Why RoHS Printed Circuit Boards Are Essential for Modern Electronics

Behind every sleek gadget and cutting-edge device lies a complex network of components—yet few are as critical to safety and sustainability as the printed circuit board. RoHS-compliant PCBs may not grab headlines, but they quietly ensure that modern electronics meet strict environmental standards while delivering the performance users expect. As the industry pushes toward greener, more reliable technology, understanding why these boards matter has never been more important.

Introduction to RoHS Printed Circuit Boards

Definition of RoHS

RoHS stands for Restriction of Hazardous Substances, a regulation that limits the use of certain toxic materials in electronic and electrical products. The main goal of RoHS is to reduce environmental pollution and protect human health by controlling harmful chemicals in electronics manufacturing.

The substances restricted under RoHS include:

Lead (Pb): Commonly used in solder, but toxic to humans and the environment.

Mercury (Hg): Found in some switches and lighting components; highly hazardous.

Cadmium (Cd): Used in batteries and coatings; can cause severe health issues.

Hexavalent Chromium (Cr6+): Often used in metal plating; carcinogenic.

Polybrominated Biphenyls (PBB) & Polybrominated Diphenyl Ethers (PBDE): Flame retardants that can accumulate in the environment.

RoHS compliance has evolved over time:

RoHS 2 (2011/65/EU): Expanded the original scope to include more products and stricter testing requirements.

RoHS 3 (2015/863/EU): Added four additional restricted substances and updated exemptions.

Example: A PCB manufacturer producing a lead-free circuit board for smartphones must ensure the solder and components contain less than the maximum allowed levels of Pb, Hg, and other restricted substances to be considered RoHS-compliant.

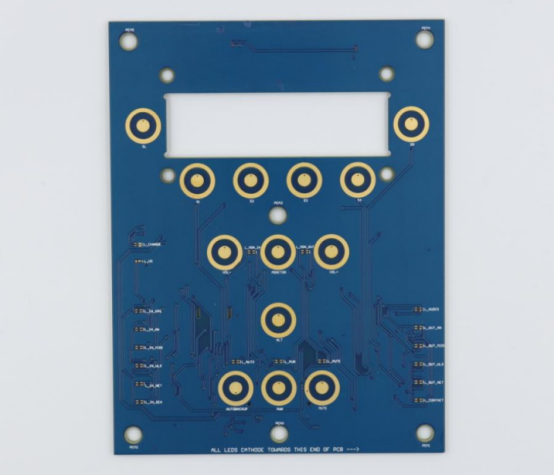

Overview of Printed Circuit Boards (PCBs)

A printed circuit board (PCB) is a flat board that electrically connects electronic components using conductive pathways, pads, and other features etched from copper sheets laminated onto a non-conductive substrate. Essentially, PCBs are the backbone of almost all electronic devices, enabling circuits to function reliably.

Types of PCBs include:

Rigid PCBs: Solid boards that provide a stable structure for complex circuits, commonly used in computers and industrial devices.

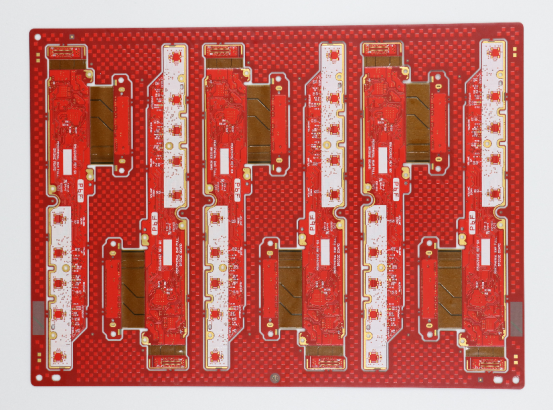

Flexible PCBs (FPCs): Thin, bendable boards ideal for wearable electronics and compact gadgets.

Rigid-Flex PCBs: A hybrid combining both rigid and flexible sections for advanced devices like medical imaging equipment or aerospace electronics.

Example: In a smartphone, the main rigid PCB houses the processor and memory, while flexible PCBs connect buttons, cameras, and sensors without adding bulk.

Why RoHS Compliance Matters in PCBs

RoHS compliance is critical for three main reasons: environmental protection, legal requirements, and consumer safety.

