Aerospace PCB Assembly Guide: Standards, Process & Best Practices

When we talk about airplanes or rockets, we all want them to be 100% safe. One small mistake in the electronics can cause a big problem. Printed circuit boards (PCBs) are like the “nervous system” of airplanes and rockets — they connect all the electronic parts and make sure everything talks to each other. That is why the PCBs used in aerospace must be very strong, very reliable, and work in any condition — hot, cold, or shaking in the air.

In this guide, I will show you step by step how aerospace PCB assembly works. You will learn what standards the industry follows, what steps are in the process, and the best ways to make sure the boards are safe and high quality.

Why Aerospace PCB Assembly Is So Important

In airplanes and rockets, even the smallest mistake can be dangerous. A single bad connection can make the navigation, communication, or control system stop working. That is why aerospace PCB assembly is done with extra care, using strict rules and many tests.

1. Reliability and Safety

Reliability means the board works every single time, not just once or twice. In aerospace, you cannot stop mid-air to fix a problem. If the circuit fails, the plane might lose control or the rocket might not reach space.

l Strong soldering: Every tiny joint where a part connects to the board must be solid.

l Careful inspection: After making the board, workers and machines check every part with cameras and X-ray to catch hidden problems.

l Redundancy: Sometimes, there are extra circuits added, so if one fails, the backup takes over.

2. High Performance and Tough Conditions

Airplanes and rockets face extreme environments that normal electronics never see:

l Temperature: The board must work from freezing cold at high altitude to very hot near engines.

l Vibration: During take-off, rockets shake so much that loose parts could break off.

l Radiation: In space, there is no protection from solar radiation, which can damage chips.

To handle this, special materials are used. For example, polyimide boards that can handle heat better than normal FR-4, and special coatings (called conformal coating) that protect circuits from moisture and dust.

3. Meeting Industry Standards

The aerospace industry follows very strict rules:

l IPC Class 3 / Class 3A: These are rules for making very high-reliability boards. They say how thick the copper must be, how clean the solder joints must look, and more.

l AS9100: This is a quality management system just for aerospace. It makes sure the factory checks every step, keeps records, and trains workers.

l NASA-STD-8739: These are NASA’s own rules for soldering and assembly, often used by space projects.

l Material safety: Boards must follow RoHS and REACH rules, so no harmful chemicals are used.

Following these standards is not optional — if a factory does not follow them, their boards cannot be used in airplanes or rockets.

Main Standards for Aerospace PCB Assembly

To keep airplanes and rockets safe, the industry follows very strict rules when making PCBs. These rules are called standards, and they tell the factory exactly how to design, build, and test each board. Here are the most important ones:

1. IPC Class 3 / Class 3A

These are some of the most famous IPC standards for making high-reliability electronics. They describe how perfect the solder joints must be, how wide the copper tracks should be, and how clean the board must look. Class 3 is used for critical systems like airplanes, and medical devices. Class 3A is even stricter and is often used in space projects.

For example, if a normal PCB can survive 5 years, a Class 3 board is built to survive 15 or more years in very tough conditions. Following these standards ensures that the board can withstand extreme environments and last a long time without failure.

2. AS9100 / ISO 9001

These are quality management system standards. They do not tell you exactly how to solder, but they make sure the factory is organized and careful at every step. AS9100 is made just for the aerospace industry. It requires the factory to check every process, train workers properly, and keep full records so that every board can be traced. ISO 9001 is a more general quality standard used in many industries, but it is still important for aerospace.

Following these standards is crucial because if a problem happens, the company can quickly find the cause and fix it, preventing the same issue from happening again.

3. NASA-STD-8739 Series

This is a group of NASA PCB assembly rules. They include special instructions for soldering, wiring, and inspection, specifically designed for space projects. In space, you cannot repair boards easily, so these standards make sure every board is built perfectly before launch.

For example, NASA-STD-8739 describes exactly how much solder to use, how shiny a joint should look, and even what tools are allowed. Following these rules ensures that the PCB can survive extreme conditions in space and continue to function reliably.

4. RoHS / REACH Compliance

These are environmental safety standards. RoHS limits the use of harmful materials such as lead, mercury, and cadmium in electronics. REACH focuses on the safe use of chemicals in Europe.

Following RoHS and REACH ensures that the boards are safe for the workers who make them, safe for the environment, and safe for the people who use airplanes or satellites. It also ensures compliance with international regulations, which is important for aerospace projects around the world.

