Aluminum Nitride Ceramic PCBs: Benefits, Applications, and Trends

As electronics get smaller and more powerful, managing heat and maintaining electrical insulation are increasingly critical. Traditional materials often can't meet these rising demands. Aluminum Nitride (AlN) ceramic PCBs offer a breakthrough solution with their exceptional thermal conductivity, high electrical resistance, and mechanical strength. These qualities make AlN ideal for industries like automotive, aerospace, telecommunications, and medical technology, where performance and reliability are essential.

What are Aluminum Nitride (AlN) Ceramic PCBs?

Aluminum Nitride (AlN) ceramic PCBs are a type of printed circuit board made from aluminum nitride ceramic material. Known for their high thermal conductivity, electrical insulation properties, and durability, AlN PCBs are ideal for high-performance applications where heat management and electrical stability are critical.

AlN is a compound of aluminum and nitrogen, which gives it exceptional thermal conductivity, making it far superior to traditional PCB materials in terms of heat dissipation. This makes AlN PCBs an excellent choice for industries like automotive, aerospace, telecommunications, and medical devices, where managing heat and ensuring safe electrical performance are crucial.

Composition and Manufacturing Process

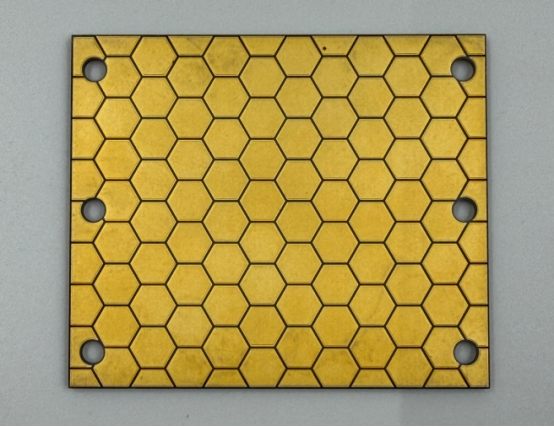

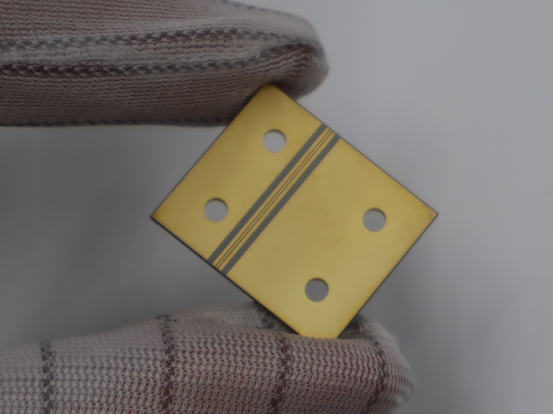

AlN ceramic PCBs are made by combining aluminum nitride powder with a binder material, which is then shaped and sintered in high-temperature furnaces to form a solid ceramic substrate. The surface of these ceramics is often plated with copper or other conductive materials to create the electrical connections needed for PCB functionality. This process ensures that the ceramic material maintains its high thermal conductivity and electrical insulation properties, while also allowing it to be used for complex circuit designs.

AlN ceramic PCBs are available in various forms and sizes, depending on the requirements of the electronic device being manufactured. Their unique properties, especially their ability to withstand extreme heat and electrical stress, make them a reliable choice for applications that push the limits of traditional PCB materials.

Comparing AlN with Traditional PCB Materials

To understand why AlN ceramic PCBs are gaining popularity, it's important to compare them to traditional PCB materials like FR-4, Alumina (Al₂O₃), and Beryllium Oxide (BeO). Below is a comparison of their key characteristics:

| Material | Thermal Conductivity (W/mK) | Electrical Insulation | Temperature Resistance | Cost |

| Aluminum Nitride (AlN) | 140–200 W/mK | High resistivity (10¹²–10¹³ ohms cm) | >600°C | $5–$20 per square inch |

| FR-4 (Standard PCB) | 0.2–0.3 W/mK | Moderate resistivity (10⁶–10⁹ ohms cm) | 130–150°C | $0.10–$0.50 per square inch |

| Alumina (Al₂O₃) | 20–30 W/mK | High resistivity (10¹² ohms cm) | Up to 1600°C | $3–$15 per square inch |

| Beryllium Oxide (BeO) | 250–300 W/mK | High resistivity (10¹² ohms cm) | Up to 2500°C | $10–$30 per square inch |

What Are the Advantages of Aluminum Nitride (AlN) Ceramic PCBs?

