Copper Through-Hole Fill (THF): Void-Free Vias for PCBs

Copper Through-Hole Fill (THF) is an advanced electroplating technology that fills PCB vias with pure copper in a single, void-free process, enhancing thermal management and signal integrity. As electronics continue to evolve—driving innovations in industries like 5G, electric vehicles (EVs), and AI—THF has emerged as a game-changer in PCB manufacturing. Unlike traditional methods, which often struggle with voids, misalignment, and poor heat dissipation, THF offers a faster, more reliable way to fill vias, improving both performance and manufacturing efficiency. Traditional techniques like conductive paste filling and blind via stacking introduce challenges such as thermal hotspots and signal loss, which can compromise the functionality of high-performance devices. THF overcomes these limitations by providing a uniform copper fill that boosts heat dissipation, reduces signal scattering, and streamlines the production process, making it an essential technology for next-gen electronics.

What Are the Key Limitations of Traditional Via Filling Methods in High-Density PCBs?

In high-density PCBs, traditional via filling methods like conductive paste filling and blind via stacking often fall short. These methods struggle to meet the demands of modern electronics, leading to performance and reliability issues in critical applications such as 5G, electric vehicles (EVs), and AI systems. Below, we’ll explore the key limitations of these methods.

The Drawbacks of Conductive Paste Filling

Voids and Incomplete Filling:

Conductive paste filling involves injecting a paste into the vias, but air bubbles frequently form during the process, creating voids. These voids, or empty spaces, inside the via can cause significant thermal and electrical issues. In electronics, heat needs to be effectively managed to prevent component failure. Voids in the conductive paste disrupt the heat flow, leading to thermal hotspots that can damage sensitive components. Similarly, voids in the vias can affect the electrical path, causing signal interruptions or even complete circuit failure in high-frequency applications like 5G or AI processing.

Outgassing Risks:

When conductive pastes are heated during the curing process, they release gases—a phenomenon known as outgassing. These gases can damage sensitive components on the PCB, especially in high-frequency applications such as 5G or AI servers, where reliability is paramount. Outgassing can cause corrosion or short circuits, leading to premature failure of electronic devices. For example, in 5G RF chips, the release of gases during curing can result in signal degradation and hardware damage.

Poor Thermal Conductivity:

One of the biggest challenges of conductive paste filling is its poor thermal conductivity. Conductive pastes, often made from polymer materials, have thermal conductivity values much lower than copper. This poor heat dissipation can be disastrous for high-power designs, like those found in electric vehicle (EV) inverters or 5G base stations, where managing heat is essential to prevent system failure. For example, an EV inverter without proper heat dissipation can overheat, leading to thermal runaway and potentially damaging the battery or powertrain system.

The Challenges with Blind Via Stacking

Misalignment Issues:

Blind via stacking is a process where multiple blind vias are stacked to create a continuous electrical connection between layers in a PCB. However, even slight misalignment during the stacking process can cause signal integrity issues. Misalignment leads to signal scattering or reflection, especially in high-speed signals such as those used in PCIe 5.0 or 5G communication. Even a 5-micron shift can result in poor signal quality, causing data transmission errors and dropped connections.

Complex Manufacturing Process:

Blind via stacking requires precise layer registration and alignment during the PCB fabrication process. This makes the manufacturing more complex, time-consuming, and expensive. Each layer must align perfectly, or it can result in connection failures. The process also requires multiple steps, including drilling, plating, and alignment, which increase both the costs and time for production. As the demand for high-density interconnect (HDI) PCBs grows, the difficulty of maintaining precision becomes a significant challenge for manufacturers.

Signal Loss in High-Frequency Applications:

Another major issue with blind via stacking is its impact on high-frequency signal transmission. The trapezoidal shape of blind vias creates irregular paths for the signals, which causes signal loss, particularly at high frequencies used in 5G communications or AI applications. For example, 5G mmWave signals (24–40 GHz) are especially sensitive to these geometric distortions. The non-cylindrical shape of the vias increases signal scattering, leading to degraded performance and, in some cases, dropped connections. In a data center server, this could result in slower processing speeds and reduced network reliability.

How Does Copper Through-Hole Fill (THF) Work?

