High TG PCBs vs. FR-4: Which Is Best for Your Project?

Printed Circuit Boards (PCBs) are essential components in virtually every electronic device, from smartphones to industrial machines. They provide the physical platform for connecting electronic components like resistors, capacitors, and chips. The material of a PCB plays a critical role in determining its performance, durability, and heat resistance.

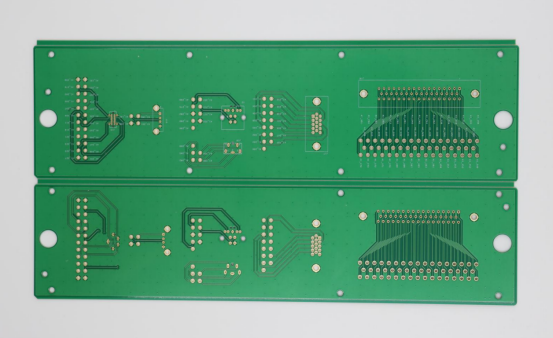

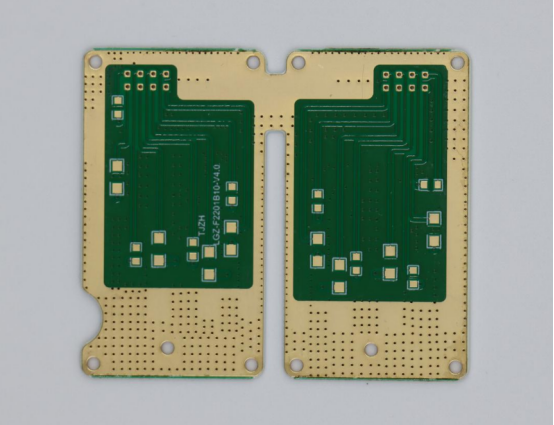

When choosing a PCB material, it’s crucial to consider the specific needs of the device. Standard FR-4 PCBs, made from fiberglass and epoxy resin, are a popular choice for everyday consumer electronics due to their affordability and reliability under moderate heat conditions. However, High TG PCBs, which have a higher glass transition temperature (TG), are designed for environments where heat is more of a concern. They resist warping and degradation in high-temperature settings, making them ideal for industrial equipment, automotive applications, and high-power devices like EVs or solar inverters.

In short, selecting between High TG and FR-4 involves understanding the heat tolerance, mechanical stress, and longevity requirements of your project. For low-heat, cost-sensitive products, FR-4 works well. But for high-performance, heat-intensive applications, High TG is the better choice, offering superior durability and heat resistance.

What Is the Difference Between High TG PCBs and Standard FR-4?

High TG PCBs and Standard FR-4 differ mainly in heat resistance and durability. High TG PCBs are built to withstand high temperatures, making them ideal for demanding applications like automotive or industrial systems. In contrast, Standard FR-4 is more affordable and suitable for low-power, consumer electronics. Understanding these differences helps you choose the right material for your project.

Overview of Materials: High TG vs. FR-4

High TG PCBs are made from a special type of resin that can withstand higher temperatures without losing its shape or performance. "TG" stands for Glass Transition Temperature, which is the temperature at which the material softens. High TG PCBs have a TG of 170°C or higher, which makes them ideal for high-heat environments like automotive engines, industrial machinery, or high-power electronics.

Standard FR-4, on the other hand, is made of fiberglass combined with epoxy resin. This material is widely used in everyday consumer electronics because it’s affordable, durable, and works well for devices that don’t generate a lot of heat. The TG of FR-4 is typically around 130–140°C, making it suitable for low- to moderate-heat applications.

Key Differences Between High TG and FR-4 PCBs

1. Thermal Resistance:

Glass Transition Temperature (TG) Comparison

The TG is a key factor in determining how a material responds to heat. High TG PCBs have a much higher TG (170°C–200°C) compared to FR-4’s TG of 130°C–140°C. This means High TG PCBs can tolerate higher temperatures before they begin to soften and lose their structural integrity. If your project involves components that generate a lot of heat (like power supplies or electric vehicles), a High TG PCB ensures the board remains stable and doesn’t warp, preventing potential failures.

