What is PCBA? A Complete Guide for Beginners in Electronics

In the world of electronics, tiny boards hidden inside our devices hold immense power. These unassuming assemblies connect circuits, control signals, and bring gadgets to life—yet most people have never stopped to wonder how they actually work. Understanding PCBA opens a window into the intricate dance of components and connections that make modern technology function seamlessly. From everyday smartphones to advanced industrial machines, this hidden layer is where innovation truly takes shape.

Introduction to PCBA

Definition of PCBA

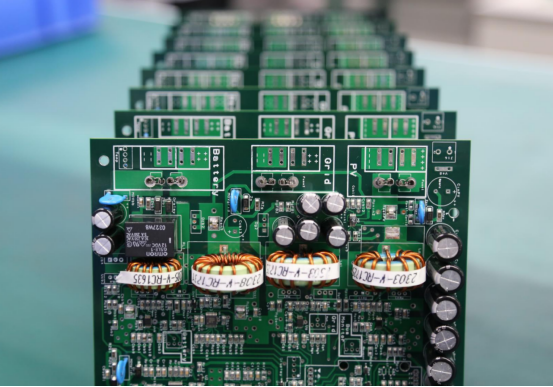

A PCBA, or Printed Circuit Board Assembly, is a circuit board that has been fully equipped with electronic components, soldered, and tested for functionality. Unlike a bare PCB (Printed Circuit Board), which is simply the physical board with copper traces and pads, a PCBA is a complete assembly ready to perform its intended function.

In simple terms, think of a PCB as an empty stage, with copper pathways forming the structure, while the PCBA is the stage with actors, lights, and props installed, ready for a performance. The assembly process involves placing components such as resistors, capacitors, integrated circuits, and connectors onto the PCB and securing them with solder. This transformation from bare board to functional assembly is what enables the device to operate.

Key differences:

PCB (bare board): Only the substrate and conductive traces; cannot operate on its own.

PCBA: Fully assembled with components; can perform electronic functions.

Importance of PCBA in Electronics

PCBAs are essential building blocks in modern electronic devices. They not only connect components but also ensure signals and power flow efficiently. Without properly assembled PCBAs, even the most advanced chips and components cannot function correctly.

Examples of devices relying on PCBA include:

Smartphones: Each smartphone contains multiple PCBAs handling everything from processing to wireless communication.

Computers and laptops: Motherboards, graphic cards, and peripheral controllers are all PCBAs.

IoT devices: Sensors, smart home devices, and wearable gadgets rely on compact, high-performance PCBAs.

The quality of a PCBA directly affects device performance and reliability. Poor assembly can lead to issues like signal loss, overheating, or component failure. Conversely, a well-designed and precisely assembled PCBA ensures that the device operates smoothly, efficiently, and safely over its expected lifespan.

Step-by-step, the impact of PCBA on performance can be summarized as:

1. Signal integrity: Correct placement and soldering prevent data errors.

2. Power distribution: Efficient routing ensures stable operation.

3. Thermal management: Proper design and assembly prevent overheating.

In short, PCBAs are the backbone of electronic functionality, transforming a simple board into a powerful and reliable electronic system.

Components of a PCBA

Passive Components

Passive components are electronic parts that do not generate power but control voltage, current, and signal flow. The most common passive components include resistors, capacitors, and inductors.

Resistors: Limit current and divide voltage in a circuit. For example, they protect LEDs from burning out by controlling current flow.

Capacitors: Store and release electrical energy, filter signals, and stabilize voltage. In smartphones, capacitors help smooth out power supply fluctuations.

Inductors: Store energy in a magnetic field and are used for filtering and energy storage in power supplies.

Passive components are often small and inexpensive but are critical for circuit stability, filtering, and energy management.

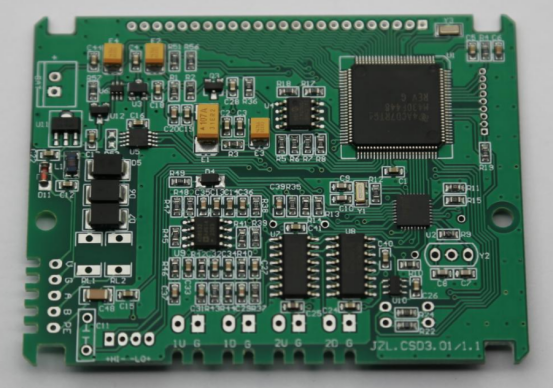

Active Components

Active components are parts that can control current or amplify signals, playing a more dynamic role in circuits. Common active components include integrated circuits (ICs), transistors, and diodes.

