What Is a PCBA Number? Complete Guide to Identification and Traceability

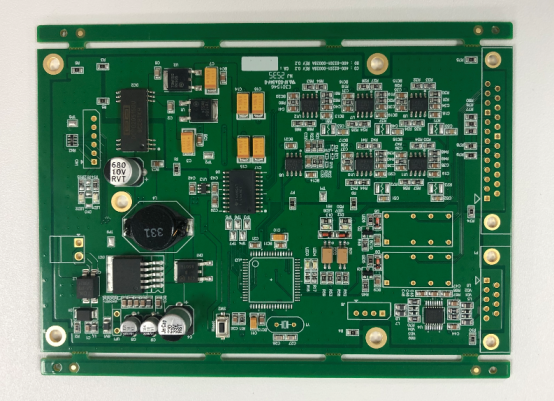

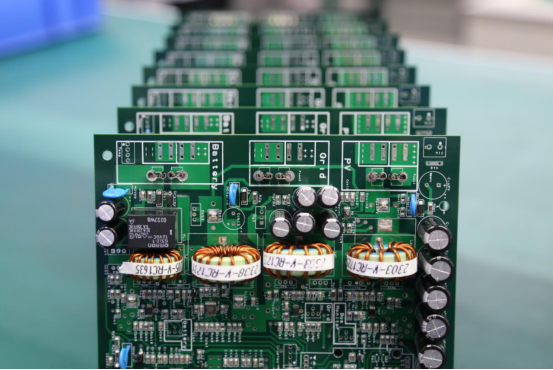

In the world of electronics manufacturing, every assembled circuit board carries a unique identity — a PCBA number. It’s more than a simple label; it’s the digital fingerprint that connects a product’s design, materials, and production history. From the moment components are placed to the final stage of quality inspection, this number ensures every board can be traced, verified, and trusted. Whether for quality assurance, compliance, or after-sales support, understanding what a PCBA number represents is essential to maintaining precision and accountability in modern electronics production.

Introduction to PCBA Numbers

What Is a PCBA Number?

A PCBA number is a unique identification code assigned to a Printed Circuit Board Assembly (PCBA). It acts as a digital identity that distinguishes one assembled circuit board from another within the production and supply chain. Each PCBA number is linked to a specific set of manufacturing details — including the components used, assembly date, process line, and testing data.

Manufacturers use this number to track, verify, and record every stage of the assembly process. This ensures that if an issue arises later—such as a component failure or soldering defect—the exact production batch can be traced quickly and accurately.

Example: A typical PCBA number might look like PCBA-2025-00123 or A1234567. These formats often include a company prefix, production year, and serial sequence. For instance, PCBA-2025-00123 could represent the 123rd board assembled in the year 2025 by a specific manufacturer.

A PCBA number is not the same as other identifiers used in electronics manufacturing:

PCB number: Refers to the bare board before components are mounted.

BOM ID (Bill of Materials ID): Identifies the list of components and materials used in a product design.

Serial number: Usually assigned at the product level, representing the finished device rather than the board itself.

By contrast, the PCBA number bridges design and production, ensuring that every board’s assembly record remains unique and traceable throughout its lifecycle.

Why PCBA Numbers Matter in Electronics Manufacturing

In high-precision industries, traceability is as critical as performance. The PCBA number serves as the backbone of product tracking and quality assurance across the entire manufacturing ecosystem.

1. Ensures full traceability.

Each PCBA number links the assembly to its raw materials, component batches, and test data. When a quality issue occurs, engineers can pinpoint the exact batch and production step, minimizing downtime and recall scope.

2. Enables quality assurance and defect analysis.

By correlating test results with PCBA numbers, manufacturers can detect recurring issues early—such as soldering defects or component mismatches—and take targeted corrective actions.

3. Supports regulatory compliance.

Industries like automotive, aerospace, and medical electronics require documented proof of traceability for safety and certification purposes. A well-managed PCBA numbering system provides this documentation automatically.

4. Improves after-sales support and reliability tracking.

When a customer reports a defect, the PCBA number allows service teams to retrieve the full history of that specific board, including component versions and test outcomes. This accelerates troubleshooting and enhances long-term reliability data.