Thermal Conductivity Comparison

Thermal conductivity refers to how well a material can transfer heat. High TG PCBs are better at dissipating heat (typically 0.4–0.6 W/m·K) compared to FR-4’s 0.29 W/m·K. This means High TG materials can handle and spread heat more efficiently, reducing the risk of overheating and component failure in power-intensive applications, like solar inverters or LED lighting. In contrast, FR-4 is better suited for lower-power devices where heat dissipation isn’t as critical.

2. Mechanical Strength & Warping Resistance:

Performance in High-Temperature Environments

In high-heat environments, such as during soldering or thermal cycling (frequent temperature changes), materials can warp or break down over time. High TG PCBs are engineered to maintain their shape and performance under extreme temperatures, making them ideal for automotive or industrial applications. In contrast, FR-4 may soften or warp at higher temperatures, leading to potential solder joint failures or component misalignment in high-performance settings.

Resistance to Warping and Breakdown

High TG PCBs also have enhanced resistance to thermal cycling—the process of repeatedly heating and cooling a material. While FR-4 can withstand 500–700 cycles (from -40°C to 125°C), High TG PCBs can handle 1,000+ cycles, making them more reliable for long-term use in environments with frequent temperature fluctuations, such as in EV battery management systems or 5G infrastructure. This extended durability helps reduce the frequency of repairs and maintenance, especially in mission-critical systems.

3. Cost and Value:

Why High TG is More Expensive

High TG PCBs typically cost 20–40% more than FR-4 due to the specialized resin and more complex manufacturing processes involved. However, the higher upfront cost is often justified by the long-term reliability of High TG PCBs. For applications where heat or mechanical stress is a concern, the durability and resistance to failure in harsh conditions can save significant money over time by reducing warranty claims, maintenance costs, and the need for rework. For example, an EV manufacturer switched to High TG for its battery management systems, resulting in a 70% reduction in warranty claims.

Cost vs. Value Comparison

While High TG is more expensive, its ability to operate in extreme conditions for 10+ years can save businesses money in the long run. FR-4 is ideal for low-cost, low-power consumer electronics like remote controls, where heat isn’t a major concern. For high-power, high-heat applications, such as solar inverters or automotive components, the investment in High TG provides much better value for money. The long lifespan of High TG PCBs, coupled with their ability to handle more demanding environments, outweighs the initial cost difference.

Comparison Table: High TG PCBs vs. FR-4

| Feature | High TG PCBs | FR-4 PCBs |

| Glass Transition (TG) | 170°C–200°C | 130°C–140°C |

| Thermal Conductivity | 0.4–0.6 W/m·K | 0.29 W/m·K |

| Mechanical Strength | High (resistant to warping, thermal cycling) | Moderate (can warp in high heat) |

| Lifespan | 10–20 years in harsh conditions | 3–8 years in mild conditions |

| Cost | 20–40% more expensive | Lower cost |

| Best For | High-power, high-heat, industrial, automotive, long-term use | Consumer electronics, low-power devices |

When Should You Choose High TG PCBs Over FR-4?

You should choose High TG PCBs over FR-4 when your project involves high temperatures, high power, or requires long-term reliability. High TG PCBs excel in harsh environments like automotive systems, industrial machinery, outdoor electronics, and high-wattage components, where heat resistance and durability are critical. For applications that demand continuous operation, such as data centers or medical devices, High TG ensures stability and performance, making it the ideal choice over Standard FR-4.

High Temperature Environments:

Automotive Use

High TG PCBs are essential for automotive applications, especially in Electric Vehicle (EV) battery systems, engine control units (ECUs), and automotive sensors. These components often operate in environments with temperatures exceeding 120°C, where Standard FR-4 may soften and lose structural integrity. High TG PCBs, with their higher glass transition temperature (170°C and above), ensure reliable performance in such harsh conditions, preventing premature failure and reducing maintenance costs.

Industrial Applications

In heavy machinery and industrial systems, temperature extremes are common. Components like factory controllers and industrial motors often face conditions that push Standard FR-4 beyond its limits. High TG PCBs offer superior heat resistance, making them ideal for these applications where long-term durability is critical. For example, industrial motors that generate substantial heat require PCBs that can withstand temperatures as high as 150°C without degrading.