Aluminum Nitride (AlN) ceramic PCBs offer several key advantages over traditional PCB materials. These include exceptional thermal management, high electrical insulation, outstanding resistance to extreme temperatures, mechanical strength, and long-term reliability in harsh environments.

1. Exceptional Thermal Management

AlN ceramic PCBs are excellent at managing heat, which is critical for high-power electronics.

High Thermal Conductivity: AlN has a thermal conductivity ranging from 140 to 200 W/mK, which is significantly higher than traditional PCB materials like FR4 (0.2–0.3 W/mK) and Alumina (20–30 W/mK). This enables AlN PCBs to effectively dissipate heat from high-power electronic components.

Performance Comparison: In power semiconductor systems, LED lighting, and electric vehicle (EV) battery systems, AlN PCBs can efficiently transfer heat away from components, preventing overheating and extending their lifespan. For instance, in EV batteries, AlN PCBs help reduce the temperature of the battery management system, enhancing its performance and lifespan.

Industry Impact: AlN’s superior thermal conductivity helps lower the operating temperature of electronics, reducing the risk of overheating and failures. For industries relying on high-power systems, such as semiconductors and LEDs, this property is a game-changer.

2. Outstanding Electrical Insulation Properties

AlN ceramic PCBs provide superior electrical insulation, ensuring stable performance in high-frequency applications.

High Volume Resistivity: AlN has a volume resistivity of 10¹²–10¹³ ohms·cm, much higher than Alumina, which is about 10 times lower. This ensures that electrical leakage and signal loss are minimized, making AlN ideal for sensitive applications where electrical isolation is critical.

Signal Stability: The high electrical insulation of AlN ensures that high-frequency signals, such as those in 5G networks and radar systems, are stable and free from interference. This makes AlN essential for modern communication systems that require fast, reliable signal transmission.

Dielectric Constant: With a dielectric constant of approximately 8.9, AlN is more suitable for high-speed signal transmission compared to materials like Alumina, which has a dielectric constant of 9.8. This property ensures that AlN ceramic PCBs maintain signal integrity in high-frequency electronic devices.

3. Superior High-Temperature and Mechanical Strength

AlN ceramic PCBs can withstand extreme temperatures and mechanical stress, making them reliable in harsh environments.

High-Temperature Resistance: AlN can operate continuously at temperatures up to 600°C, with short-term exposure to up to 2400°C. This temperature tolerance far exceeds FR4 and Alumina, making AlN the material of choice for high-heat applications in aerospace, automotive, and military equipment.

Thermal Shock Resistance: AlN's low coefficient of thermal expansion (~4.5 ppm/°C) allows it to resist rapid temperature changes without cracking. This is especially important in aerospace and EV applications, where components are subjected to frequent temperature shifts during operation.

Corrosion Resistance: AlN exhibits excellent resistance to acids, alkalis, and salts, making it highly durable in aggressive environments, such as marine or industrial machinery settings. It can withstand exposure to corrosive chemicals, ensuring that the PCB’s performance remains stable over time.

Mechanical Strength: Despite being a ceramic, AlN has a flexural strength of 300–400 MPa, making it robust enough to handle mechanical stress and vibration, which is especially valuable in automotive and aerospace industries where components are exposed to constant motion and shocks.

4. Reliability in Harsh Environments

AlN ceramic PCBs are highly reliable, even in demanding industrial environments.

Adaptability to Harsh Conditions: AlN PCBs can operate reliably in extreme temperature fluctuations and chemical environments, such as those found in automotive engines, aerospace, and military systems. This makes them indispensable in systems where temperature and chemical resistance are paramount.

Long-Term Stability: AlN’s ability to resist external pressures—whether thermal, mechanical, or environmental—ensures that electronics relying on AlN PCBs perform reliably over extended periods. For example, AlN PCBs in battery management systems (BMS) for EVs can withstand years of use without degradation, ensuring long-term performance and reliability.

Real-World Application: In modern electric vehicles (EVs), AlN PCBs are used in power electronics, thermal management, and other key systems, ensuring the vehicle's components remain stable and efficient throughout its lifecycle.

5. High Reliability and Long Service Life

AlN ceramic PCBs significantly extend the lifespan of electronic components, reducing the need for maintenance and replacements.

Durability: The high thermal conductivity and electrical insulation properties of AlN lead to reduced wear and tear in the systems that use it. As a result, devices that rely on AlN PCBs, like medical equipment and autonomous vehicles, can last longer, reducing the frequency of maintenance or replacements.

