Differences Between Lead-Free and Leaded Solder Paste in SMT Manufacturing

Introduction

What are the differences between lead-free solder paste and leaded solder paste in SMT manufacturing? The differences lie in their composition, melting points, mechanical properties, environmental impact, and cost. This article will help you understand these aspects to make the best choice for your process.

Key Takeaways

Lead-free solder paste primarily consists of tin-silver-copper alloys, while leaded solder paste is based on a tin-lead composition, with significant implications for environmental safety and manufacturing processes.

Lead-free solder has higher melting points and greater tensile strength, but may also lead to brittleness and increased likelihood of failure in thermal cycling compared to leaded solder.

Compliance with international regulations such as RoHS is driving the transition to lead-free solder, necessitating adaptations to soldering processes and equipment in SMT manufacturing.

Composition of Lead-Free and Leaded Solder Paste

The composition of solder paste significantly impacts the soldering process and the final product’s quality. Lead-free solder paste primarily consists of tin-silver-copper (SAC) alloys, with SAC 305 being a common variant. SAC 305 is composed of 96.5% tin, 3% silver, and 0.5% copper, a combination designed to provide good thermal and mechanical properties while minimizing environmental impact.

In contrast, leaded solder paste typically comprises a tin-lead alloy, commonly in a 60:40 ratio. The primary components are lead and tin, which have been used for decades due to their excellent soldering properties and lower melting points. Despite the benefits, the toxic nature of lead has led to a significant shift towards lead-free alternatives in many regions.

Furthermore, lead-free solder formulations are continually evolving. Alternatives such as tin-copper metal alloy, which contain 0.7% to 3.0% copper, offer cost-effective solutions for general electrical applications. Tin-bismuth solders, though more brittle, are suitable for low-temperature applications. As the industry seeks to balance performance with environmental responsibility, the development of new lead-free solder alloys remains a dynamic area of research.

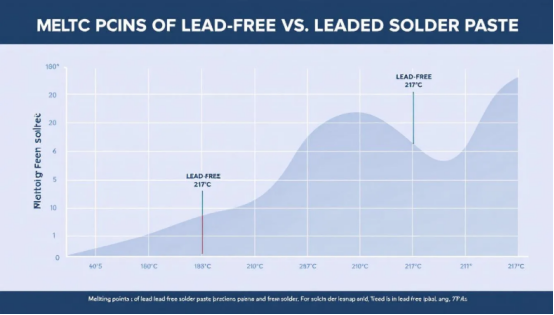

Melting Points of Lead-Free and Leaded Solder Paste

Melting points are crucial in soldering, affecting energy consumption and the integrity of solder joints. Key points include:

·Lead-free solder typically has a melting point range of 217-221°C.

·Lead-based solder melts at a significantly lower temperature of around 183°C.

·This difference necessitates higher reflow temperatures for lead-free soldering.

·Higher reflow temperatures impact the entire manufacturing process.

Higher melting points in lead-free solder often result in stronger, more reliable joints. However, these higher temperatures also introduce additional challenges. For instance, components must withstand the increased thermal stress, and soldering equipment may require adjustments or upgrades to handle the high melting point operational temperatures.

Leaded solder’s lower melting point makes it easier to work with, reducing thermal shock and damage risks to sensitive components. This characteristic has made traditional leaded solder a preferred choice for applications where thermal stress must be minimized. Despite this, the push towards unleaded solder continues, driven by environmental and health considerations. Additionally, lead solder is often compared to lead-free alternatives in terms of performance, particularly when considering leaded solders. Leaded and lead free options are being evaluated for their effectiveness in various applications.

Mechanical Properties of Solder Joints

The mechanical properties of solder joints are critical for the reliability and longevity of electronic assemblies. Lead-free solder joints, particularly those using SAC solder alloy, exhibit 25-35% greater tensile and shear strength compared to traditional leaded solder joints. This increased strength can enhance the overall durability of the soldered connections, making them more resistant to mechanical stress.

However, lead-free solder joints are not without their drawbacks. They tend to form thicker intermetallic compounds during the soldering process, leading to increased brittleness and a higher likelihood of mechanical failure. Additionally, standardized impact tests have shown that typical lead free solder joints typically have a 15-30% higher failure rate compared to their leaded counterparts.