Copper Through-Hole Fill (THF) is an innovative technology that simplifies the PCB manufacturing process by filling vias with pure copper in a single, efficient step. This process addresses the challenges of traditional via filling methods, such as voids and poor thermal conductivity. Below, we explore how THF works, including its breakthrough process and the role of pulse waveforms in ensuring void-free, high-performance vias.

The Breakthrough Process: Single-Step Electroplating

Phase-Shifted Pulse Electroplating:

The core of Copper Through-Hole Fill (THF) lies in its use of phase-shifted pulse electroplating technology. This process involves the application of a pulse waveform to electroplate copper into vias. Unlike traditional methods that require multiple steps and often result in voids or uneven copper deposition, THF uses a single-step electroplating technique. The pulse waveform controls the precise placement of copper ions, allowing the metal to fill the via uniformly without leaving gaps. This ensures that each via is filled with dense, pure copper, enhancing both thermal conductivity and electrical performance.

Seamless Workflow:

What sets THF apart is its seamless workflow, which combines multiple stages into one simplified process. Traditional via filling methods require separate processes for bridging, filling, and finishing the vias. In contrast, THF integrates these steps in a single electroplating bath. First, a phase-shifted pulse creates a thin copper bridge across the via. Then, the system switches to DC electroplating to fill the via with uniform copper. Finally, the surface is smoothed to ensure a flat profile suitable for surface-mount components. This streamlined process reduces manufacturing complexity, improves efficiency, and minimizes the risk of errors.

The Role of Pulse Waveforms in Achieving Void-Free Vias

Why Phase-Shifted Pulse is Critical:

The key to achieving void-free vias in Copper Through-Hole Fill (THF) is the use of a phase-shifted pulse waveform. Unlike traditional electroplating, which can lead to uneven copper buildup around the edges of the via, the phase-shifted pulse ensures uniform copper deposition. This waveform deposits copper evenly from the center of the via outward, preventing the formation of air bubbles or voids. This precise control results in a solid, continuous copper fill, improving both thermal conductivity and signal integrity.

Key Parameters:

For optimal results, several parameters must be controlled during the pulse electroplating process:

Pulse Current: Typically ≤1.5 ASD for the forward pulse, ensuring uniform copper placement on the via walls.

Pulse Duration: A 50 ms duration for the forward pulse prevents edge buildup, ensuring even copper thickness and avoiding void formation.

Phase Shift: A 180° phase shift ensures that the copper is deposited symmetrically, achieving centrally aligned copper bridges and preventing misalignment or voids, especially in smaller vias.

Reverse Pulse: With a current of ≤4.5 ASD, the reverse pulse dissolves excess copper from the via edges, ensuring a smooth and uniform copper fill.

By fine-tuning these parameters, THF can create void-free fills across a wide range of via sizes, from 90 μm laser-drilled vias to 400 μm mechanical vias, making it ideal for HDI PCBs and high-power applications like EV inverters.

What Are the Performance and Efficiency Benefits of THF for PCB Manufacturers?

Copper Through-Hole Fill (THF) is not just a technological breakthrough—it's a game-changer for PCB manufacturers, offering major improvements in thermal management, signal integrity, and manufacturing efficiency. Below, we explore the key benefits that make THF the preferred choice for high-performance, high-density PCBs.

Enhanced Thermal Management with Copper

Superior Thermal Conductivity:

One of the most significant advantages of THF is its use of pure copper to fill the vias. Copper boasts an exceptional thermal conductivity of 401 W/m·K, meaning it can efficiently transfer heat away from sensitive components. This is crucial for high-power designs like electric vehicle (EV) inverters, 5G base stations, and AI servers, where excessive heat can lead to component failure. With THF, the copper-filled vias act like built-in heat sinks, spreading heat more effectively and preventing thermal buildup. This enhanced heat dissipation extends the lifespan of components and improves overall system reliability.

Thermal Cycling Resistance:

In addition to its superior conductivity, copper-filled vias in THF also offer better thermal cycling resistance. Thermal cycling refers to the constant expansion and contraction of materials due to temperature fluctuations. Unlike traditional via filling methods, which may crack or degrade under extreme temperature changes, THF vias can withstand 1,000+ thermal cycles ranging from -40°C to 125°C. This resistance to thermal stress makes THF ideal for harsh environments such as automotive applications or outdoor 5G infrastructure, where components frequently experience extreme temperature shifts.

