Unlocking the Power of Rogers PCBs in High-Frequency Applications

High-frequency electronics are transforming the future of technology, powering innovations like 5G, radar, and satellite systems. These systems rely on fast, stable signal transmission at gigahertz (GHz) frequencies, which is crucial for achieving ultra-fast speeds and reliable communication. However, as technology advances, the materials used in traditional PCBs, like FR-4, struggle to meet these demanding needs.

At high frequencies, FR-4 materials face significant issues—signal loss and impedance instability. These problems can lead to weak signals, slow speeds, and unreliable connections, which are unacceptable for critical systems like 5G networks and radar. Simply put, standard PCBs aren’t built for the complexities of next-gen technologies.

Enter Rogers PCBs: specially designed to handle the high-frequency demands of modern electronics. With low signal loss, stable impedance, and excellent performance even at GHz frequencies, Rogers materials are the key to unlocking faster, more reliable communication. Whether it’s for 5G, radar, or satellite systems, Rogers PCBs offer the performance needed to keep these technologies running at their best.

What Are Rogers PCBs?

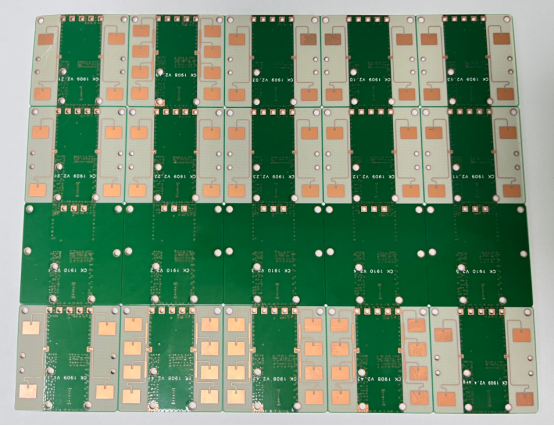

Rogers PCBs (Printed Circuit Boards) are specialized circuit boards designed to handle high-frequency signals with minimal signal loss. Unlike regular PCBs, which are often made from materials like FR-4, Rogers PCBs use advanced laminates that allow them to perform well at frequencies in the gigahertz (GHz) range. These materials are essential for modern technologies like 5G, radar, and satellite communication, where signal integrity and speed are critical.

The performance of Rogers PCBs depends on key characteristics that affect their ability to handle high-frequency signals effectively.

Dielectric Constant (Dk) and Loss Tangent (Df): Dk refers to how much a material can store electrical energy, while Df measures how much energy is lost as heat when a signal passes through. For high-frequency performance, Rogers materials feature low Dk and ultra-low Df. This means the signal experiences less energy loss and maintains higher integrity as it travels through the PCB. For example, the RO4835 laminate has a Df as low as 0.003, making it ideal for high-speed communication systems.

Thermal Conductivity and Stability: Rogers PCBs are known for their excellent thermal properties, which are crucial in extreme environments like automotive or aerospace applications. Materials like RT/duroid 5880 have high thermal conductivity, meaning they can efficiently dissipate heat, preventing overheating. This thermal stability ensures that Rogers PCBs remain reliable even in high-temperature conditions, such as in automotive radar or satellite communication systems.

These properties make Rogers PCBs not only suitable for high-frequency electronics but also reliable in harsh and demanding conditions.

Why Rogers PCBs Are Superior for High-Frequency Applications

Rogers PCBs stand out for their ability to handle high-frequency signals much better than traditional PCBs like FR-4. This makes them ideal for modern technologies that rely on fast and reliable signal transmission, such as 5G, radar, and satellite systems.

Key Performance Advantages Over FR-4

Reduced Signal Loss at High Frequencies

One of the biggest advantages of Rogers PCBs over FR-4 is their ability to reduce signal loss. As signals travel at high frequencies (like 28 GHz for 5G), materials like FR-4 cause significant attenuation, which weakens the signal and lowers performance. In contrast, Rogers materials like RO4835 are engineered to minimize signal loss. For example, RO4835 at 28 GHz shows significantly lower attenuation compared to FR-4, making it a better choice for high-speed applications where maintaining signal integrity is critical.

Impedance Stability

Impedance refers to the resistance a signal faces as it travels along the PCB. Maintaining stable impedance is essential for ensuring that signals don’t get reflected or distorted, which can cause errors. Rogers PCBs excel in this area due to their tight dielectric constant (Dk) tolerances, often as low as ±0.05. This stability ensures minimal reflection and consistent signal transmission, even at high frequencies, which is a major improvement over the variability found in FR-4 materials.