Outdoor/Environmental Electronics

Devices like solar inverters and 5G amplifiers are often exposed to intense heat in outdoor environments. High TG PCBs, with their better heat tolerance, are perfect for these applications. Solar inverters, for instance, are exposed to direct sunlight and can easily exceed 130°C. Using High TG PCBs ensures these devices remain functional for years without overheating or warping.

High-Power Applications:

High-Wattage Components

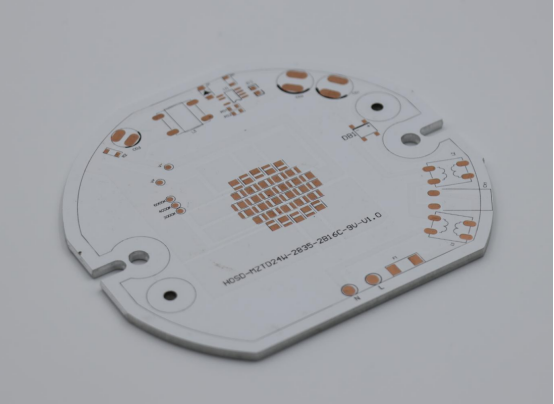

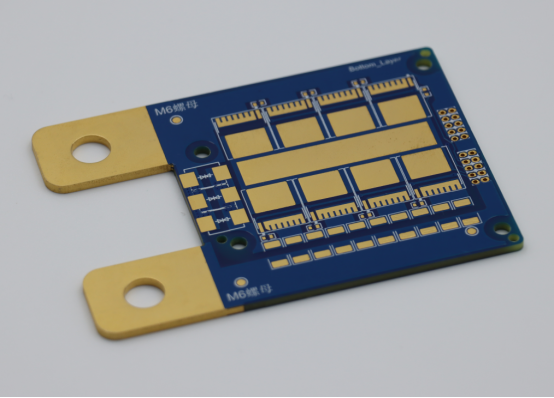

High TG PCBs are the go-to material for power inverters, high-wattage LED arrays, and DC-DC converters. These components draw significant power and generate large amounts of heat, which can cause FR-4 boards to fail. High TG PCBs, with their higher thermal conductivity, can handle the heat better, preventing the boards from warping and ensuring that power-hungry devices operate reliably over time.

Data Centers

In data centers, servers and high-performance computing hardware run 24/7, often at temperatures that can approach the limits of Standard FR-4’s heat resistance. The use of High TG PCBs ensures that the hardware’s thermal management is optimized. For example, server power supplies need to withstand high continuous power loads without compromising PCB integrity. High TG PCBs help prevent component degradation, leading to reduced downtime and more efficient thermal management in these high-power environments.

Medical Devices

Medical equipment like MRI systems and diagnostic devices require continuous operation, often under high heat conditions. High TG PCBs are crucial for these applications as they can withstand the prolonged heat exposure without breaking down. For instance, MRI machines produce significant amounts of heat, and High TG PCBs ensure that the components stay stable and reliable, ensuring patient safety and device longevity.

Long-Term Reliability:

High Durability Needs

High TG PCBs are often the preferred choice for applications requiring long-term durability, such as medical implants, infrastructure controls, and autonomous vehicles. These devices must operate reliably for years, often in extreme conditions. High TG’s superior thermal stability and resistance to thermal cycling make it ideal for applications that cannot afford to fail. A pacemaker, for example, requires a PCB that can last a decade or more without degradation, making High TG the best choice.

Critical Systems

For mission-critical systems like traffic lights, power grid controllers, and other long-lasting industrial equipment, High TG PCBs offer the necessary reliability. These systems must function without failure for years, often exposed to environmental stresses like heat, moisture, and vibrations. High TG PCBs ensure these systems remain stable, reducing the need for repairs or replacements. For instance, a power grid controller operating in an industrial environment would benefit from the durability of High TG, which resists breakdown under continuous high-temperature and mechanical stress.

Why is High TG Better for High-Heat and High-Power Applications?

High TG PCBs are better for high-heat and high-power applications because they offer superior thermal dissipation, mechanical strength, and longevity. With enhanced heat resistance, High TG PCBs effectively manage heat, preventing damage and ensuring stable performance in demanding environments. Their ability to withstand thermal cycling and resist warping makes them ideal for applications like power inverters, data centers, and medical devices, where reliability and durability are critical.