Aerospace PCB Assembly Process

Making PCBs for airplanes or rockets is very different from making a simple circuit board. Each step is carefully planned, tested, and documented to make sure the board works perfectly in extreme conditions. Here’s a detailed explanation of the process:

1. Design Review and DFM/DFX

Engineers first review the PCB design line by line. They check if the circuit layout is correct, if the traces are thick enough, and if components are spaced properly.

l DFM (Design for Manufacturing) involves making changes to ensure the board can actually be built without errors. For example, if two solder pads are too close, a short circuit could happen — DFM fixes this.

l DFX (Design for Excellence) focuses on improving the design for reliability, durability, and testability. This might include adding extra connections, improving thermal management, or making the board easier to inspect.

Catching design problems early saves time, reduces cost, and prevents failures during flight.

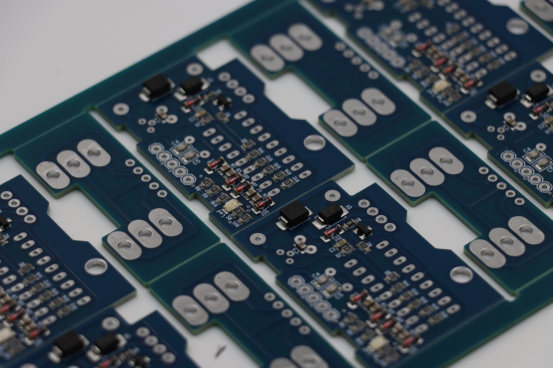

2. Material Selection

Aerospace PCBs use high TG (glass transition temperature) materials such as FR-4 or Polyimide, which resist heat, cold, and vibrations. Only aerospace-grade components are selected, meaning they are tested to survive extreme temperatures, radiation, and long-term use.

Some boards also use conformal coatings to protect circuits from moisture, dust, and corrosion. Using the wrong materials can cause circuits to fail in mid-flight, which could be catastrophic.

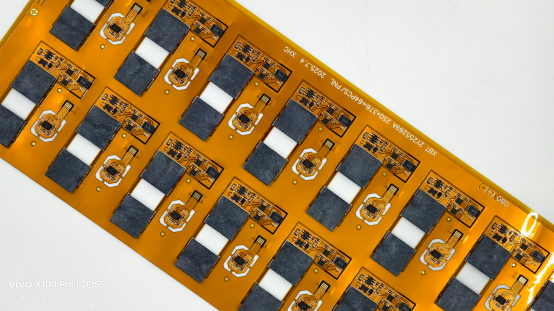

3. SMT Placement and Wave / Reflow Soldering

During SMT placement, machines place each tiny component exactly where it should go. Even a 0.5 mm misplacement can cause failure.

Soldering is performed using wave soldering for through-hole parts or reflow soldering for surface mount parts. Each process follows a precise temperature curve — too hot can damage components, too cold can create weak solder joints.

Proper soldering ensures every part stays connected, even under heavy vibration or temperature changes.

4. Automatic Optical Inspection (AOI) and X-ray Testing

After soldering, high-resolution cameras scan every solder joint using AOI to detect missing solder, bridges (short circuits), or misaligned components.

X-ray inspection is used for hidden joints under chips like BGAs. X-rays can detect cracks, voids, or cold solder joints that cameras cannot see.

Detecting defects early prevents board failures in the field, which is critical for aerospace safety.

5. Functional Testing and Environmental Stress Screening (ESS)

Boards are powered on and tested to make sure every signal and circuit works as designed.

Environmental Stress Screening subjects the boards to vibration, thermal cycling (hot and cold), and sometimes radiation simulators to simulate real flight conditions.

This step ensures that boards won’t fail during take-off, flight, or landing — it’s like a rehearsal for the real mission.

6. Quality Traceability and Documentation

Every board receives a unique serial number, and all production steps, inspections, and tests are recorded.

Documentation is kept for audits, customer verification, and future troubleshooting. If something goes wrong later, engineers can quickly track the problem, find the root cause, and prevent it in the future.

Extra Notes for Best Reliability:

l Multiple inspections at every stage.

l Cleanroom conditions to prevent dust and moisture contamination.

l Experienced technicians monitor machines to catch small errors.

Following all these steps carefully produces aerospace PCBs that are extremely reliable, durable, and ready for the harsh conditions of flight and space missions.

Best Practices for Aerospace PCB Assembly

To make sure aerospace PCBs are safe, reliable, and long-lasting, engineers and factories follow some best practices. These are steps and habits that help prevent mistakes and make the boards work perfectly in flight.

1. Involve Manufacturers Early in the Design Stage

Engineers should work with the factory before the board is built. The factory can give advice on how to make the design easier to assemble and test. This reduces errors, saves time, and prevents costly redesigns later. For example, if a board has tiny components very close together, the manufacturer may suggest spacing them a little more so soldering is easier and safer. Early collaboration helps avoid mistakes that could cause failures in flight.

