How Quick Turn PCB Assembly Can Speed Up Your Product Launch

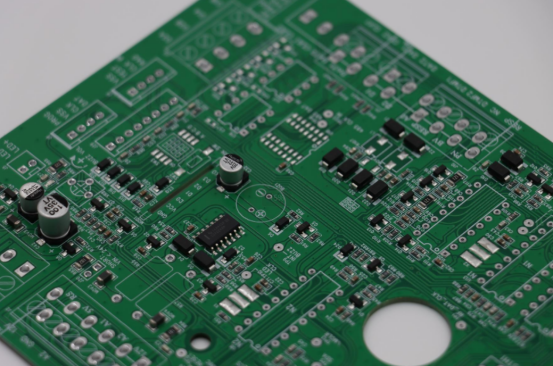

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They connect all the components, carry signals, and make devices function properly. For any electronic product, having a well-designed and high-quality PCB is essential for performance and reliability.

In today’s fast-moving market, simply having a good PCB is not enough. Companies also need to get their products to market quickly. This is where Quick Turn PCB Assembly comes in. By speeding up the assembly process, it allows boards to be ready in days instead of weeks, helping businesses launch products faster, reduce delays, and stay competitive.

What is Quick Turn PCB Assembly?

Quick Turn PCB Assembly is a specialized process that allows companies to design, assemble, and deliver PCBs much faster than traditional methods. While standard PCB assembly can take weeks, quick turn assembly focuses on speed without sacrificing quality, helping businesses meet tight deadlines and respond quickly to market demands.

1. Where is Quick Turn PCB Assembly used?

Rapid Prototyping – Engineers and designers can get a working board in just a few days. This allows them to test their ideas, find design mistakes early, and improve the product before moving to full-scale production.

Small Batch Production – Sometimes companies only need a limited number of boards, for example for pilot runs or specialized devices. Quick turn assembly handles small orders efficiently, ensuring high quality even in low volumes.

Urgent or Emergency Orders – Projects often have tight deadlines, especially when a new product needs to launch quickly. Quick turn PCB assembly ensures that boards can be produced and delivered on time, preventing delays that could cost money or market share.

2. How does Quick Turn PCB Assembly work?

The process is carefully organized to save time while keeping precision and reliability:

Design Stage – Engineers use PCB design software to plan all circuits and components. Files are checked carefully to avoid mistakes before manufacturing begins.

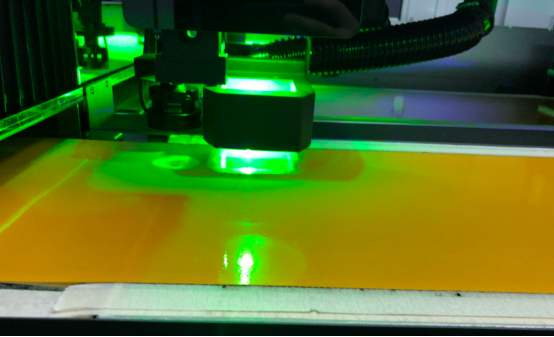

PCB Fabrication – The bare PCB boards are quickly produced, including drilling, plating, and surface finishing, to ensure they are ready for assembly.

Component Assembly – Components are placed on the PCB using automated pick-and-place machines, which can handle tiny parts with extreme accuracy, even in small spaces.

Soldering – Boards go through reflow ovens or wave soldering machines, melting the solder paste to fix components securely to the board.

Inspection and Testing – Each board is inspected using AOI (Automated Optical Inspection) and sometimes X-ray inspection for hidden solder joints. Functional tests ensure the board works exactly as it should before shipping.

3. Why Quick Turn PCB Assembly is valuable

Rapid Prototyping – Quickly creating a working prototype to test ideas and catch design issues early.

High-Speed Mass Production – Producing larger quantities efficiently without losing precision or quality.

Quick Turn Business Value – Accelerating product launch, reducing delays, and maintaining competitiveness in the market.

In the following sections, we will take a closer look at each of these aspects, explaining how they work and why they are essential for companies looking to bring products to market faster.

Rapid Prototyping: Testing Ideas Quickly

Rapid Prototyping is the process of creating a working version of a PCB or electronic product very quickly, often within a few days. This step is critical for engineers, designers, and companies, because it allows them to see, test, and improve their ideas before committing to full-scale production.