Thermal Dissipation:

Why is High TG better at dissipating heat?

High TG PCBs have superior thermal conductivity compared to FR-4. While FR-4 can dissipate heat at a rate of 0.29 W/m·K, High TG PCBs can handle 0.4–0.6 W/m·K. This means High TG PCBs can spread heat more efficiently across the board, preventing hotspots and ensuring that heat-sensitive components remain at optimal temperatures. In high-power applications like power inverters or LED arrays, this is crucial because excessive heat can cause components to fail prematurely. For example, in solar inverters that run continuously in direct sunlight, High TG PCBs can handle the high temperatures without warping, unlike FR-4, which might soften and lose stability.

Mechanical Strength:

Why do High TG PCBs resist warping and degradation better?

High TG PCBs are built with a stronger resin that enhances their mechanical strength. This makes them more resistant to thermal cycling, which refers to the repeated heating and cooling of materials over time. FR-4, with its lower glass transition temperature (130–140°C), can soften under high temperatures, causing warping and deformation. In contrast, High TG PCBs can withstand thermal cycles of up to 1,000+ cycles (ranging from -40°C to 125°C), making them ideal for environments where temperatures fluctuate dramatically, such as in automotive systems or industrial equipment. For example, an electric vehicle (EV) battery management system (BMS) requires PCBs that won't deform or fail under the heat generated by the battery during charging and discharging cycles. High TG ensures stability and durability, reducing the risk of failure.

Longevity:

How does High TG extend the lifespan of PCBs?

High TG PCBs are engineered to last longer than FR-4 in harsh conditions. The high-temperature resistance and mechanical strength of High TG materials prevent thermal aging—the breakdown of materials due to repeated exposure to heat. High TG PCBs can withstand continuous operating temperatures up to 180°C, making them ideal for high-power devices that run 24/7, like data center servers or medical equipment. This extended lifespan is especially important for critical systems, such as MRI machines, where downtime due to PCB failure can be costly and disruptive. In comparison, FR-4’s lower heat tolerance means it may degrade in a matter of years under high thermal stress, whereas High TG can provide reliable performance for 10–20 years or more, even in the harshest environments.

What Makes Standard FR-4 a Good Choice for Low-Demand Projects?

Standard FR-4 is a great choice for low-demand projects because it offers cost-efficiency, adequate performance for low-heat and low-power applications, and is ideal for environments where temperatures are stable. It’s perfect for consumer electronics, IoT devices, and hobby projects, providing the right balance of affordability and reliability without the need for more expensive materials like High TG.

Cost-Efficiency:

Why is FR-4 cost-effective for budget-sensitive projects?

FR-4 is one of the most affordable PCB materials, making it an excellent choice for low-budget projects. Its cost is typically 20–30% lower than that of High TG PCBs, which is important for consumer gadgets or hobby projects that don’t require advanced features like high-temperature resistance. For example, a simple Arduino board or a basic LED strip can be produced with FR-4, keeping the overall production costs low while still maintaining functionality and durability. This cost efficiency is especially valuable in projects where price sensitivity is a key factor, such as disposable devices or low-volume production.

Sufficient for Low-Heat and Low-Power Applications:

Why is FR-4 enough for low-heat and low-power devices?

FR-4 works perfectly in applications where heat and power demands are minimal. Its glass transition temperature (TG) of 130–140°C is more than adequate for consumer electronics like smartphones, smart TVs, and home appliances, where the components typically run below this temperature. Since these devices don’t generate significant heat, FR-4 can handle the task without risk of softening or deformation. For example, a remote control or a Wi-Fi router operates at a temperature well below 100°C, so FR-4 provides the strength and reliability needed without the extra cost of higher-performance materials.

Low-Power IoT Devices:

How does FR-4 fit in low-power IoT applications?

Many IoT devices are designed for low power usage and are not exposed to high heat. Examples include smart thermostats, motion sensors, and simple remote controls. In these cases, FR-4’s thermal conductivity and mechanical strength are sufficient, as the devices don’t demand high thermal dissipation or extreme durability. Since these devices generally consume less than 10W of power, FR-4 offers the right balance of cost, performance, and reliability. For instance, a motion sensor used in smart home systems only needs a basic PCB material, and FR-4 serves this purpose perfectly.

