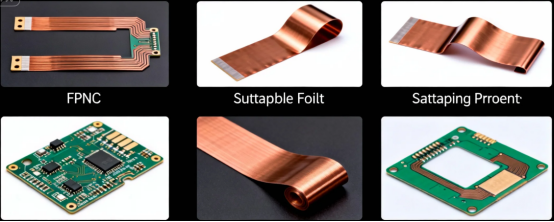

FPC Copper Foil Selection Electrolytic Copper vs. Rolled Copper – Which is the Soul of Flexible Circuit Boards

Copper Foil: The "Vascular Network" of FPCs

The Core Role of Copper Foil

Before delving into the two types of copper foil, it's essential to understand their core role in FPCs. Copper foil serves multiple functions in flexible circuit boards: conducting electricity, transferring heat, and providing mechanical support.

The Importance of Selection

This seemingly minor choice directly determines the circuit's performance, reliability, and final cost.

Electrolytic Copper Foil: The "Rugged Hero" of Mature Technology

Manufacturing Process Unveiled

Electrolytic copper foil (ED copper) is produced through an electrochemical deposition process. Copper ions are deposited from an electrolyte solution onto a large, rotating cathode drum to form the foil.

Unique Microstructure

The microstructure of electrolytic copper foil features columnar grain arrangements, with these grains growing perpendicular to the foil surface.

Surface Characteristics

This process naturally creates a micro-rough surface, which enhances adhesion to the substrate material.

Production Advantages

The production process is relatively simple, suitable for large-scale manufacturing, resulting in lower costs and excellent thickness uniformity.

Performance Characteristics and Application Scenarios

Due to its excellent cost-performance ratio, electrolytic copper foil is the preferred choice for FPCs in most consumer electronics.

Rolled Copper Foil: The "Aristocratic Artisan" of Precision Engineering

Manufacturing Process Unveiled

Rolled copper foil (RA copper) is manufactured using a completely different physical method. It starts with a copper ingot, which undergoes multiple hot and cold rolling processes to eventually form an ultra-thin foil.

Unique Microstructure

The grain structure of rolled copper foil is arranged in layers, parallel to the foil surface.

Mechanical Properties

This structure gives the material excellent flexibility and high fatigue resistance.

Surface Quality

It has extremely low surface roughness, making it suitable for fine-line circuitry fabrication.

Performance Characteristics and Application Scenarios

Rolled copper foil is the "darling" of high-end FPC applications, particularly suited for scenarios requiring frequent or dynamic bending.

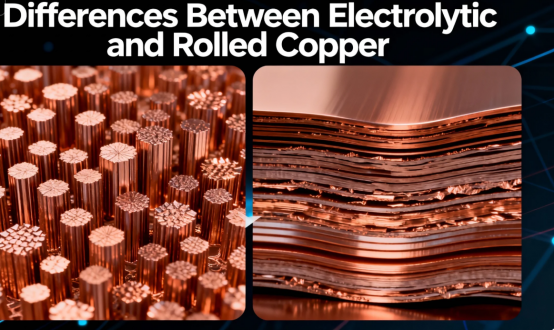

Direct Comparison: Five Key Differences Between Electrolytic and Rolled Copper

Differences in Microstructure

This is the most fundamental distinction. The columnar grain structure of electrolytic copper resembles a vertical forest, while the layered grain structure of rolled copper is akin to a stack of flattened sheets of paper.

Flexibility and Bending Performance

For the same thickness, rolled copper demonstrates significantly better bending performance than electrolytic copper.

Surface Roughness and Signal Integrity

Electrolytic copper foil has higher surface roughness, whereas rolled copper foil has an extremely smooth surface, which is beneficial for high-frequency signal transmission.

Cost and Accessibility

The production cost of electrolytic copper foil is typically 20-40% lower than that of rolled copper foil.

Thermal Stability and Reliability

Rolled copper foil exhibits better dimensional stability in high-temperature environments.

How to Choose the Right Copper Foil for Your FPC Application?

When to Choose Electrolytic Copper Foil

Cost-sensitive, high-volume consumer electronics products.

Applications with static or minimal bending requirements.

Low-frequency circuits where signal integrity requirements are not critical.

Applications requiring strong adhesion between the copper foil and substrate.

When to Choose Rolled Copper Foil

Applications with high-reliability demands, such as medical, military, or aerospace electronics.

FPC designs requiring frequent or dynamic bending.

High-speed, high-frequency circuits with stringent signal integrity requirements.

Fabrication of extremely fine lines (line width/spacing less than 50μm).

Industry Trends and Future Outlook

Development of Ultra-Thin Copper Foils

As electronic products become increasingly lightweight and thin, copper foil thickness continues to decrease. Ultra-thin copper foils of 3-5μm have become the standard for high-end FPCs.

Hybrid Structure Copper Foils

Some manufacturers are beginning to develop hybrid structure copper foils that combine the advantages of both types, seeking an optimal balance between performance and cost.

Environmental Considerations

The industry is moving towards more environmentally friendly production processes, such as using recycled copper and reducing chemical consumption.

Conclusion

FIn the world of FPCs, the "competition" between electrolytic and rolled copper is not a zero-sum game but rather provides solutions for different application needs. Understanding the fundamental differences between these two materials can help you find the optimal balance between performance, reliability, and cost.

FAQs

Q: What are the core manufacturing process differences between Electrolytic (ED) and Rolled (RA) Copper?

A: Electrolytic copper uses an electrochemical deposition method (copper ions deposit onto a cathode), resulting in a columnar grain structure. Rolled copper is made through physical rolling (repeatedly rolling a copper ingot), resulting in a fibrous/laminated grain structure.

Q: Which has better flexibility, and what are their suitable applications?

A: Rolled copper offers superior flexibility (withstanding hundreds of thousands of bends) and is suited for high-frequency dynamic bending scenarios like foldable screens and robotic joints. Electrolytic copper has moderate flexibility, limited to static applications or 3-5 assembly-related bends.

Q: Is there a difference in conductivity and signal transmission performance?

A: Electrolytic copper has higher purity and slightly better electrical conductivity. Rolled copper has a smoother surface, leading to lower signal loss and better signal integrity in high-frequency/high-speed transmission.

Q: How significant is the cost difference?

A: The manufacturing process for rolled copper is more complex, making it 2-3 times more expensive than electrolytic copper. Electrolytic copper is lower-cost and suitable for cost-sensitive applications.

Q: Which has better ductility and resistance to fracture?

A: Rolled copper has an elongation rate of 15%-40%, offering good resistance to stretching and deformation under high/low temperatures. Electrolytic copper has an elongation rate of only 5%-15% and is prone to fracture under rough handling or stretching.

Q: How do they perform in processing fine-line circuits?

A: Electrolytic copper is easier to etch, allowing for minimum trace width/spacing down to 2/2 mil. Rolled copper has greater undercut during etching, so a trace width/spacing of ≥4/4 mil and a copper thickness of ≤18μm are recommended.

Q: Which type is commonly used in new energy vehicle battery FPCs?

A: Rolled copper is generally preferred for its better ductility and vibration resistance, helping to prevent FPC fracture during battery pack operation.

Q: How to choose between the two in adhesive-less (adhesiveless) copper foils?

A: Adhesive-less Electrolytic Copper: For cost-sensitive applications, mid-to-low frequency transmission, and scenarios involving mild bending.

Adhesive-less Rolled Copper: For high-frequency/high-speed scenarios (5G/6G) and high-reliability dynamic bending applications.

Author: Jack Wang