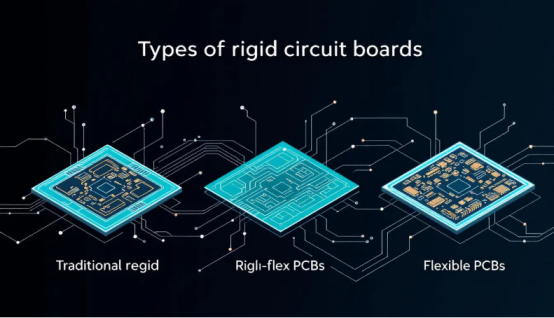

Choosing the Best PCB Type Introduce Rigid PCB, Flexible PCB, Rigid-Flex PCB

Introduction

Understanding the differences between rigid PCBs, flexible PCBs, and rigid-flex PCBs can significantly impact your electronic project’s success. In this article, we introduce Rigid PCB, Flexible PCB, and Rigid Flex PCB types, and we also introduce rigid pcb flexible pcb rigid flex pcb, explain their unique benefits, and discuss their common applications.

Key Takeaways

·Rigid PCBs provide durability and reliability for stable electronics, whereas flexible PCBs are designed for compact, dynamic applications due to their bendability and lightweight nature.

·Rigid-flex PCBs combine the advantages of both rigid and flexible types, allowing for complex designs that require mechanical strength and adaptability in demanding environments.

·The selection of the appropriate PCB type—rigid, flexible, or rigid-flex—should be based on factors like design complexity, environmental conditions, and budget while considering long-term performance and cost-effectiveness.

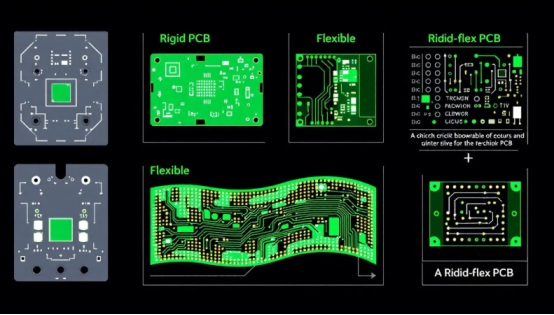

Understanding Rigid PCBs

Rigid PCBs are the stalwarts of the electronics world. These traditional rigid boards are constructed from materials that maintain their shape post-manufacturing, primarily fiberglass and copper laminates. This composition ensures that rigid PCBs provide a sturdy and durable structure, making them ideal for stable electronic devices such as televisions and desktop computers.

Rigid PCBs are incredibly reliable and robust, designed to endure temperature fluctuations and mechanical stress. Their longevity and consistent performance make them a cost-effective solution widely adopted in traditional rigid pcbs consumer electronics.

Key Features of Rigid PCBs

A key feature of rigid PCBs is their mechanical strength. Constructed from solid rigid materials like fiberglass, glass reinforced epoxy laminate, and copper laminates, these boards can withstand significant mechanical stress and temperature variations, making them ideal for stable and reliable devices with rigid layers.

Rigid PCBs are also cost-effective due to well-established manufacturing processes that lower production costs. They are a popular choice for various applications, from high-end consumer electronics to simple household gadgets.

Applications of Rigid PCBs

Rigid PCBs are ubiquitous in consumer electronics, particularly in complex electronic devices that demand stability and robustness. Televisions, desktop computers, and other stable electronic devices rely on the mechanical strength and durability of rigid PCBs and their solder joints, including the circuit board, to function effectively.

Their ability to maintain structural integrity under various conditions makes them indispensable in these applications.

Exploring Flexible PCBs

Flexible PCBs, also known as flex PCBs, are the next step in PCB technology. Made from pliable plastic substrates like flexible polyimide, these lightweight and bendable boards fit into compact and dynamic applications where rigid boards fall short, including flexible printed circuit boards designs.

Flexible PCBs are highly versatile, playing a crucial role in developing wearable technologies, smartphones, medical devices, and other compact gadgets. Their ability to adapt to device contours offers unmatched design freedom and performance, enabling engineers to create functional devices using flex pcb, printed circuit boards, and conductive adhesives.

Key Features of Flexible PCBs

Flexible PCBs excel in:

·Saving space in electronic designs

·Reducing weight, making them ideal for weight-sensitive applications

·Their lightweight nature

·Bendability, allowing use in tight spaces and complex shapes

·Offering design flexibility unmatched by rigid boards

Flexible PCBs are also remarkably durable, capable of enduring hundreds of thousands of repeated bending flex cycles without failure. This makes them perfect for applications involving constant movement and vibration, ensuring consistent performance over time with flexible substrates and flexible pcb.