In short, a PCBA number transforms a circuit board from a physical object into a traceable data entity — connecting every stage of design, manufacturing, testing, and service into one verifiable digital thread.

Structure and Format of a PCBA Number

Common PCBA Number Formats

A PCBA number typically follows a structured format that helps manufacturers identify when, where, and how a circuit board was assembled. While the exact pattern can vary between companies, the most common composition includes three parts:

Company Prefix + Year or Batch Code + Serial Number

This structure makes each PCBA number globally unique and easy to decode within internal systems.

Examples:

PM-2408-0756 → “PM” represents the company code, “2408” indicates the year and month (August 2024), and “0756” is the unique unit identifier.

PCBA-0001245 → A simpler sequential format where each assembled board receives a running number.

Manufacturers often design their own numbering logic depending on production scale, traceability requirements, and software systems used. For example, large electronics firms may use ERP or MES systems to automatically generate PCBA numbers, linking them to detailed production data such as operator, machine ID, and test results. Smaller operations might use spreadsheet-based or barcode-based systems with manual entry.

In essence, the format reflects the company’s workflow—some focus on time-based traceability (date-coded), while others emphasize product family or revision control. Regardless of structure, the goal remains the same: to ensure every PCBA can be traced back to its exact manufacturing context.

How PCBA Numbers Differ from PCB Numbers

Although the terms PCB number and PCBA number sound similar, they serve distinct purposes in the manufacturing process.

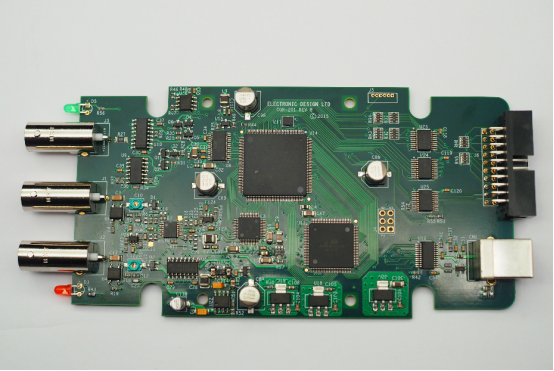

A PCB number identifies the bare printed circuit board before any components are mounted. It refers to the physical substrate that forms the electrical base of a device. A PCBA number, on the other hand, is assigned after the board has been fully assembled with components soldered onto it.

Key Differences Between PCB and PCBA Numbers:

Aspect | PCB Number | PCBA Number |

|---|---|---|

Purpose | Identifies bare board design | Tracks complete assembled board |

Production Stage | Before assembly (fabrication phase) | After assembly (post-SMT or through-hole) |

Data Stored | Board design version, layer count, material, dimensions | Component list, assembly batch, test results, operator data |

Example | PCB-2025-0021 | PCBA-2025-0021 |

Traceability Focus | Manufacturing parameters of the board | Full product history and quality control data |

In practical terms, the PCB number stops at design and fabrication, while the PCBA number continues through assembly, testing, and final inspection. Both identifiers are crucial, but the PCBA number offers a complete traceability chain—connecting design intent, assembly execution, and field performance into one unified record.

By distinguishing these two identifiers, manufacturers maintain clarity between the hardware’s structural identity (PCB) and its functional identity (PCBA)—a distinction essential for quality assurance, regulatory compliance, and lifecycle management.

PCBA Number Assignment and Management

How PCBA Numbers Are Assigned

Every PCBA number is assigned to ensure that each assembled circuit board has a distinct, traceable identity. The assignment method depends on the production environment and the level of automation in use.

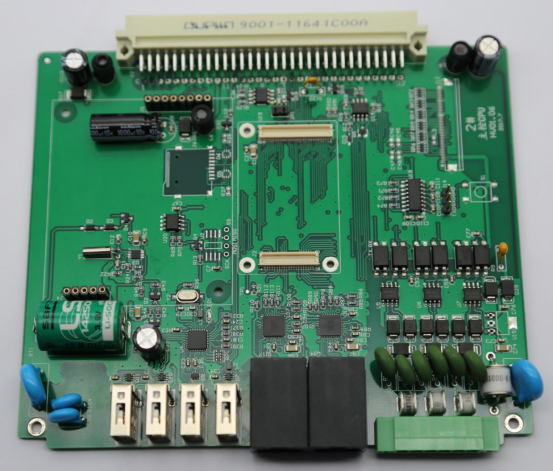

1. Automated Generation by MES or ERP Systems

In large-scale manufacturing, PCBA numbers are typically created automatically by Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) software. These systems generate a new number each time a board enters the assembly line. The number is then printed as a barcode or QR code label and attached to the board.

