What Is Contract PCB Assembly? Benefits, Process, and Key Considerations

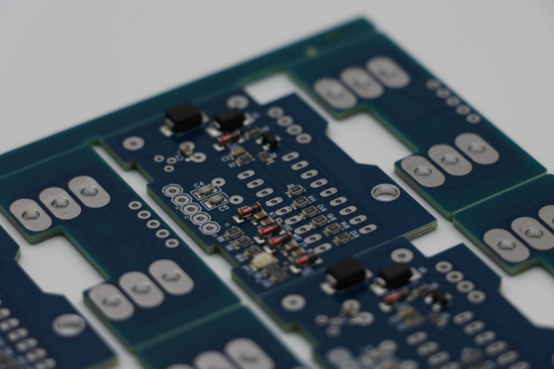

Bringing an electronic product from idea to reality can be complicated. There are tiny components to place, precise soldering to do, and every board must work perfectly. This is where Contract PCB Assembly makes a difference. Professional manufacturers take care of assembling your PCBs, handling every detail from soldering to testing, so your product works reliably from the start.

Using contract assembly saves time, lowers costs, and ensures high-quality results. It allows engineers and designers to focus on innovation and product design, instead of spending hours on tedious assembly work.

In this article, we will explore what contract PCB assembly is, why it is valuable, the detailed step-by-step process, and tips for choosing the right supplier. By the end, you’ll see why many electronics companies rely on professional PCB assembly to bring their products to market quickly and successfully.

What Is Contract PCB Assembly

1. Definition and Purpose

Contract PCB Assembly is a professional service where a company provides its PCB design files and a detailed list of required components (BOM), and a specialized manufacturer handles the entire assembly process. This means the business does not need to manage soldering, testing, or quality checks themselves, saving time and reducing the risk of errors or defects. By outsourcing assembly, companies can focus on product design, research, and innovation, leaving the intricate production details to experienced professionals.

2. Partial Turnkey Service

In the Partial Turnkey model, the customer supplies some or most of the components, while the manufacturer handles the placement, soldering, and functional testing of the PCB. This approach is particularly useful for companies that already have proprietary or specialized components but want expert assembly and testing to ensure reliability. Partial turnkey services can also speed up prototype development and reduce the chance of mistakes during soldering.

3. Full Turnkey Service

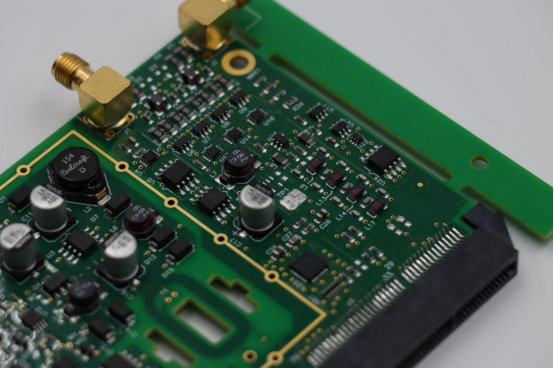

The Full Turnkey service covers the entire process from PCB fabrication to finished assembly. The manufacturer produces the PCB, purchases all necessary components, assembles the board using automated or manual processes, and performs thorough testing such as AOI, X-ray, and functional checks. This model is ideal for companies that want a complete, ready-to-use product without having to manage component sourcing, assembly scheduling, or quality control. It is also well-suited for both small-scale prototypes and large-volume production runs.

4. Who Can Benefit from Contract PCB Assembly

Contract PCB assembly is particularly valuable for:

l Electronics design companies developing new products.

l Startups that need professional assembly without investing in equipment.

l Research and development teams working on prototypes.

l Businesses requiring small or large-scale production runs.

By leveraging contract PCB assembly, companies can reduce overhead costs, accelerate time-to-market, and improve product reliability, while relying on expertise and specialized equipment provided by professional manufacturers.

Key Advantages of Contract PCB Assembly

1. Cost Savings

One of the main advantages of contract PCB assembly is reducing costs. Setting up a PCB production line is expensive—it requires machines, soldering tools, inspection equipment, and trained staff. For small businesses or startups, these investments are often unrealistic. By outsourcing assembly, companies avoid these upfront expenses and only pay for the service when needed. This approach frees up funds that can be used for product design, marketing, or research, allowing the business to grow without the financial burden of running a factory.

2. Faster Development Cycles

Contract PCB assembly enables companies to bring products to market much faster. Professional manufacturers can produce prototypes in a matter of days, even for small or medium production runs. This speed is particularly valuable for startups and tech companies, which need to test ideas quickly or respond to market trends. Rapid assembly also makes it easier to implement design revisions without delaying the overall project, allowing businesses to iterate efficiently and shorten the time-to-market.