Integrated Circuits (ICs): Pack multiple electronic functions into a single chip. Examples include microcontrollers, memory chips, and voltage regulators.

Transistors: Act as switches or amplifiers, controlling current flow in circuits. For instance, they amplify audio signals in speakers.

Diodes: Allow current to flow in one direction and block it in the opposite. LEDs (light-emitting diodes) are a visible example used for indicators.

Active components control the logic, signal processing, and power distribution in a PCBA, making them essential for functional electronics.

Connectors and Interfacing Parts

Connectors and interfaces allow PCBAs to communicate with other devices or modules. These components ensure signals, data, and power are transferred efficiently. Common types include USB ports, HDMI connectors, headers, and sockets.

USB connectors: Enable data transfer and charging in smartphones, laptops, and peripherals.

HDMI ports: Transmit high-definition video and audio in monitors and TVs.

Headers and sockets: Facilitate modular connections in microcontroller boards or development kits.

These parts are critical for device interoperability, making the PCBA functional within larger electronic systems.

Solder and Substrates

The solder and substrate materials form the physical and electrical foundation of a PCBA.

Solder: Joins components to the PCB. Options include lead solder and lead-free solder. Lead-free solder is more environmentally friendly and commonly used in consumer electronics.

PCB substrates: Provide mechanical support and electrical insulation. Common materials include:

FR4: Standard fiberglass-reinforced epoxy, widely used for general electronics.

Rogers materials: High-frequency laminates used in RF and microwave circuits.

Flexible substrates: Used in foldable devices or wearable electronics where bending is required.

Choosing the right solder and substrate affects reliability, signal integrity, and thermal performance.

PCBA Manufacturing Process

PCB Fabrication vs. Assembly

The first step in creating a functional electronic board is PCB fabrication, which produces the bare printed circuit board. This involves:

1. Substrate preparation: Cutting and layering materials like FR4 or Rogers laminates.

2. Circuit patterning: Etching copper traces to form electrical pathways.

3. Drilling and plating: Creating vias and holes for component connections.

4. Surface finishing: Applying protective coatings like HASL or ENIG.

Once the bare PCB is ready, assembly transforms it into a PCBA by adding components and making it functional. This includes:

Placing passive and active components.

Soldering them onto the board using SMT or THT techniques.

Performing testing and inspection to ensure reliability.

In short, fabrication provides the structural and electrical framework, while assembly adds the components that make the board operational.

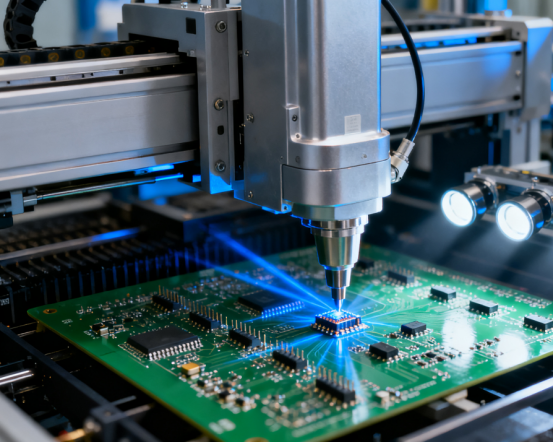

Surface Mount Technology (SMT)

SMT is a widely used method for mounting components directly onto the surface of the PCB. The process includes:

1. Solder paste application: A stencil is used to apply solder paste to the pads where components will sit.

2. Pick-and-place: Automated machines accurately place tiny components, such as resistors, capacitors, and ICs, onto the solder-pasted pads.

3. Reflow soldering: The board passes through a controlled oven where the solder paste melts and solidifies, securing the components.

Common SMT components:

0402 and 0603 resistors and capacitors

Small outline ICs (SOICs)

LEDs and surface-mount diodes

SMT allows for high-density placement, faster assembly, and automated production, making it ideal for modern electronics like smartphones and laptops.