Signal Integrity Improvements for High-Speed Electronics

Reduced Signal Scattering:

For high-speed electronics, signal integrity is a top priority. In applications like 5G and AI servers, signal degradation can cause communication errors and slowdowns. Traditional via methods, such as blind via stacking, can introduce signal scattering due to their trapezoidal shapes, leading to signal loss and interference. In contrast, THF creates cylindrical vias that minimize signal reflection and preserve signal quality. This smooth, uniform copper fill in the vias reduces scattering, ensuring that high-frequency signals (such as 28 GHz for 5G) pass through with minimal degradation.

Supporting Advanced Designs:

THF’s ability to maintain signal integrity is critical in supporting advanced electronics like 5G base stations, AI servers, and PCIe 6.0 systems. These technologies require fast and reliable data transfer with minimal signal loss. THF vias, with their void-free copper fill, deliver consistent electrical paths, enabling data transmission rates up to 128Gbps in AI servers. As high-speed communication continues to push the limits of what’s possible, THF ensures that signal performance meets the demands of next-gen electronics.

Manufacturing Advantages: Cost, Space, and Time Savings

Compact Equipment Footprint:

THF also brings space and cost savings to PCB manufacturers. Traditional via filling methods often require large, multi-step processes involving multiple pieces of equipment, which take up significant factory space. In contrast, THF uses a single-bath electroplating system. This compact design reduces the required equipment footprint by 50%, freeing up valuable factory space and reducing overall equipment costs. For example, a mid-sized PCB manufacturer could save over 100 square feet of production floor space by adopting THF.

Higher Yield Rates:

The efficiency of THF extends to its ability to improve yield rates. The precision of phase-shifted pulse electroplating ensures a void-free copper fill, which directly translates into 15–20% higher yield rates compared to traditional methods. This means fewer defective boards, reducing waste and improving cost-effectiveness for manufacturers. For a company producing 100,000 PCBs per year, this can result in an additional 15,000–20,000 sellable units annually, making the adoption of THF a smart investment.

Automation & Reduced Error:

Another significant benefit of THF is its automation. The system automatically switches between pulse electroplating and DC plating to fill the vias with copper, reducing the need for manual intervention. This automation cuts down on operator errors, speeds up production, and ensures consistency across batches. By reducing the risk of mistakes and the need for rework, THF increases production efficiency and shortens manufacturing time, saving both time and labor costs.

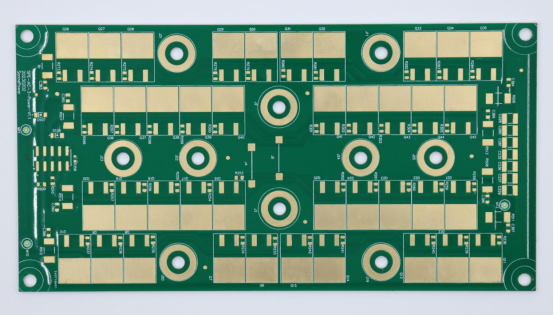

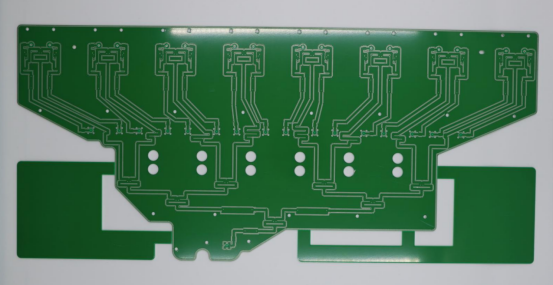

What Types of PCBs Can Benefit from THF Technology?

Copper Through-Hole Fill (THF) technology offers significant advantages across various industries that require high-performance PCBs. From small consumer electronics to high-power automotive systems, THF’s ability to create void-free, thermally efficient, and signal-optimized vias makes it an ideal solution for multiple types of PCBs.