Reduced Failure Rates: The superior heat management and electrical insulation offered by AlN help prevent failures caused by overheating or electrical leakage. This is particularly important in critical applications, such as semiconductor manufacturing and medical imaging, where failure is not an option.

Cost Savings: By improving the reliability and lifespan of electronic components, AlN PCBs help reduce operational costs over time. This is especially true in industries like medical devices and semiconductors, where the cost of downtime and system failures can be extremely high.

Widely Used Applications of Aluminum Nitride (AlN) Ceramic PCBs

Aluminum Nitride (AlN) ceramic PCBs are crucial in industries like semiconductors, electric vehicles, aerospace, and 5G communications. They offer excellent heat management, electrical insulation, and durability, ensuring reliable performance in high-power, high-frequency, and extreme environments.

1. Semiconductors and High-Power Electronics

AlN ceramic PCBs are highly valued in the semiconductor and power electronics industries for their exceptional heat management capabilities.

Efficient Heat Management: AlN’s thermal conductivity, ranging from 140 to 200 W/mK, makes it ideal for high-power applications where heat generation is a major concern. In semiconductor manufacturing, AlN PCBs help efficiently transfer heat away from sensitive components, preventing overheating that could damage delicate chips.

Application in Power Electronics and EV Batteries: In electric vehicle (EV) battery management systems (BMS), AlN ceramics help regulate the temperature of the batteries, ensuring their performance remains optimal over time. In LED lighting, AlN PCBs keep the components cool, extending their lifespan by preventing heat buildup.

LED Lighting Example: AlN ceramic PCBs reduce junction temperatures in high-power LEDs, which helps improve light output and longevity. For example, in industrial or automotive LEDs, the use of AlN can increase the operational life of the lights by up to 50%.

2. Automotive and Electric Vehicles

In the automotive industry, especially with the rise of electric vehicles (EVs), AlN ceramic PCBs are critical for providing reliable thermal management and electrical insulation.

Battery Management Systems (BMS): AlN PCBs are used in EV battery management systems to regulate temperatures during charging and discharging, preventing the batteries from overheating, which can lead to thermal runaway. This not only improves safety but also extends battery life by up to 30%.

Power Converters: In power conversion systems within EVs, such as inverters and converters that manage the flow of electricity from the battery to the motor, AlN PCBs help maintain a stable temperature, preventing damage to electronic components. This results in better performance and energy efficiency.

Autonomous Vehicle Systems: AlN’s electrical insulation properties also play a key role in the development of autonomous vehicle systems. In advanced driver-assistance systems (ADAS) like radar and LiDAR, AlN PCBs ensure signal stability and reliable operation, even under extreme environmental conditions.

3. Aerospace

AlN ceramics are well-suited for aerospace due to their durability and high-performance properties, even in extreme conditions.

Radar Systems: In aerospace, high-frequency radar systems rely on AlN PCBs for stable signal transmission. AlN’s low dielectric loss ensures that high-frequency signals used in radar systems are transmitted without interference, making them crucial for air traffic control, weather monitoring, and defense.

Satellites: AlN PCBs are also used in satellite electronics where they help manage the extreme temperature fluctuations between the cold of space and the heat of the sun. Their high thermal conductivity helps prevent overheating of sensitive electronic components in space, ensuring reliable communication and operation.

Thermal Protection: During space exploration, AlN PCBs are utilized in thermal protection systems for spacecraft re-entry. AlN’s ability to withstand temperatures as high as 2400°C helps protect onboard electronics from the extreme heat encountered during re-entry.

4. 5G Communication

AlN PCBs are becoming a key component in the 5G communication infrastructure, ensuring faster and more reliable communication.

RF Filters and Antennas: In 5G base stations, AlN ceramics are used in RF filters and antennas, where their high thermal conductivity helps dissipate the heat generated by high-frequency signals. This heat management ensures that the communication systems maintain stable operation even under heavy data loads.

Signal Integrity: The low dielectric constant of AlN (around 8.9) makes it an ideal material for high-frequency electronics, such as those used in 5G communication. It ensures that signal transmission remains stable and uninterrupted, which is crucial for the high-speed, low-latency demands of 5G.

Long-Term Durability: AlN’s ability to withstand extreme temperatures and mechanical stress ensures that 5G infrastructure remains reliable in various environmental conditions, from hot deserts to cold, snowy regions. This makes it ideal for ensuring the continuous operation of 5G networks worldwide.

