Why HDI Printed Circuit Boards Are Key for Modern Electronics

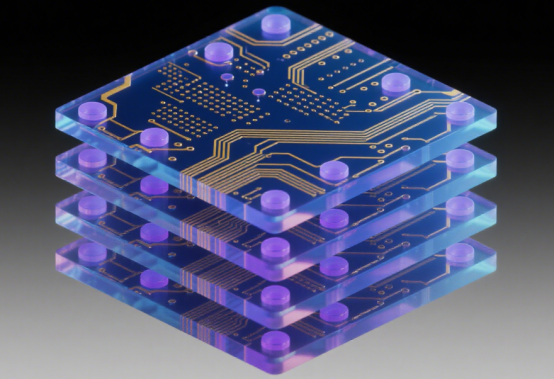

Figure 1: HDI Printed Circuit Boards Are Key for Modern Electronics

Today, our world is full of smart devices. Smartphones, 5G gadgets, smart watches, and Internet of Things (IoT) devices are everywhere. These devices are getting smaller, faster, and smarter every year.

But there is a problem. The old, traditional printed circuit boards (PCBs) cannot keep up with this fast growth. They are too big, too slow, and cannot fit all the tiny, powerful parts modern electronics need.

This is where HDI Printed Circuit Boards come in. HDI, or High-Density Interconnect PCBs, are small, smart, and strong. They help modern electronics work better, faster, and last longer. In this article, we will see why HDI Printed Circuit Boards are key for today’s high-tech devices.

What is an HDI Printed Circuit Board?

An HDI PCB is a special kind of printed circuit board that is made to be small, smart, and powerful. HDI stands for High-Density Interconnect, which means it can fit a lot of electronic parts very close together. This is very important for modern devices that are small but need to do a lot.

1. Key Features of HDI PCBs

High-Density Interconnect: This allows the board to have more tiny circuits in a smaller space. It is like packing more houses into a small city block.

Micro Vias (Blind and Buried Holes): These are very tiny holes that connect different layers of the board. Blind and buried holes help save space and make the board stronger.

Thinner, Lighter, and More Compact: HDI PCBs are smaller and lighter than regular PCBs. This is why they are perfect for smartphones, smart watches, and other tiny electronics.

2. Difference from Traditional PCBs

Traditional PCBs are bigger and cannot fit as many parts in a small space.

They do not have micro blind or buried holes, so the circuit connections are simpler and less dense.

HDI PCBs are faster, stronger, and can handle more complex electronics.

Using HDI PCBs means engineers can make electronics smaller, faster, and smarter. That is why they are now a key part of modern devices.

Key Advantages of HDI PCBs in Modern Electronics

HDI PCBs stand out because they can pack more connections into a smaller space, handle complex designs, and stay reliable under pressure. Here’s why engineers choose them for today’s devices:

1. Higher Circuit Density and Better Performance

By fitting smaller chips and more complex circuits into a tiny space, these boards allow devices to do more without getting bigger. They also improve signal quality and make electricity travel faster, helping electronics work more smoothly. For these reasons, using high-performance HDI PCBs is one of the main reasons modern devices are faster and smarter.

2. Save Space and Reduce Product Size

Their thin and compact design helps make devices smaller and lighter. This makes them perfect for smartphones, tablets, and wearable devices, and multiple layers—sometimes 4, 8, 12, or more—allow engineers to pack more circuits into a small board. Such features make it easier to design high-density PCBs for modern electronics.

3. Improved Reliability and Durability

Better heat management allows devices to last longer, while reduced signal interference lowers the chance of circuit problems. As a result, electronics become more reliable and safer to use, and HDI PCBs ensure consistent performance even in demanding environments.

4. Ready for Future Electronics

Designed for 5G, AI, IoT, and other high-speed, high-frequency applications, these boards can also handle denser and more complex circuits. In short, using HDI PCBs in modern electronics helps engineers build products that are smaller, faster, stronger, and ready for the future.

Applications of HDI PCBs

With so many advantages, HDI PCBs are used across many industries, helping devices become smarter, smaller, and more reliable.

1. Consumer Electronics

In smartphones, tablets, and laptops, HDI PCBs allow engineers to fit more circuits into smaller boards. This makes devices thinner, lighter, and more powerful, while still running fast and reliably. Thanks to high-density PCB applications, modern electronics can handle many tasks at the same time without slowing down.

2. Medical Devices

HDI PCBs are also important in medical equipment, such as implantable devices and monitoring instruments. Their small size and high reliability let doctors and patients use advanced technology safely. In these devices, high-density PCBs in electronics ensure accurate signals and consistent performance, which is critical for health applications.

3. Industrial Control and Automation

In factories and automated systems, these boards help control machines and processes precisely. They can handle complex signals and high-speed communication, making production safer and more efficient. Using HDI PCBs in industrial electronics allows engineers to build machines that are smarter and more reliable.