Applications of Flexible PCBs

Flexible PCBs are transformative in wearable devices technologies, with their compactness and flexibility making them ideal for smartwatches and fitness trackers. In the automotive sector, they connect various electronic modules, reducing assembly time and weight compared to rigid boards.

Flexible PCBs are also crucial in the development of foldable phones, allowing for the innovative form factors seen in modern smartphones. Their adaptability is key to creating the next generation of portable electronics, pushing design boundaries.

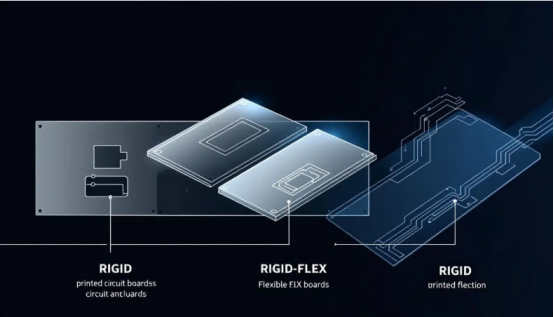

Introducing Rigid-Flex PCBs

Rigid-flex PCBs combine flexible circuits and rigid boards into a single hybrid solution, offering the structural integrity of rigid PCBs and the adaptability of flexible ones. This makes them ideal for complex and space-constrained designs, especially when using a rigid flex pcb.

Rigid-flex PCBs’ versatility allows for innovative design possibilities, saving space and increasing reliability. Integrating both rigid and flexible regions enables designers to create compact, high-performance devices that withstand mechanical stress and environmental variations, utilizing rigid flex technology and rigid and flex pcbs.

Key Features of Rigid-Flex PCBs

Rigid-flex PCBs offer several advantages:

·They can create complex board shapes and three-dimensional configurations, which is particularly useful in space-constrained applications.

·They eliminate fewer connectors in the design, reducing potential failure points.

·This elimination of connectors enhances overall device reliability.

Another advantage of rigid-flex PCBs is their resilience to mechanical stress and vibration resistance. They are designed to endure demanding environments, suitable for applications requiring both mechanical flexibility and structural support. Using flex materials with compatible thermal expansion coefficients ensures reliability during temperature changes.

Applications of Rigid-Flex PCBs

In the aerospace sector, rigid-flex PCBs are valued for their reliability and ability to function in demanding conditions. Their compact and lightweight design makes them ideal for aircraft and spacecraft, where space efficiency and weight are critical.

The automotive industry benefits from rigid-flex PCBs in advanced driver assistance and entertainment systems. These PCBs offer reliability and performance in environments with constant vibration and temperature changes.

Rigid-flex PCBs are also increasingly used in advanced medical devices, where their compactness and reliability are crucial.

Comparing Rigid, Flexible and Rigid-Flex PCBs

Choosing between rigid, flexible, and rigid-flex PCBs requires considering their construction and application potential:

·Rigid PCBs offer stability and cost-effectiveness for stable devices.

·Flexible PCBs provide adaptability for dynamic applications.

·Rigid-flex PCBs combine both strengths for compact and reliable designs.

Rigid-flex PCBs’ compact and lightweight designs highlight their versatility. Combining rigid and flexible regions allows these PCBs to adapt to intricate geometries and demanding environments, making them ideal for complex geometries and flexible layers in innovative applications.

Performance and Durability

Rigid-flex PCBs excel in performance and durability, enduring mechanical stress and thermal fluctuations. Flexible PCBs’ fewer interconnects enhance reliability in high-vibration environments, making them suitable for constant movement applications.

Thermal management is crucial for all PCB types. Rigid PCBs offer superior thermal management, while flexible PCBs benefit from fewer potential failure points. Proper grounding techniques and trace spacing are vital for maintaining signal integrity and reducing electromagnetic interference.

Cost Considerations

Rigid PCBs are often the most cost-effective due to established manufacturing methods and efficient mass production. However, the choice of PCB type should consider the project’s specific needs, including environmental conditions and manufacturing costs.

Evaluating material properties like dielectric constant and thermal conductivity is crucial for making an informed decision.

Design Flexibility

Flexible PCBs are known for their adaptability, including:

·Fitting into tight spaces and complex shapes

·Handling tighter bend radii

·Supporting three-dimensional routing These features make them ideal for compact and dynamic applications, including flex layers.

