The Method of Providing Assembly Components for PCBs Detailed Explanation of Turnkey, Kitted, and Combo Modes

Introduction

In electronics development, selecting the appropriate component supply mode is a crucial step for ensuring project success. Modern PCB assembly relies on advanced assembly processes and automated equipment to ensure efficiency and quality.

In PCB Assembly (PCBA) projects, the choice of component supply method directly impacts project cost, schedule, and quality control. Understanding the three main supply modes - Turnkey, Kitted (or Consigned), and Combo - will help you make the best decision based on your project requirements.

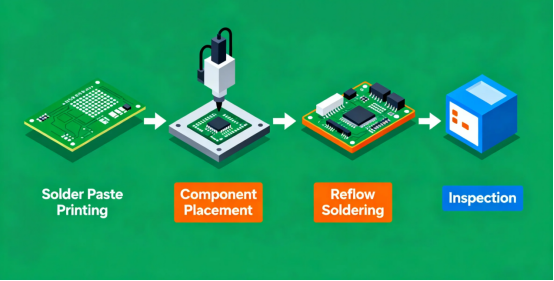

Turnkey PCB assembly services provide a comprehensive solution where the provider manages all aspects of the process, from component sourcing to final assembly and testing. These are often referred to as turnkey assembly, turnkey assembly services, or turnkey services, and are a core part of comprehensive manufacturing services in the electronics industry. The assembly process typically involves automated equipment for inspection, component placement, and soldering to ensure high quality and efficiency. Printed circuit board assembly is a critical stage in the overall pcb manufacturing process, which includes design, component sourcing, assembly, and testing. By managing the entire process, professional providers offer end-to-end pcb manufacturing and manufacturing services, streamlining the production of high-quality electronic products.

Introduction to PCB Assembly

PCB assembly is the essential process that transforms a bare printed circuit board into a fully functional electronic device. This assembly process involves the precise placement and soldering of electronic components onto the circuit board, ensuring that each connection is reliable and meets design specifications. Turnkey PCB assembly services offer a comprehensive solution by managing every stage of the project, from initial PCB fabrication and component sourcing to final assembly and quality control. With full turnkey PCB assembly, businesses can outsource the entire process to a single provider, streamlining operations and reducing the complexity of managing multiple vendors. This approach not only accelerates the assembly process but also helps control costs and maintain high standards of quality assurance. Whether for prototypes or large-scale production, turnkey PCB assembly services deliver efficient, reliable, and scalable solutions for any circuit board project, allowing companies to focus on innovation while experts handle the entire process from start to finish.

Turnkey PCB Assembly: The All-in-One, Hassle-Free Solution

The Turnkey mode, often referred to as a “turnkey project,” means the PCBA supplier manages the entire process from design support and component procurement to assembly and testing. In this model, you only need to provide the basic design files, and the supplier handles everything else.

Turnkey Mode Workflow

The supplier first conducts a Engineering Process Assessment (DFM Analysis) of your design files, evaluating PCB design rationality and component compatibility. Then, leveraging their supply chain resources, they perform centralized component procurement to ensure material quality and delivery time. The procured components undergo strict inspection, including verification of model/specification, visual inspection, performance sampling, etc. Finally, after assembly is complete, the supplier performs comprehensive testing, such as functional testing and reliability testing. Full turnkey assembly covers every aspect of board assembly, from sourcing components to final testing, ensuring a seamless and efficient assembly process.

Advantages of the Turnkey Mode

·High Time Efficiency: Saves the client significant time spent on component procurement and supply chain management, greatly shortening the product development cycle. Working with experienced contract electronic manufacturers and a reputable pcb manufacturer is essential for achieving high-quality results and reliable delivery.

·Rich Supply Chain Resources: Professional PCBA manufacturers possess extensive and robust component procurement networks, enabling cooperation with reliable distributors and suppliers to ensure components are 100% new and authentic.

·Comprehensive Quality Control: The supplier takes responsibility for the entire production process, ensuring consistent quality.

·Potential Cost Optimization: Leveraging economies of scale in procurement, suppliers may obtain better component prices and can pass the savings on to the client.

Projects Suitable for the Turnkey Mode

·Startups or teams with limited resources, lacking dedicated component procurement and supply chain management personnel.

·Products with high complexity and a wide variety of components, making self-procurement difficult.

·Projects with tight schedules that require rapid time-to-market.

Kitted or Consigned Electronic Components: The Self-Controlled, Autonomous Choice

The Kitted mode (also known as Consigned mode), opposite to Turnkey, refers to the client procuring all components required themselves and then providing these components along with the design files to the PCBA supplier for assembly.