2. Choose Factories with AS9100 and IPC Certification

Factories with these certifications follow strict aerospace rules and quality standards. Certified factories have trained workers, proper equipment, and standardized processes that ensure every board meets aerospace requirements. For instance, an AS9100-certified factory will have a detailed checklist for each board to make sure nothing is missed. Choosing a certified factory reduces risk and improves reliability.

3. Use 100% Traceable Components

Every component used on the board should be 100% traceable, meaning the source, batch number, and manufacturer are recorded. This prevents counterfeit or low-quality parts from being used, which could cause failures in flight. For example, if a resistor fails, engineers can trace it back to the batch it came from and check all similar boards. Traceability ensures that every part is reliable and verifiable.

4. Strengthen Soldering Process Control and Staff Training

Workers must be trained to follow strict soldering procedures, and machines must be monitored to ensure temperature and timing are correct. Proper soldering is crucial — a weak joint can break during vibration or thermal changes. Regular training sessions help staff understand why every joint matters and how to spot problems early. Controlling the soldering process and training personnel prevents hidden defects and improves the board’s durability.

5. Perform Full Lifecycle Testing and Reliability Verification

Boards are tested in conditions that simulate their entire life, including power-on tests, vibration, thermal cycles, and long-term reliability checks. This ensures that the board will continue working for years, even in extreme environments. For example, a board might be put in a chamber that shakes and heats it repeatedly to make sure no components come loose or fail. Lifecycle testing guarantees the PCB can survive real aerospace conditions.

Common Challenges and Solutions in Aerospace PCB Assembly

Even with careful design and manufacturing, aerospace PCB assembly has some challenges. Understanding these challenges and knowing how to solve them is very important.

Challenge 1: High Material and Testing Costs

Making aerospace PCBs requires high-quality materials and extensive testing. These materials, like high TG boards and aerospace-grade components, are expensive. Testing each board under extreme conditions also costs a lot.

Solution: Engineers can optimize the BOM (Bill of Materials) by choosing materials that meet requirements without unnecessary extras. They can also do batch testing, testing multiple boards together to share costs. This keeps quality high while controlling expenses.

Challenge 2: Supply Chain Risks

Aerospace components often come from specialized suppliers, and delays or shortages can stop production. Using counterfeit or low-quality parts is also a serious risk.

Solution: Use multiple suppliers to reduce dependence on a single source. Implement material traceability, recording every component’s origin and batch. This way, if a part fails, it can be traced and replaced quickly without stopping production.

Challenge 3: Long Certification and Delivery Cycles

Aerospace PCBs must meet strict standards and certifications, which can take a long time. This slows down production and delivery schedules.

Solution: Plan early for certifications and approvals. Parallel workflows help: while one team works on design, another prepares certification documents and test plans. This reduces overall delivery time without sacrificing quality.

Conclusion

Following the right standards, optimizing the assembly process, and applying best practices are the keys to successful aerospace PCB assembly. When every step is done carefully, the boards become safe, reliable, and ready to perform in the extreme conditions of flight and space.

If you are working with PCBs or PCBA and want your products to be high quality and dependable, it is important to partner with professional aerospace PCB manufacturers. PCB MASTER is a trusted supplier of PCB and PCBA solutions, known for delivering reliable products and excellent service. If you have any questions about PCB design, assembly, or quality, feel free to contact PCB MASTER — they can help ensure your boards meet the highest standards.

FAQs

1. Why do aerospace PCBs cost more than regular PCBs?

Aerospace PCBs are more expensive because they need to be extremely reliable and durable. They use special materials that can handle heat, cold, vibration, and radiation. Every component must be aerospace-grade and fully traceable to avoid failures. Additionally, every board goes through extensive testing, including vibration tests, thermal cycling, and functional checks. These extra materials, inspections, and processes make the cost higher than regular consumer PCBs.

2. How do engineers make sure aerospace PCBs won’t fail in extreme conditions?

Engineers design aerospace PCBs with reliability in mind. They choose strong materials like Polyimide or high TG boards, select tested components, and carefully plan the circuit layout. During assembly, soldering is done with strict temperature control, and every joint is inspected using cameras and X-rays. After assembly, boards are tested under extreme heat, cold, and vibration to simulate real flight conditions. This step-by-step process ensures the boards will work even in the harshest environments.

3. Can a small mistake in a PCB really affect an airplane or rocket?

Yes, even a tiny mistake can have serious consequences. A single loose connection or bad solder joint could stop a critical system, like navigation, communication, or engine control. That’s why aerospace PCBs follow strict standards, multiple inspections, and extensive testing. Extra safety measures, such as redundant circuits and full traceability, are also used to make sure one small error does not lead to a failure in flight.