Future Trends: Innovations and Development of Aluminum Nitride (AlN) Ceramic PCBs

The future of Aluminum Nitride (AlN) ceramic PCBs is driven by innovations in manufacturing, such as Direct Plating Copper (DPC), Active Metal Brazing (AMB), and 3D printing. AlN is also expanding in green energy and IoT applications, while sustainable production methods reduce environmental impact. These trends position AlN as a key material for the next generation of high-performance electronics.

1. Latest Innovations in AlN Ceramic PCB Manufacturing

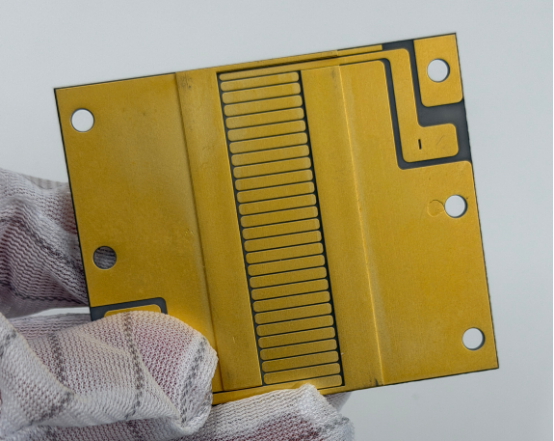

Manufacturing techniques for Aluminum Nitride (AlN) ceramic PCBs are rapidly evolving to improve efficiency and performance. Direct Plating Copper (DPC) and Active Metal Brazing (AMB) are two key innovations that are optimizing the production of AlN ceramic PCBs.

Direct Plating Copper (DPC): This method directly deposits copper onto AlN substrates, which results in better thermal conductivity and improved circuit precision. DPC reduces the production time by up to 40% and enhances heat transfer by 15%, making it ideal for high-performance electronic components.

Active Metal Brazing (AMB): AMB technology bonds AlN ceramics to metal layers (like copper) at lower temperatures, reducing thermal stress and improving the durability of the PCBs. This technique is gaining traction in applications like electric vehicles and aerospace where high thermal stability and long-lasting performance are crucial.

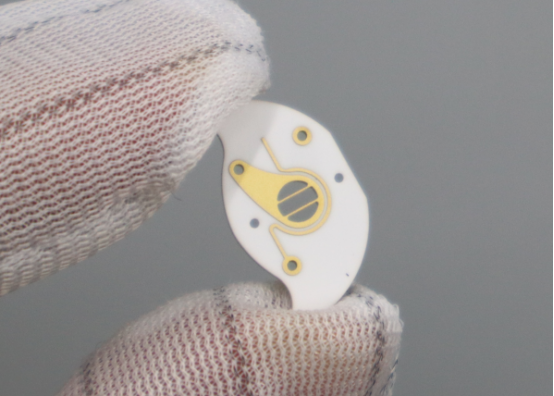

Another exciting trend is the adoption of 3D printing for AlN ceramics, allowing for more customizable and cost-effective PCB production. With 3D printing, manufacturers can create intricate, custom-shaped AlN PCBs that would be difficult or expensive to produce with traditional methods. This is particularly useful in industries like medical devices and automotive, where precise, tailored designs are needed.

2. Expansion of AlN Ceramic PCBs in Green Energy and IoT Applications

AlN ceramic PCBs are playing a vital role in the growing sectors of green energy and the Internet of Things (IoT). As the world shifts toward sustainable technologies, AlN's high heat conductivity and durability make it an ideal choice for these industries.

Green Energy: AlN PCBs are increasingly used in solar inverters and wind turbine controllers. These systems generate significant heat, and AlN helps manage that heat, improving system efficiency and lifespan. With the global push for renewable energy, the demand for AlN in green energy applications is expected to grow by 35% annually.

IoT Devices: AlN ceramics are also finding their place in IoT devices. These devices, which range from smart thermostats to industrial sensors, require small, efficient components with minimal power loss. AlN’s compact size and superior insulation make it perfect for these needs, offering improved performance and longevity.

As the market for green energy and IoT continues to expand, AlN ceramic PCBs are set to become a key component in driving the next generation of these technologies.

3. Environmental Benefits of AlN Ceramic PCB Production

The environmental impact of PCB production is a growing concern. New, more sustainable manufacturing techniques are being developed to reduce the carbon footprint and waste associated with AlN ceramic PCB production.

Recycling Innovations: New processes allow for the recycling of AlN ceramic scrap, which reduces material waste by 20%. This contributes to a more sustainable production cycle, helping to conserve resources and minimize environmental impact.

Low-Energy Sintering: The latest advancements in low-energy sintering techniques use 30% less energy than traditional methods. This reduces both the cost of production and the carbon emissions associated with the manufacturing process.

