How to Reinforce FPCs for Maximum Durability and Tear Resistance

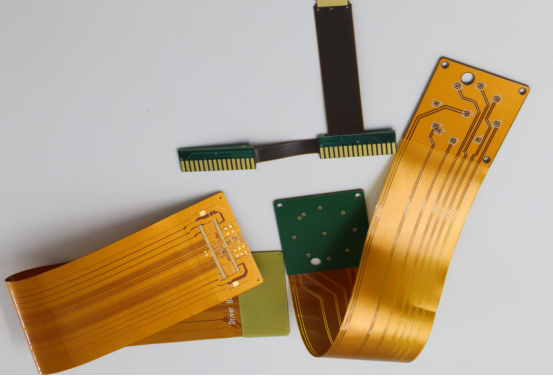

Flexible Printed Circuits (FPCs) are essential components in modern electronics, allowing devices to be compact and flexible. However, their flexibility also makes them vulnerable to tearing, which can lead to costly failures. Tearing in FPCs is one of the leading causes of circuit malfunctions, accounting for up to 50% of FPC failures in some cases. This is especially true in devices that experience frequent bending or flexing, such as smartphones, wearables, and robotics.

Reinforcing FPCs is crucial to prevent these failures. By adding stiffeners, using high-quality adhesives, and designing circuits carefully, manufacturers can significantly extend the lifespan of FPCs. Effective reinforcement not only helps prevent tearing but also improves the overall durability of the circuit, ensuring reliable performance over time. Understanding the risks and implementing proper reinforcement strategies is essential for producing long-lasting, high-quality electronic devices.

Understanding the Vulnerability of FPCs to Tearing

FPCs are incredibly useful in modern electronics due to their ability to bend and fit into compact spaces. However, this flexibility also makes them susceptible to various types of damage, especially tearing. Understanding why FPCs tear and which areas are most vulnerable can help prevent these failures and improve the overall durability of electronic devices.

Common Causes of FPC Tearing

Delamination and Cracks from Bending

FPCs are made up of multiple layers, and repeated bending can cause these layers to separate or crack, leading to delamination. When an FPC is bent beyond its recommended radius, the layers of copper, adhesive, and dielectric material can start to peel apart. This weakens the circuit and may eventually cause it to tear. For example, foldable phones often experience this issue when bent repeatedly at the hinge.

Soldering Defects and Inadequate Adhesives

Poor soldering techniques or the use of weak adhesives can also lead to FPC failure. If there is too much solder on a connection, it can create pressure points that cause tearing. Similarly, if the adhesive used to bond layers or attach components is not strong enough, it can lead to the layers coming apart under stress, resulting in tearing.

Thermal Stress and Oxidation

FPCs are often exposed to temperature fluctuations during use. Repeated heating and cooling (thermal cycling) can cause the materials in the FPC to expand and contract, creating internal stress. Over time, this can lead to cracking or tearing, particularly at weak points like connectors. Oxidation of the copper traces due to heat or exposure to air can also make the FPC more brittle, increasing the likelihood of tearing.

Misalignment and Excessive Strain at Connectors

If components on an FPC are not properly aligned, it can create uneven stress during bending. Connectors, in particular, are vulnerable to this kind of strain. When too much pressure is applied to these areas, it can cause the FPC to tear or break, especially where the connections are made.

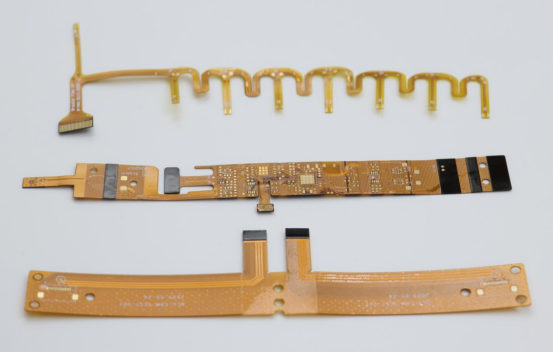

Stress-Prone Areas in FPCs

Delicate Spots Around Bends and Connectors

FPCs tend to tear at the points where they are most stressed—around bends and connectors. These areas often experience the most physical strain, especially in devices that are frequently folded or bent. Without reinforcement, these spots are highly vulnerable to damage, leading to cracks or delamination.