Hobby and Education Projects:

Why is FR-4 a good choice for hobbyist and educational use?

For hobby projects and education, FR-4 is the go-to material because it is both affordable and easy to work with. Many beginner electronics projects, such as Arduino kits, Raspberry Pi accessories, or DIY electronics kits, use FR-4 PCBs because of its availability and cost-effectiveness. In education, FR-4 is commonly used to teach students the basics of PCB design, soldering, and circuit building, as it offers good performance at a low cost and is easy to handle. It allows students and hobbyists to focus on their projects without worrying about expensive materials or overly complex designs.

Ideal for Indoor, Climate-Controlled Environments:

Why is FR-4 perfect for indoor, climate-controlled environments?

FR-4 is well-suited for use in indoor environments, such as home electronics and office equipment, where temperature fluctuations are minimal. Devices like printers, laptops, and TVs are typically kept in climate-controlled spaces with temperatures ranging from 20°C to 30°C. Under these conditions, the material properties of FR-4 are sufficient to ensure reliable performance without the need for the high heat resistance found in materials like High TG. For example, a desktop computer or home sound system that remains at a steady, moderate temperature does not require the extra durability provided by High TG, making FR-4 the ideal choice for cost-effective, everyday applications.

How Do You Calculate When to Use High TG vs. FR-4?

Calculating when to use High TG vs. FR-4 involves assessing key factors like temperature, power consumption, and lifespan needs. Start by evaluating the heat your device will generate and its temperature tolerance. Consider how long the device needs to last, especially in high-stress environments. Then, balance the initial cost with long-term savings—High TG may cost more upfront but can save you from future breakdowns. Lastly, consulting with PCB manufacturers helps ensure the right material choice for your project.

Step-by-Step Decision Guide:

1. Assess Temperature and Power Needs:

How do you assess temperature and power requirements?

The first step is to understand how much heat your device will generate and how much temperature the PCB will experience. Thermal simulation tools (like Ansys Icepak) can help estimate the maximum temperature on your PCB by simulating the flow of heat based on the components used. Additionally, you can refer to component datasheets to find out the maximum operating temperatures of your key components.

For power needs, you must calculate the total power consumption of your device. This includes the sum of the power draw from all components. A simple power calculation can help you understand how much heat will be generated. For instance, a high-power LED array that generates 50W or more will need a High TG PCB for optimal heat dissipation, as standard FR-4 may not handle the heat load effectively.

2. Consider Lifespan and Reliability Goals:

How do you consider lifespan and reliability?

Evaluate how long the device is expected to last under real-world conditions. For critical systems like medical devices or automotive electronics, you need a PCB that will last 10+ years. High TG PCBs are designed for such longevity due to their better resistance to thermal cycling, mechanical stress, and high temperatures.

On the other hand, for shorter lifespan devices or those with low reliability requirements (such as consumer electronics or low-power IoT devices), FR-4 can be sufficient. These devices don’t require the same durability and can comfortably operate within the limits of FR-4’s lower temperature tolerance, typically 3–5 years.

3. Cost vs. Value:

How do you balance cost with long-term value?

While High TG PCBs are more expensive (20-40% higher cost per square inch than FR-4), they offer long-term value by reducing failures, rework costs, and improving system reliability. If your project involves high heat or high power, the initial investment in High TG may prevent expensive breakdowns down the line.

For example, consider a solar inverter with an expected 8–10-year lifespan. While High TG materials cost more upfront, they ensure the inverter performs reliably without PCB degradation, saving money in the long term by reducing warranty claims and maintenance. Conversely, for low-power devices (like a basic Arduino project), the cost savings of using FR-4 far outweigh the benefits of High TG, as it will provide adequate performance for the expected lifespan of a few years.

4. Consulting with Manufacturers:

Why is consulting with PCB manufacturers important?

Manufacturers, like PCBMASTER, can offer expert guidance tailored to your project. They have the experience to help assess whether High TG or FR-4 is the better choice based on your specific needs. A professional manufacturer can also provide samples of both materials and assist with thermal testing to ensure the right material is selected.