This method ensures consistency and eliminates duplicate IDs. It allows each PCBA number to be linked directly to real-time production data, such as component batch numbers, test results, and operator records.

2. Manual Assignment for Prototypes or Small Batches

For low-volume or prototype runs, manufacturers may assign PCBA numbers manually. This can involve:

Maintaining a logbook or spreadsheet to record each number.

Printing small custom labels using desktop barcode printers.

Manually entering the PCBA number into a tracking database.

While less efficient than automation, manual assignment offers flexibility during R&D and early production phases.

3. Step-by-Step Example of a PCBA Number Assignment Process

A practical illustration of how a PCBA number is assigned in an automated environment:

1. Design import: The product design and BOM are uploaded into the MES.

2. Batch creation: The system generates a new batch number for the day’s production.

3. PCBA ID generation: The MES assigns sequential PCBA numbers (e.g., PCBA-2408-01001 to PCBA-2408-01050).

4. Label printing: Each number is printed as a barcode or QR label and placed on the board at the start of the SMT line.

5. Data linking: Test, inspection, and repair data are automatically stored under the corresponding PCBA number.

6. Traceability completion: At shipment, the PCBA number connects to product serial numbers for full lifecycle tracking.

This structured process ensures that every board is uniquely identified and traceable from the moment it enters production until it reaches the end user.

Best Practices for Managing PCBA Numbers

Effective management of PCBA numbers ensures traceability, quality assurance, and compliance throughout the manufacturing lifecycle.

1. Maintain a Centralized Database or Digital Twin Record

All PCBA numbers should be stored in a single source of truth, such as an integrated MES or cloud-based traceability platform. A digital twin record — a virtual representation of each assembled board — allows engineers to instantly access production and testing data by scanning the PCBA number.

2. Link PCBA Numbers to BOM, Revision, and Testing Data

Each PCBA number should be connected to its Bill of Materials (BOM), design revision, and inspection results. This linkage creates a complete manufacturing profile that simplifies audits, recalls, and quality reviews.

3. Implement Version Control for Design Updates

Whenever a design revision occurs, the PCBA numbering system should reflect the update. For example, PCBA-2408-01023-A might represent version A, while PCBA-2408-01023-B identifies the same assembly with a design modification. This approach prevents confusion between production runs using different revisions.

4. Prevent Duplicate or Missing IDs with Software Integration

Integrating the PCBA numbering process into MES/ERP systems minimizes the risk of duplication or skipped numbers. Automated validation ensures that each new PCBA ID is unique, while real-time synchronization prevents errors between departments or production lines.

When properly managed, PCBA numbering becomes a foundation of intelligent manufacturing — ensuring full visibility, data integrity, and product accountability from design to delivery.

Role of PCBA Numbers in Traceability

How PCBA Numbers Enable Traceability

A PCBA number plays a central role in product traceability, allowing manufacturers to track every detail of a board’s production history — from the source of its components to the results of its final tests. Each PCBA number acts as a digital link that unites all process data under a single, unique identifier.

1. Tracing component sources and process steps

Every component placed on a circuit board — from resistors to microcontrollers — can be traced back to its supplier batch through the PCBA number. This connection allows engineers to identify which materials or assembly lots were used in each product, enabling faster detection of potential quality risks or supply chain issues.

2. Connecting data across the production lifecycle

The PCBA number serves as a bridge between all production stages:

Assembly line: Records SMT and through-hole processes, soldering parameters, and operator data.

Quality inspection: Links test results, AOI (Automated Optical Inspection), and ICT (In-Circuit Testing) data.

Shipment: Tracks finished products as they move into packaging and distribution.

By unifying this information, manufacturers gain end-to-end traceability — a complete digital record that can be accessed at any time for audits, analysis, or warranty verification.