Traces and Vias Under Frequent Flexing or Thermal Cycling

Copper traces, which carry electrical signals, are often at risk of breaking when an FPC is bent or flexed. The bending can cause these traces to crack or break, especially where vias (small holes used for connecting different layers of an FPC) are located. Repeated thermal cycling can also weaken these traces, making them more prone to failure.

The Role of Copper Type (RA vs. ED Copper) in Durability

The type of copper used in an FPC affects its flexibility and durability. Rolled Annealed (RA) copper is more flexible and resistant to cracking, making it ideal for FPCs that experience repeated bending, such as those used in foldable phones. Electrolytic Deposition (ED) copper, on the other hand, is stiffer and more prone to breaking under repeated bending, which makes it better suited for static applications where bending is minimal.

Key Reinforcement Strategies for FPCs

Reinforcing FPCs is crucial to enhance their durability and prevent damage, such as tearing. By using stiffeners and selecting the right adhesives, manufacturers can strengthen FPCs and ensure long-lasting performance. In this section, we will explore key reinforcement strategies to improve FPC reliability.

The Role of Stiffeners in Preventing Tear Damage

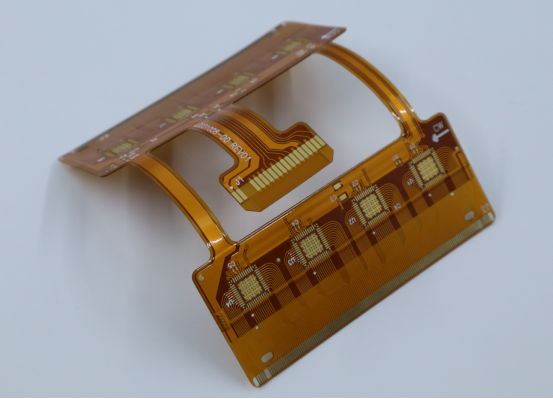

Stiffeners play a vital role in reinforcing FPCs by providing additional support to areas that are most vulnerable to bending and stress. These materials help maintain the structural integrity of the FPC, preventing it from tearing under repeated flexing. The primary function of stiffeners is to reduce the bending stress at critical points, such as connectors and bends. This is especially important in applications where the FPC will experience continuous motion, like foldable phones and wearables.

Real-Life Example: Consider a foldable phone, which repeatedly bends at the hinge. Without stiffeners, the constant flexing could cause the FPC to tear, especially around the connector areas. By placing stiffeners at these vulnerable spots, the FPC is better able to withstand the repeated bending motion, significantly reducing the risk of damage.

Best Stiffener Materials for Different FPC Needs

The material chosen for stiffeners depends on the specific application and the conditions the FPC will endure. Different materials offer varying levels of support, flexibility, and heat resistance. Here are the best options for different needs:

Polyimide is the most flexible and durable material, making it ideal for dynamic applications where the FPC will experience constant bending. It is commonly used in devices like foldable phones and flexible displays. PI stiffeners are known for their ability to bend without breaking, ensuring that the FPC can survive thousands of cycles of bending without tearing.

FR4:

FR4 is a rigid, heat-resistant material commonly used in static applications, such as FPCs that do not require constant bending. It is excellent for areas that experience high temperatures, like solder joints. FR4 stiffeners provide strong support in these static areas but lack the flexibility needed for dynamic applications.

For FPCs exposed to extreme heat or heavy-duty environments, aluminum and steel sheets are used as stiffeners. These metals offer high mechanical strength and heat resistance, making them perfect for high-performance devices, such as industrial equipment and automotive electronics. However, they are less flexible than PI or FR4, so they should only be used in areas where bending is minimal or not required.

Adhesives and Their Role in Strengthening FPCs

The right adhesive is essential for securely bonding stiffeners to FPCs. A strong adhesive ensures that the stiffener stays in place, even under stress, and prevents the layers of the FPC from separating. Choosing the appropriate adhesive type is critical for achieving long-lasting durability.

