider Td (delamination temperature) when selecting PCB materials. Td indicates the material's ability to resist delamination under heat stress, such as during soldering and thermal cycling, and is crucial for ensuring long-term durability and performance.

Future Development Trends

As electronic products evolve toward higher performance and reliability, market demand for high-Tg materials is growing. The adoption of lead-free soldering processes and increasing environmental requirements are also driving the development of high-Tg materials. Future materials will aim to improve properties such as thermal expansion to enhance reliability.

In the future, we may see materials with even higher Tg values emerge, along with new material solutions that offer better performance-cost balance. The need for materials that can maintain stable performance under humid conditions and higher temperatures is a key driver for ongoing innovation in this field.

Conclusion

Both TG150 and TG170 are high-performance members of the FR-4 material family, each with advantages in different application scenarios. TG150 provides a good balance between performance and cost, suitable for most industrial and high-demand consumer electronic applications. Meanwhile, TG170 offers top-tier heat resistance and reliability, designed for extreme environments and high-end applications.

When selecting materials, designers must comprehensively consider the product's operating environment, performance requirements, complexity, and cost factors to make the most appropriate choice between TG150 and TG170. The correct material selection not only ensures product performance and reliability but also optimizes overall costs, enhancing the product's market competitiveness.

Regardless of which material is chosen, it's recommended to work closely with experienced PCB manufacturers who can provide valuable insights and recommendations to help optimize designs and avoid potential production issues.

Author: Jack Wang