Real-World Performance Impact

Extended Range for 5G mmWave Base Stations

Rogers PCBs significantly improve the performance of 5G mmWave base stations. These base stations use higher frequencies (often above 24 GHz) to provide ultra-fast wireless connectivity. Due to the low signal loss and stable impedance of Rogers materials, base stations equipped with Rogers PCBs can transmit signals over longer distances with less degradation. This results in increased coverage and more reliable connections, which is especially important in dense urban environments where 5G signals need to travel through various obstacles.

Improved Throughput and Reliability

Rogers PCBs are also crucial for supporting high-speed data throughput, particularly in 5G systems. For example, a 5G base station using Rogers materials can handle data rates of 8 Gbps over a distance of 1 km, ensuring high-speed connectivity even in challenging conditions. The low signal loss and minimal distortion provided by Rogers materials contribute to a more reliable and faster connection, which is essential for delivering the high-performance capabilities promised by 5G networks.

By reducing signal loss, ensuring impedance stability, and improving real-world performance like extended range and throughput, Rogers PCBs are the ideal solution for high-frequency applications, ensuring next-generation technologies work at their best.

Rogers PCB Materials Breakdown

Rogers PCBs are made from different types of specialized materials, each tailored to specific applications in high-frequency electronics. These materials offer distinct advantages, such as low signal loss, thermal stability, and high performance at various frequencies. Let’s take a look at the key Rogers materials.

Detailed Analysis of Key Materials

RO4835

RO4835 is an excellent choice for 5G base stations and automotive radar systems, supporting frequencies up to 60 GHz. It offers low dielectric loss (Df), meaning it causes very little signal attenuation, and it also has strong thermal stability. This makes RO4835 ideal for high-speed, high-frequency applications where both signal quality and reliability in challenging environments are crucial. For example, it is used in the 5G networks to ensure that signals maintain strength over longer distances and in dense environments.

RO4350B

RO4350B is a versatile material commonly used in Wi-Fi 6E routers and Internet of Things (IoT) devices. It supports frequencies up to 30 GHz, making it a great choice for these mid-range applications. RO4350B offers a balanced combination of performance and cost, making it an affordable yet efficient option for consumer electronics. This material is known for its good signal integrity and moderate thermal stability, making it a popular choice for devices that don’t require the extreme performance of higher-end materials.

RT/duroid 5880

RT/duroid 5880 is a premium material designed for satellite radar systems. It supports frequencies up to 110 GHz and is well-known for its ultra-low Df, which minimizes signal loss even at extremely high frequencies. This material is typically used in demanding applications, such as high-performance communication systems in aerospace or defense, where both signal quality and reliability are essential. Its exceptional performance at frequencies above 100 GHz makes it the ideal choice for cutting-edge technology.

Ultralam 3850

Ultralam 3850 is a high-performance material used for high-power RF applications. It supports power levels up to 100W, making it ideal for amplifiers, industrial systems, and other power-hungry applications. Ultralam 3850 is designed to handle high frequencies while maintaining low loss and providing excellent thermal stability. Its ability to withstand high power makes it suitable for industrial that need to operate reliably under extreme conditions.

Summary table

| Applications | Frequency Range | Key Features | Typical Uses | ||

| RO4835 | 5G base stations, automotive radar systems | Up to 60 GHz | Low dielectric loss (Df), strong thermal stability, minimal signal attenuation | High-speed, high-frequency applications (e.g., 5G) | ||

| RO4350B | Wi-Fi 6E routers, IoT devices | Up to 30 GHz | Good signal integrity, moderate thermal stability, cost-effective | Consumer electronics, mid-range frequency applications | ||

| RT/duroid 5880 | Satellite radar systems | Up to 110 GHz | Ultra-low Df, exceptional performance at high frequencies, high reliability | Aerospace, high-performance communication | ||

| Ultralam 3850 | High-power RF applications, amplifiers | Supports up to 100W |

| Industrial systems, high-power RF applications |

Application-Based Selection

When choosing the right Rogers PCB material for a specific application, it is essential to match the laminate with the frequency and power requirements of the design.