Modified Acrylic Adhesives:

Modified acrylic adhesives offer high peel strength, which helps prevent the separation of the stiffener from the FPC, even under heavy bending. They are commonly used for bonding polyimide stiffeners because they can withstand both high temperatures and physical stress.

Low-Modulus Adhesives (Silicone/Polyurethane):

Low-modulus adhesives, such as silicone or polyurethane, are flexible and durable. These adhesives are ideal for dynamic FPCs that will undergo repeated bending. Their flexibility allows them to handle the stress of constant motion without losing bond strength. These adhesives are typically used for FPCs in devices like wearables and robotics, where flexibility is crucial.

UV-Curable Adhesives:

UV-curable adhesives, like Krylex KU517x, offer fast curing times and strong bonding to polyimide FPCs. These adhesives are commonly used for quick assembly processes and are aging-resistant, making them a good choice for high-performance FPCs that will be exposed to long-term use.

Matching Adhesive with FPC Material:

It is important to select an adhesive that is compatible with both the stiffener and the FPC material. For example, when bonding aluminum stiffeners to polyimide FPCs, it is essential to choose an adhesive designed to work well with both materials. Using the wrong adhesive can lead to poor bonding and eventual failure of the FPC.

Ensuring Proper FPC Design for Tear Resistance

Designing a Flexible Printed Circuit (FPC) with tear resistance in mind is crucial for preventing failures and ensuring longevity. Proper design choices, including routing, component placement, and layer configuration, can greatly enhance the durability of the circuit. In this section, we will explore key design considerations that help prevent FPC tearing.

Design Considerations for Tear Prevention

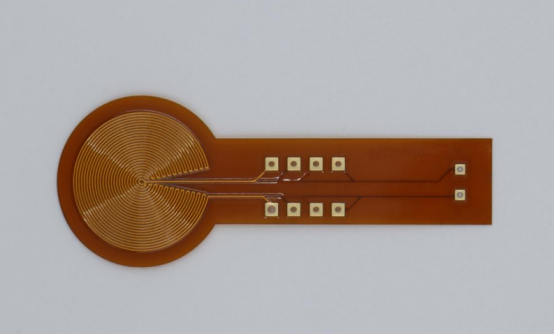

Use of Curved Routing and Tear-Drop Pad Designs

Curved routing helps to distribute stress more evenly along the FPC, reducing the concentration of strain at sharp angles or corners. Sharp corners in trace paths can lead to weak spots where the FPC is more likely to tear. By designing the traces with smooth, gradual curves, the stress is spread out, reducing the risk of damage.

Tear-drop pad designs are also effective. These pads are designed with rounded edges to ensure a smoother connection between the trace and the pad, minimizing stress points at the junctions. The gentle curve eliminates sharp angles, which are common tear-prone areas.

Proper Placement of Components to Avoid High-Stress Areas

Component placement plays a critical role in FPC durability. Placing components, such as connectors or chips, directly on bends or in areas that will experience frequent motion can create points of excessive strain. This can result in the FPC tearing over time.

Best Practice: Keep components away from areas that will experience bending or stress. Leave enough space around bend zones to prevent the components from bearing unnecessary pressure. This design consideration ensures that the FPC will last longer without developing cracks or separation at stress points.

Avoiding Sharp Corners: Benefits of Rounded or Slotted Edges

Sharp corners in the FPC’s layout can concentrate stress, leading to delamination or tearing. To prevent this, it is best to design the edges of the FPC with rounded or slotted corners.

Real-Life Example: Imagine a PCB with 90-degree corners—over time, as the circuit is bent, the sharp corners will be under more stress, leading to cracks. Rounded or slotted edges, on the other hand, help distribute that force more evenly, greatly reducing the risk of failure.

Bend Radius Guidelines and Their Importance

Understanding the IPC-2223 Bend Radius Standards for Different FPC Types

The IPC-2223 standard provides guidelines for the minimum bend radius of FPCs based on their type (single-layer, double-layer, or multi-layer). The bend radius is the smallest curve that the FPC can be bent without causing damage. Failing to follow these guidelines can result in cracks or delamination of the FPC layers.

For instance:

Single-layer FPCs: Should be bent at a minimum radius of 6 times the thickness of the FPC.