Applications in High-Density Interconnect (HDI) PCBs

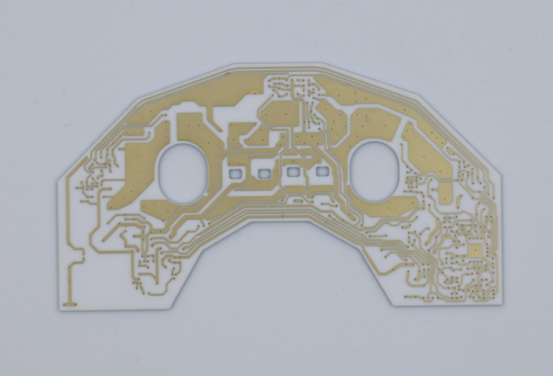

Smartphones and Wearables:

HDI PCBs are essential in the manufacture of modern smartphones, wearables, and other compact electronic devices. These PCBs require high-density interconnections to support miniaturized components while ensuring reliable electrical connections. THF technology plays a critical role in HDI PCBs by filling small vias (as small as 90 μm) with copper in a single, void-free process. This technology is especially important in smartwatches, smartphones, and other wearable devices where both size and performance are paramount. The superior thermal management and signal integrity provided by THF help keep these devices running efficiently, even in the most compact designs.

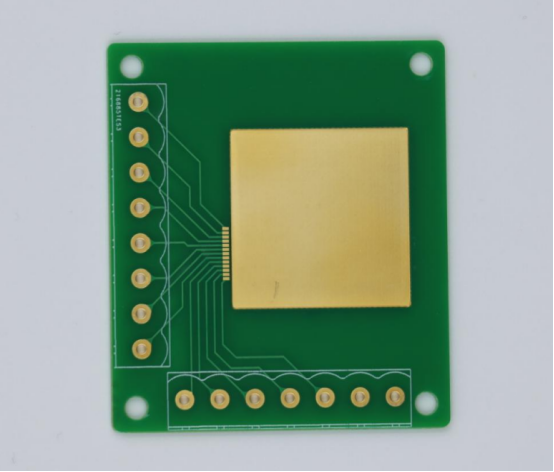

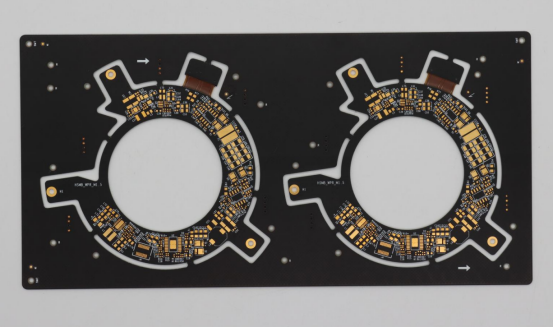

Advanced Electronics:

In addition to consumer devices, THF is also used in advanced electronics that demand high precision and performance. Devices like medical implants, advanced sensors, and next-gen computing hardware benefit from THF’s ability to create uniform copper fills in extremely small vias. These applications require miniaturized components that often work in extreme environments where heat dissipation and reliable signal integrity are critical. THF ensures that the PCBs can handle these challenges, offering reliable thermal management and signal transmission, both essential for the performance of high-precision systems.

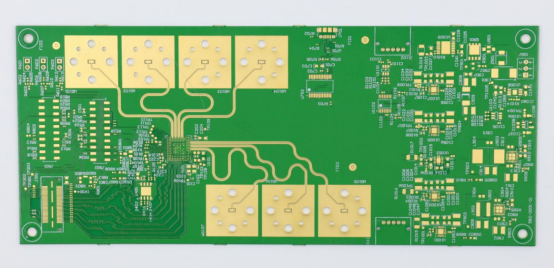

EV Power Systems and 5G Infrastructure

Electric Vehicle Inverters and Battery Management Systems:

Electric vehicles (EVs) depend on efficient power systems to manage high currents and heat generated during operation. THF technology significantly improves the reliability and thermal management of EV inverters and battery management systems (BMS). Copper’s high thermal conductivity (401 W/m·K) helps to dissipate heat from power modules, preventing overheating and improving battery life. This is crucial in EVs, where failure of components due to heat buildup can result in significant operational issues. THF-filled vias are used to provide a solid copper connection with enhanced heat dissipation, ensuring the EV systems stay efficient and durable, even under high-power conditions.