Environmental Impact: Non-compliant PCBs contain toxic metals and flame retardants that can leach into soil and water during disposal or recycling. RoHS-compliant boards reduce pollution and facilitate eco-friendly recycling.

Regulatory Requirements: Many countries enforce RoHS laws, including the European Union, China, and Japan. Non-compliant electronics can face fines, recalls, or bans from international markets.

Consumer Safety: Lead, mercury, and cadmium pose serious health risks. By using RoHS PCBs, manufacturers reduce exposure for both production workers and end-users.

Comparison Example: A standard PCB with lead solder may perform well electrically, but its disposal contributes to soil contamination. A RoHS-compliant PCB eliminates lead, maintaining performance while protecting health and the environment.

Environmental and Health Benefits of RoHS PCBs

Reduction of Toxic Materials

RoHS-compliant PCBs are specifically designed to limit the use of hazardous metals and chemicals that can harm both the environment and human health. By restricting substances such as lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr6+), PBB, and PBDE, RoHS PCBs ensure that electronic devices are safer throughout their lifecycle.

Comparison of Conventional vs. RoHS PCBs:

Conventional PCBs: Often contain lead-based solder, mercury-containing switches, and flame retardants like PBDE, which can accumulate in soil and water after disposal.

RoHS PCBs: Use lead-free solder and alternative materials, drastically reducing toxic metal content and meeting strict environmental standards.

Example: A lead-free RoHS PCB soldered with a tin-silver-copper alloy performs similarly to traditional leaded PCBs while eliminating lead exposure risks during manufacturing and recycling.

Eco-Friendly Manufacturing

RoHS compliance encourages safer and greener production methods for PCBs. Manufacturers must adopt processes that minimize environmental impact and allow easier recycling.

Step-by-step improvements in eco-friendly PCB production:

Material Selection: Use non-toxic laminates and lead-free solder.

Component Assembly: Employ soldering techniques that avoid hazardous fumes.

Testing & Quality Control: Verify RoHS compliance through chemical analysis before shipment.

Recycling and Disposal: End-of-life boards can be recycled more efficiently because toxic metals are minimized.

Example: A factory implementing RoHS processes can safely recover copper and other reusable materials from discarded PCBs without releasing toxic substances into the environment.

Long-Term Health Advantages

RoHS PCBs significantly reduce exposure to harmful substances for both manufacturing workers and end-users. Handling non-compliant PCBs can lead to skin irritation, respiratory issues, or more severe long-term health problems due to metals like lead and cadmium.

Case Example: Workers in electronics assembly lines exposed to lead-based solder have historically shown elevated blood lead levels. Switching to RoHS-compliant, lead-free solder has reduced these health risks dramatically.

Consumer Safety: Devices containing RoHS PCBs lower the chance of heavy metal exposure during normal use or accidental damage. For instance, children handling RoHS-compliant toys or electronic devices are less likely to come into contact with toxic substances.

Technical Advantages of RoHS PCBs

High Reliability and Durability

RoHS-compliant PCBs use lead-free solder and carefully selected materials, which can improve the long-term reliability and durability of electronic circuits. Lead-free solders often have higher melting points, which can reduce the risk of solder joint degradation under prolonged heat exposure.

Comparison: Lead-Free vs Leaded Solder Performance

Leaded Solder: Easier to work with and slightly more ductile, but susceptible to tin whiskers and long-term corrosion.

Lead-Free Solder: Slightly harder to process, but forms stronger, more stable joints under thermal stress, reducing failures in high-temperature applications.

Example: In automotive electronics, RoHS PCBs using tin-silver-copper (SAC) lead-free solder have shown longer operational lifespans under engine heat compared to leaded alternatives.

Thermal and Electrical Performance

One concern with RoHS compliance is that lead-free solder has different thermal and electrical characteristics than traditional leaded solder. Lead-free joints can be less forgiving during thermal cycling, potentially leading to cracking if not designed properly.

Mitigation Methods and Design Adjustments:

Increase Pad Size: Larger solder pads improve mechanical strength.

Optimize Trace Widths: Wider traces reduce current density and thermal stress.

Use Appropriate Solder Alloys: Tin-silver-copper (SAC) is common for high-reliability applications.

Thermal Management: Add heat sinks or copper pours to disperse heat effectively.