Thermal cycling tests show that lead-free solder joints perform comparably to leaded joints under moderate conditions but often fall short under severe thermal cycling. Rework cycles can degrade the reliability of lead-free joints, reducing their thermal cycling performance. Despite superior creep resistance at room temperature, the microstructural changes in lead-free joints, such as more significant grain coarsening, can compromise long-term reliability.

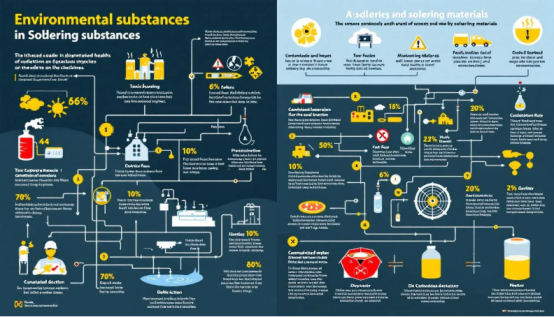

Environmental and Health Impacts

Using lead-based solders has significant environmental and health risks. Lead is a documented health hazard, causing developmental issues in children, neurological impairment, and even cancer, including lead poisoning. This toxic nature of lead is a primary concern, driving the shift towards lead-free alternatives in electronics manufacturing.

Lead solder’s disposal and recycling pose additional environmental threats, potentially leading to soil and water contamination. Regulatory efforts, such as the Restriction of Hazardous Substances (RoHS) directive, aim to reduce the use of hazardous substances like lead in electronic products. These regulations have accelerated the transition to lead-free soldering, enhancing product safety and reducing environmental impact.

Switching to lead-free solder aligns with environmental protection goals and improves worker safety by eliminating exposure to toxic lead. As bans on leaded solder become standard in consumer electronics, the industry continues to innovate and adopt safer, more sustainable practices.

Cost Considerations in SMT Manufacturing

Cost is a critical factor in adopting lead-free solder paste in SMT manufacturing. Lead-free solder pastes are generally more expensive due to the higher cost of raw materials like silver and the need to meet stringent environmental regulations. The price of silver, for instance, exceeds $750 per kilogram, significantly impacting the overall cost of lead-free solder paste.

Moreover, the higher melting temperatures required for lead-free soldering can increase energy consumption during the soldering process, adding to operational costs. Recalibrating soldering equipment and potentially upgrading to handle the higher temperatures also incurs additional expenses. However, bulk purchasing of solder paste can help mitigate some of these costs, making it a more viable option for large-scale manufacturers.

Price fluctuations in the market can further affect the cost of solder paste, influenced by factors such as supply and demand, brand, packaging, and whether the paste meets environmental standards. Manufacturers must carefully consider these variables when selecting soldering materials to balance cost-effectiveness with compliance and performance.

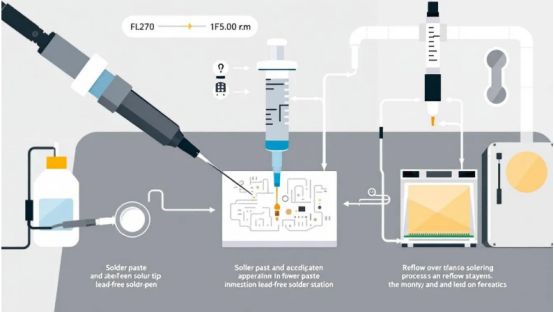

Soldering Process Adaptations for Lead-Free Solder Paste

Adapting the soldering process for lead-free solder paste requires several key changes. Lead-free soldering generally requires higher reflow temperatures, which can introduce additional thermal stress on components. This necessitates the development of customized thermal profiles for reflow ovens to ensure proper soldering without damaging the components.

Recalibrating soldering equipment is necessary to accommodate the higher temperatures needed for lead-free alloys. Additionally, the introduction of nitrogen in the reflow soldering process can greatly enhance the quality of solder joints by minimizing oxidation, which is crucial for achieving reliable connections.

Operators involved in lead-free soldering need specialized training to understand the unique requirements and potential defects of these processes. Components must be rated for higher temperatures, and storage conditions of solder paste must be carefully controlled to maintain performance and stability.

Surface Tension and Wettability

Surface tension and wettability are vital factors in forming strong solder joints. Lead-free solder exhibits higher surface tension compared to leaded solder, which can affect its ability to create reliable connections. This higher surface tension can lead to less effective wetting of the metal surface, posing challenges in achieving high-quality solder joints.