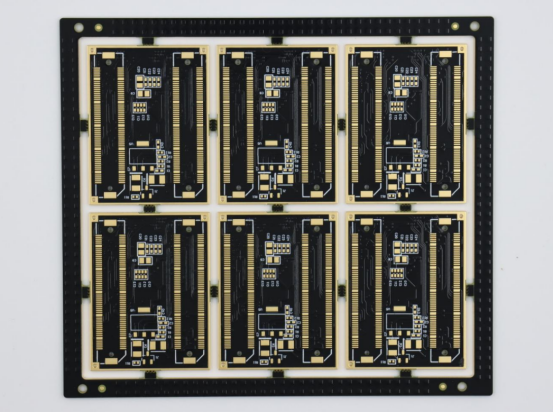

5G Base Stations & AI Servers:

In 5G infrastructure and AI servers, high-speed communication is critical. These applications require fast, reliable data transfer and the ability to handle massive amounts of data at high frequencies. THF vias reduce signal scattering and loss, improving signal integrity and allowing for smooth data flow across PCBs. For 5G base stations, THF ensures that high-frequency signals (24–40 GHz) are transmitted without distortion, maintaining signal clarity even at long distances. Similarly, AI servers benefit from THF’s ability to handle high-speed data transfer (up to 128Gbps), ensuring that interconnects between components like CPUs and GPUs remain fast and efficient. The void-free copper fills provided by THF are essential for minimizing signal degradation in these high-speed, high-frequency environments.

How Does Copper Through-Hole Fill (THF) Outperform Traditional Methods in Real-World Applications?

Copper Through-Hole Fill (THF) technology is setting a new standard for via filling in high-performance PCBs. By offering superior thermal management, signal integrity, and yield rates, THF outperforms traditional methods like conductive paste and blind via stacking in real-world applications. Let’s dive deeper into how THF shines in comparison to these older technologies.

Comparison with Conductive Paste and Blind Via Stacking

Void Rate & Thermal Conductivity:

THF significantly outperforms conductive paste and blind via stacking in two key areas: void rate and thermal conductivity. Traditional conductive paste methods often result in voids—air pockets that cause thermal hotspots and signal disruptions. These voids reduce thermal conductivity, which is critical in high-power applications like EVs and 5G base stations. THF, using phase-shifted pulse electroplating, ensures a void-free fill, providing uniform copper deposition with superior thermal conductivity (401 W/m·K). In comparison, conductive pastes have much lower conductivity, leading to poor heat dissipation and higher risk of component failure.

Signal Loss & Yield:

Blind via stacking often leads to misalignment, causing signal loss and increased insertion loss, especially for high-frequency signals like 5G mmWave. The trapezoidal via shapes cause signal scattering, weakening the signal. THF uses cylindrical vias, which reduce signal reflection and maintain signal integrity, even at high frequencies (24–40 GHz). THF also improves yield rates by 15–20%, reducing defective boards and enhancing manufacturing efficiency.

Comparison Table:

| Metric | THF | Conductive Paste | Blind Via Stacking |

| Void Rate | 0% (void-free fill) | 15–25% (common in thick vias) | 10–18% (misalignment risk) |

| Thermal Conductivity | 401 W/m·K (copper) | <10 W/m·K (polymer-based) | 380 W/m·K (copper, limited by alignment) |

| Signal Loss (28 GHz) | 40% less than blind via stacks | 2x more than THF | High (trapezoidal shape causes scattering) |

| Yield Rate | 95–98% | 75–80% | 80–85% |

| Suitable Via Sizes | 90–400 μm (mechanical/laser) | ≥200 μm (too thick for HDI) | ≤150 μm (limited by alignment) |

Real-World Performance in Critical Applications

EV Power Modules:

THF technology plays a pivotal role in enhancing the thermal management and current flow in electric vehicle (EV) power modules, including inverters and battery management systems (BMS). These systems require high-power handling and efficient heat dissipation to maintain performance during fast charging and high-output scenarios.

By filling vias with pure copper, THF ensures that heat generated in the power module is quickly dissipated, preventing the buildup of hot spots and reducing the risk of thermal failure. In fact, THF vias provide a 300% better thermal performance than traditional methods, allowing EVs to operate more reliably and efficiently. With better thermal cycling resistance, THF-filled vias can withstand over 1,000 temperature cycles from -40°C to 125°C, crucial for EVs used in varied environmental conditions.