3. Enabling root cause analysis and continuous improvement

When a failure occurs, the PCBA number allows engineers to quickly locate the affected units and identify the root cause. For example, if a specific component batch causes short circuits, the PCBA number instantly reveals which assemblies used that batch. This enables targeted recalls and data-driven process improvement, reducing downtime and cost.

In summary, PCBA numbers transform production data into actionable insight. They ensure that every product’s history — including components, operators, and test outcomes — is permanently traceable and verifiable.

Real-World Traceability Example

To illustrate how PCBA numbers support traceability, consider an automotive electronics manufacturer that uses barcode-based tracking throughout production.

Case Study: Automotive PCBA Traceability via Barcode System

Each car contains dozens of electronic control units (ECUs), and every one must meet strict quality and safety requirements. The manufacturer uses PCBA numbers encoded as barcodes to track every ECU board from start to finish.

Step-by-Step Workflow:

1. Assign PCBA number at SMT line — When the bare board enters the assembly line, an MES system automatically generates a unique PCBA number and prints a barcode label.

2. Record inspection and test data — As the board passes through AOI, functional tests, and visual inspections, all results are recorded under its PCBA number.

3. Store information in the MES database — The PCBA number becomes a key reference that connects assembly parameters, component batches, and operator records.

4. Retrieve record for warranty or recall analysis — If a vehicle component fails in the field, the service team scans the PCBA number to instantly access its full production history — including manufacturing date, equipment used, and test results.

This real-world workflow demonstrates how PCBA-based traceability ensures compliance, reliability, and accountability. By linking every stage of manufacturing to a unique identifier, companies can deliver safer, more consistent electronic products while maintaining full visibility across their supply chain.

Labeling and Tracking Methods for PCBA Numbers

Physical Labeling Techniques

A PCBA number must be clearly marked on every assembled board so it can be easily identified during production, testing, and service. The method of labeling directly affects the board’s traceability, durability, and readability over time.

Common physical labeling methods include:

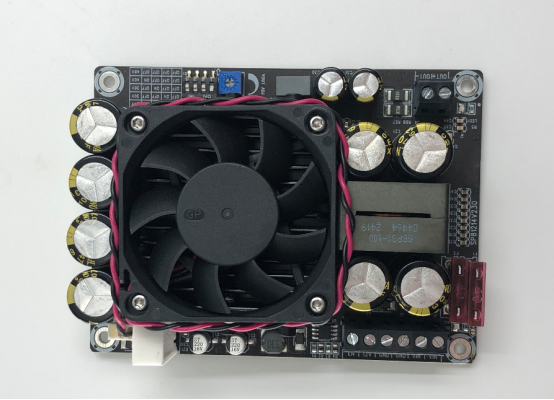

1. Silkscreen Printing – The PCBA number is printed directly onto the board’s surface during manufacturing.

Advantages: Simple, low-cost, and permanent.

Limitations: Limited readability if the board undergoes coating, wear, or rework.

2. Barcode Stickers – Adhesive labels containing a linear barcode or alphanumeric PCBA number.

Advantages: Easy to apply and compatible with barcode scanners.

Limitations: Can peel or fade under heat, humidity, or handling.

3. QR Codes – Two-dimensional barcodes that store more data, including serial information, batch codes, and production dates.

Advantages: High data capacity and quick scanning from any angle.

Limitations: Requires clear printing space and optical scanners.

4. Laser Marking – The PCBA number or QR code is etched directly onto the board or metal surface using a laser.

Advantages: Extremely durable and resistant to chemicals or abrasion.

Limitations: Higher equipment cost and setup complexity.

Comparison of PCBA Number Labeling Methods:

Method | Durability | Readability | Cost | Typical Use |

|---|---|---|---|---|

Silkscreen Printing | Medium | Medium | Low | Mass production with minimal wear |

Barcode Sticker | Medium | High | Low–Medium | General electronics |

QR Code Label | High | Very High | Medium | IoT, consumer, or smart devices |

Laser Marking | Very High | High | High | Automotive, aerospace, industrial PCBs |

Example: In IoT manufacturing, QR code labels are often preferred for PCBA tracking. Each QR code links to a digital record containing component details, test data, and firmware version. When scanned, it instantly retrieves the PCBA’s full production history — enabling rapid troubleshooting and device authentication.

By choosing the right labeling method, manufacturers balance cost, environment, and traceability needs, ensuring every PCBA remains identifiable throughout its entire lifecycle.