Double-layer FPCs: Should be bent at a minimum radius of 10 times the thickness of the FPC.

Multi-layer FPCs: Can require a minimum bend radius of up to 40 times the thickness of the FPC.

Calculating and Respecting the Minimum Bend Radius Based on Layer Count

To calculate the minimum bend radius for an FPC, measure the thickness of the FPC, and multiply it by the required factor (6x, 10x, 20x, etc.). This ensures that the FPC does not undergo excessive stress during bending, which could lead to internal cracking or layer separation.

Example: If you have a single-layer FPC with a thickness of 0.2mm, the minimum bend radius should be 1.2mm (0.2mm x 6).

Impact of Bend Radius Violations on FPC Longevity

Violating bend radius guidelines can cause immediate damage, such as cracking or tearing, and will significantly shorten the lifespan of the FPC. When FPCs are bent too sharply, the copper traces and internal layers may separate, leading to electrical failures or complete circuit failure.

Real-Life Case Study: A manufacturer of a wearable device used an FPC with bends that were too tight, resulting in several devices failing prematurely. By adhering to proper bend radius guidelines, the company was able to reduce FPC failures and improve the product’s longevity.

Layer Symmetry and Material Choice

Ensuring Even Layer Distribution Around the Neutral Axis

In FPC design, the neutral axis is the central point of the FPC that doesn’t stretch or compress during bending. Proper FPCs should have symmetrical layer distribution around this axis to balance the stress during bending. If the layers are uneven, the FPC may bend unevenly, leading to cracks or delamination.

Best Practice: Design the FPC with an even distribution of copper and dielectric material around the neutral axis to ensure that stress is spread uniformly. This makes the FPC more durable and less prone to damage under normal operating conditions.

Choosing the Right Copper Foil (RA vs. ED Copper) to Match Flexibility Needs

The type of copper foil used in an FPC plays a significant role in its flexibility and durability.

Rolled Annealed (RA) Copper: This copper is more flexible and resistant to cracking, making it ideal for dynamic applications like foldable phones or wearables that will experience frequent bending.

Electrolytic Deposition (ED) Copper: ED copper is stiffer and more prone to cracking under stress, so it’s better suited for static applications where bending is minimal, such as in medical devices or fixed electronics.

Example: For a wearable device that requires flexibility, RA copper is the best choice due to its ability to withstand constant bending without cracking. However, for a stationary device like a medical equipment interface, ED copper may be sufficient because it doesn’t experience much bending.

Cost-Effective Approaches to FPC Reinforcement

Reinforcing FPCs doesn't have to be expensive. By choosing the right materials and strategies, manufacturers can achieve durability and tear resistance while staying within budget. In this section, we’ll explore budget-friendly materials and methods to reinforce FPCs effectively, ensuring high performance at a lower cost.

Choosing Budget-Friendly Materials for Reinforcement

Cost-Effective Stiffener and Adhesive Options for Low-Budget Projects

When working with a limited budget, choosing the right stiffeners and adhesives can make a significant difference. Polyester (PET) is one of the most affordable stiffener materials and is ideal for low-heat and low-stress applications. It provides basic reinforcement without adding significant cost.

For adhesives, modified acrylic or silicone-based adhesives are cost-effective options that offer sufficient bonding strength for less demanding applications. These adhesives can effectively hold stiffeners in place without the high price tag of more specialized options like UV-curable adhesives.

Example: A budget-friendly wearable device manufacturer might opt for PET stiffeners and modified acrylic adhesive to provide basic durability at a fraction of the cost of higher-end materials like polyimide (PI) or aluminum stiffeners.

Bulk Ordering Stiffeners and Adhesives for Large-Scale Production

For companies producing FPCs at a larger scale, bulk ordering stiffeners and adhesives can significantly reduce unit costs. Purchasing materials in bulk not only lowers the per-unit price but also ensures that the same materials are used consistently, improving quality control. Many suppliers offer discounts for large orders, making it a cost-effective solution for high-volume production runs.

Real-Life Case: A company manufacturing low-cost smartphones could purchase PET stiffeners and acrylic adhesives in bulk, reducing material costs for each unit. By ordering in large quantities, they can improve production efficiency and meet market demand without overspending.