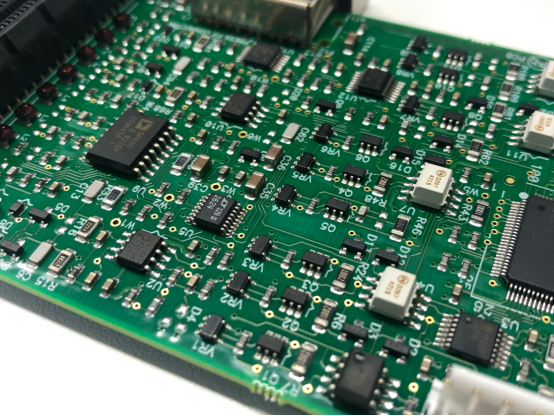

3. High-Quality Production

Outsourcing PCB assembly ensures consistent, high-quality production. Professional manufacturers use advanced technologies such as automated surface-mount technology (SMT), automated optical inspection (AOI), X-ray testing, and functional tests. These processes help detect errors early, including misplaced components, solder bridges, or cold joints, significantly reducing the risk of defective products. Companies can therefore deliver reliable electronics that work correctly the first time, which enhances customer satisfaction and strengthens brand reputation.

4. Flexibility and Adaptability

Contract PCB assembly provides high flexibility. It supports small-batch production, rapid prototyping, and iterative design testing, which is ideal for companies experimenting with new products or adjusting designs frequently. Businesses can increase or decrease production volumes easily based on demand or testing results, without the limitations of managing a full-scale factory. This flexibility allows companies to adapt quickly to changes in the market or product requirements.

5. Optimized Supply Chain Management

Another key advantage is supply chain optimization. Many contract manufacturers offer component sourcing, inventory management, and logistics coordination. This reduces risks such as component shortages, delayed shipments, or incorrect orders, which can disrupt production. By integrating procurement and assembly under one service, companies can focus on product innovation and business strategy, while the manufacturer ensures timely delivery and smooth production flow. Efficient supply chain management also helps reduce production delays and enhances overall operational efficiency.

Step-by-Step Process of Contract PCB Assembly

1. Submission of Design Files

The first step in contract PCB assembly is for the customer to submit all necessary design documents to the manufacturer. These typically include Gerber files (which describe the PCB layout), a Bill of Materials (BOM) listing all required components with specifications, and assembly drawings showing where each part goes.

Providing clear, complete, and accurate files is critical. Missing information or errors in the design files can lead to assembly mistakes, delays, or additional costs. A well-prepared submission ensures the manufacturer fully understands the board’s layout, components, and technical requirements.

2. Engineering Review (DFM Check)

Once the files are submitted, engineers perform a Design for Manufacturability (DFM) check. This review evaluates whether the PCB design can be efficiently and reliably assembled.

Engineers check factors like component placement, spacing between parts, soldering accessibility, and potential electrical or mechanical issues. Identifying and resolving these problems before production begins reduces the chance of errors, improves yield, and saves both time and money.

3. Material Preparation

Next, the required electronic components are prepared. In a Partial Turnkey service, the customer provides some or all parts, whereas in a Full Turnkey service, the manufacturer sources all components.

Proper handling and inventory management are crucial here. Components must be accurately labeled, verified, and stored in suitable conditions to prevent damage or loss. Errors at this stage, such as missing or wrong parts, can delay production or cause assembly failures.

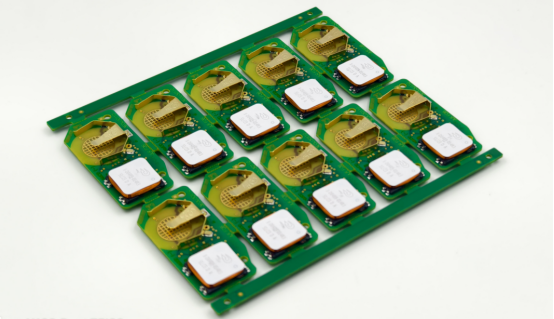

4. PCB Fabrication

If the service includes full fabrication, the manufacturer produces the PCB according to design specifications. This involves creating copper traces, drill holes, solder pads, and surface finishes.

High-quality fabrication is essential because it ensures the PCB will function reliably once assembled. Any defects in the board, such as misaligned traces or uneven copper thickness, could lead to electrical failure or assembly problems later.

5. SMT Assembly and Soldering

During assembly, surface-mount (SMT) components are placed on the PCB using automated pick-and-place machines, followed by reflow soldering to secure them.

For through-hole components, manufacturers may use wave soldering or hand soldering, depending on the design and batch size.

Precision at this stage is vital to avoid defects such as misaligned components, cold solder joints, or bridging, which could compromise the PCB’s performance.

6. Inspection and Functional Testing

After assembly, the PCBs undergo rigorous inspection and testing.

l Automated Optical Inspection (AOI) checks for visible soldering issues and component placement.

l X-ray inspection detects hidden soldering defects, especially in dense or multilayer boards.

l In-Circuit Testing (ICT) and functional testing verify that each component performs as intended.