Digital Tracking Systems

While physical labels make the PCBA number visible, digital tracking systems manage the data behind it — connecting the physical board to its digital record.

1. Integration with MES and ERP Software

Modern manufacturers integrate PCBA numbers into Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) platforms. Each time a PCBA passes through an assembly or testing stage, the system automatically logs process data under its unique number.

This integration provides real-time visibility into production status. Engineers can search by PCBA number to retrieve component history, test outcomes, or rework details instantly.

2. RFID and Cloud-Based Tracking for Real-Time Monitoring

Some factories use RFID (Radio Frequency Identification) or cloud-connected systems to enhance tracking precision.

RFID tags store the PCBA number electronically and can be read without direct line-of-sight, speeding up inspections and material movement. Cloud-based systems synchronize PCBA data across locations, allowing remote teams to access traceability records from anywhere.

3. Advantages of Digital Tracking

Digital systems offer multiple operational benefits:

Faster data retrieval: Engineers can locate and review PCBA records within seconds.

Error reduction: Automated logging minimizes human mistakes and data loss.

Analytics insights: Traceability data can be analyzed to identify quality trends, recurring defects, or process inefficiencies.

In essence, digital tracking transforms the PCBA number into a dynamic data key—linking every assembly to its full manufacturing history, improving transparency, and enabling predictive quality management across the production ecosystem.

Compliance and Quality Requirements

Industry Standards Involving PCBA Identification

Proper PCBA numbering is not only a best practice for manufacturing efficiency—it is also a critical factor in meeting industry standards and regulatory requirements.

1. Key Standards:

ISO 9001: Requires documented processes for traceability, ensuring that each product can be tracked throughout production and delivery.

IATF 16949: Automotive-specific standard emphasizing component traceability, defect prevention, and quality management systems.

IPC-1782: Dedicated traceability standard for PCBAs, outlining guidelines for unique identification, data recording, and lifecycle management.

2. Regulatory Relevance:

Medical devices: PCBA identification is essential for compliance with FDA and ISO 13485 standards, supporting patient safety and device recall procedures.

Aerospace and defense: Traceability ensures boards meet rigorous reliability requirements and facilitates failure analysis in high-stakes environments.

Automotive electronics: Proper numbering is critical to comply with IATF 16949 audits and to support warranty and recall investigations.

3. Supporting Audits and Certification:

A well-managed PCBA numbering system simplifies audits by providing a complete, easily accessible record of every assembled board. Inspectors can quickly verify:

Which components were used and in which batch.

Manufacturing dates and assembly locations.

Test and inspection results tied to each PCBA number.

By aligning PCBA practices with these standards, manufacturers reduce regulatory risk, improve product safety, and maintain quality certification across industries.

Common Pitfalls and How to Avoid Them

Even with clear standards, errors in PCBA numbering can compromise traceability and quality management.

1. Inconsistent numbering formats across product lines

Problem: Different formats between product families or revisions can create confusion and complicate database searches.

Solution: Establish a company-wide numbering convention that incorporates batch, version, and serial identifiers consistently.

2. Lack of linkage between PCB and PCBA records

Problem: Disconnecting the bare board (PCB) data from the assembled board (PCBA) makes root cause analysis difficult.

Solution: Ensure every PCBA number is linked to its corresponding PCB number, BOM, and revision history in the MES or ERP system.

3. Poor data backup or manual errors in documentation

Problem: Lost records, duplicated numbers, or incorrectly logged data can undermine traceability and compliance.

Solution: Implement automated number assignment and centralized digital storage. Regular audits and backup procedures prevent data loss and human errors.

By addressing these pitfalls proactively, manufacturers maintain robust traceability, regulatory compliance, and product quality, turning the PCBA number from a simple identifier into a reliable quality assurance tool.

Future Trends in PCBA Number Traceability

Smart Manufacturing and Digital Twins

The future of PCBA traceability is closely tied to smart manufacturing and the use of digital twins—virtual replicas of physical products. By assigning each PCBA a unique digital identifier, manufacturers can track the board’s entire lifecycle, from assembly to end-of-life, with unprecedented precision.

Integration with Advanced Technologies:

IoT sensors: Continuously monitor environmental conditions, assembly parameters, and component performance, all linked to the PCBA number.