5G Modules:

5G infrastructure, such as base stations, relies heavily on signal integrity for fast, reliable data transmission. Traditional blind via stacking often leads to signal loss at high frequencies, which is detrimental for applications requiring fast, clear communication, such as 5G and AI servers. In these environments, THF technology ensures that 28 GHz signals pass through the vias without distortion, enhancing data reliability and reducing the likelihood of dropped connections.

By using void-free copper-filled vias, THF minimizes signal scattering, a common issue with blind via stacks, and supports the high-speed data transfer essential for 5G modules. This makes THF the ideal choice for next-gen mobile communication and high-speed AI server systems, where minimal signal degradation and maximum efficiency are paramount.

What Are the Manufacturing and Reliability Gains with THF Technology?

Copper Through-Hole Fill (THF) technology not only improves PCB performance but also brings significant advantages in manufacturing and reliability. From extending the lifespan of components to speeding up production, THF is a game-changer for PCB manufacturers. Here’s how it leads to long-term gains in reliability and cost-effectiveness.

Enhanced Reliability and Durability

Long Lifespan: How THF Ensures Component Durability Over 10+ Years in Harsh Environments

THF technology greatly improves the reliability of PCBs by ensuring durable connections that can withstand the toughest conditions. Copper’s high thermal conductivity (401 W/m·K) means that THF-filled vias are better at dissipating heat, which reduces the risk of thermal stress on components. This heat resistance allows THF-filled PCBs to last over 10 years, even in harsh environments such as automotive electronics, industrial machinery, and aerospace applications.

The void-free copper fill provided by THF prevents weak points in the PCB structure that could lead to premature failure. For instance, in electric vehicles (EVs) or 5G infrastructure, where components undergo extreme temperature cycling, THF ensures that the vias remain intact without cracking or degrading over time. In fact, THF vias show improved thermal cycling resistance, lasting over 1,000 cycles from -40°C to 125°C, while traditional methods fail after only 300-500 cycles.

Zero Outgassing: Eliminating Risks in Sensitive Applications such as Medical Devices and Aerospace

One of the unique advantages of THF is its ability to eliminate outgassing—a problem with conductive pastes and blind via stacking. Outgassing occurs when gases are released from materials during the curing or operation of electronic devices, which can lead to contamination or damage to sensitive components, especially in medical devices, aerospace electronics, and military systems.

THF uses pure copper for via filling, which does not outgas, making it a safe and reliable choice for hermetic packages that require long-term stability. This ensures that pacemakers, glucose monitors, and space technology will remain functional without the risk of damage from outgassing.

Faster Production and Cost-Effectiveness

Reduced Rework and Defects: THF’s Low Void Rate Translates into Fewer Defective Units and Rework

One of the key benefits of THF technology is its low void rate, meaning that PCBs filled with THF vias are much less likely to suffer from defects. Traditional via filling methods, such as conductive pastes, often result in voids—air bubbles trapped inside the via that can lead to signal loss, thermal failure, and component damage. These issues require time-consuming rework, which delays production and increases costs.

THF’s phase-shifted pulse electroplating process ensures that vias are filled void-free in a single step, minimizing the risk of defects. This leads to fewer defective units, as X-ray and cross-sectional analysis have shown that THF-filled vias are consistently void-free. As a result, manufacturers can save time and money by reducing rework and scrap.

Cost Comparison: Analyzing the Initial Investment vs. Long-Term Savings with THF

While THF technology may require a higher initial investment in equipment—such as pulse electroplating systems and automated plating baths—the long-term savings make it a highly cost-effective solution.

Traditional via filling methods, like conductive pastes, are prone to higher waste and rework costs due to the voids that often occur. These problems can result in rework costs that range from $20k to $30k per year in a mid-sized production facility. In contrast, THF’s higher yield rates (up to 95-98%) and void-free filling reduce defects and rework, translating to savings of 15–20% in overall production costs. Over time, manufacturers often recoup their investment in THF technology within 6–12 months due to the reduced need for corrective actions and the improved quality of the products.

