Benefits of Turnkey PCB Assembly for Prototyping and Production

Every electronics product starts with an idea, but turning that idea into a real, working device can be complicated and time-consuming. You need the right parts, careful assembly, and testing to make sure it works perfectly.

Turnkey PCB Assembly solves these problems by combining all steps into one service. Instead of buying parts from many suppliers, assembling them yourself, and testing each board, the turnkey provider does it all. This means fewer mistakes, less waiting, and a smoother process overall.

Using turnkey services also helps you adapt quickly. If you need to change a design, test a new component, or scale up production, the supplier can make adjustments fast. This makes it easier to move from a small prototype to larger production without extra delays.

In short, Turnkey PCB Assembly saves time, reduces stress, and ensures your electronics projects are ready to work reliably, whether for testing ideas or making hundreds of boards for the market.

What Is Turnkey PCB Assembly?

1. Definition: A One-Stop Solution

Turnkey PCB Assembly is a complete, one-stop service for making printed circuit boards. Instead of handling each step yourself or dealing with multiple suppliers, a turnkey provider does everything for you. This makes the process faster, simpler, and less stressful.

A turnkey service usually includes:

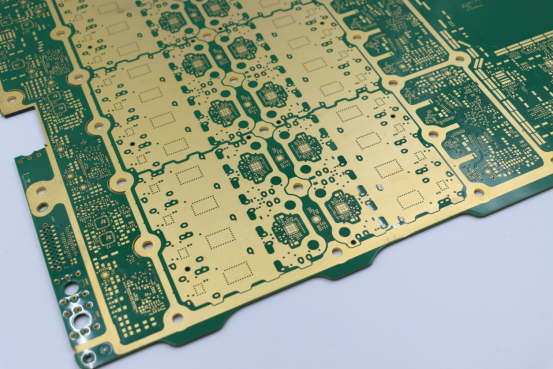

Material Sourcing – The supplier gets all the parts and components you need, like resistors, chips, connectors, and PCBs. You don’t have to search for them or manage multiple orders.

PCB Assembly – All components are carefully placed and soldered using professional equipment. This ensures accuracy and reliability, even for tiny parts.

Testing – Every board is checked to make sure it works correctly. The supplier tests connections, power, and functionality to prevent mistakes.

Delivery – The finished and tested boards are sent directly to you, ready to use or integrate into your product.

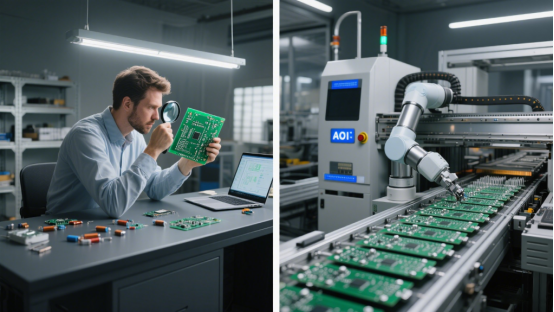

2. Difference from Traditional PCB Production

In traditional PCB production, you might have to buy components from different suppliers, assemble the boards yourself, and coordinate testing. This takes more time and often causes mistakes or delays.

Turnkey PCB Assembly integrates all steps under one roof. This approach:

Saves time by reducing communication with multiple suppliers

Reduces mistakes because every step is handled by professionals in one place

Simplifies project management and shortens production cycles, making it easier to meet deadlines

3. Unique Advantages for Prototyping and Production

Turnkey PCB Assembly is especially useful for:

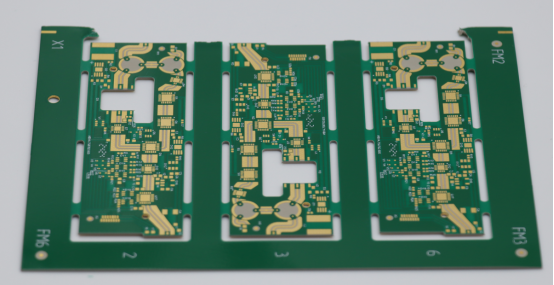

Prototyping – You can make small batches quickly to test your ideas. This allows you to check designs and make improvements before mass production.

Production – You can scale up to hundreds or thousands of boards with consistent quality. The same professional process is used for small and large batches, ensuring reliability.

With turnkey services, you get faster results, higher reliability, and smoother production. From the very first prototype to large-scale manufacturing, your boards are handled professionally, saving you time, effort, and costs.

Advantages of Turnkey PCB Assembly for Rapid Prototyping

1. Reduce Waiting Time

With Turnkey PCB Assembly, the supplier manages all steps and materials in one place. You don’t need to contact multiple vendors or wait for parts from different sources. For example, if you need resistors, capacitors, or chips, the supplier already has them ready or orders them quickly. This reduces delays and lets you get your first prototype much faster. You can start testing your design sooner, which is very important if you want to bring a product to market quickly.

2. High Flexibility

Turnkey services allow you to change your design or Bill of Materials (BOM) quickly during prototyping. For instance, if a component doesn’t fit well or you want to test a better one, the supplier can update the assembly process immediately. In traditional production, changing a design often requires coordinating multiple suppliers, updating documents, and repeating tests, which wastes time. Turnkey PCB Assembly makes these changes fast and simple, so your prototype can evolve smoothly.

3. Ensure Prototype Reliability

A high-quality turnkey process ensures your first prototype actually works. Every board is assembled carefully, soldered correctly, and tested thoroughly. This reduces the risk of errors, like missing connections or damaged components, which can happen when handling multiple steps separately. Reliable prototypes mean you can focus on testing your ideas, making improvements, and presenting your product confidently, instead of spending time fixing avoidable mistakes.