1. How Rapid Prototyping Helps R&D Teams

Testing Designs Early: Engineers can check if the circuits and components work as intended. This goes beyond simulations or drawings—it shows how the real product behaves.

Finding and Fixing Mistakes Quickly: Small issues like a misconnected circuit, incorrect component placement, or incompatible parts can be spotted and corrected before expensive production.

Experimenting with New Ideas: Teams can try different layouts, materials, or features on the prototype, which encourages innovation without high risk.

2. Reducing Costs and Time

Catching Errors Early: Fixing problems in the prototype stage is much cheaper than after mass production, where mistakes can affect hundreds or thousands of boards.

Avoiding Delays: Rapid prototyping helps avoid production delays caused by unexpected design flaws, keeping the product launch on schedule.

Minimizing Waste: Only a few boards are produced initially, so materials and labor are used efficiently, reducing unnecessary costs.

3. Advantages for Startups and Innovative Projects

Fast Feedback: Startups can show prototypes to customers, investors, or partners to get feedback and make improvements quickly.

Lower Risk: Small companies often have limited budgets. Rapid prototyping allows them to test ideas without committing to a large, expensive production run.

Accelerating Innovation: By testing and iterating rapidly, teams can bring new products to market faster than competitors.

High-Speed Mass Production: Producing Large Quantities Quickly

Quick Turn PCB Assembly is a process that helps companies get their PCBs designed, built, and delivered much faster than traditional methods. This is important in today’s fast-moving electronics market, where speed can make a big difference.

1. Automated SMT Machines Increase Production Efficiency

Modern SMT Equipment: Automated Surface Mount Technology machines can place thousands of tiny components on a PCB in just minutes.

Precision and Speed: These machines are faster than humans and reduce errors, ensuring that even very small or delicate parts are positioned correctly.

Continuous Operation: Machines can work for long periods without fatigue, producing large volumes of boards consistently.

2. Quick Batch Delivery Shortens Production Cycles

Organized Workflow: Boards move through assembly, soldering, and testing in a streamlined process, minimizing idle time.

Faster Reflow and Soldering: Reflow ovens heat the boards uniformly, fixing all components quickly and reliably.

Reduced Lead Time: By shortening each step, companies can produce boards much faster than traditional methods, meeting tight deadlines.

3. Positive Impact on Supply Chains and Customer Satisfaction

Reliable Delivery: Fast production allows companies to fulfill orders on time, preventing delays in the supply chain.

Customer Confidence: When customers receive high-quality boards quickly, they trust the company more and are more likely to return.

Flexible Response to Demand: High-speed mass production makes it easier to adjust quantities quickly based on changing market needs.

Cost Efficiency: Automation and faster processes reduce labor and waste, saving money while maintaining high quality.

Business Value: Bringing Products to Market Faster

Quick Turn PCB Assembly helps companies not only produce boards faster but also gain significant advantages in the market. By speeding up production and delivery, businesses can make smarter decisions, save money, and get ahead of competitors.

1. Gaining Market Advantage

Early Market Entry: By reducing the time from design to delivery, businesses can introduce products before others.

Competitive Edge: Launching quickly helps companies capture market share and establish their brand.

Adaptability: Fast assembly makes it easier to respond to customer feedback or changes in market demand, keeping products relevant.

2. Shortening Time-to-Market

Rapid Design-to-Delivery Cycle: With fast prototyping, high-speed production, and quick testing, companies can move from idea to finished product in days or weeks.

Faster Product Iterations: If a design needs improvement, it can be updated and re-produced quickly, reducing delays in launching the next version.

Meeting Tight Deadlines: Shorter production cycles help companies release products in time for key events or sales opportunities.

3. Reducing Inventory Pressure and Capital Use

Lower Inventory Requirements: Fast production means companies don’t need to store large amounts of boards, reducing storage costs.

Reduced Capital Lockup: Money is not tied up in unused inventory, which allows better cash flow for other projects.

Minimized Waste: Producing only what is needed, when it is needed, reduces overproduction and material waste.

Typical Applications of Quick Turn PCB Assembly

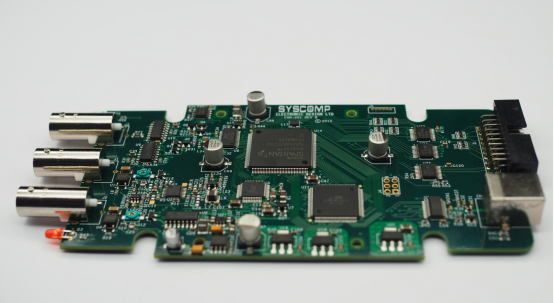

Quick Turn PCB Assembly is used in many types of electronic products. By producing PCBs quickly and reliably, companies can create smaller, smarter, and faster devices for various industries.