Furthermore, THF’s smaller equipment footprint (50% smaller than traditional systems) leads to space savings, reducing operational costs in factories.

How Does Copper Through-Hole Fill (THF) Integrate with Existing PCB Manufacturing Lines?

Integrating Copper Through-Hole Fill (THF) into existing PCB manufacturing lines is a straightforward process, offering compatibility with standard electroplating systems and flexibility in terms of via sizes and board thicknesses. This ease of integration allows manufacturers to adopt THF without significant changes to their current infrastructure. Here’s how it works.

Compatibility with Standard Electroplating Equipment

Integration Simplicity: How Manufacturers Can Adopt THF Without Overhauling Their Existing Setups

One of the biggest advantages of THF technology is that it integrates easily into existing PCB manufacturing lines. Manufacturers don’t need to overhaul their entire production setup, which makes adopting THF both cost-effective and time-efficient. The technology works with standard electroplating equipment, meaning manufacturers can use their existing electroplating baths and rectifiers. The only requirement is the addition of specialized hardware and software modifications to support THF’s unique process.

The key is the use of pulse electroplating. While this requires precise control of the pulse waveforms, it can be easily added to the existing electroplating line without needing to replace core systems. This adaptability reduces the risk of large upfront costs, allowing manufacturers to gradually transition to THF without a complete system upgrade.

Software Adjustments: Modifying Existing Systems to Generate Phase-Shifted Pulses for THF

THF technology requires a software modification to generate the phase-shifted pulse waveforms needed for the process. Existing electroplating systems can be reprogrammed to create the required pulse parameters (e.g., pulse current, duration, phase shift) for void-free filling. This software adjustment allows the existing system to perform the phase-shifted pulse electroplating, which is critical for achieving uniform copper deposition inside vias.

Manufacturers can work with software providers to adjust the parameters specific to their via sizes and board designs. This ensures that THF is optimized for their needs without disrupting overall production schedules.

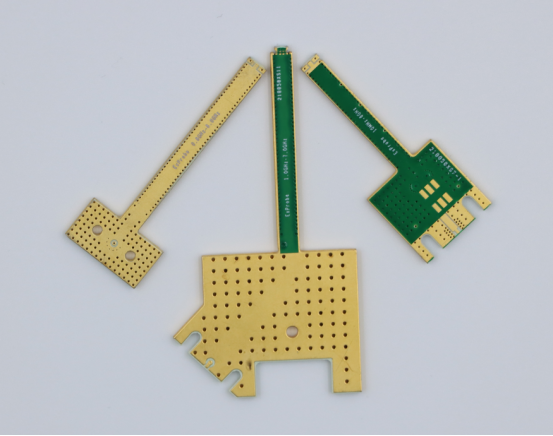

Versatility in Via Sizes and Board Thicknesses

Adapting to Different Via Sizes: How THF Works for Both Mechanical and Laser-Drilled Vias, from 90 μm to 400 μm

THF is designed to work across a wide range of via sizes, from small laser-drilled vias (around 90 μm) to larger mechanical vias (up to 400 μm). This versatility allows THF to be used in a variety of applications, including high-density interconnect (HDI) PCBs, 5G modules, and EV power systems.

For laser-drilled vias, which have a non-cylindrical shape (a narrow waist in the middle), THF can still achieve a void-free fill thanks to its precise control of pulse parameters. For mechanical vias, THF works efficiently in filling thicker vias with consistent copper, ensuring reliable connections. THF ensures that no matter the via size, it can precisely fill the via, offering superior thermal and signal performance.

Application to Various Board Thicknesses: Filling Vias in Boards Ranging from 250 μm to 800 μm

THF is adaptable to different board thicknesses, with the ability to fill vias in boards ranging from 250 μm to 800 μm thick. This makes it suitable for a wide array of PCB designs, from mobile devices to industrial electronics and EV power modules.

For thicker boards (up to 800 μm), THF’s single-step filling process provides consistent copper deposition that ensures thermal efficiency and signal integrity even in demanding applications like automotive electronics. For thinner boards (like those used in smartphones and wearables), THF offers the ability to fill smaller vias with the same high reliability.

In both cases, THF maintains its void-free quality, ensuring that thermal management and signal integrity are not compromised by the thickness of the board or the size of the vias.

