Copper Base PCBs: Key Advantages, Applications, and How to Choose

As we all know, thermal management and durability are crucial in today's high-performance industrial electronics. This is one of the main reasons why copper base PCBs (Printed Circuit Boards) are widely used. With their exceptional thermal conductivity and high current-carrying capacity, copper base PCBs effectively transfer heat away from sensitive components, helping to maintain system stability and extend the lifespan of electronic devices. They have become the ideal choice for high-power applications.

So, what exactly is a copper base PCB? What is its structure, what are its main advantages, and how is it applied in real-world scenarios? And how should we choose the right one for our applications?

What Are Copper Base PCBs? Key Components and Layer Structure

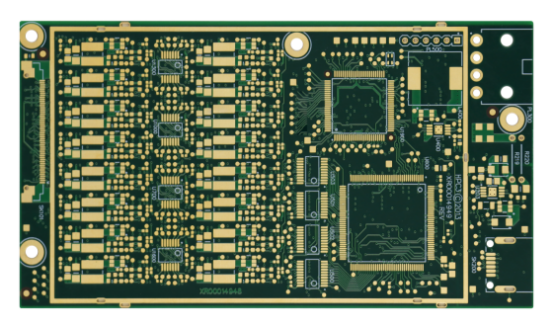

Copper base PCBs are a type of circuit board that uses copper as the substrate material, replacing traditional FR4 or aluminum substrates. The key advantage of copper-based PCBs lies in copper’s superior thermal conductivity, which makes them highly effective for applications requiring efficient heat dissipation, such as high-power devices.

Key Components and Layer Structure

1. Copper Base Layer

The core of a copper base PCB is a thick copper plate, typically ranging from 1mm to 10mm in thickness. This layer serves a dual purpose:

Electrical Connectivity: It forms the foundation of the PCB’s circuit, providing electrical connections.

Heat Dissipation: The copper base acts as an integrated heat sink, directly transferring heat away from sensitive components, preventing overheating.

Example: In high-power LED lighting systems, the copper base helps keep the LED temperature low, ensuring long-lasting performance.

2. Insulating Layer

Located between the copper base and the circuit layer, the insulating layer is typically made from high thermal conductivity materials like polyimide or epoxy resin. This layer performs two functions:

Electrical Isolation: It electrically isolates the copper base from the circuit layer, preventing short circuits.

Thermal Conductivity: While it provides electrical isolation, it also allows for some heat transfer, ensuring that heat moves from the copper base to the circuit layer.

3. Circuit Layer

The circuit layer is made from 1-3oz copper, which is etched to create the circuit patterns. This layer carries electrical signals and connects components like LEDs, MOSFETs, and connectors.

Function: The circuit layer is responsible for carrying the power and electrical signals to the components.

Example: In industrial motor drive systems, this layer helps to manage power distribution effectively, ensuring smooth operation.

Comparison with Other Types of PCBs

Understanding how copper base PCBs compare to other types of PCBs can help highlight their advantages for specific applications:

Copper Base PCB vs. Aluminum Base PCB

Thermal Conductivity: Copper has a significantly higher thermal conductivity (401 W/m·K) than aluminum (205 W/m·K). This makes copper base PCBs more effective at dissipating heat, which is crucial in high-power systems.

Performance: Copper base PCBs generally outperform aluminum base PCBs in high-power applications, providing better heat management and lower temperatures for sensitive components.

Example: In electric vehicle (EV) charging stations, copper base PCBs are preferred due to their ability to manage higher power levels and heat dissipation.

Copper Base PCB vs. FR-4 PCB

Thermal Conductivity: The thermal conductivity of FR-4 PCBs ranges from 0.3 to 0.5 W/m·K, which is far lower than that of copper. This makes FR-4 suitable for low-power applications but inadequate for high-power, heat-intensive designs.

Applications: Copper base PCBs are better suited for high-power and heat-sensitive applications, while FR-4 PCBs are typically used in consumer electronics or other low-power devices.

Example: Copper base PCBs are often used in industrial automation systems, where effective heat dissipation is necessary to keep motors and drives running efficiently.