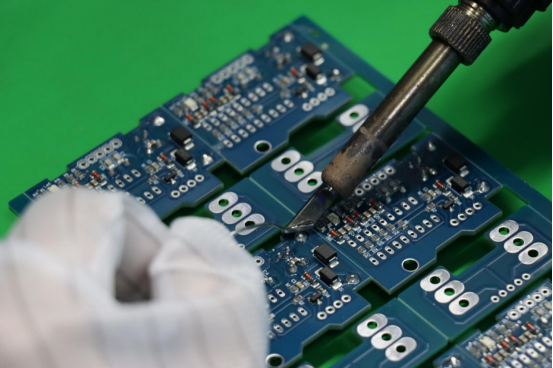

Through-Hole Technology (THT)

THT involves inserting component leads through pre-drilled holes in the PCB and soldering them, usually with wave soldering. The process steps include:

1. Component insertion: Manual or automated placement of through-hole components like connectors, large capacitors, or transformers.

2. Wave soldering: The board passes over molten solder, which secures the component leads to the pads.

Comparison with SMT:

Durability: THT connections are generally stronger and better for mechanical stress.

Cost: THT is more labor-intensive and slower, making it more expensive for large-scale production.

Application: Often used for connectors, high-power devices, or rugged industrial electronics.

Inspection and Quality Control

Ensuring a PCBA functions correctly requires rigorous inspection and testing. Common techniques include:

Automated Optical Inspection (AOI): Cameras scan the board to detect missing, misaligned, or incorrectly soldered components.

X-ray inspection: Reveals hidden solder joints, such as under Ball Grid Array (BGA) ICs.

Functional testing: Powers the board to verify performance and ensure it meets specifications.

Detecting defects before final assembly is critical to avoid failures in the field, reduce repair costs, and maintain product reliability.

PCBA Design Considerations

Layout and Footprint Design

The layout of components on a PCBA directly affects its performance, reliability, and manufacturability. Best practices include:

Logical grouping: Place components according to their function, such as power, signal processing, or input/output sections.

Minimizing trace lengths: Shorter connections reduce resistance, signal delay, and noise.

Avoiding signal interference: Sensitive analog circuits should be separated from high-speed digital traces.

Example: In a microcontroller board, placing analog sensors away from the high-frequency processor lines prevents signal distortion and ensures accurate readings.

Footprint design—the shape and size of pads where components mount—is equally important. Correct footprints prevent solder bridging, misalignment, and rework, supporting smoother assembly.

Signal Integrity and Thermal Management

High-speed circuits are particularly sensitive to signal integrity and heat. Proper design ensures that signals remain clear and components operate within safe temperature ranges.

Key considerations:

Thermal vias: Small plated holes that connect heat-generating components to internal or bottom copper layers, helping dissipate heat.

Heat sinks and thermal pads: Metal surfaces or pads attached to ICs that transfer heat away from critical areas.

Step-by-step example:

1. Identify components generating significant heat, such as voltage regulators or CPUs.

2. Place thermal vias beneath the component pads to channel heat to inner or backside layers.

3. Attach heat sinks or copper planes to further distribute heat and prevent hotspots.

This careful planning prevents overheating, reduces signal distortion, and enhances PCBA reliability in demanding applications.

Design for Manufacturability (DFM)

DFM ensures that a PCBA can be produced efficiently, cost-effectively, and with high yield. Design decisions influence assembly speed, defect rates, and overall production costs.

Considerations include:

Component spacing: Adequate gaps prevent solder bridges and allow pick-and-place machines to operate accurately.

Standardized footprints: Using industry-standard component sizes simplifies sourcing and assembly.

Minimizing complex vias and layers: Excessively intricate designs increase fabrication costs and risk of defects.

Common DFM mistakes:

Placing components too close to the board edge, making assembly or testing difficult.

Using non-standard or obsolete footprints that are hard to source.

Overcomplicating routing, causing excessive layers and higher cost.

Following DFM principles balances performance with manufacturability, ensuring a PCBA is both functional and economically viable.

PCBA Testing and Reliability

Functional Testing

Functional testing is the process of verifying that a PCBA performs its intended tasks before it is installed in a device. This ensures that all components, traces, and connections work correctly.

How it works:

Connect the PCBA to a power source and any necessary peripherals.

Run diagnostic software or test programs to check signal flow and component operation.

Measure voltage, current, and output signals to confirm they meet specifications.

Example: For a microcontroller board, functional testing may include powering the board, checking LED indicators, running a sample program, and confirming that input/output pins respond correctly.

Functional testing is crucial because it catches design or assembly errors early, reducing repair costs and product failures.

Environmental and Stress Testing

PCBAs must endure a range of real-world conditions, including heat, vibration, and humidity. Environmental and stress testing evaluates how well a PCBA performs under such conditions.

Common tests:

Temperature cycling: Exposing the PCBA to repeated hot and cold temperatures to check thermal resilience.