For instance, RO4835 is perfect for 5G base stations that operate around 28 GHz. Its low loss and thermal stability ensure optimal performance in dense urban environments where high-frequency signals need to travel over longer distances without degradation. On the other hand, for applications like satellite communication, where frequencies reach up to 110 GHz, RT/duroid 5880 is the better choice due to its ultra-low Df and exceptional performance at these extreme frequencies.

When working with devices that operate at frequencies up to 30 GHz, such as Wi-Fi 6E routers or IoT devices, RO4350B strikes the right balance between cost and performance. It’s ideal for applications that need reliable performance without the high cost associated with higher-end materials like RT/duroid 5880.

Finally, for high-power RF applications such as industrial amplifiers or systems requiring up to 100W of power, Ultralam 3850 is the optimal material. Its ability to handle high power while maintaining low loss and thermal stability makes it the best choice for these demanding systems.

By selecting the right Rogers PCB material for each application, you can ensure maximum performance, efficiency, and reliability in high-frequency designs.

Key Advantages of Rogers PCBs for High-Frequency Designs

Rogers PCBs are designed to meet the demanding needs of high-frequency applications like 5G, radar, and satellite systems. These boards offer significant advantages in terms of signal integrity, thermal performance, and environmental resistance, making them ideal for use in complex, high-speed systems.

Signal Integrity in GHz Range

Insertion Loss and Signal Dispersion

Rogers PCBs are engineered to minimize signal loss and dispersion, even at multi-Gbps speeds. In high-frequency applications, signals lose power as they travel through the PCB, a phenomenon called "insertion loss." Rogers materials, such as RO4835, reduce this loss, ensuring that signals remain strong and clear. This is critical for applications like 5G, where data must be transmitted quickly and without degradation. By minimizing insertion loss, Rogers PCBs help maintain high-quality, high-speed connections.

Electromagnetic Interference (EMI) Reduction

Rogers PCBs also help reduce electromagnetic interference (EMI), which can distort signals and cause errors in communication. The dense, uniform structure of Rogers materials reduces radiation and cross-talk between signal traces. This ensures that the signals stay clear, even in complex systems with many components. For example, in automotive radar or satellite communication, where multiple signals are transmitted in close proximity, Rogers materials help prevent unwanted interference, ensuring reliable performance.

Thermal and Mechanical Performance

High-Temperature Performance

One of the key advantages of Rogers PCBs is their ability to withstand higher operating temperatures than standard materials like FR-4. In industries like automotive and aerospace, electronic components are often exposed to extreme heat. Rogers laminates, such as RO4835, can endure temperatures up to 280°C without losing performance. This makes them ideal for applications where high temperatures are a concern, ensuring that the PCB will remain reliable even in harsh environments.

Dimensional Stability Under Thermal Cycling

Rogers materials also perform well under temperature fluctuations, a critical factor in many industrial and automotive applications. The lower coefficient of thermal expansion (CTE) of Rogers laminates means they experience less expansion and contraction when exposed to temperature changes. This ensures that the PCB remains stable and functional, even when exposed to the heat and cold cycles that occur in environments like engines or outdoor equipment.

Environmental Resistance

Moisture Resistance

Rogers PCBs are highly resistant to moisture, which can affect the performance of traditional PCBs. Moisture absorption can lead to shifts in the dielectric constant (Dk), which can disrupt signal transmission. Rogers laminates absorb minimal moisture, ensuring that their performance remains stable even in high-humidity environments. This is especially important for outdoor applications like 5G small cells, which must operate in all kinds of weather conditions. By resisting moisture, Rogers materials ensure long-lasting performance and reliability in challenging environments.

In summary, Rogers PCBs offer several key advantages for high-frequency designs, including enhanced signal integrity, excellent thermal performance, and superior environmental resistance. These properties make Rogers materials the ideal choice for demanding applications in 5G, radar, automotive, aerospace, and other industries that rely on high-speed, reliable electronic systems.