Copper Base PCB vs. Ceramic Base PCB

Thermal Conductivity: Ceramic PCBs have excellent thermal conductivity, often outperforming copper, but they come at a higher cost.

Cost vs. Performance: Copper base PCBs provide a balance between performance and cost, offering 80% of the thermal performance of ceramic PCBs at a fraction of the cost.

Example: For most renewable energy applications like solar inverters, copper base PCBs provide adequate thermal performance without the high cost of ceramic materials.

Comparison Table

| PCB Type | Thermal Conductivity (W/m·K) | Max Operating Temperature (°C) | Weight (g/cm³) | Cost (Relative) | Best For |

| Copper | 401 | 150 | 8.96 | 3× | High-power LEDs, EV charging |

| Aluminum | 205 | 125 | 2.70 | 1.5× | Low-to-mid-power industrial sensors |

| FR-4 (Standard) | 0.3–0.5 | 130 | 1.80 | 1× | Low-power consumer electronics |

| Ceramic (Alumina) | 20–30 | 250 | 3.90 | 5× | Extreme-temperature aerospace |

The Advantages of Copper Base PCBs

Copper base PCBs offer several unique advantages over other types of PCBs, particularly in industrial electronics where thermal management and high current capacity are critical. Let's explore these benefits in detail.

1. Superior Thermal Management Performance

Copper base PCBs are designed with a thick copper base layer that acts as an integrated heat sink. This structure allows them to efficiently transfer heat away from high-power components, keeping the system cool. Compared to aluminum base and FR4 base PCBs, copper base PCBs show much greater heat dissipation, making them ideal for heat-intensive applications.

Real-life example: In a 100W LED system, copper base PCBs can lower the temperature by 35°C compared to aluminum base PCBs. This reduction in temperature helps increase the lifespan of the components by preventing overheating, which can lead to failure.

By using copper’s high thermal conductivity (401 W/m·K), copper base PCBs ensure that heat is efficiently conducted away from sensitive components, improving system reliability and reducing the need for external cooling.

2. High Current-Carrying Capacity

Copper base PCBs feature thick copper traces (usually 1–3oz), allowing them to carry much higher currents than other types of PCBs. This makes copper base PCBs ideal for high-power systems that require substantial current handling.

Example: A 2oz copper trace on a copper base PCB can handle up to 40A, whereas the same trace on an aluminum base PCB can only handle 25A. This increased current capacity helps reduce power loss, increase efficiency, and ensure more stable operation in systems like electric vehicle (EV) charging stations and industrial motor drives.

In high-power applications, copper base PCBs can reduce the risk of thermal overload and power loss, making them more reliable and efficient.

3. Durability and Reliability

Copper base PCBs offer excellent vibration resistance, moisture resistance, and thermal cycling resistance, allowing them to perform reliably in harsh environments. These qualities make copper base PCBs ideal for automotive, industrial, and aerospace applications where systems are subject to extreme conditions.

Moisture Resistance: Copper base PCBs typically feature nickel or gold plating, which gives them low moisture absorption (less than 0.1%), compared to FR4 PCBs that may absorb up to 0.5%. This improves the reliability of copper base PCBs in environments with high humidity.

Thermal Cycling Resistance: Copper base PCBs can handle extreme temperature fluctuations from -40°C to 150°C without delaminating, undergoing over 1,000 thermal cycles. This makes them suitable for applications where temperature changes are frequent, such as LED lighting and automotive electronics.

Copper base PCBs ensure long-term durability, maintaining performance even in the toughest conditions.