For instance, if you are working on a 5G amplifier that will operate under high temperatures, a manufacturer can help confirm if you need a 170°C or 190°C High TG grade for optimal performance. They can also suggest how to adjust the design to make the best use of the material, ensuring your PCB works effectively for the long term.

What Are the Common Misconceptions About High TG and FR-4?

There are several common misconceptions about High TG and FR-4 PCBs. Some believe High TG is always the superior choice, but it's only necessary for high-heat environments. Others think FR-4 can be easily modified to handle higher temperatures, but it has clear limits. Finally, many assume High TG is only useful in industrial and automotive sectors, while it can also benefit high-power consumer electronics. Let’s break these myths down and clarify when each material is the best choice.

Misconception 1: High TG is always better than FR-4.

Is High TG always better than FR-4?

No, High TG is not always better than FR-4. While High TG offers superior heat resistance and mechanical strength, it’s not necessary for every project. FR-4 is more than adequate for low-power, low-heat devices like smartphones or IoT sensors, where cost-efficiency and performance at lower temperatures are prioritized. High TG is ideal for environments that experience sustained high temperatures or frequent thermal cycling, such as automotive or industrial applications. If a device doesn’t face these challenges, opting for FR-4 is both a practical and economical choice.

Misconception 2: FR-4 can be modified to withstand higher temperatures.

Can FR-4 be modified to handle higher temperatures?

While some modifications, like adding thermal vias or heat sinks, can improve FR-4’s performance in higher temperatures, it has limitations. FR-4's glass transition temperature (TG) typically ranges from 130°C to 140°C, meaning it will start to soften and lose structural integrity above that point. These modifications may slightly improve heat dissipation but won't enable FR-4 to reliably perform in high-heat environments. For long-term reliability in temperatures above 150°C, High TG PCBs, which have a TG of 170°C or higher, are necessary for preventing issues like warping, cracking, or thermal failure.

Misconception 3: High TG is only for industrial and automotive use, not consumer electronics.

Is High TG only for industrial and automotive use?

This is a common misconception. High TG PCBs are often associated with industrial and automotive applications because of their excellent heat resistance. However, they can be used in consumer electronics too, especially in high-power devices. For example, gaming consoles, LED lights, and smart TVs that handle higher power consumption or generate more heat can benefit from High TG’s durability. While High TG may not be necessary for basic consumer electronics like remote controls or entry-level gadgets, it can be advantageous for more advanced products that require extra heat resistance and longer lifespans.

Best Practices for Designing High TG and FR-4 PCBs

When designing High TG and FR-4 PCBs, it's essential to follow best practices tailored to the specific material's strengths. For High TG PCBs, focus on efficient thermal management, selecting the right high-temperature solder, and conducting thermal cycling tests for durability. For FR-4 PCBs, managing heat generation, using heat sinks for sensitive components, and limiting reflow cycles will help maintain board integrity and performance. These design tips ensure optimal performance and reliability in various applications, from consumer electronics to industrial systems.

For High TG PCBs

1. Design Tips for Efficient Thermal Management

When designing High TG PCBs, effective thermal management is critical to avoid overheating and ensure reliable performance in high-power or high-heat environments. Using copper pours is an effective method to spread heat across the board. This involves using large copper areas that help dissipate heat away from hot components, such as power transistors or LED drivers. Additionally, incorporating thermal vias—small holes filled with conductive material—can help channel heat from one layer to another, improving overall heat dissipation. These strategies are essential to keep your High TG PCB running efficiently in demanding environments like automotive or industrial applications.

2. Choosing the Right High-Temperature Solder for Durability

For High TG PCBs, it’s important to use high-temperature solder that can withstand the board’s elevated temperatures. Traditional solders, like those made with tin-lead (SnPb), may not perform well at higher temperatures, so opting for SnAgCu (tin-silver-copper) solder or other high-temperature alloys is crucial. These solders have higher melting points, ensuring that the joints remain intact even under extreme thermal cycling. This choice contributes to the long-term reliability of your PCB, especially in automotive or aerospace applications where components endure prolonged temperature fluctuations.

3. Testing for Long-Term Thermal Cycling Stability

To ensure that your High TG PCB performs well over time, it’s important to test for thermal cycling stability. This process involves subjecting the PCB to repeated temperature changes (such as from -40°C to +125°C) to simulate real-world conditions. High TG materials are designed to handle thermal stress better than FR-4, but testing ensures that the solder joints and copper traces remain intact over years of operation. By conducting these tests, you can avoid failures in critical applications like medical devices or 5G communication systems where long-term performance is essential.