Balancing Durability and Budget in FPC Design

How to Prioritize Reinforcement Strategies Without Over-Spending

In low-budget projects, it's essential to focus on the most critical reinforcement strategies that provide the most value. For example, prioritize reinforcement near areas that experience the most stress, such as bends and connectors. Using low-cost materials like PET for these areas can offer sufficient strength while saving on more expensive materials.

Additionally, proper handling and design, such as routing traces away from high-stress areas, can also reduce the need for excessive reinforcement. By combining smart design with affordable materials, it’s possible to ensure durability without overspending on unnecessary reinforcement.

Example: A low-cost consumer electronics manufacturer might focus on reinforcing areas where the FPC is likely to bend frequently, like at the device’s hinges, while leaving other areas less reinforced, as they don’t experience as much stress.

Case Studies of Successful Low-Cost Reinforcement in Mass-Market Products

Several successful mass-market products have used cost-effective reinforcement methods to achieve both affordability and durability. One notable example is budget smartphones, which often use PET stiffeners and acrylic adhesives to reinforce their FPCs without compromising performance. These devices are designed to handle regular use and light bending without tearing, all while keeping production costs low.

Another example is in wearables, where manufacturers often use polyester (PET) for stiffeners and silicone-based adhesives to reduce cost, while still offering flexibility and sufficient tear resistance for everyday use.

Real-Life Example: A well-known budget-friendly fitness tracker used PET stiffeners and modified acrylic adhesives, successfully reducing costs while still offering the durability needed for a product that undergoes frequent bending. This strategy allowed the manufacturer to sell the product at an affordable price while ensuring quality.

Conclusion

Reinforcing FPCs is crucial for ensuring their long-term performance and reliability. With the right strategies, such as using stiffeners, selecting durable adhesives, and designing with stress-prone areas in mind, manufacturers can prevent common issues like tearing and delamination. These proactive steps significantly extend the lifespan of FPCs and reduce the risk of costly failures.

Regular inspections and prompt repairs are essential for maintaining FPCs. Catching small problems early can prevent them from becoming bigger, more expensive issues later on.

For those seeking high-quality FPCs, PCBMASTER offers customized solutions that meet the most demanding industry requirements. With over 20 years of experience, we specialize in providing durable and reliable FPCs for aerospace, medical, and consumer electronics applications. Let us help you design circuits that stand the test of time.

FAQs

What’s the most effective method to prevent FPC tearing?

The most effective way to prevent FPC tearing is to combine several key strategies. First, reinforce the FPC with stiffeners near bends and connectors to provide structural support. Second, handle the FPC with care by holding it by the edges to avoid unnecessary stress on sensitive areas. Lastly, strictly follow bend radius guidelines based on the FPC's layer count to prevent cracks or layer separation. This comprehensive approach significantly reduces the risk of tearing and enhances the lifespan of FPCs.

How often should I inspect my FPCs for damage?

The frequency of inspection depends on the application. For devices with frequent use, such as wearables or foldable phones, it’s recommended to inspect the FPCs monthly to catch any signs of wear early. For critical applications, like medical devices or aerospace, inspections should be more frequent—ideally before each use. Regular inspections help identify small issues before they become major problems, ensuring the continued functionality and reliability of your FPCs.

Can I repair a torn FPC myself?

Minor FPC tears, such as broken traces or lifted pads, can often be repaired at home using basic tools like a soldering iron, flux, and copper tape. Small repairs involve cleaning the damaged area, tinning the copper traces, and reconnecting them with a solder bridge or a piece of wire. However, for more severe damage, such as internal layer delamination or complex electrical issues, it's best to consult a professional. DIY repairs on these larger problems may worsen the damage and impact the device’s performance.

What type of stiffener is best for foldable electronics?

For foldable electronics, Polyimide (PI) stiffeners are the ideal choice. Polyimide is known for its excellent flexibility, making it perfect for high-stress, high-bend applications like foldable phones. PI stiffeners are durable enough to withstand repeated flexing without cracking, ensuring that the FPC remains intact even after thousands of folds. This material also provides good chemical and thermal resistance, making it suitable for dynamic, wear-resistant applications.