PCBA Inspection Guide - A Comprehensive Guide to Circuit Board Component Inspection for Electronics Engineers

In modern electronic products, the quality of PCB Assembly (PCBA) directly determines device performance. Statistics show that 60% of circuit board failures originate from component quality issues. As an electronic engineer with 15 years of experience, I will share the most critical component inspection techniques in PCB assembly to help you build highly reliable electronic products.

1. Resistor Inspection: The "Blood Pressure Monitor" of PCB Assembly

On PCBA production lines, resistor inspection is akin to measuring the "blood pressure" of a circuit board. Three common methods are:

1.1 Wheatstone Bridge Method (Precision Medical-Grade)

• Principle: Accurately measures resistance by balancing a bridge circuit.

• Accuracy: Up to ±0.01%.

• Application: Medical equipment and other precision PCBA inspections.

1.2 Multimeter Rapid Screening Method

• Advantage: Completes single-point detection in 30 seconds.

• Tip: Always power off the circuit before measurement to avoid interference from parallel components.

1.3 Laser Matrix Inspection (Industry 4.0 Solution)

• Efficiency: Inspects 2000+ components per hour.

• Case Study: A automotive electronics factory achieved a 23% improvement in PCBA yield after adoption.

2. Capacitor Inspection: The "Cardiac Function Test" for PCBA

In high-speed PCB assembly lines, capacitor failures are a common cause of system crashes:

▶ Bridge Detection Method

• Accurately measures tiny capacitances down to pF levels.

• Key Note: Eliminate the influence of stray capacitance.

▶ Oscilloscope Dynamic Observation Method

• Advantage: Visualizes charge/discharge curves in real-time.

• Typical Use: Effectiveness testing of power filter capacitors.

3. Diode/Transistor Inspection: The "Nervous System Check" for PCB Assembly

3.1 Dual-Purpose Multimeter Test

• Forward Voltage Drop: 0.3–0.7V indicates normal operation.

• Reverse Resistance: Should exceed 500kΩ.

3.2 Dynamic Characteristic Tester

• Detects nanosecond-level response speeds.

• Essential Equipment: Curve tracer.

3.3 Temperature-Controlled Testing

• Range: -40℃ to 125℃.

• Importance: Mandatory for automotive electronics PCBA.

4. Transistor Inspection: The "Brain Check-Up" for Circuit Boards

[Static Parameter Testing]

• Key Metrics: Beta value (β), saturation voltage drop.

• Industry Standard: IEC 60747 series.

[Dynamic Characteristic Analysis]

• Frequency Response Test: 10Hz–100MHz.

• Case Study: PCB assembly inspection for 5G communication modules.

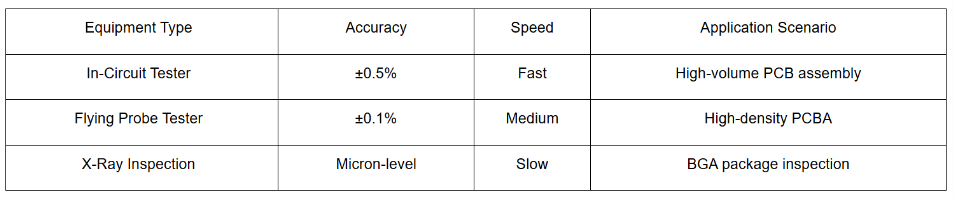

5. PCBA Inspection Equipment Selection Guide (2024 Update)

[Engineer’s Advice] During PCB assembly, adopt a "Three-Level Inspection" strategy:

1. Incoming Inspection (Full Check for Critical Components)

2. In-Process Inspection (Sampling at Each Stage)

3. Final Product Inspection (Functional + Environmental Testing)

Through systematic PCBA inspection, a smart home manufacturer reduced product return rates from 5% to 0.3%. Remember: High-quality PCB assembly is not accidental—it is the inevitable result of systematic inspection.