Vibration testing: Simulating mechanical stress from shipping or device use.

Humidity testing: Ensuring the PCBA can operate in high-moisture environments without corrosion or short circuits.

Why it matters: These tests ensure long-term reliability, prevent field failures, and verify that the assembly meets industry standards for durability.

Common PCBA Defects and Troubleshooting

Even with careful assembly, PCBAs can have defects that impact performance. The most common include:

Cold solder joints: Poorly soldered connections causing intermittent contact.

Solder bridges: Unintended solder connections between pads, causing short circuits.

Component misplacement: Parts installed in the wrong orientation or location.

Step-by-step troubleshooting guide:

1. Visual inspection: Look for visible solder defects or misplaced components.

2. Electrical testing: Use a multimeter to check continuity and detect shorts or open circuits.

3. Rework: Resolder cold joints, remove solder bridges with a solder wick, and reposition misaligned components.

4. Functional retest: After fixing defects, repeat functional tests to ensure proper operation.

Effective testing and troubleshooting improve PCBA reliability, reduce failure rates, and ensure that the board can perform under normal and extreme conditions.

Applications of PCBA in Everyday Electronics

Consumer Electronics

PCBAs are the heart of modern consumer electronics, providing the electrical connections and processing capabilities that power our daily devices.

Smartphones: Multiple PCBAs manage processing, communication, and battery management, enabling features like touchscreens, cameras, and wireless connectivity.

Laptops: Motherboards, graphic cards, and peripheral controllers are all PCBAs that handle computing, memory, and input/output functions.

Wearable devices: Smartwatches and fitness trackers rely on compact PCBAs for sensors, displays, and wireless communication.

In these devices, PCBAs ensure compact design, high performance, and energy efficiency, making electronics more portable and functional.

Industrial Electronics

In industrial applications, PCBAs provide robust and reliable operation in demanding environments.

Control systems: PCBAs manage machinery, production lines, and automated processes.

Sensors: Environmental, motion, and temperature sensors use PCBAs to process signals and transmit data.

Robotics: PCBAs control actuators, motors, and feedback systems to enable precise robotic movements.

Industrial PCBAs are often designed with higher durability, heat tolerance, and resistance to vibration, compared to consumer electronics, to ensure long-term reliability in challenging conditions.

Emerging Technologies

PCBAs are also driving innovation in cutting-edge technologies that shape the future.

IoT devices: Smart home devices, connected appliances, and wearable health monitors rely on PCBAs for wireless connectivity and low-power operation.

Electric vehicles (EVs): PCBAs control battery management systems, inverters, charging modules, and infotainment systems.

Medical electronics: PCBAs are critical in devices like portable diagnostic equipment, patient monitors, and implantable devices, where reliability and precision are essential.

In these applications, PCBAs enable miniaturization, energy efficiency, and high functionality, supporting technological advancement and new user experiences.

Future Trends in PCBA

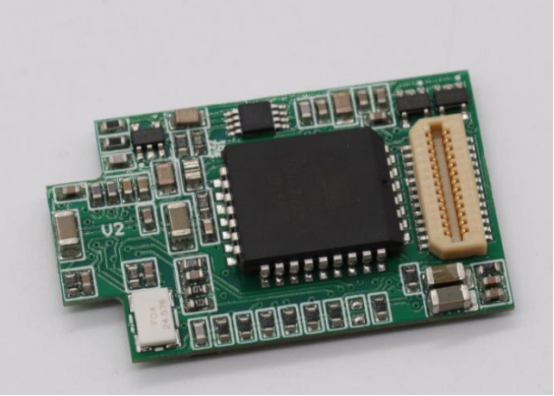

Miniaturization and High-Density PCBA

One of the most significant trends in PCBA design is miniaturization, which involves using smaller components and increasing the number of layers on a PCB.

Smaller components: Tiny resistors, capacitors, and ICs allow more functionality to fit in a smaller footprint.

High-layer boards: Advanced boards can have 12, 18, or even more layers, supporting complex signal routing for high-speed applications.

Impact: Miniaturization enables slimmer smartphones, compact medical devices, and lightweight wearable electronics without compromising performance.

This trend emphasizes the need for precise manufacturing techniques and careful thermal management, as densely packed boards generate more heat and require accurate assembly.

Advanced Materials and Processes

To meet the demands of high-speed, high-frequency, and flexible applications, new materials and manufacturing processes are emerging in PCBA production.