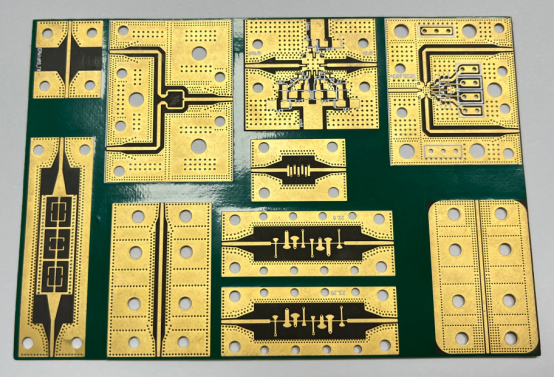

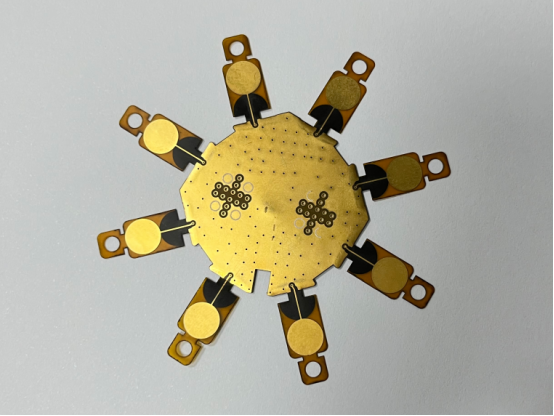

Design Flexibility with Rogers PCBs

Rogers PCBs offer significant design flexibility, making them ideal for advanced applications like radar systems, 5G beamforming, and compact electronics. Their ability to support complex, high-density designs allows engineers to create efficient, high-performance systems, even in tight spaces. This flexibility is a key advantage when working with cutting-edge technologies that demand precision and compactness.

Advanced Routing Capabilities

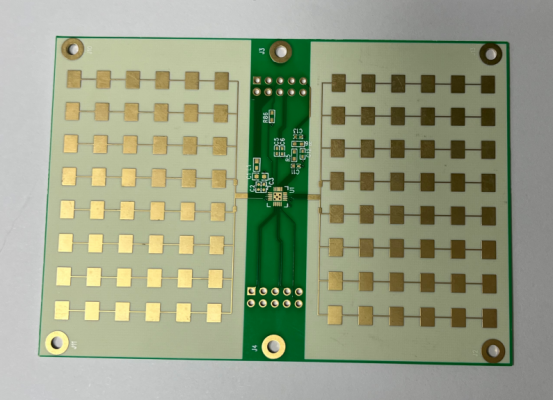

Fine-Pitch Routing and Microvia Compatibility

Rogers PCBs support fine-pitch routing and microvias, which are essential for dense, high-frequency designs. Fine-pitch routing refers to the ability to place smaller and more precise traces on the PCB, allowing for more components to fit in a smaller area. This is critical for applications like radar arrays or 5G beamforming integrated circuits (ICs), where signal integrity and high precision are essential. Microvias are tiny holes drilled in the PCB to connect different layers, enabling complex designs with high-density routing. For example, in 5G technology, microvias allow for smaller, more efficient designs while maintaining signal clarity, which is key for fast, high-frequency communication.

Hybrid Stackups

Rogers PCBs offer the option of hybrid stackups, where Rogers laminates are combined with standard materials like FR-4. Hybrid stackups allow engineers to optimize their designs by balancing cost and performance. For example, while Rogers materials may be used for the high-frequency layers of a PCB to ensure signal integrity, FR-4 can be used for the lower-frequency layers, reducing overall costs without sacrificing performance. This combination is commonly used in applications like Wi-Fi routers or IoT devices, where high-frequency performance is needed, but cost considerations are important.

Integration with Complex Systems

HDI Designs for Compact Form Factors

Rogers PCBs are ideal for high-density interconnect (HDI) designs, which are used to create compact, high-performance PCBs with reduced size and complexity. HDI designs use advanced techniques like microvias, fine-pitch routing, and stacked vias to fit more components into a smaller space. This makes them perfect for applications where space is limited, such as wearable devices, smartphones, and compact radar systems. Rogers materials ensure that these high-density designs maintain high signal integrity, even at high frequencies, making them suitable for cutting-edge technology.

For example, in the aerospace industry, HDI designs using Rogers materials can fit complex radar systems into smaller spaces while ensuring that the system operates at high frequencies without signal degradation. This capability reduces the overall size of the system, making it more efficient and cost-effective.

In summary, Rogers PCBs provide the flexibility needed for advanced, high-performance designs. Whether it’s fine-pitch routing, hybrid stackups, or HDI designs, these materials support a wide range of applications that require compact, efficient, and reliable PCBs. This makes Rogers an excellent choice for industries like 5G, radar, aerospace, and beyond.