Conclusion: The Future of PCB Manufacturing Is Copper Through-Hole Fill (THF)

Copper Through-Hole Fill (THF) is reshaping the future of PCB manufacturing by enhancing thermal management, improving signal integrity, and boosting manufacturing efficiency. Its ability to create void-free fills in vias offers better heat dissipation and stronger, more reliable connections, crucial for high-performance electronics. THF also streamlines the manufacturing process, reducing waste and rework while increasing yield rates—key factors for PCB makers looking to stay competitive in the fast-evolving market.

Looking ahead, adopting THF technology is essential for PCB manufacturers aiming to meet the growing demands of industries like 5G, electric vehicles (EVs), and AI. By leveraging THF, companies can produce high-density interconnect (HDI) boards and other advanced PCBs with greater precision, faster turnaround, and higher reliability. PCBMASTER, a leading PCB supplier, is at the forefront of this transformation, offering high-quality products backed by advanced THF technology. As electronics continue to evolve, THF will play a central role in ensuring that manufacturers can meet the challenges of the future.

FAQs

Is THF Technology More Expensive Than Traditional Via Filling Methods?

While the initial investment for Copper Through-Hole Fill (THF) technology is higher compared to traditional via filling methods—such as conductive paste filling or blind via stacking—the long-term benefits significantly outweigh the upfront costs. THF requires less rework due to its void-free filling process, reducing the number of defective units and the associated costs for corrections. This technology also increases production yield by 15-20%, meaning fewer boards are scrapped, translating to better cost-effectiveness over time.

Moreover, THF’s higher thermal conductivity and improved signal integrity mean that products manufactured with THF have a longer lifespan, reducing failures in high-demand applications like EV power systems or 5G base stations. The reduction in rework time and defective units combined with fewer production delays makes THF an economically sound choice for PCB manufacturers in the long run, ensuring that any higher initial expenditure is offset by enhanced productivity and reliability.

Can THF Be Used for Vias Smaller Than 90 μm?

Yes, THF can indeed be used for vias smaller than 90 μm, with modifications to certain process parameters. In lab tests, THF has successfully filled vias as small as 50 μm, showing its adaptability for even the most miniature high-density interconnect (HDI) PCBs. The key to achieving this is adjusting the pulse duration—a shorter pulse (around 30 ms) is typically used for smaller vias to prevent excessive edge buildup, ensuring that copper is deposited evenly without forming voids.

This flexibility allows THF to be applied in a variety of applications, such as smartphones, wearables, and other miniaturized electronics that require tight via sizes and high reliability. With the ability to handle small vias alongside larger ones, THF offers a versatile solution for a wide range of modern PCB designs, including those with laser-drilled vias used in advanced electronics.

How Can I Ensure Quality with THF Via Filling?

To ensure quality with THF via filling, several critical validation methods are used, ensuring that the process meets the highest standards of reliability and performance. Here are the most common quality checks:

X-ray Imaging: This is the primary method for detecting voids or incomplete copper fills within vias. X-ray inspection is especially useful for high-density boards where visual inspection is not feasible. It helps verify that there are no air pockets or gaps inside the vias, ensuring optimal thermal and electrical conductivity.

Cross-Sectional Analysis: After filling the vias, cross-sectional cutting is performed to examine the copper fill's uniformity and thickness. This test confirms whether the copper deposition is consistent and whether the via walls are properly covered, preventing issues such as thin spots.

Thermal Cycling Tests: Since THF vias are often used in high-power, high-temperature applications like EV inverters, thermal cycling is essential to confirm durability. The vias are exposed to extreme temperature variations (typically between -40°C to 125°C) to simulate real-world conditions. This test ensures that THF vias can withstand thermal stresses without cracking or delaminating.

Signal Integrity Testing: For high-speed applications like 5G or AI servers, signal integrity tests are performed to ensure minimal loss or distortion in the electrical signals traveling through the vias. Using tools such as S-parameters, manufacturers check how well the THF vias maintain signal fidelity at high frequencies.

By employing these comprehensive validation methods, manufacturers can confidently guarantee the quality of THF-filled vias, ensuring that the PCBs meet industry standards for performance and durability.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!