1. Consumer Electronics

Devices like smartphones, tablets, and wearable gadgets rely on PCBs for all their functions.

Small and Lightweight Designs: Quick turn assembly allows manufacturers to use tiny components and fit them into compact spaces.

Fast Development: Companies can bring new consumer devices to market quickly, keeping up with trends and customer demand.

2. Medical Devices

Medical electronics, such as monitors, pacemakers, and wearable health trackers, need high precision and reliability.

Critical Accuracy: Every part must be placed correctly to ensure patient safety.

Rapid Prototyping Benefits: Quick turn assembly allows engineers to test and improve designs before producing the final medical device.

Fast Response: Hospitals and healthcare providers can get the devices they need without long delays.

3. Communication Equipment

Routers, 5G base stations, and RF modules require high-performance PCBs with low signal loss.

Reliable Signal Transmission: Accurate placement of components ensures the devices work efficiently and consistently.

Speed to Market: Quick turn assembly helps telecom companies launch new products faster to meet network demands.

4. Industrial and IoT Devices

Industrial sensors, smart controllers, and IoT systems depend on PCBs for reliable operation.

High-Volume Needs: Quick turn assembly supports small pilot runs and rapid scaling for new smart factory or IoT solutions.

Flexibility: Companies can adjust production quickly based on demand or new project requirements.

Stable Operation: Precise assembly ensures that industrial devices work safely and continuously in demanding environments.

Conclusion

Quick Turn PCB Assembly offers important advantages for companies in today’s fast-moving electronics market. By using rapid prototyping and automated production, businesses can move from design to finished boards much faster, reducing time-to-market and helping products reach customers sooner.

This approach is also highly flexible. It works well for prototypes, small batches, or urgent orders, allowing companies to adapt to changing needs and respond quickly to market demand. At the same time, early testing and precise assembly reduce mistakes, prevent production delays, and ensure reliable performance, lowering the risk of costly errors.

In short, Quick Turn PCB Assembly is essential in modern electronics manufacturing. It helps companies stay competitive, deliver high-quality products quickly, and meet customer expectations. If you need fast, reliable PCB assembly services, professional suppliers like PCB MASTER—who excel at small to medium Quick Turn batches—can provide the right solutions.

FAQs

1. Can Quick Turn PCB Assembly handle very complex circuit designs?

Yes. Quick Turn PCB Assembly can work with complex boards, including multi-layer PCBs, high-frequency circuits, and dense component layouts. Automated machines place tiny parts accurately, and advanced inspection methods like AOI and X-ray ensure that even difficult designs are assembled correctly and reliably. This means companies can launch sophisticated electronics quickly without compromising quality.

2. How does Quick Turn PCB Assembly reduce production errors compared to traditional methods?

Quick Turn PCB Assembly uses automated pick-and-place machines, reflow soldering, and continuous inspection. Machines place components precisely, and cameras or X-rays check for mistakes before boards leave the factory. By catching problems early, it reduces the risk of faulty boards, which is much harder to fix in traditional manual assembly.

3. Is Quick Turn PCB Assembly only useful for small companies or prototypes?

No. While it is ideal for rapid prototyping and small batches, Quick Turn PCB Assembly is also valuable for large-scale production. Automated processes and organized workflows allow companies to produce thousands of boards efficiently while maintaining high quality. This flexibility makes it useful for startups and big manufacturers alike.

4. Can Quick Turn PCB Assembly improve product quality, not just speed?

Absolutely. Speed does not mean lower quality. Quick Turn PCB Assembly uses precise component placement, high-quality soldering, and thorough testing. Each board is inspected carefully, and defects are caught early. This ensures that the final products are reliable, durable, and perform as intended, even when produced quickly.

5. How does Quick Turn PCB Assembly help reduce costs for businesses?

It reduces costs in several ways. First, catching design issues early prevents expensive mistakes during mass production. Second, efficient automated production lowers labor costs and material waste. Third, companies don’t need to store large inventories, which frees up money and space. Overall, Quick Turn PCB Assembly helps companies save time, reduce risks, and use resources efficiently.