4. Aerospace

Finally, HDI PCBs are used in aerospace equipment, where high reliability, compact size, and durability are essential. They help airplanes, and satellites operate in tough conditions, and high-density PCB applications make it possible to fit advanced electronics into small, rugged spaces.

Figure 2: Four Applications of HDI PCBs

How to Choose the Right HDI PCB

After seeing how HDI PCBs are used in so many industries, the next question is: how do you choose the right one for your project? Picking the right board and manufacturer is key to making sure your device works well and lasts long.

1. Check the Manufacturer’s Experience

When choosing an HDI PCB, it is important to pick a manufacturer with real experience. Experienced companies know how to handle high-density designs and can produce boards that are reliable and accurate. A skilled manufacturer will also help solve problems faster if something goes wrong.

2. Look at Material Quality

The materials used in the board matter a lot. Good HDI PCBs use high-quality materials like FR-4 or high-TG substrates, which make the board stronger, more durable, and able to handle heat better. Choosing the right material ensures your device works well over time.

3. Consider Design and Production Capabilities

Different devices need different designs. Make sure the manufacturer can handle the number of layers, fine lines, and micro vias your project requires. HDI PCB production needs precision, so check if the company has the right machines and skills for complex boards.

4. Evaluate Delivery Time and Cost

Some projects need boards very quickly, while others have more flexible schedules. Compare different manufacturers for lead time, cost, and quality. Sometimes paying a bit more is worth it to get a high-density PCB that works perfectly.

5. Ask About Support and Communication

A good manufacturer should answer questions clearly and provide support during the design and production process. Clear communication helps avoid mistakes and ensures your HDI PCB application meets your expectations.

Conclusion

In summary, HDI Printed Circuit Boards play a key role in modern electronics. They allow devices to be smaller, faster, and more reliable, and they make advanced technology possible in smartphones, medical devices, industrial machines, and even aerospace equipment.

Looking to the future, high-density PCB technology will only become more important as devices get smarter and more connected. There is no real substitute for the precision and performance that HDI PCBs offer.

If you want your products to stay ahead in today’s fast-moving world, learning about HDI Printed Circuit Boards and working with the right manufacturers is a smart first step.

If you’d like to learn more about PCBs or find the right solution for your project, contact PCB MASTER today, your professional and reliable PCB supplier.

FAQs

1. What is the typical lifespan of an HDI PCB?

The lifespan of an HDI PCB depends on the materials used, the operating environment, and how the device is handled. High-quality boards made with strong substrates like FR-4 or high-TG materials can last 10–15 years in consumer electronics such as smartphones and laptops. In industrial, or aerospace, where devices face extreme temperatures, vibrations, and heavy use, HDI PCBs may last even longer because they are designed to resist wear, heat, and signal degradation over time. Proper design and assembly also play a key role in ensuring longevity.

2. Can HDI PCBs be repaired if a layer or circuit fails?

Repairing an HDI PCB is very challenging due to the dense layers, tiny micro vias, and compact design. Even a small defect can affect multiple circuits. In most cases, manufacturers recommend replacing the board rather than repairing it. However, for minor issues like broken traces on single layers, skilled technicians may sometimes use advanced soldering or laser repair techniques. Still, these repairs are time-consuming, costly, and not guaranteed to restore full performance, which is why high-density PCB applications are usually designed to minimize the risk of failure in the first place.

3. How does HDI PCB technology impact device energy efficiency?

HDI PCBs help improve energy efficiency in several ways. Their short, dense circuits reduce electrical resistance, which means less energy is lost as heat. They also reduce signal interference, which allows components to operate more efficiently and with lower power consumption. This is especially important in smartphones, tablets, and wearable devices, where battery life is critical. Devices using high-density PCB technology often run cooler, last longer on a single charge, and maintain stable performance even during heavy use.

4. Are HDI PCBs more expensive than traditional PCBs?

Yes, HDI PCBs are generally more expensive because they require advanced materials, micro vias, multiple layers, and precise manufacturing processes. These factors increase production complexity and cost. However, the higher price is often justified because HDI PCBs allow devices to be smaller, faster, and more reliable. For high-performance products like smartphones, medical devices, or aerospace electronics, the benefits of higher efficiency, better signal integrity, and longer lifespan far outweigh the extra cost.

5. What industries are likely to see increased use of HDI PCBs in the future?

Beyond consumer electronics like smartphones and laptops, HDI PCBs are becoming essential in industries that need compact, high-performance circuits. This includes autonomous vehicles, where boards control sensors and communication; robotics, where precise and reliable circuits are required; wearable healthcare devices, which need small and lightweight electronics; and 5G telecommunications, which demand high-speed, high-frequency circuits. As technology advances, any field that requires miniaturized, high-density electronics is likely to rely more on high-density PCB technology in the coming years.