4. Support Small Batch Production

Turnkey PCB Assembly works well even for small production runs. You can start with just a few boards to test the market or check your design. Even in small batches, you still get the same professional assembly, testing, and quality control as full-scale production. This keeps costs under control, avoids waste, and allows you to scale up smoothly when your design is ready for mass production.

Advantages of Turnkey PCB Assembly for Mass Production

1. Integrated Supply Chain

With Turnkey PCB Assembly, the supplier manages all materials and components in one place. This means they handle purchasing, inventory, and organization so you don’t have to contact multiple vendors or worry about missing parts. For example, resistors, chips, connectors, and PCBs are all tracked and ready for assembly. This reduces mistakes, prevents delays, and keeps production running smoothly, even for large orders.

2. Lower Production Costs

Producing a large number of boards with turnkey services is more cost-effective. By making many boards in a single batch, suppliers save labor, shipping, and handling costs. They can also buy components in bulk, which lowers the price per part. Compared to managing each step separately with multiple vendors, turnkey assembly reduces overall production costs while maintaining quality. This is especially important for companies that want to scale up without wasting money.

3. Higher Production Efficiency

Turnkey PCB suppliers use automated machines for assembly, optical inspection, and functional testing to make hundreds or thousands of boards quickly. Automation reduces errors and speeds up the process. For example, placing tiny components by hand can be slow and inconsistent, but automated machines ensure each board is assembled exactly the same way. This efficiency means your product can reach the market faster without compromising quality.

4. Consistent Product Quality

High-volume production can sometimes create inconsistent boards if quality checks are not strict. Turnkey services standardize every step, from assembly to soldering to final testing. This ensures all boards are uniform, reliable, and ready to use. Fewer defective boards mean less rework, fewer delays, and more trust in your product, especially when delivering to customers or clients.

Bridging the Gap Between Prototyping and Mass Production

1. Smooth Transition from Small to Large Batches

Turnkey PCB Assembly makes it easy to move from a few prototype boards to hundreds or thousands of production boards. Because the same supplier handles all steps—including material sourcing, assembly, testing, and delivery—the process is smooth and consistent.

You don’t have to worry about switching vendors, coordinating multiple suppliers, or repeating steps, which often causes delays. For example, if you tested 10 prototype boards and they work perfectly, the supplier can scale up to 500 production boards without changing processes. This saves a lot of time and ensures all boards meet the same high-quality standard.

2. Avoid Delays from Design Changes or Process Adjustments

During product development, design changes or adjustments in production are normal. A turnkey supplier can quickly update the prototype design, change the BOM, and adjust assembly steps without disrupting production schedules.

This reduces mistakes and prevents miscommunication between multiple vendors, which often causes delays. For instance, if you decide to swap a component or add a new feature after testing the prototype, the turnkey supplier can implement the change immediately and scale it to mass production. This keeps your project on schedule and your product development efficient.

Conclusion

In summary, Turnkey PCB Assembly is a powerful way for companies to save time, reduce costs, and make the transition from prototypes to full production much smoother. Instead of worrying about buying parts, assembling boards, and testing them yourself, a turnkey service handles all of these steps in one place. This allows you to focus on designing and improving your product, while the supplier takes care of the complex manufacturing work.

Choosing a professional and reliable supplier is very important. A good supplier ensures that every board is high-quality, tested, and delivered on time, reducing the chance of mistakes that could delay your project or increase costs.

If you want your products to reach the market quickly and with confidence, partnering with a trusted Turnkey PCB Assembly provider is the smart choice. For example, PCB MASTER offers expert support, high-quality assembly, and seamless production, helping your electronics projects move from idea to reality without unnecessary delays.

By using turnkey services, you can launch your products faster, with better reliability, and with less stress, making it easier to compete in today’s fast-moving electronics market.

FAQs

1. What components are usually included in Turnkey PCB Assembly?

Turnkey PCB Assembly usually includes all the parts needed for your board, such as resistors, capacitors, chips, connectors, and the PCB itself. The supplier sources these components for you, so you don’t need to spend time finding each part separately. They make sure everything is high-quality and compatible, which helps prevent problems during assembly.

2. How long does it take to get a prototype with Turnkey PCB Assembly?

The time depends on the complexity of the design and the supplier, but usually a prototype can be ready in a few days to a couple of weeks. Because the supplier handles all materials, assembly, and testing, you don’t have to wait for parts from different vendors. This is much faster than doing each step yourself or using multiple suppliers.

3. Can Turnkey PCB Assembly handle both small and large orders?

Yes! Turnkey services are flexible. They can make a few prototype boards for testing ideas, or hundreds to thousands of boards for full production. The same assembly process is used for all orders, which ensures consistent quality no matter the quantity. This makes it easy to scale up production as your product demand grows.

4. What happens if I need to change my design after prototyping?

If you need to change your PCB design or switch a component, a turnkey supplier can quickly update the production process. They can adjust the BOM, assembly steps, and testing procedures without starting over. This saves time, reduces mistakes, and allows you to test new ideas efficiently before moving to full-scale production.

5. How do I choose a reliable Turnkey PCB Assembly supplier?

Look for a supplier that has:

Experience and certifications (like ISO or UL)

Advanced assembly and testing equipment

Good communication and technical support

Ability to handle both small and large orders

A reliable supplier ensures high-quality boards, faster delivery, and fewer errors, which helps your product reach the market on time.