Kitted Mode Workflow

The client is responsible for supplying all components required for the assembly, ensuring the supplier receives every part necessary for the process. All components, along with the BOM file and a detailed packing list, must be shipped to the supplier, indicating the project number, manufacturer’s part number, and the quantity in the kit. Upon receiving the materials, the supplier will perform Incoming Quality Control (IQC) to inspect the components required, but the primary responsibility lies with the client. Subsequently, the supplier carries out assembly and testing according to the client’s requirements.

Advantages of the Kitted Mode

·Transparent and Controllable Costs: The client has complete control over component procurement costs, facilitating accurate BOM cost calculation.

·Utilize Existing Inventory: If the client already has component stock, they can utilize this inventory, reducing capital tied up in stock.

·This mode is particularly suitable for clients who wish to use their own components and maintain control over inventory and sourcing.

·Autonomous Procurement of Special Components: For critical or special components, the client can ensure their source and authenticity, especially for sensitive or customized parts.

·Supply Chain Autonomy: The client can maintain their own supply chain system, independent of the PCBA manufacturer’s supply chain.

Projects Suitable for the Kitted Mode

·Large companies with strong procurement teams and supply chain resources, who have already established stable partnerships with component suppliers.

·Products involving proprietary technology or special components where the client wishes to strictly control the source of components.

·Small batch production runs where the client already has most components in stock.

Combo (Hybrid Mode) PCB Assembly: The Balanced, Flexible Approach

The Combo mode, as the name suggests, is a combination of the Turnkey and Kitted modes. In this model, the client provides some key components, while the PCBA supplier is responsible for procuring the remainder. This approach is also known as partial turnkey, offering a tailored solution that balances client control and supplier support. This is a very flexible and common cooperation method.

Combo Mode Workflow

The client and supplier jointly determine who is responsible for procuring which components. The supplier is also responsible for procuring and assembling the necessary pcb boards not provided by the client. Typically, the client provides the core, critical, or already-in-stock components, while the supplier procures the generic, standard, or components where they have a procurement advantage. The supplier will seek client approval for every detail regarding the price, quality, and availability of the supplementary components. Subsequently, the process is similar to Turnkey, where the supplier handles the procurement, inspection, assembly, and testing of the remaining components.

Advantages of the Combo Mode

·High Flexibility: Combines the advantages of Turnkey and Kitted, allocating responsibilities flexibly based on project needs and the strengths of both parties.

·Risk Diversification: The client can control the source of key components while transferring the procurement burden for generic components to the supplier.

·Optimized Resource Allocation: The client can focus on managing core components while leaving the tedious procurement of generic components to a professional team.

Projects Suitable for the Combo Mode

·Most companies that have specific requirements regarding the source of certain components but also wish to reduce part of the procurement burden.

·Companies in Transition: Enterprises transitioning from fully self-managed procurement to partial outsourcing.

·Projects needing to balance risk and control.

Quality Control and Assurance in PCB Assembly

Quality control and assurance are fundamental to achieving reliable PCB assemblies. Throughout the pcb assembly process, advanced inspection methods such as automated optical inspection (AOI) and X-ray inspection are employed to detect defects and ensure the integrity of solder joints and component placement. AOI is particularly effective for surface mount assemblies, quickly identifying issues like missing components or misaligned parts, while X-ray inspection uncovers hidden defects that are not visible to the naked eye. Turnkey pcb assembly services implement these automated testing protocols as part of their standard assembly services, ensuring that every board meets stringent quality control standards. Real-time data monitoring and regular audits at each stage of the assembly process further enhance quality assurance, allowing for immediate detection and correction of any issues. By leveraging automated inspection systems, turnkey pcb assembly providers deliver consistent, high-quality results, giving customers confidence in the reliability and performance of their finished products.

Production Capacity and Capability Considerations

When choosing a pcb assembly service provider, it’s crucial to assess their production capacity and technical capabilities to ensure they can meet your project’s demands. A reliable turnkey pcb assembly partner should be equipped to handle a wide range of production volumes, from small prototype batches to high-volume manufacturing runs. Their expertise should extend to various types of printed circuit boards, including single-sided, double-sided, and multi-layer designs, as well as the ability to assemble both through-hole and surface mount electronic components. Efficient assembly services rely on advanced equipment and streamlined production processes to minimize lead times and manufacturing costs while maintaining high standards of quality. By selecting a provider with proven experience and the right resources, you can be confident that your pcb assembly project will be completed on time, within budget, and to the highest quality standards.