Conclusion

As technology evolves, Rogers PCBs will remain essential for high-frequency systems, powering faster and more reliable communication from 5G to future 6G networks. These materials are built to handle high-speed signals, ensuring the performance of next-gen technologies.

While Rogers PCBs may have a higher initial cost, the long-term benefits—such as reduced signal loss, stable impedance, and better thermal stability—lead to more reliable and cost-effective systems over time. This makes them a smart investment for industries like telecommunications, aerospace, and automotive.

For those needing high-quality Rogers PCBs, PCBMASTER offers expert production services, delivering reliable, custom solutions for advanced applications. Whether for 5G or radar systems, PCBMASTER ensures precision and performance.

FAQs

Why can't I use FR-4 for 5G mmWave applications?

FR-4 is a commonly used material for standard PCBs, but it becomes unsuitable for high-frequency applications like 5G mmWave (frequencies above 10 GHz) due to its high loss tangent (Df). The Df of FR-4 is relatively high, meaning it causes excessive signal loss as the signal travels through the material. This signal loss, or attenuation, increases with frequency, leading to significant degradation of signal quality, especially at the higher end of the millimeter-wave spectrum used in 5G applications. As a result, FR-4 cannot maintain the high-speed, long-range communication required for 5G, where minimal signal loss and stable impedance are crucial. Rogers materials, such as RO4835, are specifically designed to handle high frequencies with lower Df, allowing for better performance in mmWave applications.

How do Rogers PCBs handle high temperatures?

Rogers PCBs, particularly those made from materials like RO4835, are designed to handle higher operating temperatures compared to traditional FR-4 PCBs. The glass transition temperature (Tg) of Rogers laminates can reach up to 280°C, which is much higher than FR-4's typical Tg of around 130-150°C. This makes Rogers materials more resilient to heat, allowing them to withstand lead-free soldering processes (which often require higher temperatures) and extreme temperature fluctuations in environments like automotive and industrial applications. The ability to maintain reliable performance under high temperatures ensures that Rogers PCBs are suitable for systems that operate in harsh conditions, such as automotive radar or aerospace electronics, where temperature stability is critical.

Are Rogers PCBs cost-effective for high-frequency applications?

While Rogers PCBs are more expensive than FR-4, they offer substantial long-term benefits that make them a worthwhile investment, especially in high-frequency applications. The higher upfront cost of Rogers materials is justified by their superior performance in minimizing signal loss and attenuation, providing impedance stability, and thermal management. These advantages reduce the need for complex designs and expensive compensations in the system, such as additional signal conditioning or power management. Furthermore, Rogers PCBs lower the risk of performance failures, maintenance costs, and long-term system degradation, leading to better reliability and efficiency. In applications like 5G infrastructure and radar systems, where consistent performance is critical, Rogers materials help ensure that the system operates efficiently, reducing overall infrastructure and operating costs over time.

Can Rogers PCBs be used for aerospace systems?

Yes, Rogers PCBs are widely used in aerospace applications, particularly materials like RT/duroid 5880. These materials are specifically designed to meet the demanding requirements of high-frequency communication and radar systems used in aerospace industries. RT/duroid 5880 is known for its ultra-low loss tangent (Df) and stable dielectric constant (Dk), which minimize signal degradation at high frequencies—essential for communication systems and radar applications. These properties make Rogers PCBs ideal for high-frequency radar systems, and satellite communication that need to operate reliably in harsh environments with high-performance requirements. The thermal stability and environmental resistance of Rogers materials also ensure that aerospace systems maintain their functionality even in extreme conditions such as high altitudes, vibrations, or temperature fluctuations.

How do Rogers PCBs reduce signal degradation at high frequencies?

Rogers PCBs significantly reduce signal degradation in high-frequency applications due to their unique material properties, particularly the low loss tangent (Df) and stable dielectric constant (Dk). Df is a measure of how much signal is lost as it passes through the material—lower Df values indicate less signal loss and better high-frequency performance. Rogers materials like RO4835 have an ultra-low Df (typically around 0.003), which helps preserve the integrity of high-frequency signals, even at frequencies exceeding 100 GHz. The stable Dk ensures consistent impedance, which is crucial for maintaining signal clarity and minimizing reflections or distortions. In practical terms, this means that signals transmitted through Rogers PCBs experience much less attenuation and dispersion compared to standard materials like FR-4. As a result, Rogers PCBs are ideal for applications like 5G communication, radar systems, and satellite communication, where reliable, high-speed signal transmission is essential.