For FR-4 PCBs

1. Managing Heat Generation to Avoid Hotspots

For FR-4 PCBs, heat generation needs to be carefully managed to prevent hotspots that could compromise the board’s integrity. Hotspots occur when heat builds up in specific areas of the PCB, causing potential damage to components or solder joints. To prevent this, heat-sensitive components should be placed near the edges of the board where heat can dissipate more effectively. Additionally, using heat management tools, such as thermal simulation software, can help predict and manage where heat will accumulate, guiding optimal component placement and routing.

2. Using Heat Sinks to Protect Sensitive Components

In cases where heat cannot be fully avoided, using heat sinks can provide additional protection. Heat sinks are physical components that attach to the PCB and help dissipate heat away from sensitive areas, such as voltage regulators or power transistors. These heat sinks act like radiators, improving airflow and ensuring that the PCB remains within safe operating temperatures. In consumer electronics, such as smartphones or gaming consoles, heat sinks can help prevent components from overheating during extended use.

3. Limiting Reflow Cycles to Preserve PCB Integrity

FR-4 PCBs are susceptible to degradation if exposed to too many reflow cycles during manufacturing. A reflow cycle involves heating the PCB to high temperatures to melt solder and form reliable electrical connections. However, excessive reflow cycles can lead to delamination or warping of the board, especially in low-cost FR-4 materials. To avoid this, limit the number of reflow cycles during assembly and ensure that the soldering process is done efficiently. This practice is particularly important in low-cost consumer electronics, where durability and cost-effectiveness are key. By adhering to optimal reflow settings, manufacturers can preserve the integrity of FR-4 PCBs while still achieving reliable results.

Conclusion: Which PCB Material is Right for Your Project?

When selecting the right PCB material for your project, it’s crucial to match your material choice with your project’s needs. High TG PCBs are ideal for applications requiring high heat resistance, power handling, and long-term reliability, such as automotive systems, industrial equipment, and medical devices. On the other hand, FR-4 is perfect for cost-sensitive projects, such as low-power consumer electronics, IoT devices, and indoor gadgets. To make the best decision, assess your project’s heat, power, and lifespan requirements carefully. Avoid overspending on high-end materials if they aren't necessary for your application. By understanding your specific needs, you can choose the most suitable material without compromising performance or exceeding your budget. For personalized advice, PCBMASTER, a trusted PCB supplier, can help you choose the best material and design based on your unique project requirements.

FAQs

Can FR-4 be used for designs with higher heat requirements?

Yes, but with added thermal management.

FR-4 can work in higher heat designs if thermal strategies like thermal vias, heat sinks, or copper pours are used to dissipate heat. However, for sustained high temperatures (like in EV power systems or solar inverters), High TG PCBs are a more reliable choice, as they offer better thermal conductivity and can withstand long-term heat exposure.

How do I choose between 170°C and 190°C High TG PCBs?

170°C is enough for most applications, but 190°C is needed for extreme environments.

For typical industrial or automotive uses, 170°C High TG is sufficient. For applications facing extreme temperatures or thermal stress, such as aerospace environments, a 190°C High TG PCB provides additional durability.

Can High TG PCBs be used in consumer electronics like smartphones?

Generally, no, unless the device generates significant heat.

High TG PCBs are designed for high-heat, high-power applications. Consumer electronics like smartphones usually don’t require the extra heat resistance provided by High TG, and standard FR-4 is sufficient. Using High TG in such cases would add unnecessary costs.

Are High TG PCBs more expensive than FR-4?

Yes, High TG PCBs cost about 20-40% more than FR-4.

The additional cost is due to the specialized resins and curing processes required. However, the increased price can be justified if the application demands higher durability and heat resistance, such as in automotive electronics or industrial systems.

Can FR-4 be modified to withstand higher temperatures?

Somewhat, but not as reliably as High TG PCBs.

FR-4 can handle moderate heat with added thermal management solutions. However, for high-temperature environments (≥150°C), High TG PCBs are a better choice for maintaining long-term reliability and thermal stability.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!