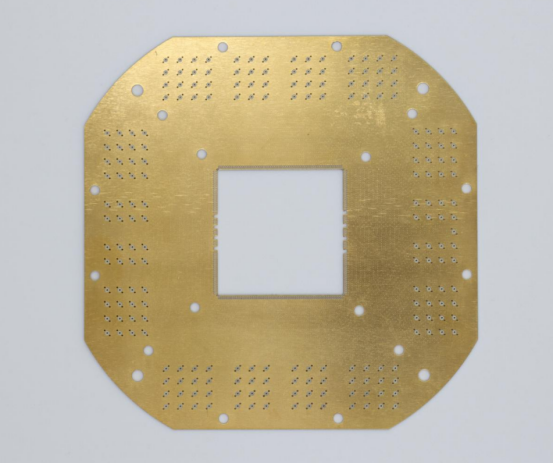

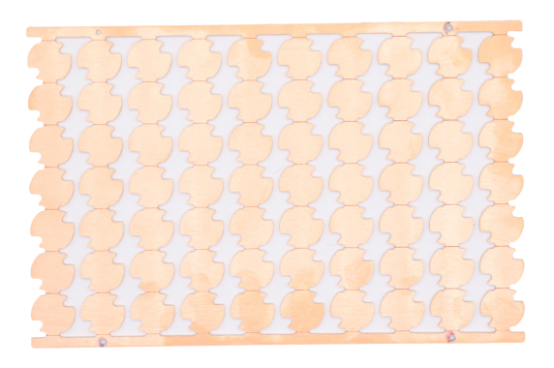

4. Design Flexibility

Copper base PCBs offer design flexibility, allowing manufacturers to tailor the board to the specific needs of different applications. This includes options for copper thickness (ranging from 1mm to 10mm), layer count (from 2 to 12 layers), and various surface finishes (such as ENIG, HASL, or immersion silver).

Example: For a high-power industrial inverter, you might choose a 10mm copper base for maximum heat dissipation, while a 2-layer design might be sufficient for a simpler, low-power application like wearable electronics. The ability to adjust the design ensures copper base PCBs can meet the specific performance and durability requirements of the application.

This customization allows copper base PCBs to be optimized for a wide range of industries, from renewable energy to medical devices.

Applications of Copper Base PCBs

Copper base PCBs are widely used across industries that require high power and efficient heat management. Their ability to dissipate heat and handle large electrical currents makes them the go-to solution for critical applications in industries like LED lighting, electric vehicles (EVs), industrial automation, and renewable energy systems. Let’s explore the key areas where copper base PCBs are used.

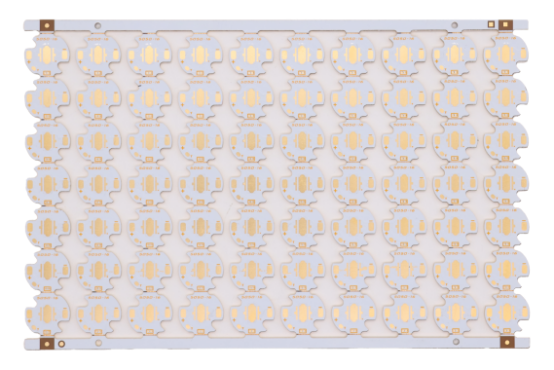

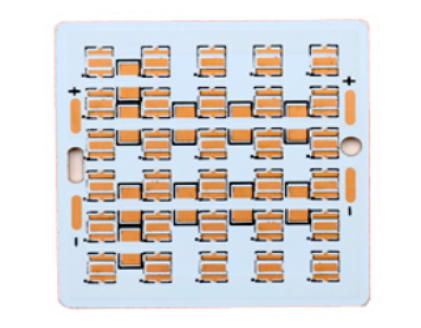

1. High-Power LED Lighting Systems

Copper base PCBs play a crucial role in LED lighting systems by efficiently managing the heat generated by high-power LEDs. LEDs, especially high-wattage ones, can overheat quickly, leading to lumen degradation (loss of brightness) and shortened lifespan. Copper base PCBs help dissipate heat effectively, preventing overheating and ensuring consistent lighting performance over time.

Example: In streetlights and stadium lighting, copper base PCBs are used to keep the LEDs cool, preventing thermal runaway and maintaining optimal brightness levels throughout their lifespan. In UV LED curing systems (used for printing or coating applications), copper base PCBs handle high-power UV LEDs, ensuring reliable and stable operation under demanding conditions.

The thermal conductivity of copper (401 W/m·K) allows copper base PCBs to efficiently draw heat away from the LED chips, extending their operating life and improving their performance.