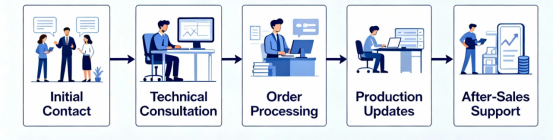

Customer Support and Communication with PCB Providers

Strong customer support and clear communication are key to a successful pcb assembly project. A dependable assembly service provider will offer a dedicated team to manage your inquiries, provide regular updates on the production process, and promptly address any concerns that arise. Transparent communication ensures that your requirements are fully understood and that the final product aligns with your expectations. Responsive customer service also means that any necessary adjustments can be made quickly, minimizing delays and ensuring a smooth assembly process. By working with a pcb assembly provider that prioritizes customer support, you gain a single point of contact for your project, making it easier to coordinate every stage of production and achieve the best possible results.

How to Choose the Right Supply Mode for Your Project?

Choosing which component supply mode to use requires considering the following factors:

·Team Resources: Assess whether you have an internal professional procurement and supply chain management team, and their workload.

·Project Budget: Determine whether you prefer a lump-sum price (Turnkey) or want clear control over the cost of each component (Kitted).

·Time Requirements: If time is critical, Turnkey is usually the faster option.

·Component Characteristics: If the project uses many scarce or customized components, Kitted or Combo might be more suitable.

·Supply Chain Relationships: If you already have established good relationships with component suppliers, Kitted or Combo can help you maintain those relationships.

·Production Scale: For high volume production, turnkey or partial turnkey solutions can offer greater efficiency, cost savings, and streamlined management.

For projects that require advanced quality assurance and precise assembly, in circuit testing and surface mount technology are important considerations. Projects involving other leadless package parts, such as QFN, Micro-BGA, or other leadless package parts, may require specialized assembly capabilities. Additionally, conformal coating can be an important finishing process to enhance product reliability and protection, especially in demanding environments.

Regardless of the mode chosen, successful PCBA projects are built on a foundation of clear communication and sufficient trust.

Ensure you discuss your needs, expectations, and constraints in detail with your PCBA supplier. Choosing the cooperation mode that best fits your project requirements is key to ensuring smooth project progress and getting your product to market quickly.

If you have more questions about PCB assembly or need professional services, feel free to contact a professional PCBA supplier for more advice and quotes.

Conclusion

In conclusion, turnkey pcb assembly services present a comprehensive and efficient solution for businesses seeking reliable pcb assembly for their products. By offering a single point of contact for the entire process—from pcb fabrication and component sourcing to final assembly and quality control—these services simplify project management and ensure consistent results. Careful consideration of factors such as quality control, production capacity, and customer support will help you select a pcb assembly service provider that meets your specific needs. Turnkey pcb assembly services enable businesses to streamline their assembly process, reduce manufacturing costs, and enhance product quality, whether for consumer electronics, medical devices, or industrial electronics. By entrusting the entire process to experienced professionals, you can focus on your core business while ensuring your circuit board projects are completed efficiently and to the highest standards.

FAQs

Q. What is Turnkey PCB Assembly?

A. Turnkey PCB Assembly is an end-to-end service that manages every stage of a PCB project, from initial design review to final delivery. The customer simply provides design files to a single supplier, who then handles everything else—including component procurement, board fabrication, assembly, testing, and shipping.

Q. What are the advantages of Turnkey PCB Assembly?

A. It saves the customer time and effort by eliminating the need to manage multiple suppliers. Additionally, the supplier typically possesses specialized equipment and expertise, ensuring high-quality results and often enabling faster project completion.

Q. What is Kitted PCB Assembly?

A. In Kitted PCB Assembly, the customer supplies both the bare PCBs and all components. The manufacturer then places the components onto the boards according to the provided Gerber files, Bill of Materials (BOM), and component placement files, before shipping them to the specified location.

Q. What are the file requirements for Kitted PCB Assembly?

A. Typically required files include:

·Gerber files for PCB fabrication.

·A Bill of Materials (BOM) detailing component quantities, reference designators, part numbers, and other relevant parameters.

·A component placement file (or pick-and-place file) containing component coordinates, rotation values, and reference designators.

Q.What is Combo PCB Assembly?

A. Combo PCB Assembly is a hybrid approach where the customer supplies some of the components, and the manufacturer provides the rest, after which the full assembly is performed.

Q. In Combo PCB Assembly, how does the manufacturer handle customer-supplied components?

A. The manufacturer typically inspects and verifies the customer-supplied parts to ensure they meet required quality standards and quantities. If any issues are found with the provided components, the manufacturer will generally contact the customer to discuss potential solutions.

Author: Jack Wang