This ensures that only fully functional, high-quality PCBs are shipped to the customer, reducing the risk of returns or failures in the field.

7. Packaging and Delivery

Finally, the assembled PCBs are carefully packaged to protect them from mechanical shock, moisture, or electrostatic discharge during shipping.

Proper packaging materials, such as antistatic bags, foam inserts, or protective trays, are used to ensure that fragile components remain intact. The manufacturer then ships the boards to the customer, ensuring they arrive safe, fully functional, and ready for use.

Key Considerations When Choosing a Contract PCB Assembly Supplier

1. Delivery Capability

One of the most crucial factors when selecting a contract PCB assembly supplier is their ability to deliver on time. This means the supplier must have sufficient production capacity to handle both small prototype batches and larger production runs without delays.

Lead times, or the time it takes from order placement to delivery, should be reliable and consistent, and the supplier should be responsive to urgent or last-minute requests. Timely delivery ensures that your product development schedule is maintained, avoiding costly delays in testing, marketing, or product launch. Checking past performance, client reviews, or case studies can provide insight into the supplier’s real-world delivery reliability.

2. Quality Management System

Quality is the backbone of any successful PCB assembly project. Look for suppliers who hold recognized certifications, such as ISO 9001, UL, and compliance with IPC standards. These certifications indicate that the manufacturer follows strict quality control processes at every stage, from incoming material inspection to final testing.

A high-quality assembly process reduces the likelihood of defective boards, misaligned components, or soldering issues, which can otherwise result in product failures. Consistently reliable PCBs also improve end-product performance, customer satisfaction, and brand reputation.

3. Engineering Support

A strong contract PCB assembly supplier should offer engineering support beyond simple assembly. This includes Design for Manufacturability (DFM) analysis, advice on component placement, and guidance on layout adjustments to optimize the PCB for production efficiency, cost, and reliability.

Collaboration with your design team can prevent assembly errors, reduce rework, and enhance overall board performance. Suppliers that actively engage in engineering support can also suggest alternative components or assembly techniques that save time and cost while maintaining high quality.

4. Pricing Transparency

Clear and fair pricing is essential for budgeting and avoiding surprises. A good supplier provides detailed quotes that break down all costs, including assembly, testing, component sourcing (if applicable), and shipping.

Transparent pricing allows you to compare multiple suppliers accurately, plan your project budget, and avoid hidden fees or unexpected charges. It also demonstrates the supplier’s honesty and professionalism, which is important for long-term business relationships.

5. After-Sales Service

Finally, consider the supplier’s after-sales support. Even with careful planning, issues can arise after delivery, such as defective boards, missing components, or technical questions.

A reliable supplier offers responsive customer service, troubleshooting assistance, and effective problem resolution. Strong after-sales support ensures that any issues are handled quickly, minimizing downtime and keeping your project on track. Knowing that help is available gives you peace of mind throughout the production process.

Conclusion

Contract PCB Assembly offers significant value and advantages for businesses of all sizes. By outsourcing PCB assembly, companies can save costs, reduce production time, ensure high-quality output, and gain flexibility in prototyping and small-to-medium production runs.

Choosing the right contract manufacturer is crucial. Businesses should consider factors such as delivery capability, quality management, engineering support, pricing transparency, and after-sales service. A professional supplier like PCB MASTER specializes in contract PCB assembly, providing reliable service and expertise to help you bring your electronic products to market smoothly and efficiently.

Partnering with the right assembly provider not only enhances product quality but also allows companies to focus on innovation and growth, making contract PCB assembly a smart choice for modern electronics development.

FAQs

1. Can small startups benefit from contract PCB assembly even if they only need a few prototypes?

Yes, small startups can greatly benefit. Even for a few prototypes, contract PCB assembly provides precision, reliability, and professional testing that is hard to achieve in-house. It ensures your prototype works correctly, reducing errors during product development. This allows small teams to focus on design and innovation instead of worrying about assembly challenges. Many suppliers also support small batch runs, making it cost-effective for early-stage projects.

2. How does contract PCB assembly help when design changes are needed?

Contract PCB assembly is very flexible. If your design changes, professional manufacturers can quickly adjust the assembly process, update component placement, or swap parts. Their engineering teams can suggest improvements to make the design easier to assemble or more reliable. This flexibility reduces delays and allows rapid iteration, which is especially useful for R&D projects or products under tight development timelines.

3. Are there risks involved in using a contract PCB assembly service, and how can they be minimized?

Yes, risks include delays, quality issues, or incorrect component use. These can be minimized by choosing a reputable supplier with proper certifications, clear communication, and proven experience. Providing accurate design files and BOMs reduces mistakes. Additionally, requesting sample prototypes and thorough testing before full production ensures that potential problems are identified early. Strong collaboration with the supplier helps maintain high-quality and timely delivery.