2. Electric Vehicles (EVs) and Charging Infrastructure

Copper base PCBs are a critical component in EV charging stations and battery management systems (BMS). These systems require effective heat dissipation to prevent overheating during fast charging, which could lead to battery failure or safety hazards.

Example: In EV charging stations, copper base PCBs ensure that high-power components like power modules and charge controllers remain cool, preventing thermal damage. Similarly, in battery management systems, copper base PCBs help manage the heat generated while monitoring battery cell temperatures, ensuring that the battery pack operates efficiently and safely.

Copper’s high thermal conductivity allows these systems to handle significant heat loads during rapid charging, making them more efficient and safer for both the vehicle and the charging infrastructure.

3. Industrial Automation and Motor Drives

In industrial automation, copper base PCBs are extensively used in motor drives, variable frequency drives (VFDs), and power supply units. These applications often involve high currents, and copper’s excellent current-carrying capacity and heat dissipation make copper base PCBs the ideal choice.

Example: In motor drives that control heavy machinery in factories, copper base PCBs ensure that power is delivered reliably while preventing overheating. Similarly, in VFDs, which regulate the speed and torque of motors, copper base PCBs help prevent the power components from overheating, extending the lifespan of the entire system.

The high current capacity of copper base PCBs, combined with their ability to handle thermal loads, ensures the reliability and efficiency of motor control systems in industrial automation.

4. Renewable Energy Systems

Copper base PCBs are crucial in solar inverters and wind turbine controllers, where they handle high currents and dissipate heat generated by power conversion and control systems. These renewable energy devices often operate in extreme environments (e.g., outdoor conditions or remote locations), requiring reliable, durable components.

Example: In solar inverters, copper base PCBs manage high-power DC to AC conversion, ensuring efficient operation and preventing overheating. Similarly, in wind turbine controllers, copper base PCBs are used to manage and regulate the power output, withstanding vibration and temperature fluctuations common in harsh environmental conditions.

The thermal performance and durability of copper base PCBs make them an ideal choice for renewable energy applications, ensuring that solar panels and wind turbines can operate at peak efficiency over their lifespan.

How to Choose the Right Copper Base PCBs for Your Specific Needs

When selecting copper base PCBs for a particular application, buyers must consider several key factors to ensure optimal performance. The right combination of copper thickness, layer count, surface finish, and environmental tolerance can make a significant difference in the reliability and longevity of the system. Below, we break down these factors to help you make an informed decision.

1. Choosing the Right Copper Base Thickness

The thickness of the copper base layer plays a crucial role in the heat dissipation capabilities of the PCB. The thicker the copper base, the better the heat is drawn away from high-power components, ensuring that the system doesn’t overheat. For different applications, the required copper thickness can vary:

High-Power Applications: For systems with high heat loads, such as 500W industrial inverters or high-power LEDs, a thicker copper base (e.g., 10mm) is necessary to efficiently manage the increased heat generation.

Low to Medium Power Applications: For lower-power systems, such as wearables or low-power motor drives, a thinner copper base (e.g., 1-3mm) is usually sufficient to keep temperatures under control.

By choosing the right copper base thickness, you can optimize thermal performance, extend the lifespan of components, and improve the overall efficiency of your system.

2. Layer Count and Surface Treatment Selection

Layer Count: The number of layers in a PCB determines its complexity and signal routing capabilities. A 2-layer PCB is suitable for simple designs with fewer components, while a 12-layer PCB may be needed for complex circuits with high-density components or high-frequency signals. The higher the layer count, the more efficient the PCB can handle power distribution and signal integrity.

Surface Treatment: The surface finish of a PCB can affect solderability, electrical performance, and reliability. Common surface treatments include:

ENIG (Electroless Nickel Immersion Gold): This provides excellent solderability, corrosion resistance, and electrical performance. It's commonly used in high-reliability applications.

HASL (Hot Air Solder Leveling): A more cost-effective option that is often used in mass production. It offers decent solderability but is less reliable than ENIG for demanding applications.