Step-by-Step Guidance:

1. Evaluate operating temperatures of the PCB

2. Select a lead-free solder alloy compatible with components.

3. Adjust pad sizes and spacing to accommodate higher melting points.

4. Test prototypes under thermal cycling to ensure durability.

Example: High-speed communication boards use these design adjustments to maintain signal integrity while complying with RoHS.

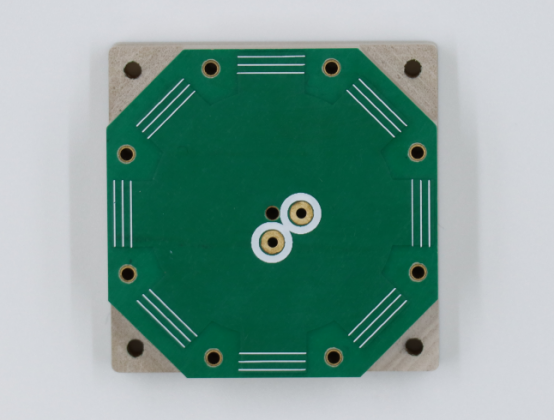

Compatibility with Modern Electronics

RoHS PCBs are well-suited for modern electronics, including smartphones, IoT devices, wearables, and medical equipment. Compliance ensures these boards can meet both regulatory standards and performance demands without compromising device miniaturization or complexity.

High-Tech Applications:

Smartphones: Flexible RoHS PCBs connect components like cameras and sensors without adding bulk.

IoT Devices: Small, lead-free boards integrate sensors and processors safely for home automation.

Medical Electronics: Pacemakers and diagnostic devices use RoHS-compliant PCBs to avoid toxic material exposure while maintaining precision and reliability.

Automotive Electronics: Electric vehicles rely on RoHS boards for battery management and power control.

Example: A wearable health tracker uses a flexible RoHS PCB to connect multiple sensors while ensuring the device remains lightweight, non-toxic, and durable under daily use.

Choosing the Right RoHS PCB Manufacturer

Quality Standards and Certifications

When selecting a RoHS PCB manufacturer, it is essential to prioritize quality standards and certifications. Reputable manufacturers adhere to internationally recognized standards to ensure compliance, reliability, and safety.

ISO Certifications: ISO 9001 ensures consistent quality management systems, while ISO 14001 focuses on environmental management practices.

IPC Standards: IPC-A-600 and IPC-6012 set requirements for PCB workmanship, acceptability, and performance.

RoHS Documentation: Manufacturers must provide clear RoHS compliance certificates and material declarations for each batch of PCBs.

Example: A manufacturer with ISO 9001 and IPC-certified processes guarantees that every RoHS PCB meets both environmental and technical standards, reducing risks of non-compliance.

Evaluating Manufacturing Processes

A reliable RoHS PCB manufacturer follows a structured process to maintain quality and compliance. Key steps include:

1. Material Sourcing: Use certified lead-free laminates and components that comply with RoHS limits.

2. Lead-Free Soldering: Employ tin-silver-copper (SAC) or other approved lead-free solder alloys.

3. Assembly and Testing: Conduct electrical and mechanical tests, including thermal cycling, to verify durability.

4. Final Inspection & Documentation: Ensure RoHS certification and traceability for all batches.

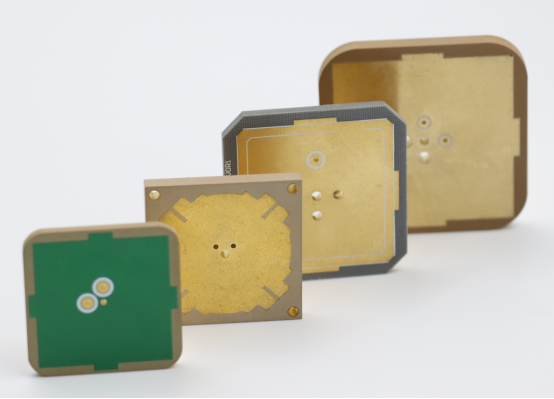

Examples of Advanced RoHS PCB Technologies:

ENIG (Electroless Nickel Immersion Gold): Provides excellent corrosion resistance and surface flatness for fine-pitch components.

OSP (Organic Solderability Preservative): Protects copper pads and maintains lead-free solderability.