Specific flux formulations are often needed to improve the wettability of lead-free solders through hole soldering. Understanding and managing these properties is essential in surface mount technology, where the reliability of solder joints directly impacts the performance of electronic devices.

Longevity and Reliability of Solder Joints

The long-term reliability of solder joints is a significant concern in electronics manufacturing. Lead-free solder joints can experience increased brittleness and more severe crack formation, especially under thermal cycling conditions. This brittleness is often due to intermetallic compounds, which can compromise the solder joint reliability and mechanical strength of the joints.

Innovative lead-free solders like Innolot and SB6NX demonstrate improved thermal cycling performance, whereas traditional SAC305 solder can suffer significant degradation in maximum shear force after multiple thermal cycles. These issues highlight the need for ongoing research and development to enhance the reliability of lead-free solder joints in extreme conditions, including the use of eutectic alloy formulations.

Despite these challenges, lead-free solders provide better environmental and health benefits, making them a preferred choice in many applications. Balancing these benefits with the need for reliable joints is a key focus for the industry.

Practical Challenges in Using Lead-Free Solder Paste

Lead-free solder paste presents several practical challenges. The higher melting point of lead-free solder makes it more difficult to work with, requiring adjustments in the PCB layout to prevent damage to components. Higher temperatures also increase the risk of thermal fatigue in solder joints, potentially compromising their long-term reliability.

Lead-free solder tends to have a different viscosity compared to leaded solder, affecting the overall flow during the soldering process. This can lead to issues like cold solder joints and signal integrity problems in high-frequency applications. These factors must be carefully considered to ensure successful implementation of lead-free soldering techniques.

Compliance with International Regulations

International regulations drive the shift to lead-free solder. The RoHS directive, introduced by the EU in 2006, mandates the reduction of hazardous substances like lead in electronic products and electrical and electronic equipment. This hazardous substances directive aims to protect human health and the environment by limiting the use of toxic materials in the electronics industry and electronics manufacturing.

The WEEE directive complements RoHS by ensuring proper disposal and recycling of electronic waste, further reducing environmental impact. Manufacturers must adapt their practices to include lead-free soldering techniques to meet regulatory requirements and access international markets. Compliance involves not only adhering to laws but also coordinating with PCB manufacturers to ensure material compliance.

Summary

The comparison between lead-free and leaded solder paste highlights the complexities involved in choosing the right materials for SMT manufacturing. While lead-free solder offers significant environmental and health benefits, it also presents challenges such as higher costs, increased thermal stress, and potential reliability issues. On the other hand, leaded solder, with its lower melting points and excellent mechanical properties, remains a reliable choice in certain applications.

Ultimately, the choice between lead-free and leaded solder depends on multiple factors, including regulatory compliance, cost considerations, and the specific requirements of the electronic products being manufactured. As the industry continues to innovate, finding the right balance will be key to achieving both high performance and sustainability in electronics manufacturing.

FAQs

Q.What type of solder paste for SMT?

A.For surface mount technology (SMT), solder pastes with Type 3 and Type 4 particle sizes are recommended, as they are reliable and widely available, making them suitable for most applications. Using these types helps minimize defects like solder balling.

Q.What is the difference between leaded and lead-free solder paste?

A.Leaded solder tends to cause issues such as voids and fillet lifting during application, whereas lead-free solder provides stronger bonds and minimizes stencil wear, resulting in better performance for PCBs in electronics. Therefore, lead-free solder is generally considered the superior choice for modern applications.

Q.What are the main components of lead-free solder paste?

A.Lead-free solder paste mainly consists of tin-silver-copper (SAC) alloys, often featuring SAC 305, which is composed of 96.5% tin, 3% silver, and 0.5% copper. This composition ensures effective soldering while eliminating the use of lead.

Q.Why is leaded solder still used despite its health risks?

A.Leaded solder continues to be utilized due to its advantageous lower melting point, which facilitates easier application and lessens thermal stress on components, alongside its superior mechanical properties and reliability.

Q.What are the environmental benefits of using lead-free solder?

A.Using lead-free solder significantly decreases the risk of lead poisoning and enhances worker safety while ensuring compliance with environmental regulations such as RoHS, thereby promoting a healthier ecosystem.

Author: Jack Wang