Immersion Silver or Immersion Tin: These finishes are commonly used for RF applications or in designs that require higher-frequency performance.

Depending on the complexity of your circuit and the environmental conditions of your application, the right choice of layer count and surface treatment will improve the reliability, performance, and durability of your copper base PCB.

3. Temperature and Environmental Tolerance

Environmental conditions like temperature extremes, moisture, and vibration can have a significant impact on the performance and longevity of copper base PCBs. To ensure reliable operation, it is essential to select PCBs that are tested for environmental resistance.

Temperature Tolerance: Copper base PCBs are typically designed to operate in environments with temperatures ranging from -40°C to 150°C. However, for extreme conditions or aerospace applications, you might need PCBs that can withstand even greater temperature fluctuations.

Moisture and Vibration Resistance: Applications in harsh environments, such as automotive electronics or industrial automation, require PCBs that are resistant to moisture and vibration. Copper base PCBs, when coated with nickel or gold, offer excellent moisture resistance, with low moisture absorption (typically under 0.1%). Vibration resistance ensures that the PCB will remain stable under mechanical stress, which is critical for automotive systems and heavy machinery.

Compliance with MIL-STD: For mission-critical applications in defense, aerospace, or medical fields, ensure that the copper base PCB complies with MIL-STD standards, which guarantee high reliability and long-term performance under extreme conditions.

By carefully considering the temperature range, moisture resistance, and vibration resistance, you can ensure that your copper base PCB will operate reliably in the specific environment where it will be deployed.

Conclusion

Copper base PCBs provide exceptional heat management, high current capacity, and reliability, making them ideal for demanding applications like LED lighting, electric vehicles, and industrial automation.

Selecting the right copper base PCB ensures better performance and extends the lifespan of your devices. With the right supplier, such as PCBMASTER, you can customize your PCBs to meet specific needs and industry standards, ensuring long-term reliability.

Choose copper base PCBs to enhance the efficiency and durability of your high-power systems.

FAQs

1. Are Copper Base PCBs RoHS Compliant?

Yes, copper base PCBs are RoHS compliant. They are made using lead-free copper materials and environmentally friendly surface finishes. This ensures they meet global environmental standards for reducing harmful substances in electronics, making them safe for both users and the environment.

2. Can Copper Base PCBs Be Used in Flexible Designs?

Yes, copper base PCBs can be designed for flexible applications. By using flexible materials like polyimide for the insulating layer, these PCBs can bend and adapt to applications that require flexibility, such as in wearable devices or curved displays. This flexibility expands the potential applications, allowing for designs that traditional rigid PCBs cannot support.

3. What Is the Maximum Power Capacity a Copper Base PCB Can Handle?

Standard copper base PCBs can handle up to 500W of power. However, customized designs can support even higher power loads, with some copper base PCBs capable of managing 1kW or more. These customizations are typically achieved by increasing the copper base thickness and adjusting other parameters to accommodate higher thermal and electrical demands, making them suitable for industries like industrial motor drives and high-power LEDs.

4. How Does the Cost of Copper Base PCBs Compare to Ceramic PCBs?

Copper base PCBs are typically one-third to one-half the cost of ceramic base PCBs. Despite this lower cost, copper base PCBs still deliver 80% of the thermal conductivity of ceramic-based alternatives. This makes them a more cost-effective solution for many industrial applications where high thermal performance is required but the budget is a concern. The cost savings come without compromising on performance, making copper base PCBs a better choice for most applications.

5. How Do Copper Base PCBs Perform in Extreme Environments?

Copper base PCBs are built to withstand extreme environmental conditions, including high vibrations, moisture, and temperature fluctuations. They exhibit excellent vibration resistance, making them suitable for industries like automotive and aerospace. Additionally, their moisture resistance is enhanced by coatings like nickel or gold, reducing the risk of corrosion. Copper base PCBs can endure temperature cycles ranging from -40°C to 150°C, maintaining stability over 1,000+ thermal cycles without delamination. This durability ensures that copper base PCBs perform reliably in harsh conditions, making them ideal for demanding industrial, automotive, and outdoor applications.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!