Rigid-flex designs enhance complex routing options and component densities, accommodating innovative and intricate designs. These PCBs enable miniaturized, highly functional devices, pushing the boundaries of designing rigid flex pcbs.

Selecting the Right PCB for Your Project

Selecting the right PCB type involves considering factors like size, environment, and budget. The complexity of the design and specific application needs should drive your choice between rigid, flexible, and rigid-flex PCBs. Consulting with PCB experts can reduce design errors, enhance production efficiency, and ensure project success.

Partnering with top PCB manufacturers offers benefits like advanced prototyping techniques and design optimization services. These services enhance manufacturability, leading to faster project completion and improved outcomes.

Design Tips for Optimal PCB Selection

Maintaining signal integrity is crucial when designing PCBs, especially for high-speed signals. Managing the bend radius in flexible PCBs preserves their integrity. Effective thermal management techniques ensure the reliability of rigid-flex designs, preventing overheating and heat dissipation while maintaining improved signal integrity.

Considering copper thickness, substrate material, and other design parameters helps create a PCB that meets your project’s needs. Focusing on these design tips optimizes PCB selection and ensures the success of your electronic devices.

Partnering with Experts for PCB Manufacturing--H2

Partnering with PCB manufacturing experts can enhance your project’s success in several ways:

·Reduce rework

·Speed up prototyping

·Lower production costs Their experience in designing and optimizing PCBs ensures an efficient process, leading to significant cost reductions and improved outcomes.

Engaging professionals helps navigate the complexities of PCB design and manufacturing. From next-gen medical tech to cutting-edge consumer gadgets, PCB experts’ involvement can make a significant difference in achieving your project’s goals.

Services Offered by Leading PCB Manufacturers

Leading PCB manufacturers offer various services to support your project. Rapid prototyping, with turn-times as fast as one day, allows for quick iterations and testing. Full turnkey boards can be assembled and delivered within five days, demonstrating these manufacturers’ efficiency in meeting tight deadlines during the assembly process and managing assembly costs.

Comprehensive design support using advanced PCB design software helps create custom layouts that meet your needs. Additionally, global logistics support ensures timely delivery across different regions, keeping your project on track with multi layered boards.

Summary

In conclusion, understanding the differences between rigid, flexible, and rigid-flex PCBs is crucial for making an informed decision for your next project. Each type offers unique benefits and applications, from the stability and cost-effectiveness of rigid PCBs to the adaptability of flexible PCBs and the hybrid versatility of rigid-flex designs. By considering factors such as performance, cost, and design flexibility, you can select the best PCB type to meet your project’s needs.

Partnering with experienced PCB manufacturers further enhances the success of your project, providing expert guidance, rapid prototyping, and comprehensive design support. As you embark on your next electronic innovation, remember that the right PCB choice can make all the difference.

FAQs

Q.What are the main differences between rigid, flexible, and rigid-flex PCBs?

A.The main differences between rigid, flexible, and rigid-flex PCBs lie in their construction and applications: rigid PCBs offer durability and stability for stationary devices; flexible PCBs provide lightweight and adaptable designs for dynamic uses; and rigid-flex PCBs merge both properties, catering to complex, space-constrained applications. Each type serves distinct needs based on structural requirements and design flexibility.

Q.What factors should I consider when choosing a PCB type for my project?

A.When choosing a PCB type, it is essential to consider the size and environment of your application, your budget, the complexity of the design, and specific project requirements. Engaging with PCB experts can further mitigate design errors and improve production efficiency.

Q.How do rigid-flex PCBs improve design flexibility and reliability?

A.Rigid-flex PCBs significantly enhance design flexibility and reliability by integrating the advantages of both rigid and flexible circuits, enabling complex shapes and configurations. Their construction eliminates connectors, thereby minimizing potential failure points and ensuring durability under mechanical stress and temperature fluctuations.

Q.What are some common applications of flexible PCBs?

A.Flexible PCBs are commonly utilized in wearable technologies, automotive systems, and foldable phones due to their lightweight and adaptable properties. This versatility allows for innovative designs and enhanced performance in compact applications.

Q.Why is partnering with PCB manufacturing experts beneficial?

A.Partnering with PCB manufacturing experts is beneficial as it minimizes rework, accelerates prototyping, and reduces production costs. Their expertise in design optimization and efficient production processes ensures superior project outcomes.

Author: Jack Wang