Water-Based Coatings: Traditional PCB coatings often involve toxic solvents. New water-based coating technologies are now being implemented to replace these harmful substances, making the production process safer for workers and more eco-friendly.

By integrating these sustainable practices, manufacturers are ensuring that AlN ceramic PCBs can contribute to the development of greener technologies, while minimizing their own environmental impact.

Conclusion

As industries demand more powerful and efficient technologies, the need for high-performance materials, such as Aluminum Nitride (AlN) ceramic PCBs, continues to rise. This growing demand has driven manufacturers to refine production processes, enhancing both the performance and cost-effectiveness of AlN ceramic PCBs. As a result, specialized solutions are now available to meet the diverse needs of various sectors.

Among these manufacturers is PCBMASTER, a company that draws on years of expertise and cutting-edge technologies to produce high-quality AlN ceramic substrates. By utilizing advanced techniques like Direct Plate Copper (DPC) and Active Metal Brazing (AMB), PCBMASTER ensures that their products meet the rigorous demands of industries such as automotive, medical, and energy, providing durable and reliable PCB solutions.

FAQ: Common Questions About Aluminum Nitride (AlN) Ceramic PCBs

1. What are the main applications of Aluminum Nitride (AlN) ceramic PCBs?

AlN ceramic PCBs are essential in industries that require high heat dissipation, electrical isolation, and durability. They are commonly used in semiconductors, automotive electronics, electric vehicle (EV) battery management systems, power electronics, LED lighting, and communication technologies. In semiconductors, AlN is used for heat sinks and power devices due to its superior thermal conductivity. In automotive and EV applications, it provides efficient thermal management for battery systems and power converters. In high-frequency communications like 5G and radar, AlN ensures signal integrity by reducing electrical interference.

2. Why is AlN ceramic more expensive than FR4?

The higher cost of AlN ceramic PCBs stems from both the raw material cost and the advanced manufacturing processes required. AlN ceramics are made from specialized materials and undergo a more complex production process, including sintering and copper bonding techniques, which are more time-consuming and resource-intensive than the simpler FR4 manufacturing process. However, the investment in AlN ceramic pays off in the long run, as it offers superior thermal management, greater reliability, and longer lifespan, reducing the frequency of system failures and maintenance costs in high-performance applications.

3. How does AlN ceramic maintain stability in environments with significant temperature fluctuations?

AlN ceramic PCBs are known for their low thermal expansion coefficient, which is about 4.5 ppm/°C, allowing them to resist thermal shock and sudden temperature changes without cracking or warping. This stability makes AlN ideal for high-temperature environments and applications where rapid heating and cooling cycles are common, such as in automotive engines, aerospace equipment, and power electronics. Additionally, its ability to sustain operation at temperatures up to 1200°C further enhances its reliability in extreme conditions.

4. Is AlN ceramic recyclable?

Yes, AlN ceramic can be recycled, although the technology for large-scale recycling is still developing. The recycling process involves extracting the aluminum and nitrogen components from the ceramic material, which can then be reused in other manufacturing processes. As the demand for eco-friendly manufacturing grows, the development of low-energy sintering techniques and recycling methods is expected to increase. This aligns with the broader industry trend toward green technologies and sustainable production methods, reducing environmental impact.

5. How does AlN perform in high-frequency applications?

AlN ceramics offer exceptional performance in high-frequency applications like 5G, radar systems, and communication devices. With a low dielectric constant of around 8.9, AlN ensures minimal signal loss and interference, making it ideal for high-speed data transmission and RF applications. Additionally, AlN’s electrical insulation properties and thermal conductivity help maintain signal stability while effectively dissipating heat generated by high-frequency signals. This combination of features makes AlN an excellent choice for 5G base stations, radar components, and other critical communication technologies.

Author Bio

Hi, I'm Carol, the Overseas Marketing Manager at PCBMASTER, where I focus on expanding international markets and researching PCB and PCBA solutions. Since 2020, I've been deeply involved in helping our company collaborate with global clients, addressing their technical and production needs in the PCB and PCBA sectors. Over these years, I've gained extensive experience and developed a deeper understanding of industry trends, challenges, and technological innovations.

Outside of work, I'm passionate about writing and enjoy sharing industry insights, market developments, and practical tips through my blog. I hope my posts can help you better understand the PCB and PCBA industries and maybe even offer some valuable takeaways. Of course, if you have any thoughts or questions, feel free to leave a comment below—I'd love to hear from you and discuss further!