Flexible PCBs: Made from bendable substrates, they are used in foldable smartphones, wearable devices, and automotive electronics where space and flexibility are critical.

High-frequency laminates: Materials like Rogers or PTFE enable reliable signal transmission at GHz frequencies, essential for RF modules, 5G devices, and high-speed networking equipment.

Impact: Advanced materials allow PCBAs to perform reliably under mechanical stress, high frequencies, and thermal challenges.

These innovations support smarter, faster, and more compact electronics, expanding the possibilities for modern devices.

Automation and AI in Assembly

Automation and artificial intelligence are revolutionizing PCBA manufacturing, improving accuracy, speed, and quality control.

AI in pick-and-place machines: Enhances component placement accuracy, reducing misalignment and errors in high-density boards.

Automated inspection: AI-driven optical and X-ray systems detect defects faster and more reliably than manual inspection.

Predictive quality control: Machine learning analyzes production data to predict and prevent assembly defects before they occur.

By integrating automation and AI, manufacturers achieve higher yields, lower costs, and consistent quality, enabling the production of sophisticated PCBAs at scale.

Conclusion

PCBAs play a critical role in modern electronics by turning bare circuit boards into fully functional systems. They provide the connections and control necessary for devices such as smartphones, laptops, IoT gadgets, and industrial machinery to operate efficiently. Through precise manufacturing techniques like SMT and THT, combined with thorough testing for functionality, environmental tolerance, and reliability, PCBAs ensure consistent performance, energy efficiency, and long-term durability. The quality of a PCBA directly impacts how well a device performs in real-world conditions.

For beginners looking to explore PCBA design and assembly, starting with simple microcontroller boards or DIY kits is a practical approach. Learning the functions of passive and active components, understanding connectors, and practicing proper soldering techniques build a solid foundation. Hands-on experimentation with breadboards, along with studying layout, signal integrity, thermal management, and design-for-manufacturability principles, helps develop both skills and confidence in creating reliable assemblies.

If you have additional questions, PCBMASTER is available to help. As an experienced PCB and PCBA supplier, we provide high-quality products and professional guidance, supporting your projects from design and assembly to testing and troubleshooting.

FAQs

What is the difference between PCB and PCBA?

A PCB (Printed Circuit Board) is the bare board that provides the physical structure and conductive pathways for electrical signals. It consists of a substrate, copper traces, and pads but cannot perform any electronic function on its own. A PCBA (Printed Circuit Board Assembly), on the other hand, is a PCB that has been fully populated with components such as resistors, capacitors, ICs, and connectors, and soldered into place. Once assembled, a PCBA can perform its intended electronic functions, whereas a bare PCB cannot.

Why is quality control important in PCBA manufacturing?

Quality control ensures that each PCBA meets the required performance, reliability, and safety standards. Even minor assembly defects, like poor solder joints or misaligned components, can cause device failures, signal errors, or overheating. Rigorous inspection methods, such as automated optical inspection (AOI), X-ray inspection, and functional testing, help detect defects early. By maintaining strict quality control, manufacturers reduce failure rates, improve product lifespan, and enhance customer satisfaction.

Can I assemble a PCBA at home as a beginner?

Yes, beginners can assemble simple PCBAs at home, especially using DIY kits or microcontroller boards. It is recommended to start with basic projects that include clearly labeled components, such as Arduino or Raspberry Pi kits. Basic soldering skills, safety precautions, and understanding component functions are essential. However, complex or high-density PCBAs with tiny surface-mount components require professional equipment and expertise, so beginners should avoid advanced boards until they gain experience.

What are the most common PCBA defects?

Common PCBA defects include:

Cold solder joints: Solder that does not properly bond to the component or pad, causing intermittent connections.

Solder bridges: Excess solder connecting adjacent pads unintentionally, leading to short circuits.

Component misplacement or wrong orientation: Parts installed incorrectly, which can prevent the circuit from working or even damage components.

Missing components: Omissions during assembly that disrupt the circuit’s function.

Identifying and correcting these defects is crucial for ensuring device performance and reliability.

How does PCBA impact device performance?

The PCBA determines how efficiently a device can transmit signals, manage power, and handle thermal loads. Well-designed and properly assembled PCBAs ensure accurate signal flow, stable voltage levels, and effective heat dissipation. Poorly designed or defective PCBAs can lead to slow performance, unexpected shutdowns, overheating, and reduced lifespan. Essentially, the quality and design of a PCBA directly influence the reliability, functionality, and user experience of the finished electronic device.