Blockchain: Provides tamper-proof, decentralized records of each board’s production and testing history.

AI-based defect tracking: Uses historical PCBA data to predict potential failures, optimize production processes, and reduce scrap rates.

For example, a smart factory might use IoT-enabled PCBA boards where each identifier feeds real-time performance data into a digital twin platform. Engineers can then simulate failures, analyze root causes, and implement design improvements before a widespread issue occurs.

This combination of digital identifiers, IoT, AI, and virtual twins allows manufacturers to achieve full lifecycle visibility, predictive quality management, and faster corrective actions—turning PCBA traceability into a proactive tool rather than a reactive measure.

Moving Toward Universal Standardization

Another significant trend in PCBA traceability is the push toward global numbering standardization. Standardized formats simplify supply chain management, reduce errors, and ensure that PCBA records are interoperable across manufacturers, suppliers, and regulators.

Example: The adoption of GS1-compliant electronic traceability systems allows PCBA numbers to follow a globally recognized structure. GS1 identifiers can include product type, manufacturing location, batch, and serial number, making it easier to:

Track PCBA boards across multiple factories and countries.

Facilitate audits, recalls, and warranty claims with consistent data.

Integrate seamlessly with digital supply chain platforms.

Universal standards also support cross-industry collaboration, enabling automotive, aerospace, and medical electronics sectors to exchange traceability information efficiently. As more manufacturers adopt these standards, PCBA numbers will become globally recognized keys, ensuring clarity, accountability, and interoperability across the electronics ecosystem.

By combining smart manufacturing techniques with standardized numbering, the future of PCBA traceability promises enhanced efficiency, improved product reliability, and seamless global supply chain visibility.

Conclusion

In modern electronics manufacturing, a PCBA number is far more than a simple identifier—it is a critical tool for ensuring product quality, traceability, and regulatory compliance. By uniquely linking each assembled board to its components, production processes, and test data, PCBA numbers enable manufacturers to quickly pinpoint issues, streamline audits, and maintain high reliability standards.

Effective management of PCBA numbers directly translates into efficient manufacturing and dependable after-sales support. When each board is properly tracked from assembly to delivery, companies can reduce errors, optimize production, and respond faster to recalls or warranty claims. At PCBMASTER, this meticulous approach to PCBA numbering ensures that every high-performance PCB assembly meets exacting quality standards while providing customers with full lifecycle visibility and confidence in their products.

Ultimately, a well-structured PCBA numbering system is a cornerstone of smart, traceable, and accountable electronics production, supporting both operational efficiency and long-term product reliability.

FAQs

What information is included in a PCBA number?

A PCBA number typically contains a company code, production date or batch, and a unique serial sequence. Some formats may also include revision codes or identifiers for specific production lines. This information allows manufacturers to trace each board back to its assembly process, component sources, and testing results, ensuring full lifecycle visibility.

How can I find the PCBA number on a circuit board?

The PCBA number is usually printed, labeled, or laser-etched directly on the assembled board. Common locations include near the edge of the PCB, close to connectors, or next to major components. It may appear as a barcode, QR code, or alphanumeric string, depending on the labeling method used by the manufacturer. Scanning a QR code or entering the printed number into a tracking system can reveal the board’s full production history.

Is a PCBA number the same as a serial number?

No. A serial number typically identifies the finished product as a whole, such as a complete device, while a PCBA number specifically tracks the assembled circuit board within that product. The PCBA number focuses on the board’s production details, including components, assembly steps, and test results, making it essential for traceability and quality control.

How are PCBA numbers used in warranty tracking?

PCBA numbers allow manufacturers and service teams to retrieve the complete history of a specific board, including production date, component batches, and testing records. When a product fails under warranty, the PCBA number helps identify whether the issue is isolated or part of a broader batch problem, speeding up repairs, replacements, and potential recalls while ensuring accurate customer support.

What’s the difference between PCBA number and part number?

A part number identifies a specific component or board design, such as a resistor, microcontroller, or PCB type. In contrast, a PCBA number is unique to each assembled board, linking it to its production batch, component sources, and quality data. While part numbers tell you what the board is made of, PCBA numbers tell you when, where, and how it was assembled and tested.