Example: A high-speed communication PCB using ENIG finish ensures reliable signal integrity while remaining fully RoHS-compliant.

Cost Considerations and ROI

While RoHS PCBs may have slightly higher initial costs due to lead-free materials and stricter quality control, the long-term benefits outweigh the expense.

Initial Cost vs Long-Term Benefits: Reduced risk of recalls, fines, and regulatory issues; improved product reliability; and alignment with global market demands.

Case Study: A consumer electronics company switched to RoHS-compliant PCBs and avoided potential EU market fines, while also reducing waste disposal costs by 20%.

Example: Investing in higher-quality RoHS PCBs reduces long-term operational risks and supports sustainable manufacturing practices.

PCBMASTER: Advanced RoHS PCB Solutions

PCBMASTER specializes in high-performance, fully RoHS-compliant PCBs. Key advantages include:

Strict adherence to IATF 16949, ISO 9001, and UL Certification.

Advanced technologies like ENIG, OSP, and high-layer-count PCBs.

Robust quality control and traceable RoHS documentation for every order.

Cost-effective solutions with an emphasis on long-term reliability and regulatory compliance.

Example: PCBMASTER provides RoHS PCBs for complex applications such as medical devices, automotive electronics, and high-speed communication boards, ensuring both compliance and performance.

Conclusion

RoHS-compliant PCBs are essential for modern electronics, combining environmental safety, technical reliability, and regulatory compliance. They reduce hazardous substances like lead and mercury, support durable and high-performance circuits, and ensure global market access.

For designers and manufacturers, adopting RoHS PCBs means safer, more sustainable products and long-term reliability while avoiding fines or recalls. Companies that integrate RoHS-compliant boards gain a competitive edge and meet growing consumer demand for eco-friendly electronics.

The message is clear: prioritize RoHS PCBs to create innovative, safe, and environmentally responsible devices.

FAQs

1. What types of electronics require RoHS-compliant PCBs?

RoHS-compliant PCBs are required in virtually all electronic and electrical products sold in regulated markets, including:

Consumer electronics: Smartphones, laptops, tablets, and wearable devices.

Medical devices: Pacemakers, diagnostic equipment, and monitoring systems.

Automotive electronics: Electric vehicle controllers, infotainment systems, and battery management boards.

Industrial electronics: Robotics, automation controls, and communication equipment.

Essentially, any device containing printed circuit boards and sold in regions enforcing RoHS, such as the EU, China, or Japan, must comply.

2. How does RoHS compliance affect PCB cost and performance?

Cost: RoHS PCBs can have slightly higher upfront costs due to lead-free materials and stricter manufacturing standards.

Performance: Lead-free solder has a higher melting point, which can affect thermal handling. However, proper design adjustments—like optimized pad sizes, trace widths, and heat management—ensure equal or even improved durability and reliability.

Long-term benefits: Reduced risk of recalls, compliance fines, and environmental penalties often outweigh the initial cost difference.

3. Can RoHS PCBs be recycled more efficiently than traditional PCBs?

Yes. By limiting hazardous substances such as lead, mercury, and cadmium, RoHS PCBs reduce toxic waste during disposal. This allows for:

Safer material recovery, including copper, gold, and other metals.

Lower environmental contamination during recycling.

Compliance with stricter e-waste management regulations, making recycling processes safer and more cost-effective.

4. What is the difference between RoHS 2 and RoHS 3 standards?

RoHS 2 (2011/65/EU): Expanded the original directive to include more types of electronic equipment and mandatory testing for restricted substances.

RoHS 3 (2015/863/EU): Added four additional restricted substances and updated exemptions while maintaining the limits on lead, mercury, cadmium, hexavalent chromium, PBB, and PBDE.

Key takeaway: RoHS 3 is essentially an update that tightens and broadens compliance requirements for modern electronics.

5. How can small electronics manufacturers ensure RoHS compliance?

Material Sourcing: Use certified lead-free components and laminates.

Partner with compliant PCB manufacturers: Ensure all boards come with valid RoHS documentation and testing reports.

Testing & Verification: Perform in-house or third-party tests for restricted substances.

Documentation & Traceability: Keep records of materials, certificates, and manufacturing processes to demonstrate compliance to regulators.

Continuous Updates: Stay informed about changes in RoHS regulations and exemptions, including RoHS 2 and RoHS 3 updates.